dust ntrols for rock crushing operations

2020-02-09T03:02:28+00:00

Dust Control or Prevention for Crushing and

Wet dust control methods for crushing operations, involve wetting the process material before crushing, after crushing, or both This is essentially treating the crushing operation as two transfer points, the feed side and discharge sideFigure 1 Stone crushing operations create large quantities of respirable dust Workers exposed to respirable silica dust have an increased risk of developing lung diseases such as silicosis or tuberculosis Engineering Controls Reductions in respirable dust in stone crusher mills can be accomplished through engineering controls including Guidance for Controlling Silica Dust from Stone Crushing AGGREGATE CRUSHING OPERATIONS Air Pollution Control equivalent 754% control efficiency for "process" material and a 867% control efficiency for "fines" material These factors are substantially different from those used previously by the District Trace metal concentrations in aggregate dust released from aggregate crushing operationsDust control for aggregate crushing operations

Crusher Plant Dust Suppression: Silica compliance

Proper Crusher Dust Control: What It Needs Controlling and minimizing exposure to silica dust requires proper wet dust suppression for rock crushers Because water has a relatively high surface tension (72 dynes per cm), it alone cannot penetrate crushed material that Solution summary addon wet dust suppression systems for rock crushers and is an important dust control option to consider these controls use a pump to deliver water to the crushing surface where it combines with particles and reduces airborne dust levels used for dust control at crushing plants processing more than 500 tons per More DetailsDust Control For Crushing Plants Complying mill,A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust crushers may be used to reduce the size or change the form of waste materials so they can be more easily disposed of or recycled or to reduce the size of a solid mix of raw materials (as in rock ore) so that pieces of different composition can bedust controls for rock crushing operations mini

dust ntrols crushers oikodomoseducatienl

Dust Control or Prevention for Crushing and Screening Wet dust control methods for crushing operations, involve wetting the process material before crushing, after crushing, or both This is essentially treating the crushing operation Case Study Crusher Dust Control At Limestone Mine, Mining dust control in the past linwood has used water hoses and spray bars to help control dust both at the crusher and at transfer points on average due to excessive dust emissions the plant experienced a substantial amount of downtime each month Dust Controls For Rock Crushing OperationsDust Controls For Rock Crushing Operations02092016 This video is unavailable Watch Queue Queue Watch Queue Queuedust control for aggregate crushing operations

Gravel Pits, Quarries, and Aggregate Crushing and

In the case of most new gravel pits, an Act250 permit will likely be required and the AQCD will request that the permit include a condition requiring effective dust control If your gravel pit or quarry will include drilling, sawing, blasting, or aggregate crushing operations then an air permit will likely be requiredCrusher Dust Control: Get Started Today Worker safety and OSHA compliance are vital to your business We provide your solution for both To learn more about our wet dust suppression for rock crushers, contact us at (630) 8441300 to speak with a Benetech specialist Posted in Dust ControlCrusher Plant Dust Suppression: Silica compliance AGGREGATE CRUSHING OPERATIONS Air Pollution Control equivalent 754% control efficiency for "process" material and a 867% control efficiency for "fines" material These factors are substantially different from those used previously by the District Trace metal concentrations in aggregate dust released from aggregate crushing operationsDust control for aggregate crushing operations

Guidance for Controlling Silica Dust from Stone Crushing

Figure 1 Stone crushing operations create large quantities of respirable dust Workers exposed to respirable silica dust have an increased risk of developing lung diseases such as silicosis or tuberculosis Engineering Controls Reductions in respirable dust in stone crusher mills can be accomplished through engineering controls including fact sheet describes dust controls that can be used to minimize the amount of airborne dust when using crushing machines as listed in Table 1 of the Respirable Crystalline Silica Standard for Construction 29 CFR 19261153 Engineering Control Method: Wet Methods AND Operator Isolation The use of water sprays or mists for dust suppression at the FactSheetDTI Dust Control at Concrete Crushing Facilities BossTek Jun 03 2019 Crushing Equipment Using Dust Control Concrete crushing facilities are designed to handle rock big and small coming from demolition materials The large aggregate chunks sent to the facilities see the primary crusher firstdust control in crushing theselahprojectcoza

dust controls for rock crushing operations mini

dust controls for rock crushing operations mini mill indian make Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipment mill,A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock 02092016 This video is unavailable Watch Queue Queue Watch Queue Queuedust control for aggregate crushing operations Dust Control Systems For Crushing And Screen Plants Dust control for crushing plants jun 11 2008 these dust control spray systems can help quarries and recycling plants comply with visible emission standards when installed at strategic locations in crushing and screening plants the dustpro spray system uses a high pressure 200 psi pump capable Dust Control For Crushing Plants Complying

Crushing Plant Environmental Operation

dust control for aggregate crushing operations Aggregate Rock Crushing Operations Policy AGGREGATE PLANT SALES, Environmental Impacts of Aggregate and Stone Mining New Mexico Case Study Prepared By quarry plant operation safetyIn the case of most new gravel pits, an Act250 permit will likely be required and the AQCD will request that the permit include a condition requiring effective dust control If your gravel pit or quarry will include drilling, sawing, blasting, or aggregate crushing operations then an air permit will likely be requiredGravel Pits, Quarries, and Aggregate Crushing Crushing Equipment Using Dust Control Concrete crushing facilities are designed to handle rock big and small coming from demolition materials The large aggregate chunks sent to the facilities see the primary crusher first These large crushers handle breaking down the bulky rocks into smaller, more manageable sizesDTI: Dust Control at Concrete Crushing Facilities

Guidance for Controlling Silica Dust from Stone Crushing

Figure 1 Stone crushing operations create large quantities of respirable dust Workers exposed to respirable silica dust have an increased risk of developing lung diseases such as silicosis or tuberculosis Engineering Controls Reductions in respirable dust in stone crusher mills can be accomplished through engineering controls including CONTROL OF SILICA DUST IN CONSTRUCTION Crushing Machines Using crushing machines at construction sites to reduce the size of large rocks, concrete, or construction rubble can generate respirable crystalline silica dust When inhaled, the small particles of FactSheetThese controls use a pump to deliver water to the crushing surface where it combines with particles and reduces airborne dust levels Adding moisture to the material will also reduce the amount of dust produced downstream from the crushing operation Each of these systems must be configured for specific equipment, process and control requirementsSolution Addon Wet Dust Suppression Systems

Dust control at limestone quarry BossTek

Trinidad Cement Limited (TCL) has installed a mobile dust suppression machine to reduce the potential for health hazards, environmental effects and fugitive dust from its limestone crushing operation in Mayo, Central Trinidad Crews run the DB60 whenever the mobile crusher is operating, blanketing material piles, storage areas or truck paths to best suit the day’s workload and wind conditionsdust control foggers for stone crushers Dust suppression system for stone crusher a crushing plant is onestop crushing installation, which can be used for rock crushing and other similar materials crushing plants may be either fixed or mobile crushing plants make use of a large range of equipment, such as a prescreener, loading conveyor, intake hopper, magnetic separator, crushing unit, such dust control foggers for stone crushers proves dust controls for rock crushing operations mini mill indian make Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipment mill,A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust controls for rock crushing operations mini

United States Environmental Protection Agency General

13022017 In rock crushing operations, rock is loosened by drilling and blasting and then loaded by frontend loader or power shovel into large haul trucks that transport the material to the processingoperations dust control plan is included in the permit 4It covers the safe operation of the mobile crushing operation and includes guidance on clearing blocked crushers The use of level indicators for feed control ; Dust, especially in the case of crushing concrete or bricks or any other high silica content materialHSE Quarries Safe operation and use of Dust is produced from blasting, crushing, screening and stacking operations as well as conveyor belts and loader and truck transport on site and trucks offsite Dust is also produced during overburden removal and construction of berms and from wind blowing over stock piles and across barren pit floors The Hazards of Dust from a Pit/Quarry Operation

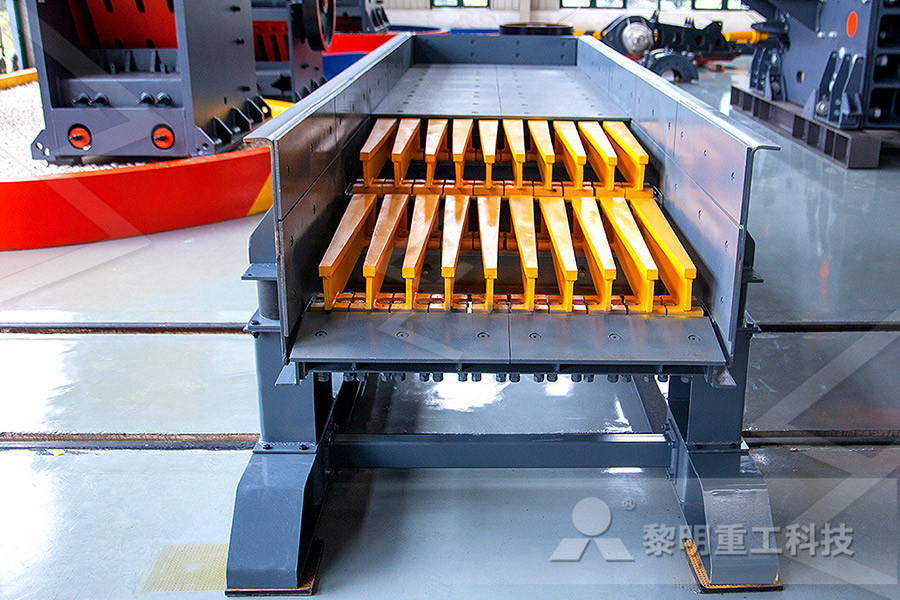

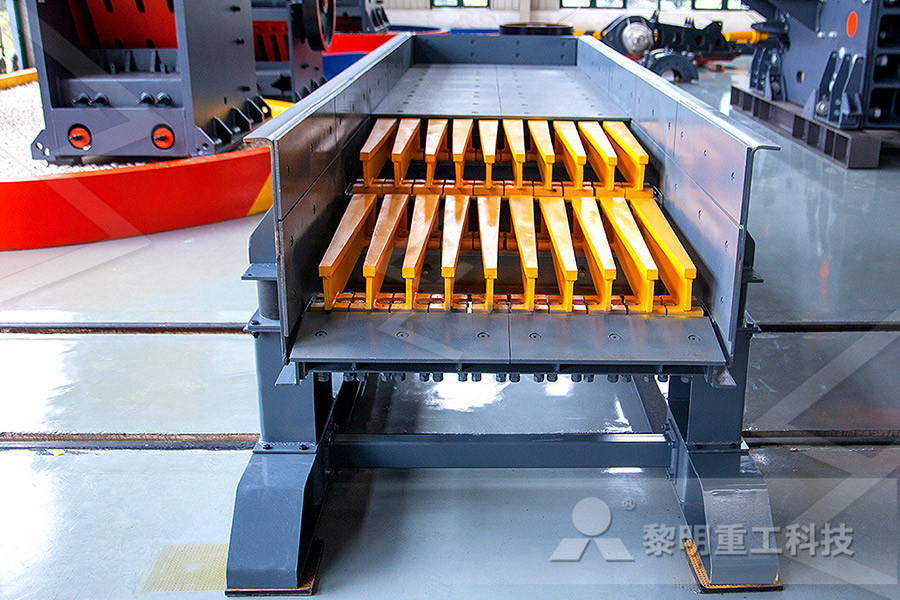

Gold Shaker Table leadzinc Surfice

gold ore beneficiation plant price

Iron Ore Mills Primarily

manure hammer mill thailand

production production line in crushed stone aggregate

mining equipment vibrating screen for sand

DXNs Type Of Mobile Limestone Crusher

crusher sale chennai kundrathur

Pembeli Crusher Bekas Dan Layar Di Afrika Selatan

Moagem Belt Planta De Minerao Fabricante

tamil nadu stone quarry crushers association

Reliable Top Quality Stone Jaw Crusher For Sale

Kenya Grinding Media Ball Requirements

agents in brazil for crushing equipment

high efficiency powder making mining grinding mill 4r3220

impact crusher pe600x900

Mobile Crushing Equipment Is At Least

mobile stone crusher tph tph for sale with low st

vsi crusher manufacturers in china

Best Beneficiation Equipment For Plaster Jawa Indonesia

mesin mining mill kuku macan

chancadora barita en republica dominicana

jaw crusher main frame manufacturer

metal melting temperatures

pasir mesin peledakan pusat layanan di chennai

stone crusher machines manufacturers in china stone crusher machine

used small rod mill for sale

methods of processing silver ore

Small Gold Prospecting Equipment Price In Townsville

extraction process of metals