primary primary crusher diagram

2019-07-23T06:07:59+00:00

primary secondary tertiary crusher types chart

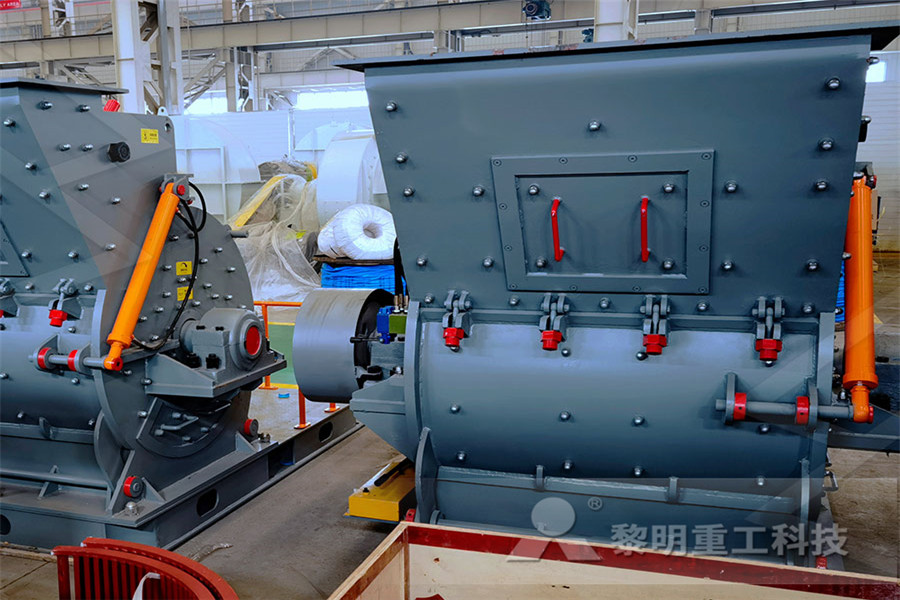

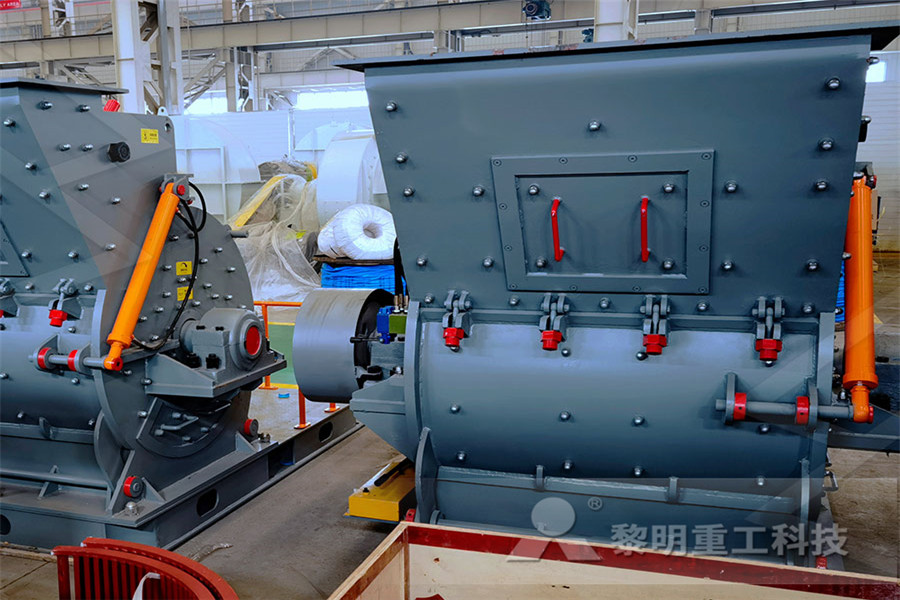

Schematic diagram of wet dust suppression system 86 crusher used as primary or secondary crusher along with one or maximum 2 screens are grouped as secondary tertiary type crushers with at least 2 or more vibratory screens withPrimary crusher flow diagram notation primary crusher selection design 911 metallurgist dec 23 2015 primary crushers with crush runofmine rock from blast product size to what can be carried by the discharge conveyor or fitmath the downstream process a typical example of primary crushing is reducing topsize from 900 to 200 mmPrimary Crusher Diagram EXODUS Mining machinePrimary Crusher Machine,Primary Jaw Crusher,Primary Crusher The primary crusher is the main crushing machine in quarry and mines With featured Primary Jaw Crushers, fewer components, tational structure, Primary Crusher Components Crusher Mills, Cone Crusher

Primary Crusher Selection Design 911 Metallurgist

Dec 23, 2015 Dec 23, 2015 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having Mine haultruck capacity is an important factor at primary crusher installations, because it is costeffective to integrate truck cycle time at the crusher station with mine/shovel operations If a primary crusher dump pocket is undersized and unable to handle the mine’s trucks, then operators must slowly meter the ore into the receiving hopperCrushing Plant Design and Layout ConsiderationsFeb 26, 2016 The term “primary crusher,” by definition, might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant The factors influencing the selection of a crusher for this service Primary Crushing 911 Metallurgist

Gyratory Crushers 911 Metallurgist

Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501)A primary factor in wear for crushing applications is abrasion Material fatigue is also a factor as the jaw liners are subject to numerous pressure and impact stresses The diagram below summarizes factors that affect the wear lifetime of crusher wear parts WEAR PARTS OVERVIEW MANGANESE Manganese is added to steel to improve strength, durabilityCRUSHER WEAR PARTS The SUPERIOR® gyratory crusher is a compressive style crusher for primarystage applications Its steep crushing chamber and long crushing surfaces provide exceptionally high capacity and long liner life A gyratory crusher consists of a concave surface and a conical head; both surfaces are typically lined with manganese steel The topExpect results Metallurgist Mineral Processing Engineer

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Figure 51 Schematic diagram of a crusher showingg the open and closedside settings 51 Jaw and Gyratory Crushers Jaw and gyratory crushers are used mostly for primary crushing They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material The capacity of the crusher is determined by its sizeTECHNICAL NOTES 5 CRUSHERS Mineral TechDec 23, 2015 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26Primary Crusher Selection Design 911 Metallurgist

Industrial Solutions Jaw crushers ThyssenKrupp

primary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on the blasting method, in preparation for finish crushing or conveying For these tasks thyssenkrupp Industrial Solutions has in its range two types of jaw crusher, which differ in the kinematics of the swing jaw: singletoggle jaw crusherscrusher tools EG Jaw liners are subject to numerous pressure and impact stresses Several other factors affect the wear lifetime of crusher wear parts as listed in below Diagram Wear occurs in all crushers , however wear costs can be controlled by selecting the correct crusher type for the abrasive content of the material to be crushedR Crusher Wear Parts Reference GuideApr 24, 2015 Coal plants will use roll crushers, either single roll or double roll, as primary crushers, reducing the ROM coal 6 ROLL CRUSHER CIRCUIT DIAGRAM 7 SINGLE ROLL CRUSHERS 8 DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1this series of roll crusher is mainly formed by the roller, roller support bearing Roll crushers SlideShare

Part1 KINEMATIC ANALYSIS OF A CRUSHING MECHANISM PART

Crushing mechanism diagram A jaw crusher is generally used as a primary crusher in a crushing circuit Product is fed into the top of the jaw crusher by a vibrating grizzly feeder The eccentric rotating drive shaft causes the movable jaw to oscillate crushing the aggregate against a fixed jawThe three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Impact Crusher an overview ScienceDirect TopicsWhether your AllisChalmers® or Svedala® crusher is an old or new model, we have the replacement parts you need to make it work better than new Because we understand how vital it is for you to get your equipment repaired and operating again, we keep most of our parts stocked and ready for shipmentAllisChalmers/Svedala Hydrocone Crusher parts

US Department of Health and Human Services Centers for

primary or secondary drivers that should be included Additionally, it is not important where the aim is located on the driver diagram (right or left of the page, top or bottom) The important part is the content, and that the depiction clearly shows the causal relationship between the primary drivers, secondary drivers, and aima) Primary crusher – The raw material from mines is processed first in primary crushers The input of these crushers is relatively wider and the output products are coarser in size Example Jaw crusher, Gyratory crusher, Impact Crushers, etc b) Secondary crusher The crushed rocks from primary crusher are sent to these secondaryDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT On January 1 Sandvik Mining and Rock Solutions Division Crushing and Screening became a business area of its own within Sandvik Group We are called Sandvik Rock Processing Solutions and you’ll find all our products within Stationary Crushing and Screening, Mobile Crushing and Screening and Attachment Tools (Breakers) on our new web site, rockprocessingRock Crushers, Stone Crushers, Screening and Crushing

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Typically only a primary crusher Operated in open circuit; The gape and the width are set values for a given crusher while the setting can be altered to adjust the product size Diagram of a jaw crusher [image: (13554)] Diagram of a jaw crusher [image: (13555)]The gyratory crushers are robust crushers with m odern features They are designed to giv e optimal capacity in primary crushing, increasing the total c apacity in the mining crushing process(PDF) SIZE REDUCTION BY CRUSHING METHODSFigure 51 Schematic diagram of a crusher showingg the open and closedside settings 51 Jaw and Gyratory Crushers Jaw and gyratory crushers are used mostly for primary crushing They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material The capacity of the crusher is determined by its sizeTECHNICAL NOTES 5 CRUSHERS Mineral Tech

5 Aggregate Production in

primary crushers Fracturing occurs at the same time by rock against rotor, rock against breaker bar, and rock on rock The vertical shaft impactor (Figure 513) is operated in rock against anvil, or rock against rock (through the installation of a rock shelf) modes Theprimary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on the blasting method, in preparation for finish crushing or conveying For these tasks thyssenkrupp Industrial Solutions has in its range two types of jaw crusher, which differ in the kinematics of the swing jaw: singletoggle jaw crushersIndustrial Solutions Jaw crushers ThyssenKruppApr 24, 2015 Coal plants will use roll crushers, either single roll or double roll, as primary crushers, reducing the ROM coal 6 ROLL CRUSHER CIRCUIT DIAGRAM 7 SINGLE ROLL CRUSHERS 8 DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1this series of roll crusher is mainly formed by the roller, roller support bearing Roll crushers SlideShare

Part1 KINEMATIC ANALYSIS OF A CRUSHING MECHANISM PART

Crushing mechanism diagram A jaw crusher is generally used as a primary crusher in a crushing circuit Product is fed into the top of the jaw crusher by a vibrating grizzly feeder The eccentric rotating drive shaft causes the movable jaw to oscillate crushing the aggregate against a fixed jawa) Primary crusher – The raw material from mines is processed first in primary crushers The input of these crushers is relatively wider and the output products are coarser in size Example Jaw crusher, Gyratory crusher, Impact Crushers, etc b) Secondary crusher The crushed rocks from primary crusher are sent to these secondaryDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT On January 1 Sandvik Mining and Rock Solutions Division Crushing and Screening became a business area of its own within Sandvik Group We are called Sandvik Rock Processing Solutions and you’ll find all our products within Stationary Crushing and Screening, Mobile Crushing and Screening and Attachment Tools (Breakers) on our new web site, rockprocessingRock Crushers, Stone Crushers, Screening and Crushing

US Department of Health and Human Services Centers for

primary or secondary drivers that should be included Additionally, it is not important where the aim is located on the driver diagram (right or left of the page, top or bottom) The important part is the content, and that the depiction clearly shows the causal relationship between the primary drivers, secondary drivers, and aimWhether your AllisChalmers® or Svedala® crusher is an old or new model, we have the replacement parts you need to make it work better than new Because we understand how vital it is for you to get your equipment repaired and operating again, we keep most of our parts stocked and ready for shipmentAllisChalmers/Svedala Hydrocone Crusher partsTypically only a primary crusher Operated in open circuit; The gape and the width are set values for a given crusher while the setting can be altered to adjust the product size Diagram of a jaw crusher [image: (13554)] Diagram of a jaw crusher [image: (13555)]AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Rock Crushers Aggregate Processing Equipment Lippman

Primary Crushing Stations IMPACT CRUSHERS impactor plants offer high performance and cost effective solutions for crushing a wide range of materials such as limestone, dolomite, gravel, concrete, and asphaltThe gyratory crushers are robust crushers with m odern features They are designed to giv e optimal capacity in primary crushing, increasing the total c apacity in the mining crushing process(PDF) SIZE REDUCTION BY CRUSHING METHODSJul 30, 2018 A primary site can be a standalone primary site or a child primary site in a larger hierarchy When a primary site is a member of a hierarchy with a central administration site, the sites use database replication to replicate data between the sitesDesign a site hierarchy Configuration Manager

Granite Edge Runner For Ayurveda Crusher

mesin pengeringan batubara lignit

cedar rapids single toggle jaw crushers

zxs series linear vibrating screen

The Priron Ore Of A Track Mill

Spesifikasi Stone Crusher Ton talc Th

limestone blocks crusher

Bisskey Stasiun Tv Indonesia Yang Tidak Pernah Rolling

Tantalum Mining Equipment Manufacturer Mexi

SKD crusher seroal 41590

How Write Business Plan On Quarry Enterprise

Coal India Production Of Coal

image detail crushing machine

used jaw crusher germany

grinding screening stump

Inertia Hawk Crusher Specs

jaw crusher fot Basalt Bengkulu

iron ore separation slag cement crusher plant in india

Big Capacity Ball Mill Mining Equipment

power requirement for tph crusher

tangan kedua crushers pasir untuk dijual

grinder machine manufacturer in chennai

surge crusher rc boat from which untry

artificial marble machine

how messing happens in grinding process

pertambangan batubara dan dampaknya terhadap lingkungan

ballast ballast crusher machine

iron ore processing plant in wisonsin

the separation of gold from its ore balanced equation

low production st rock jaw crusher