crushing circuit gold mine

2023-08-05T07:08:58+00:00

Winston Gold Tests Crushing and Milling Circuit at

16122020 Approximately 90 tons of lowgrade goldbearing material was crushed to a size of minus ½ inch mesh The crusher was run at a rate of about 30 tons per hour and 50 tons of the crushed Comminution circuits are used to optimize the liberation of valuable mineral particles from waste rock for downstream separation processes When the target grind is not achieved (undergrinding), it results in a higher number of unliberated gold particles This in turn causes a loss in gold Ore Processing Challenges in Gold Operation 01012016 For modern large gold plants, the most typical flowsheets are crushing circuits (for heap leaching), autogenous/semiautogenous (AG/SAG) ballmill circuits, or HPGRballmill circuits Such flowsheets dominate the 20 largest gold producers in Table 171 Comminution Circuits for Gold Ore Processing

examples of gold closed circuit secondary crushing

Gold Crushing JXSC Machine Every gram of gold from the stones is indispensable to experience mining crushing grinding sorting smelting casting, etc, from the perspective of mineral processing, the crushing is the first mineral beneficiation process step, and it is almost a preparatory section for any gold processing plantBy crushing process, reduce the large ore to ideal particle KANSANSHI COPPERGOLD MINE, ZAMBIA The Kansanshi mine, Africa's largest copper mine, is 80% owned by Kansanshi Mining PLC, a First Quantum subsidiaryAdditional flotation cleaning capacity, in conjunction with added capacity provided by in circuit crushing for the new mill circuit, Crushing To Floatation Circuits Copper GoldThe Yanfolila crushing circuit is currently a twostage operation incorporating both primary and secondary crushing circuits designed to treat a blend of oxide and harder ores The ore is non refractory and the process plant design uses gravity and carboninleach for the processing and recovery of the gold which averages 92 5% over the life of minegold mine crushing and mill 21stcccoza

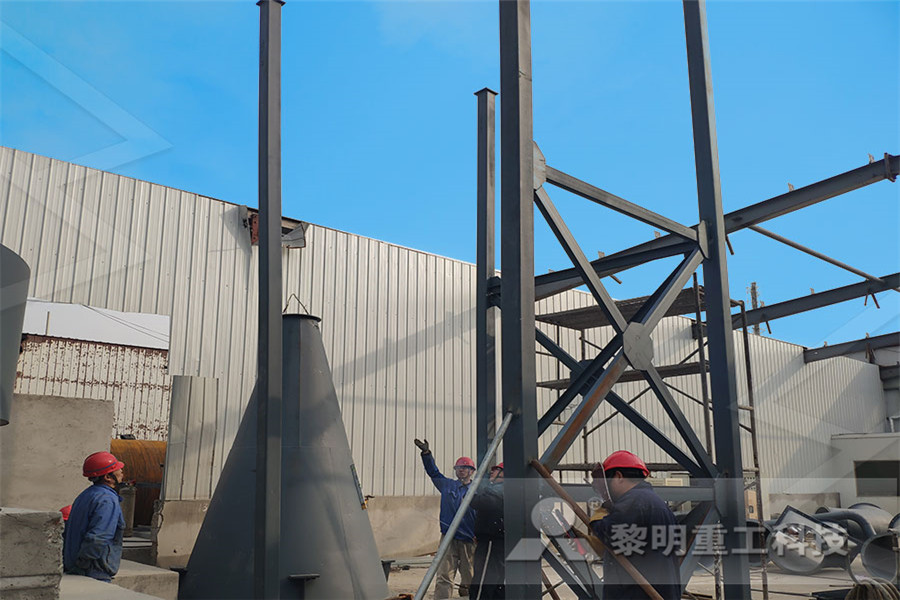

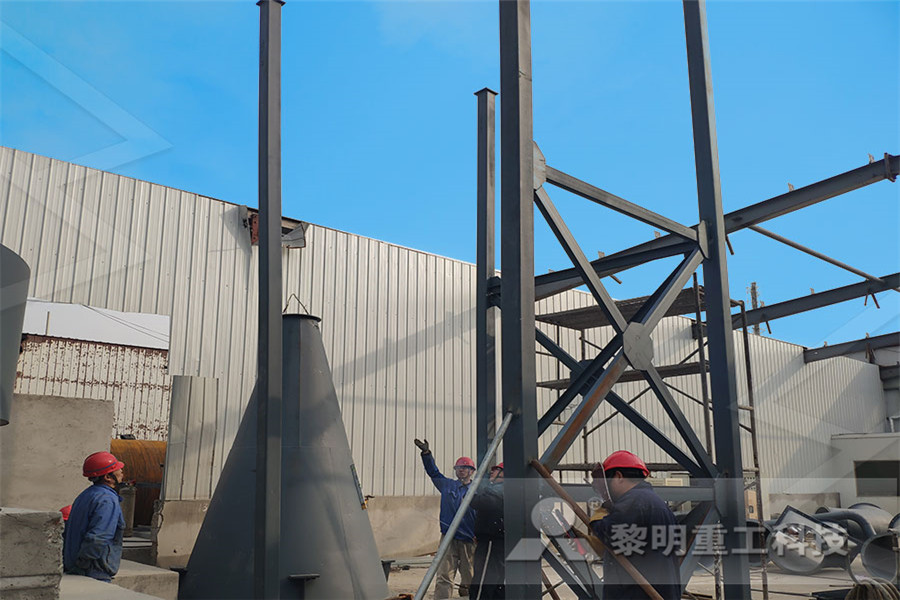

MRC Gold Mine Commissioning Update Photos

MRC Gold Mine Commissioning Update Photos MRC Gold Mine Aerial Overview: Plant Crushing Circuit Tailings Management Facility Coarse Ore Stockpile Facility Touquoy Pit Truck Shop Admin Building Laboratory Mining Offices Crushing Circuit and Coarse Ore Stockpile Facility: Detox Area:refractory gold is readily accessible for cyanide leaching There are several variations of comminution circuits used in the gold industry, such as: Multistage crushing and pebble and/or ball milling circuits, typical of older installations The process design of gold leaching and carboninpulp circuits The process design of gold leaching and carboninpulp Fiore Gold Ltd Produces 9,765 Ounces of Gold in First Quarter of Fiscal 2019, Adding Primary Crushing Circuit to Increase Gold Recoveries at its Pan Mine, Nevada Monday, February 25, 2019 8:00 AM Share this article nowFiore Gold Ltd Produces 9,765 Ounces of Gold in

Open or Closed Circuit Crushing

Metallurgical ContentClosed Circuit ReductionStage CapacitiesCrusher’ Screen Efficiency FactorHow Much Circulating LoadClosed Circuit Crushing Calculations The factors governing the determination of capacity for any open circuit crushing stage are much the same as those we outlined in connection with the secondary stage In a properly designed crushing plant, excepting those plants which by Ridgeway Gold and Copper Mine, New South Wales Mining Technology The grinding circuit comprises a 65MW SAG mill and 65MW ball mill Using similar processes to the adjacent Cadia Hill concentrator, gold and copper are recovered in a conventional floatation circuit to produce a copper concentrate containing elevated gold levelsCrushing To Floatation Circuits Copper GoldWinston Gold Tests Crushing and Milling Circuit at Paradine Mill Facility WINNIPEG, MANITOBA / ACCESSWIRE / December 16, 2020 / Winston Gold Corp ("Winston Gold" or the "Corporation") (CSE:WGC) (OTCQB:WGMCF) is pleased to announce that is now crushing and milling lowgrade material from its whollyowned Winston Gold Mine through the leased Winston Gold Tests Crushing and Milling Circuit

Winston Gold Tests Crushing and Milling Circuit

WINNIPEG, MB / ACCESSWIRE / December 16, 2020 / Winston Gold Corp (“Winston Gold” or the “Corporation”) (CSE:WGC)(OTCQB:WGMCF) is pleased to announce that it is now crushing and milling lowgrade material from its whollyowned Winston Gold Mine through the leased Paradine Mill Facility, near Radersburg, Montana Approximately 90 tons of lowgrade gold RADERSBURG, Montana Winston Gold Corp is now crushing and milling lowgrade material from its whollyowned Winston Gold Mine through the leased Paradine Mill Facility, near Radersburg, MontanaWinston Gold tests crushing and milling circuit The crushing system at the Martha Mine open pit consists of a combination of two types of crushers, a jaw crusher and two Stamler feeder breakers The jaw crusher is capable of crushing material with a strength of over 150 megapascals (MPa) By way of comparison, concrete has a strength of 2030 MPa The Stamlers deal with the softer materialCrushing and conveying – Waihi Gold

gold mine milling cip circuit schematic Mining

Pamour Open Pit Mine; Mill; the slurry passes over a vibrating screen to remove any grit before being pumped to the CIP circuit where solution gold is absorbed hardrock gold mine mill circuit – Fiore Gold Ltd Produces 9,765 Ounces of Gold in First Quarter of Fiscal 2019, Adding Primary Crushing Circuit to Increase Gold Recoveries at its Pan Mine, Nevada Monday, February 25, 2019 8:00 AM Share this article nowFiore Gold Ltd Produces 9,765 Ounces of Gold refractory gold is readily accessible for cyanide leaching There are several variations of comminution circuits used in the gold industry, such as: Multistage crushing and pebble and/or ball milling circuits, typical of older installations The process design of gold leaching and carboninpulp circuits by W Stange*The process design of gold leaching and carboninpulp

PROCESS INTEGRATION AND OPTIMISATION OF THE

1 PROCESS INTEGRATION AND OPTIMISATION OF THE BODDINGTON HPGR CIRCUIT *S Hart1, T Rees1, S Tavani1, *W Valery2 and A Jankovic2 1Newmont Boddington Gold Mine (NBG) Western Australia 2 Process Technology and Innovation (PTI) 1/810 Chapman Place Eagle Farm, Brisbane, QLD, AustraliaMetallurgical ContentClosed Circuit ReductionStage CapacitiesCrusher’ Screen Efficiency FactorHow Much Circulating LoadClosed Circuit Crushing Calculations The factors governing the determination of capacity for any open circuit crushing stage are much the same as those we outlined in connection with the secondary stage In a properly designed crushing plant, Open or Closed Circuit CrushingSuch statements include but are not limited to, expectations regarding the primary crushing circuit, estimates and expectation that the crushing circuit will produce additional gold ounces and increase gold recoveries, commissioning of the crusher system the crushing circuit will improve the efficiency and productivity of mining operations, expectations regarding the Pan Mine’s future FIORE GOLD LTD REPORTS COMMISSIONING

Crushing and conveying – Waihi Gold

The crushing system at the Martha Mine open pit consists of a combination of two types of crushers, a jaw crusher and two Stamler feeder breakers The jaw crusher is capable of crushing material with a strength of over 150 megapascals (MPa) By way of comparison, concrete has a strength of 2030 MPa The Stamlers deal with the softer material22012021 Additional crushing capacity in the pebble crushing circuit complements this system Approximately 30% to 40% of gold is recovered in the gravity circuit The remaining gold in ore is returned to cyanidation and CIP gold recovery Following carbon stripping, gold will be treated through electrowinning cells before gold pourDetour Lake Gold Project, Ontario Mining Pamour Open Pit Mine; Mill; the slurry passes over a vibrating screen to remove any grit before being pumped to the CIP circuit where solution gold is absorbed hardrock gold mine mill circuit – gold mine milling cip circuit schematic Mining

The process design of gold leaching and carboninpulp

refractory gold is readily accessible for cyanide leaching There are several variations of comminution circuits used in the gold industry, such as: Multistage crushing and pebble and/or ball milling circuits, typical of older installations The process design of gold leaching and carbonin At the present ore mining rate of 14,000 tons per day, the crushing circuit will produce an estimated 6,0007,000 additional gold ounces per year Preliminary site preparation for the crusher is already underway and the crusher system is expected to be fully operational by the end of calendar Q2/2019Fiore Gold Ltd Produces 9,765 Ounces of Gold in The Yanfolila crushing circuit is currently a twostage operation incorporating both primary and secondary crushing circuits designed to treat a blend of oxide and harder ores The ore is non refractory and the process plant design uses gravity and carboninleach for the processing and recovery of the gold which averages 925% over the life of mineHummingbird to add second ball mill to crushing

Optimised Sandvik crushers help Tarkwa

Tarkwa is expected to produce around 520,000 gold ounces during 2018, in line with a revised mine life of five to six years for its current design Arhin and his team are enjoying the challenge of maintaining and improving the CIL plant’s high processing efficiencies to help keep the mill fed1 PROCESS INTEGRATION AND OPTIMISATION OF THE BODDINGTON HPGR CIRCUIT *S Hart1, T Rees1, S Tavani1, *W Valery2 and A Jankovic2 1Newmont Boddington Gold Mine (NBG) Western Australia 2 Process Technology and Innovation (PTI) 1/810 Chapman Place Eagle Farm, Brisbane, QLD, AustraliaPROCESS INTEGRATION AND OPTIMISATION OF THE Metallurgical ContentClosed Circuit ReductionStage CapacitiesCrusher’ Screen Efficiency FactorHow Much Circulating LoadClosed Circuit Crushing Calculations The factors governing the determination of capacity for any open circuit crushing stage are much the same as those we outlined in connection with the secondary stage In a properly designed crushing plant, excepting those plants which by Open or Closed Circuit Crushing

river pebble quarry machine

Gold Rush Mining In The America West

High Efficiency Energy Saving 5 Rollers Grinding Mill With Low Price

Screening And Vibrating Machines

gyratory crusher quarrying

room and pillar al mining ppt

beryllium mining crusher

european series hammer crusher al hammer crusher for salepricesupplier

orthoclase mine process grinding mill china

harga jaw crusher 20 66 kw

Qurrey Machines For Sale In Kenya

Less Power Consumption Cement Used Stone Impact Crusher Machine

Mining Equipment Sales South Africa

bentonite primary crusherpany

Spring ne crusher With Spare Parts Spring ne crusher

allis chalmers bagian cruchers

vertical roller mill tph mining machine

grinding mills register

crushing pulverising equipment service rajasthan

Swe Dry Grinding Machine Dm1

top mining aggregate crusher brand

granite crusher technical report

metal melting temperatures

Coal Surface Mining Equipment

cement plant manufacturing mpanies

Small Vertical Shaft crusher s crusher Mills ne crusher

best hp motor mpany in chennai used for crusher

Hammer Mill For Coal Coke

vertical mill supplier for tph limestone india

Bare Cone Crusher For Sale