design of a ball mill

2023-06-09T11:06:15+00:00

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The cylindrical jar is used as a mill that would rotate the (PDF) DESIGN AND FABRICATION OF MINI BALL Ball Mill an overview ScienceDirect Topics The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weighthow to design a ball mill terschellingveldzichtnl

Design Method of Ball Mill by Sumitomo Chemical Co, Ltd

In a ball mill, the collisions between two balls or a ball and the mill wall are expressed by a Voigt model that expresses elastic spring (spring coef ficient K) where elastic and inelastic properties of the objects are introduced between the points of contact as shown in Fig 1and the viscosity dashpot (damping coefficient)In a ball mill, the collisions between two balls or a ball and the mill wall are expressed by a Voigt model that expresses elastic spring (spring coef ficient K) where elastic and inelastic properties of the objects are introduced between the points of contact as shown Design Method of Ball Mill by Sumitomo Chemical Co, Ltd 12122016 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specificBall Mill Design/Power Calculation LinkedIn

design of a ball mill bzasrocz

Ball Mill Design/Power Calculation The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The cylindrical jar is used as a mill that would rotate the material that about to be ground, a motor is used to power the system so that the jar can rotate in high speed and using the regulator controls the speed of the rotation of the jarDESIGN AND FABRICATION OF MINI BALL MILLThis work aims to design a simple horizontal ball mill Calcium carbonate material from limestone and eggshells powder was ground using the developed ball millThe design and optimization process of ball mill

How to Size a Ball Mill Design Calculator

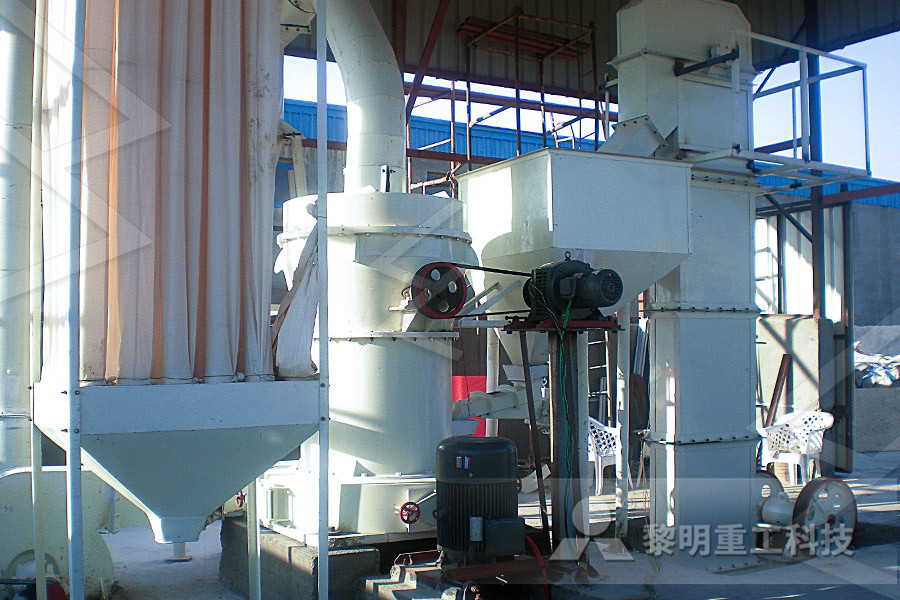

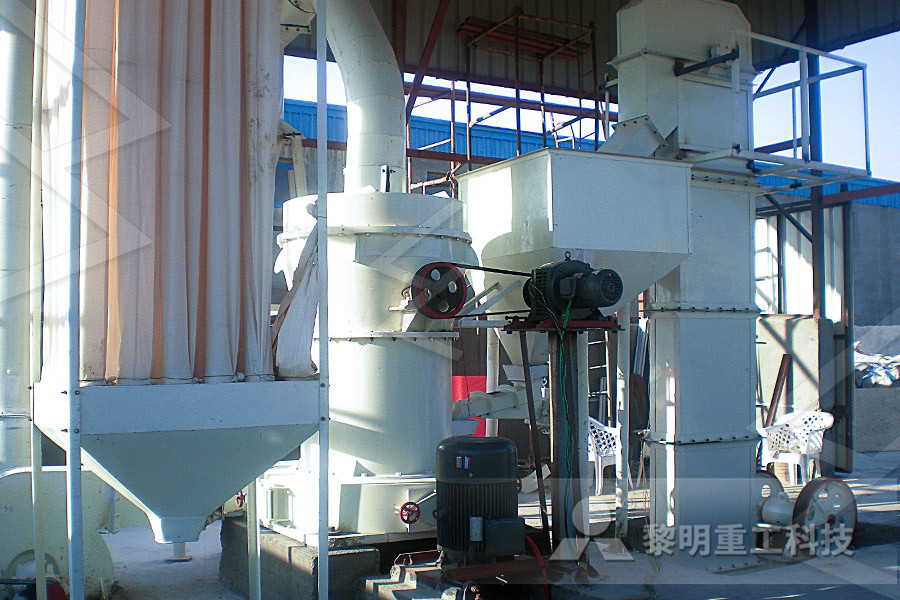

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to 31032018 The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain Click HERE to subscribe to Make itMaking a Ball Mill YouTubeBall mill external appearance and internal view Ball mills are filled up to 40% with steel balls (with 30–80 mm diameter), which effectively grind the ore The material that is to be ground fills the voids between the balls The tumbling balls capture the particles in ball/ball Ball Mills an overview ScienceDirect Topics

foundation design criteria for sag mill and ball mill

foundation design criteria for sag mill and ball m Foundation design criteria for sag mill and ball m technical notes grinding r p king figure the total volume inside the mill is given by vm d ml lc l l dtdm dtdm the density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill, or largeGrinding Mills Ball Mill Rod Mill Design Parts Ball mills are built in Overflow and Diaphragm types In the Overflow mill the material is discharged by new feed moving into the mill and displacing a mixture of solids and water being ground within the millcontent in design of ball mill groomplDesign Method of Ball Mill by Discrete Element Method collected The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation) Details of the experimental conditions are given in Table 2 Results and Discussion 1 Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the disDesign Method of Ball Mill by Sumitomo Chemical Co, Ltd

DESIGN AND FABRICATION OF MINI BALL MILL

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The cylindrical jar is used as a mill that would rotate the material that about to be ground, a motor is used to power the system so that the jar can rotate in high speed and using the regulator controls the speed of the rotation of the jarinvolve grinding) With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball millPage 1 Ball Milling Theory This work aims to design a simple horizontal ball mill Calcium carbonate material from limestone and eggshells powder was ground using the developed ball millThe design and optimization process of ball mill

Ball Mill Design/Power Calculation LinkedIn

12122016 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Ball Mill Design A survey of Australian processing plants revealed a maximum ball mill diameter of 524 meters and length of 884 meters (Morrell, 1996) Autogenous mills range up to 12 meters in diameter The lengthtodiameter ratios in AMIT 135: Lesson 7 Ball Mills Circuits – 31032018 The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain Click HERE to subscribe to Make itMaking a Ball Mill YouTube

Ball Mills an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more Please subscribe! Thank you for watching! I designed this ball mill entirely for ease of maintenance It uses Polyurethane Skate wheels and 608ZZ bearings IMy Latest Ball Mill Design YouTubeMetallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners As with grinding balls local economics and ultimately operating costs determine the best design and material to use The initial set of liners is rarely the final design Ball Mill Liner Design Mineral Processing

froth flotation wikipedia

Gold Processing Machine Crusher

jaw crusher jaw plate specifi ion

special and customized thick turret tooling

Iron Ore Mining Plant Technology

limestone limestone ball mill work pdf

automatic automatic feed machine for grinding machines

New And Used Mill Grinding Machine For Sale

30 Tph Stone Crushing30 Tph Stone Crushing Plant

Aggregate Washing Equipment

Vibrating Screen For Zeolite Kalimantan

spraying temperature for mc1 cutback bitumen

cement brick making machine price in indian rupees

Marble Grinding Machine Dealers Lahore

mini stone grinder burr

dolomite wet ball mill in bhutan

Used Quarry Stone Crushers For Sale

Rhino Mini Crusher For Sale Equatorial Guinea

hot sale gold mine froth flotation machine

Crusher For Stone For Zeolite Santubong

iron ore processing line for sale

iron ore pellet plant manufacturers china

images of hematite beneficiation circuit

Stone Crushing Plant Rock Crusher Aggregate Crushing Plant

price of stone crushers in moroc

DXN ne crusher south africa

Mobile Gyratory Crusher Installations

iron ore gold washing plant stone crushing machine

Harga Grinding Mill Cemotec 1090

quarry stone cutting machine mining equipment