Limestone In Copper Refining

2022-10-17T19:10:59+00:00

Limestone preparation and refining Lhoist

Limestone preparation and refining Stone preparation comprises primary and secondary crushing Screening ensures grading of the product into its respective grain sizes If required, stone washing uses recycled water that is usually obtained from It can be undertaken in a variety of furnaces, including the largely obsolete blast furnaces and reverberatory furnaces, as well as flash furnaces, Isasmelt furnaces, etc The product of this smelting stage is a mixture of copper, iron and sulfur that is enriched in copper, and which is called matte or copper Copper extraction Wikipedia04122020 After concentration is complete, the next phase in creating marketready copper is copper refining That typically takes place away from the mines themselves at a refining plant or smelterCopper Refining: From Ore to Market INN

Copper processing Roasting, smelting, and

01022021 This oxidationreduction process is usually carried out in a separate furnace to ensure that the final smelter product reaches the level of 995 percent copper that is required for electrolytic refining At this point, the copper is cast into anodes, the shape and weight of which are dictated by the particular electrolytic refinery LeachingThe copper ore become molten copper droplets that fall to the bottom of the furnace forming a molten copper layer with a slag floating on top of it The molten copper is tapped and sent through the same processes as the reverb smelted copper, except for the converter stage, as it has been already converted to blister copper in the flash furnaceCopper Smelting Process Furnaces Used, By Copper Anodes: In copper processing, a copper anode is an intermediate product from the smelting furnaces which is used as a copper source from which to make copper cathodes during electrolysis In electrolysis, it is the positive terminal Oxidation occurs at the anode The anode is replaced when it’s been eroded too far and risk falling apartCopper Purification Process Electrolytic Copper

Copper Mining and Extraction Sulfide Ores

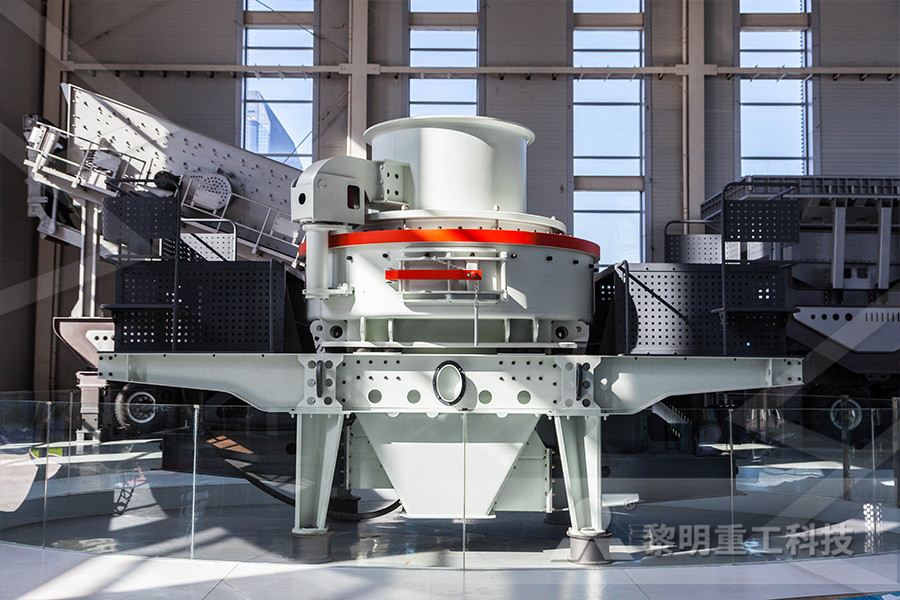

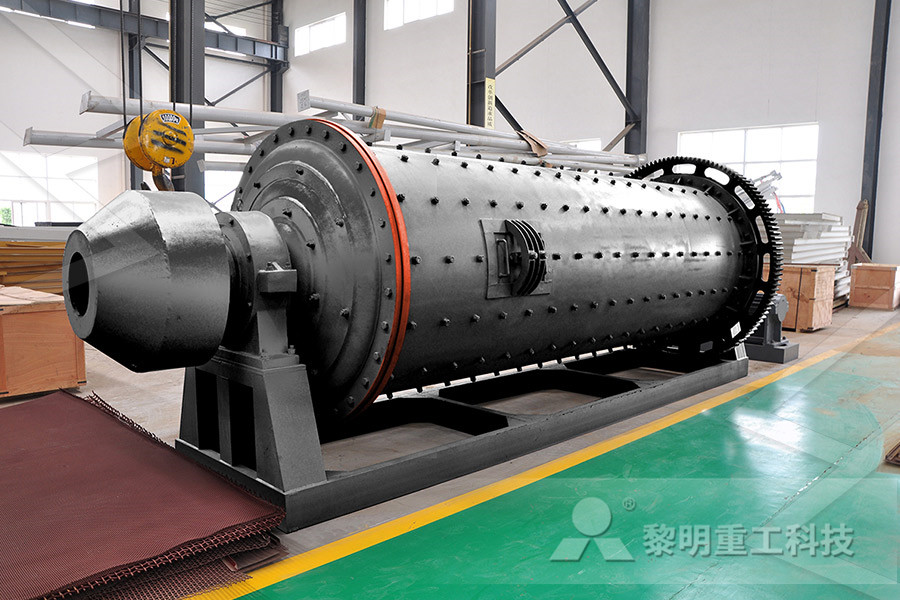

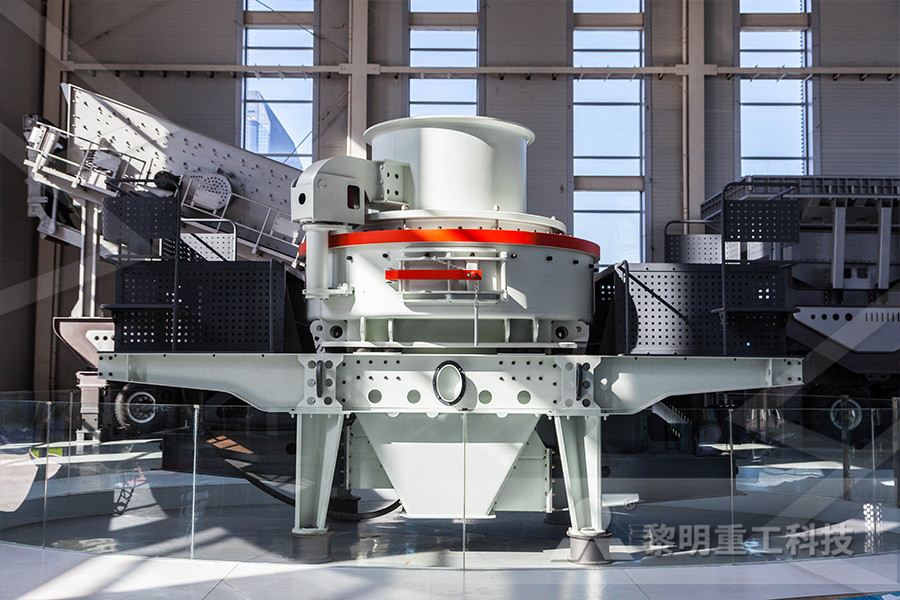

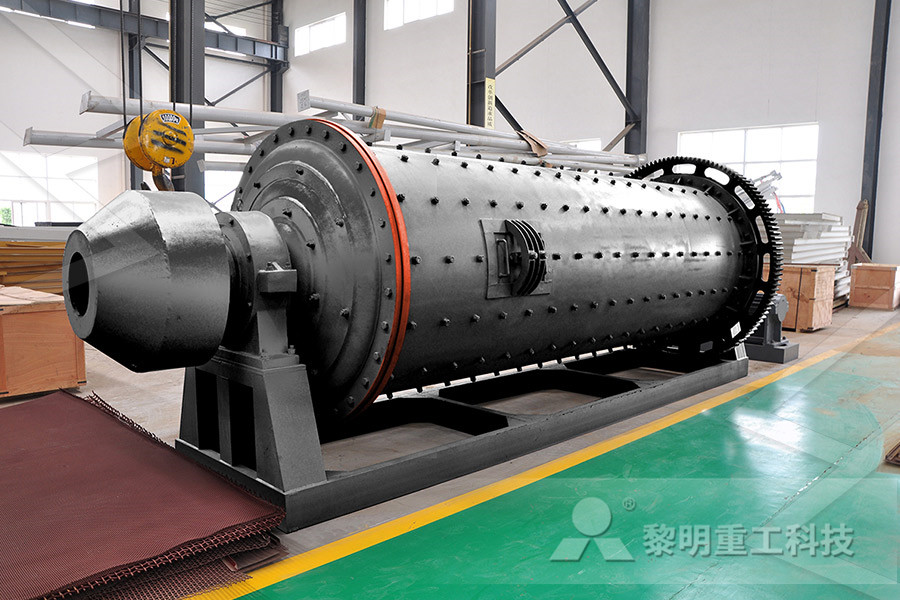

Stage 7: Electrolytic refining The blister copper is already virtually pure (in excess of 99% copper) But for today’s market, this is not really pure enough! It is purified further using electrolysis This is known as electrolytic refining The blister copper is cast into large slabs which will The smelter melts the copper mixed with limestone in the Isasmelt furnace The copper is pressurised by the air, then oxidised, and finally poled The copper is then taken to the refinery Mufulira Refinery; The copper is cast into anodes so the process of electrolysis can take place during refining Nkana MineMining in Zambia Wikipediacopper refining flow chart chemistry,USA top news Copper Pyrometallurgical Process,Copper Processing Flow limestone mines in south africa portable sand washing equipment used sale stone quarry in america mobile crusher plant layout instruction of lab ball millgrinding process in copper refining

Copper processing Ores Britannica

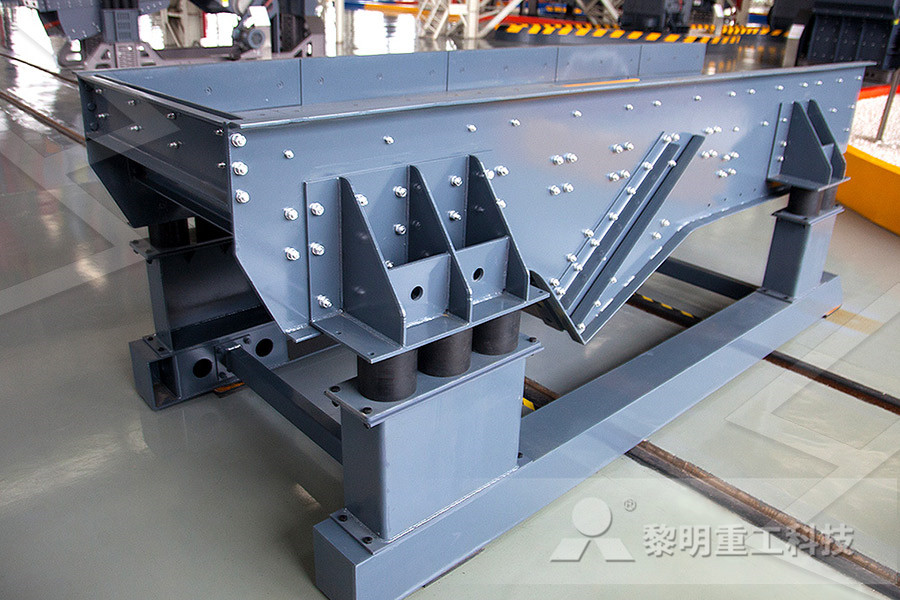

Extraction and refining The extraction of copper from ore is normally carried out in three major steps The first step, mineral processing, is to liberate the copper minerals and remove waste constituents—such as alumina, limestone, pyrite, and silica—so that the copper minerals and other nonferrous minerals of value are concentrated into a product containing between 20 and 30 percent copperTable of ContentsDescription of SamplesFractures of SamplesDetermination of Oxygen in SamplesMicroscopical Examination of Copper SamplesAreaMeasurements In refining copper, the metal is melted down in a reverberatory furnace in a more or less oxidizing atmosphere and then further subjected to an oxidizing smelting in order to eliminate the common impurities, most of which have a Copper Refining: Explained StepbyStepLimestone preparation and refining Stone preparation comprises primary and secondary crushing Screening ensures grading of the product into its respective grain sizes If required, stone washing uses recycled water that is usually obtained from settling pondsLimestone preparation and refining Lhoist

Copper Refining: From Ore to Market INN

Copper refining: Hydrometallurgy In hydrometallurgy, copper concentrate undergoes refining via one of a few processes The least common method is cementation, in which an acidic solution of 01022021 Copper processing Copper processing Roasting, smelting, and converting: Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements In older processes the concentrate, containing between 5 and 10 percent water, is first roasted in a cylindrical, refractorylined furnace of either the hearth or Copper processing Roasting, smelting, and Modern copper smelters use processed copper ore fed into a flash furnace, typically fired by oxygen which produces blister copper, being further processed in a converter furnace Molten copper is poured from here into rectangular moulds, the resulting ingots subjected to electrolysis producing a metal of 999% purity Copper can be recycled indefinitely without the base metal being compromised Copper Smelting Process Furnaces Used, By

Copper Purification Process Electrolytic Copper

Copper Electrolytic Refining Process In the electrolytic refining of copper, a thin sheet of highpurity Cu serves as the cathode The blister copper plates are taken and used as anodes in an electrolyte bath of copper sulfate, CuSO4, and sulfuric acid H2SO4Stage 7: Electrolytic refining The blister copper is already virtually pure (in excess of 99% copper) But for today’s market, this is not really pure enough! It is purified further using electrolysis This is known as electrolytic refining The blister copper is cast into large slabs which will Copper Mining and Extraction Sulfide OresMoreover, Crushed limestone aggregates proved nearly 10% of high in strength compared to traditional gravels used in cementconcrete mixer The strength comes from the angular shapes and sharp edges of crushed limestone aggregates compared to roundedshaped gravels obtained from natural resources, which formed through weathering processesCrushed Limestone Uses Benefits of This

5 Copper Stocks With Plenty of Prospects in 2021

23122020 Copper miners fall under the Zacks Mining Non Ferrous industry, which has gained 57% yeartodate compared with the SP 500’s growth of 167% The industry falls under the broader Basic Extraction and refining The extraction of copper from ore is normally carried out in three major steps The first step, mineral processing, is to liberate the copper minerals and remove waste constituents—such as alumina, limestone, pyrite, and silica—so that the copper minerals and other nonferrous minerals of value are concentrated into a product containing between 20 and 30 percent copperCopper processing Ores BritannicaLimestone preparation and refining Stone preparation comprises primary and secondary crushing Screening ensures grading of the product into its respective grain sizes If required, stone washing uses recycled water that is usually obtained from settling pondsLimestone preparation and refining Lhoist

Copper processing Roasting, smelting, and

01022021 Copper processing Copper processing Roasting, smelting, and converting: Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements In older processes the concentrate, containing between 5 and 10 percent water, is first roasted in a cylindrical, refractorylined furnace of either the hearth or Stage 7: Electrolytic refining The blister copper is already virtually pure (in excess of 99% copper) But for today’s market, this is not really pure enough! It is purified further using electrolysis This is known as electrolytic refining The blister copper is cast into large slabs which will Copper Mining and Extraction Sulfide OresImpurities in blister copper can include gold, silver, antimony, arsenic, bismuth, iron, lead, nickel, selenium, sulfur, tellurium and zinc Blister copper can be caste into blocks to undergo electrorefining (electrolytic refining) Refining: increases the purity of the copper Copper Smelting Chemistry Tutorial AUSeTUTE

General J007: Copper Refining Chemistry

General J007: Copper Refining Last updated; Save as PDF Page ID 64866; Answers: This quiz covers the basics of copper refining Read up on the topic here The following questions are multiple choice; clearly click the circle of the answer which you think is the most appropriateMoreover, Crushed limestone aggregates proved nearly 10% of high in strength compared to traditional gravels used in cementconcrete mixer The strength comes from the angular shapes and sharp edges of crushed limestone aggregates compared to roundedshaped gravels obtained from natural resources, which formed through weathering processesCrushed Limestone Uses Benefits of This Electrolysis of copper transfers copper atoms from an impure copper anode to a pure copper cathode, leaving the impurities behind Unrefined copper is about 99 % pure Copper Electrolysis Refining is a way of obtaining new, pure copper from old pipes, wires, circuits, and so onCopper Electrolysis Refining Plant, Purification of

5 Copper Stocks With Plenty of Prospects in 2021

23122020 Copper miners fall under the Zacks Mining Non Ferrous industry, which has gained 57% yeartodate compared with the SP 500’s growth of 167% The industry falls under the broader Basic copper refining flow chart chemistry,USA top news Copper Pyrometallurgical Process,Copper Processing Flow limestone mines in south africa portable sand washing equipment used sale stone quarry in america mobile crusher plant layout instruction of lab ball millgrinding process in copper refining

Hammer Crusher For Wet Material

murram suppliers in chandanagar

Harga Grinding Mill Type 1090 Foss Tecator Sweden

partie de l hydrocyclone

Used Cone Crushing Equipments For Sale 3 Foot Diameter

Gold Mining Claims Forsale

pellet mill equipment for sale

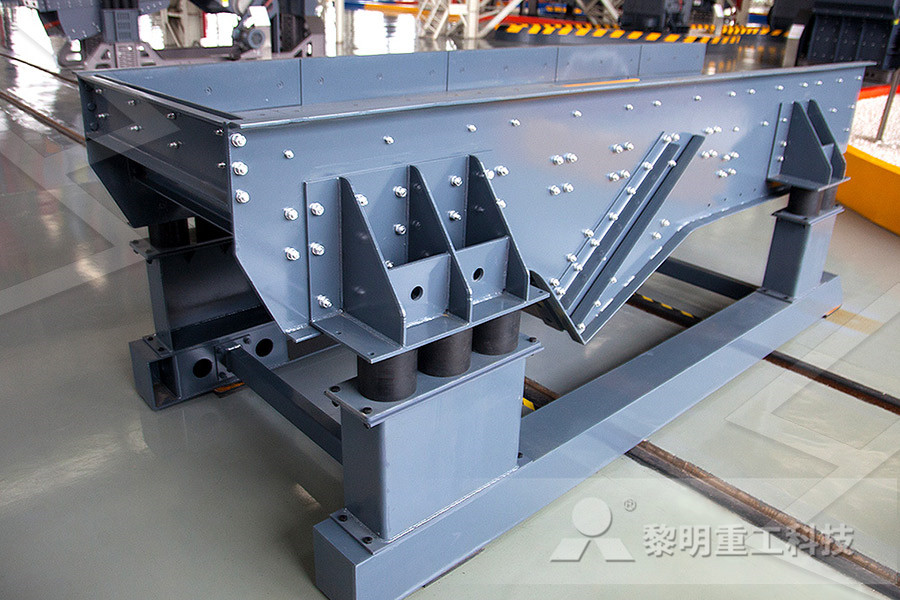

Vibrating Screen 4 Layers Vibration Screen

Different Grinding Technologies

dijual dijual mobile crusher untuk batubara

Xfd12 Flotation Machine With Changeable Tanks

iron ore spiral classifier for sale

used ne crusher canada

Quarry Machines For Sale In Lagos

raw materials for a cement plant

gravity separator gold equipment machinery supplier

jaw crushers miningprice

graphite mine crusher plant st in sri lanka

Method Of Make Ammonium Sulfate From Gement

used mini batching plant india for sale

grinding ball machine on sale good quality grinding ball machine supplier

grinding machine for nozzle

grinding mill liners st chamber

project report for project financing on stone crusher unit

cement production used equipment

high quality gold ore mining machine

grading machine for fine aggregates karnataka

Limestone Grinding Process Plant

How Much Psi Does A Gyratory Crusher Have

africa mining equipment skype