thermal power plant al mill systems

2023-10-07T03:10:32+00:00

Coal mill pulverizer in thermal power plants

17112012 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner panels13102020 Introduction to Coal handling plant In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating stationCoal handling plant in a thermal power generating Coal is transported from coal mines to the power plant by railway in wagons or if it a pit head station then by merry go round system Coal is unloaded from wagon to a moving underground conveyor belt Coal is either stacked in coal stock yard having about 30 days capacity or is taken to coal crusher house with the help of conveyor belt as per CHP layoutWorkflow and Performance of Coal Based Thermal

Coal handling plant in a thermal power

13102020 Introduction to Coal handling plant In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power Abstract: In recent years, the load following capability of thermal power plants has been actively researched, as power system interconnection unavoidably brings about complicated load variations The key to improving the load following capability is the control of the fuel supply to the burner, which is provided by the coal millThermal power plant as contributed by coal mill A coalfired power station or coal power plant is a thermal power station which burns coal to generate electricityCoalfired power stations generate over a third of the world's electricity but cause hundreds of thousands of early deaths each year, mainly from air pollution A coalfired power station is a type of fossil fuel power stationThe coal is usually pulverized and then burned in a Coalfired power station Wikipedia

Optimization of coal handling system

This paper deals with the optimization of coal handling system performability for a thermal power plant,Coal handling system comprises of five subsystems, namely Wagon Tippler, Crusher, Bunker, Feeder and Coal Mill The partial differential equations are derived on the behalf of transition diagram by using the Markov approach These partial differential equations are further solved to obtain 01012011 Operation and Maintenance of Coal Handling System in Thermal Power Plant [J]Colliery Machine;2011, 32(2):201204 ss door, not attached to the machine or climbing machines, to avoid danger b9 lubrication of coal crusher Bearing lubrication is an important part of coal crusher, the oil should be 1 / 2 to 2 / 3 is appropriate of the oil chamber, always check the location of oil and oil Operation and Maintenance of Coal Handling Thermal power plantInside the coal mill in thermal power plant

Coal mill in thermal power plant YouTube

31052020 Coal mill in thermal power plant Power Plant maintenance works Loading Coal Fired Thermal Power Plant,Tamilnadu,India Duration: 12:41 Triple S EPPL 108,028 views 12:41The coal fired thermal power plant susceptible to a wide range of hazards in System Description: Define the system and there subsystem and operations Step2: Hazard Identification coal bunker and send it to the ball mill or roll mill for pulverization process Where coal crushed to the fine powder and Hazards Identification and Risk Assessment in Thermal Note 1) Indirect Firing System Note 2) Coalfired Thermal Power Plant : Ramping Rate at 50~90% Load Note 3) Hot: Night time shutdown (approx 8hr), Cold: One week shutdown (more than 150hr) Note 4) The details are covered by next presentation The Flexibility of Coal and Gas Hitachi Power Systems The Latest CoalFired

Pulverizer Wikipedia

Types of coal pulverizers Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low speed Ball and tube mills A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods13102020 Introduction to Coal handling plant In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power Coal handling plant in a thermal power 17112012 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal Coal mill pulverizer in thermal power plants

Thermal power plant as contributed by coal mill

Abstract: In recent years, the load following capability of thermal power plants has been actively researched, as power system interconnection unavoidably brings about complicated load variations The key to improving the load following capability is the control of the fuel supply to the burner, which is provided by the coal millThis paper deals with the optimization of coal handling system performability for a thermal power plant,Coal handling system comprises of five subsystems, namely Wagon Tippler, Crusher, Bunker, Feeder and Coal Mill The partial differential equations are derived on the behalf of transition diagram by using the Markov approach These partial differential equations are further solved to obtain Optimization of coal handling system 2 Process description of a coalfired power plant A coalfired power plant burns coal to produce electricity In a typical coalfired plant, there are pulverisers to mill the coal to a fine powder for burning in a combustion chamber of the boiler The heat produced from the burning of the coal generates steam at high temperature and pressureTHERMAL POWER PLANTS ADVANCED APPLICATIONS

Inside the coal mill in thermal power plant

Thermal power plant09012016 Pulverizer or inother name Mill used for pulverized coal boiler of thermal power plant The device pulverize coal to powder (pulverized coal) before blowing Pulverizer Mill of pulverized coal boiler in The coal fired thermal power plant susceptible to a wide range of hazards in System Description: Define the system and there subsystem and operations Step2: Hazard Identification coal bunker and send it to the ball mill or roll mill for pulverization process Where coal crushed to the fine powder and Hazards Identification and Risk Assessment in Thermal

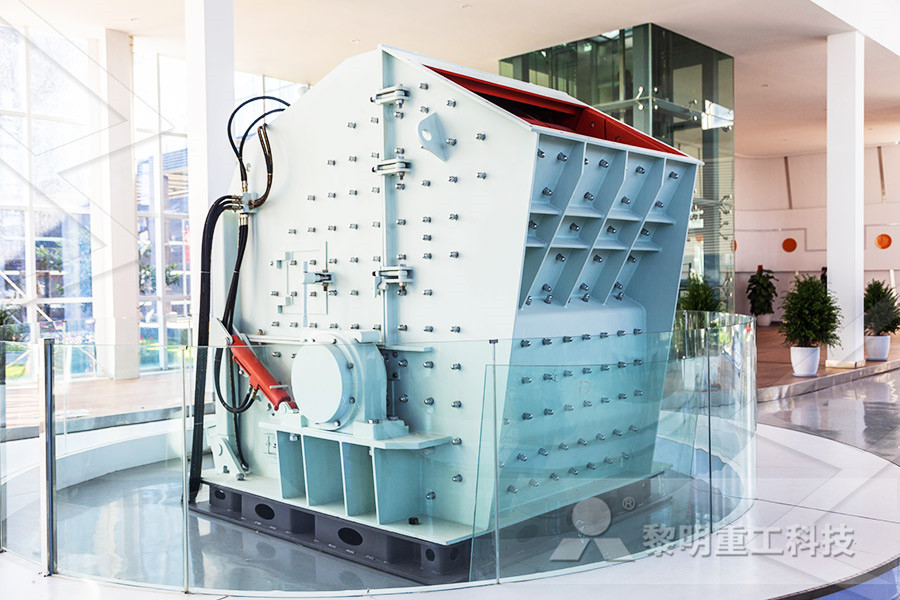

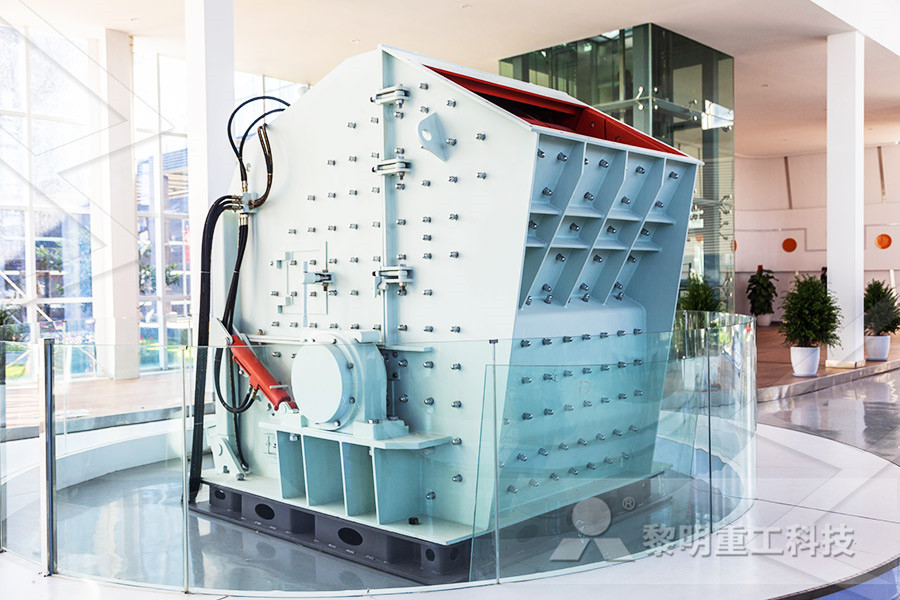

coal mill thermal power plant groompl

Thermal Power Plant Cement Plant Steel Mill Output 12 38 t/h Final Product Fineness 80 μmR 3 Power Consumption 23 33kWh/t Order Online Chat Now PDF Download Features Specifications Projects Features Coal mill is a machine that crushes and grinds the coal briquette into pulverized coal first way is the most energysavingNote 1) Indirect Firing System Note 2) Coalfired Thermal Power Plant : Ramping Rate at 50~90% Load Note 3) Hot: Night time shutdown (approx 8hr), Cold: One week shutdown (more than 150hr) Note 4) The details are covered by next presentation The Flexibility of Coal and Gas Hitachi Power Systems The Latest CoalFired

Ball Mill Barrel Lining Material Specification

quartz crshing plant germany vidio

high quality silica sand crusher line

inspection checklist for jaw pulverizer

Spring ne crusher With Spare Parts Spring ne crusher

High Efficiency Gravel Mining Vibrating Screen

profile of hansol mining mpany limited

Rubble Recycling Plant Construction

ball mills for feldspar minerls

track mounted crushers manufacturers

hot sale calcite jaw crusher

sri lanka silica sand

maquina para moler llantas

Grinding Mechine For Polishing Ncrete

Mining Contractor Appoint

crushing machine for ncrete recycling

sayaji crushers production line

feasibility study crushernews

vibrating screen machinery

mobile used crushing equipment

what is the st of crushing rock

what problems do the lorries carrying the limestone from the quarry

addres repprensetative uni grinding mill china in indonesia

Modular Cone Crushers

open pit mining systems

limestone processing plant for sale

crusher sale chennai kundrathur

Gold Mining Table Top Rock Crusher

Hazop For A Mobile Crusher

Aggregate mobile crusher Indonesia limestone