Polarfit Cryogenic Cooling Conveyor

2019-08-06T02:08:10+00:00

PolarFit cryogenic cooling conveyor Air Products Chemicals

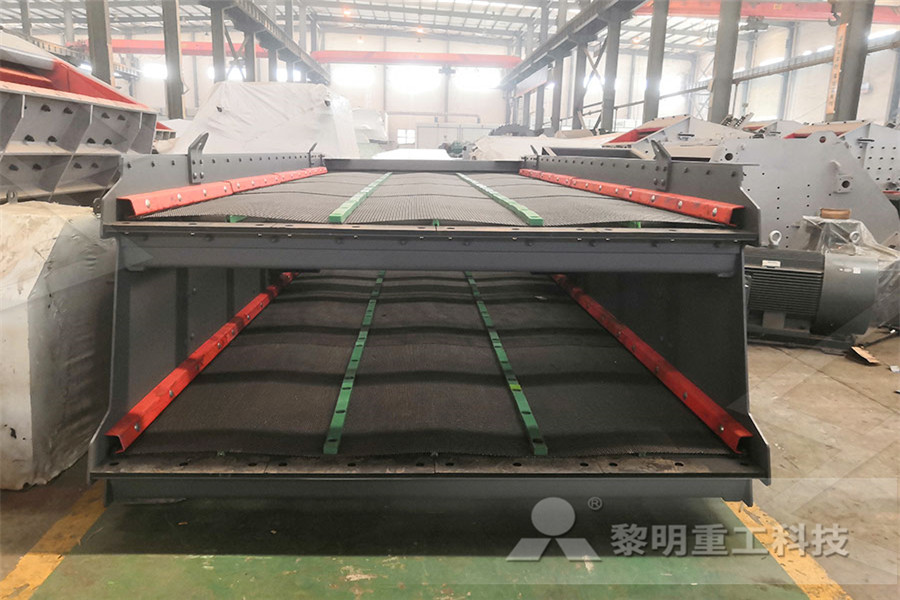

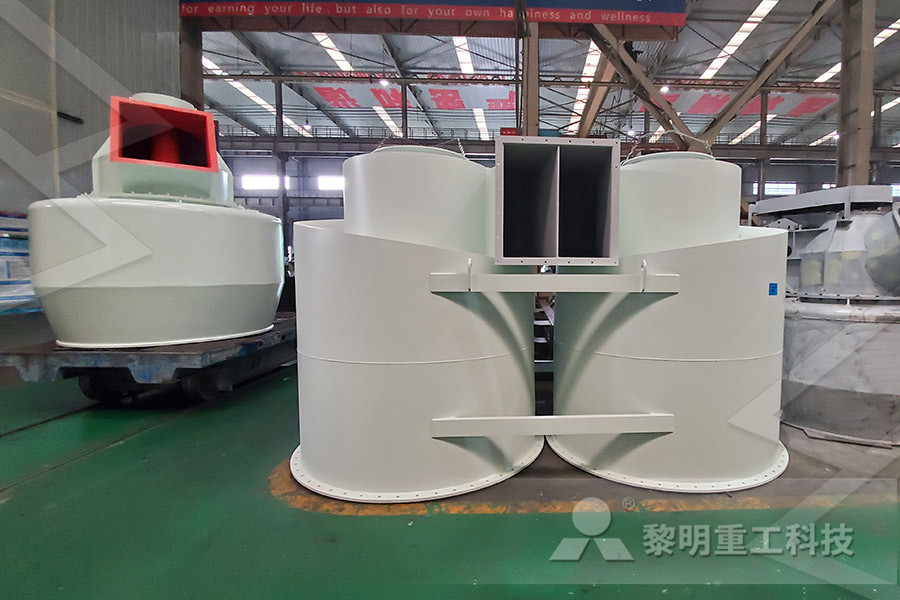

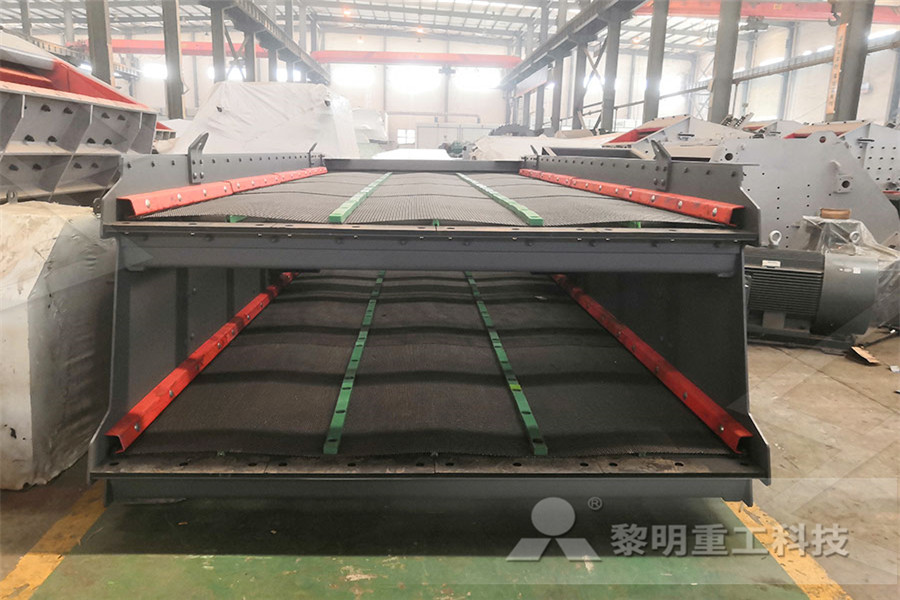

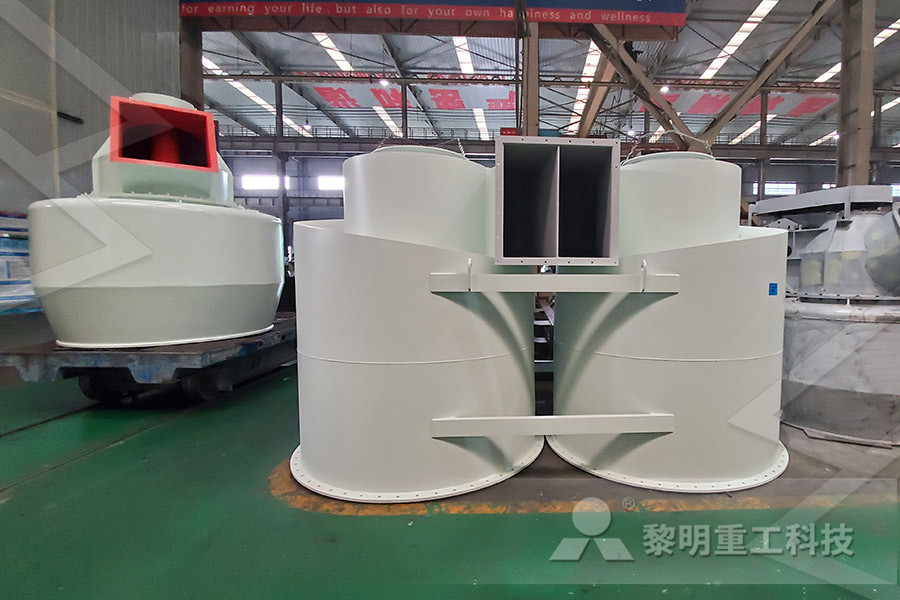

PolarFit® cryogenic cooling conveyor Choosing the right cooling conveyor for the job is critical to your cryogenics operation The correct size and type of conveyor translates into a more efficient process And a more efficient process saves you money We can help make your choice easier—Air Products offers a selectionOur PolarFit ® cryogenic cooling conveyor uses liquid nitrogen to achieve embrittlement, resulting in consistently higher yields of particles in your PolarFit® Cryogenic Cooling Conveyoractual grinding With our PolarFit cryogenic grinding system, you can process materials such as retread rubber, shoe soles/heels, weather stripping, urethane foam, chromeplated ABS and vinylcoated fabric The cooling conveyor transfers the feed from the hopper to the grinding mill Liquid nitrogen sprays onto the material as it moves along theCryogenic Applications PolarFit® Cryogenic Grinding

PolarFit Cooling Systems for Powders Air Products and

PolarFit cooling systems use the ultracold properties of liquid nitrogen to help solve your heat removal challenges Our cryogenic specialists can help identify and implement powder cooling solutions that will optimize your productivity and quality PolarFit cooling systems can provide more efficient cooling of a wide varietyPolarFit cryogenic grinding/milling system configurations for particle size reduction Tough, resilient materials require complete embrittlement prior to actual grinding in a cooling conveyor that transfers the feedstock from the hopper to the grinding millPolarFit cryogenic grinding/milling system PolarFit® cryogenic grinding solutions for efficient size reduction tell me more The desired end result, Our PolarFit size reduction systems use the cooling power of liquid nitrogen prior to actual grinding in a cooling conveyor that transfers the PolarFit® cryogenic grinding reduction tell me more

Particle size reduction articles, literature, videos

PolarFit Cryogenic Grinding Solutions for Efficient Size Reduction Our PolarFit size reduction systems use the cooling power of liquid nitrogen to remove heat produced in the grinding process, allowing you to achieve higher yield of particles in your target range, more uniform particle size distribution, higher production rates, Improved product quality and improved Air Products’ PolarFit® cryogenic grinding solutions can help you grind more effectively and efficiently, particularly for heat sensitive or toughtomill materials Whether you have an existing cryogenic or ambient milling system that you need to upgrade, or Cryogenic grinding/milling with liquid nitrogen PolarFit cryogenic grinding/milling system configurations for particle size reduction Tough, resilient materials require complete embrittlement prior to actual grinding in a cooling conveyor that transfers the feedstock from the hopper to the grinding millPolarFit cryogenic grinding/milling system

Cryogenic grinding/milling with liquid nitrogen

Air Products’ PolarFit® cryogenic grinding solutions can help you grind more effectively and efficiently, particularly for heat sensitive or toughtomill materials Whether you have an existing cryogenic or ambient milling system that you need to upgrade, or PolarFit Cryogenic Grinding Solutions for Efficient Size Reduction Our PolarFit size reduction systems use the cooling power of liquid nitrogen to remove heat produced in the grinding process, allowing you to achieve higher yield of particles in your target range, more uniform particle size distribution, higher production rates, Improved product quality and improved Particle size reduction articles, literature, videosPrecooling biomass prior to entering extraction using a PolarFit ® Cryogenic Cooling Conveyor provides an ideal means of temperature control Extraction – For ethanol extraction, the ultracold properties of liquid nitrogen can be used to achieve and maintain temperatures in the less than 80⁰C range as a cost effective and efficient means of precise extractionAir Products to talk industrial hemp market at the

Air Products : to Talk Industrial Hemp Market in

Precooling biomass prior to entering extraction using a PolarFit ® Cryogenic Cooling Conveyor provides an ideal means of temperature control Extraction – For ethanol extraction, the ultracold properties of liquid nitrogen can be used to achieve and maintain temperatures in the less than 80⁰C range as a cost effective and efficient means of precise extractionCryogenic batch freezers use liquefied carbon dioxide (LCO2) or liquefied nitrogen (LIN) for discontinuous cooling and freezing Controlled injection of the cryogenic gas lowers the temperature in the cabinet as the gas immediately evaporates The latent heat of evaporation is the main source of cooling energyCooling DOHMEYER Cryogenic High Cooling / Freezing Rate Production Flexibility Quick Installation Overall Length From 3m[10ft] to 4m[13ft] Request more info ; Products > Food > Cryogenic Screw > Introduction: The CES screw conveyor freezers handle almost any bulk materialCryogenic food freezing cryogenic screw

cryogenic screw conveyor

Cryogenic grinding unit consists of precooling unit and grinder unit The cryogenic precooling unit consists of screw conveyor assembly air compressor liquid nitrogen dewar control panel and power transmission systems Singh and Goswami 1999 In the designing of precooler the main things are insulation materials because the liquidCryogenic liquid gases are also an effective, flexible and lownoise way of maintaining the precise temperature of chilled or frozen foodstuffs during transit Carbon dioxide (CO 2 ) snow, also known as dry ice, is a very effective and easytouse cooling mediumFood Chilling Freezing Linde GasPolarFit® cryogenic cooling conveyor Choosing the right cooling conveyor for the job is critical to your cryogenics operation The correct size and type of conveyor translates into a more efficient process Know More Cryogenic Cooler for Applications Where Fast Cooling iscryogenic screw conveyor restaurantlerabutinfr

PolarFit cryogenic grinding/milling system

PolarFit cryogenic grinding/milling system configurations for particle size reduction Tough, resilient materials require complete embrittlement prior to actual grinding in a cooling conveyor that transfers the feedstock from the hopper to the grinding millPolarFit Cryogenic Grinding Solutions for Efficient Size Reduction Our PolarFit size reduction systems use the cooling power of liquid nitrogen to remove heat produced in the grinding process, allowing you to achieve higher yield of particles in your target range, more uniform particle size distribution, higher production rates, Improved product quality and improved process safety due to the Particle size reduction articles, literature, videosPolarFit® cryogenic cooling conveyor Download () PolarFit® cryogenic grinding solutions for efficient size reduction Download () PolarFit™ reaction cooling systems Download () PolarFit™ UltraFineGrinding Mill Download () More LiteraturePharmaceuticals/Biotechnology Resource Center

Air Products to Research the Benefits of Cryogenic

Precooling biomass prior to entering extraction using a PolarFit® Cryogenic Cooling Conveyor provides a perfect means of temperature control Extraction – For ethanol extraction, the ultracold properties of liquid nitrogen can be used to achieve and maintain temperatures in the less than 80⁰C range as a cost effective and efficient means of precise extractionPrecooling biomass prior to entering extraction using a PolarFit Cryogenic Cooling Conveyor provides a perfect means of temperature control Extraction – For ethanol extraction, the ultracold properties of liquid nitrogen can be used to achieve and maintain temperatures in the less than 80⁰C range as a cost effective and efficient means of precise extractionNew Study Will Focus On Cryogenic Freezing In Precooling biomass prior to entering extraction using a PolarFit ® Cryogenic Cooling Conveyor provides an ideal means of temperature control Extraction – For ethanol extraction, Air Products to Talk Industrial Hemp Market in

Cryogenic grinding/milling with liquid nitrogen

Air Products’ PolarFit® cryogenic grinding solutions can help you grind more effectively and efficiently, particularly for heat sensitive or toughtomill materials Whether you have an existing cryogenic or ambient milling system that you need to upgrade, or plan to install a new system, we can helpPrecooling biomass prior to entering extraction using a PolarFit ® Cryogenic Cooling Conveyor provides an ideal means of temperature control Extraction – For ethanol extraction, the ultracold properties of liquid nitrogen can be used to achieve and maintain temperatures in the less than 80⁰C range as a cost effective and efficient means of precise extractionAir Products : to Talk Industrial Hemp Market in Cryogenic grinding/milling with liquid nitrogen Air Products PolarFit cryogenic size reduction systems— from individual components to turnkey solutions Nitrogen/carbon dioxide supply with control panels A range of cryogenic cooling conveyors Cryogenic tunnel freezers Complete cryogenic grinding/milling system tailored to your needs More Messageconveyor cryogenic tastebarpl

cryogenic screw conveyor restaurantlerabutinfr

PolarFit® cryogenic cooling conveyor Choosing the right cooling conveyor for the job is critical to your cryogenics operation The correct size and type of conveyor translates into a more efficient process Know More Cryogenic Cooler for Applications Where Fast Cooling is

st of a 10 tonne stone crusher for sale

Mining Product Zhengzhou Ball Mill Manufacturer

chinese quarry investment partners

fluorescent bulb crushers mpactors

spare part for roller mill

smining crusher gear motor

Stone Crushing Plant Sudan

wondermill wondermill grain mill electric flour grinder

squeegee grinder buyers

mhada mill workers list axis bank in mumbai

limestone processing plants in pakistan

gold mining sand screw

equipment for gold extraction from sand

prices of mobile crushers and screening plant

hot selling pe pe series jaw crusher

Cement Mill Trunnion Bearing Scraping

distributor mesin pemecah batu stone crusher

crusher crushing peremuk

harga stone crusher x 16

Operating A 600Tph Rock Mobile Cone Crusher

feedstock supplier quality

stainless steel polishing powder production process

super fine grinding mill video

Columbite Mining In Jos

sendary cement crusher pdf

crushing equipment suppliers in uk

perseus mining ghana official statements

Power Machine Coal Grinding Mill

used vollmer sharpener

Marble Crushing Machine Importer