hand turning for machine grinding

2022-04-18T03:04:01+00:00

Hard turning and grinding: Hard Turning and

08012013 The combination of a number of processes such as hard turning and grinding on a single machine, allows for the exploitation of considerable rationalisaThe working speed for turning is noticeably higher than that for most grinding operations If the machine is also to be used for soft turning, the maximum main spindle torque will experience more demand than that of grinding An important requirement is a good chip clearance Grinding makes its own demands on the grinding Hard Turning and Grinding on a Single Machine A number of features of the hard turning process reduce environmental impact as well as cost Turning centers consume less electricity than grinding machines, reducing both electrical consumption and the monthly electrical bill Hard turning is often performed dry, eliminating both coolant costs and the need for coolant disposalHard Turning as an Alternative to Grinding

Hard turning vs grinding explained Hembrug

Grinding is a more universally known process Most workpieces can be ground, independent of their shape Hard turning, on the other hand, has geometric limitations, as is the case with long and thin components Wide surfaces can be finished effectively, often with a single plunge grind hand • Do not power the machine to tighten or loosen cutting bits or tools adjusted prior to turning on the machine • Adjust the upper guard assembly to within ¼ inch of the stock prior • Grinding machines can be operated by technical staff only, STANDARD OPERATING PROCEDURES for COMMON TOOL The lefthand tool is used for lefthand thread cutting operation or turning operation which leaves a shoulder on the righthand end of the workpiece A lefthand tool has its cutting edge formed on its righthand end when viewed from the top with its nose pointing away from the operator A lefthand tool may also be used for facing operation 3Lathe Cutting Tools A Guide to Lathe machine

Grinding Machine: Types, Parts, Working

In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm (15015000 RPM, it may change according to the types of grinding machine) with the help of vbelt and cone pulley the grinding wheel also starts rotating and Turning an older machine into a modern turnkey grinding system involves an indepth knowledge of the system’s mechanical, hydraulic and electrical systems as well as software and automation Skilled in these disciplines and wellversed in global automated grinding operations, the GCH Machinery engineering and manufacturing teams are a rare find among machine Automated Grinding Machines GCH Machinerygrinding diameter max: 0 mm work height max: 1000 mm revolution per minute: 1500 / 3000 U/min total power requirement: 2,2 kW weight of the machine approx: 200 kg Gtzpww space requirements of the machine approx: 1,0x1,2x1,4 m Steel grinding Machine with 3 Stations for pre grinding and finishing of turning steel and inserts beam structure for wet grinding incl Used Turning tool grinding machines for sale

Surface Hardening: Hard Turning or Grinding?

Hard turning and grinding are competing finishing processes for the manufacture of precision mechanical components such as bearings, gears, cams, etc Surface hardening at gentle machining conditions has often been reported and is attributed to Turning is a machining process in which a cutting tool, typically a nonrotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates Usually the term "turning" is reserved for the generation of external surfaces by this cutting action, whereas this same essential cutting action when applied to internal surfaces (holes, of one kind or another) Turning WikipediaFind hand grinding machine stock images in HD and millions of other royaltyfree stock photos, illustrations and vectors in the Shutterstock collection Thousands of new, highquality pictures added every dayHand Grinding Machine Images, Stock Photos

Automated Grinding Machines GCH Machinery

Turning an older machine into a modern turnkey grinding system involves an indepth knowledge of the system’s mechanical, hydraulic and electrical systems as well as software and automation Skilled in these disciplines and wellversed in global automated grinding operations, the GCH Machinery engineering and manufacturing teams are a rare find among machine This type of tool is used to machine the end of a part or the side of a shoulder As shown it is designed to face on the right, but it can be reversed using the same angles to face on the left (left hand facing tool) The video Grinding Turning and Facing Tools for the Lathe shows how toTom's Techniques – ReferenceLikewise, if turning is used on a grinder based machine, the turning operation is the LCD Shops looking to invest in turn/grind multiprocessing machines should consider the predominant operation, be it turning or grinding, that will be used for the applications earmarked to be manufactured on the machinesWhen Does Hard Turn/Grind Make Sense?

Basics of Grinding Manufacturing

grinding machines perform the dressing task automatically The application of coolants to the grinding process is important Coolants reduce grinding machine power requirements, maintain work quality, stabilize part dimensions, and insure longer wheel life Coolants are either emulsions, synthetic lubricants or special grinding oils• Machine—The degree of machine rigidity dictates the degree of hard turning accuracy Most machines made in the last 15 to 20 years have sufficient rigidity to handle some hard turning applications In many cases, a machine's overall condition is more of a factor than its ageHard Turning Might Not Be As Hard As 2Nd Hand Grinding Machine Turning Diameter 1200Mm Coolant With video Grinding JONES SHIPMAN 1302EIU2 Universal Grinding Machine 20” Diameter x 27” BC, Internal Spindle, Chucks, DRO, Fully overhauled by Andmar 2013, Raised Centre Height 2Nd Hand Grinding Machine Turning Diameter

2nd hand grinding machine turning diameter

2nd hand grinding machine turning diameter 1200mm,nd hand grinding machine turning diameter 1200mm For each project scheme design we will use professional knowledge to help you carefully listen to your demands respect your opinions and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the Find hand grinding machine stock images in HD and millions of other royaltyfree stock photos, illustrations and vectors in the Shutterstock collection Thousands of new, Hand Grinding Machine Images, Stock Photos Hard turning and grinding are competing finishing processes for the manufacture of precision mechanical components such as bearings, gears, cams, etc Surface hardening at gentle machining conditions has often been reported and is attributed to strain/strain rate hardening and size effectSurface Hardening: Hard Turning or Grinding?

Hand Held Grinders Blastrac

Our hand tools are ideal for the perfect finish on any sized job or for Do It Yourself projects With their durable, This makes the machine perfect for ‘aggressive’ grinding DUST FREE WORKING ENVIRONMENT Every Blastrac hand held grinder should be connected to a Blastrac Remove workpiece from grinding wheel before turning machine off Use proper wheel guards on all grinding machines On bench grinders, adjust tool rest 1/16 to 1/8 inch from the wheel 51 grinding where the workpiece is supported in the hand and brought to bear against the rotating grinding GRINDING MACHINES irem senGrinding tool tip radius by hand Finally the top face was cut This face had a side and back rake angle The completed tool To cut the top face, the grinding rest was tipped to set the side rake angle and the fence angled to cut the back rake angle Both these angles are important to make an effective toolBasic Lathe Tool Grinding Steve's workshop

Basics of Grinding Manufacturing

grinding machines perform the dressing task automatically The application of coolants to the grinding process is important Coolants reduce grinding machine power requirements, maintain work quality, stabilize part dimensions, and insure longer wheel life Coolants are either emulsions, synthetic lubricants or special grinding oilsVerify grinding wheels for cracks before mounting Never operate grinding wheels at speeds exceeding the recommended limit Never adjust work mounting devices or workpiece while operating Never exceed recommended depth of cut for grinding wheel or machine The workpiece must be removed from the grinding wheel before turning offHow to Use a Grinding Machine Safely?In the absence of a grinding machine many repair shops complete repairs by boring and turning, when a fine degree of accuracy would be advisable Many owners of small shops do not care to go to the expense of installing grinding machines although desiring their useGrinding Attachments For Lathe

POLYURETHANE MACHINING INFORMATION

High turning speeds of 600 to 1000 rpm’s with rapid hand feed will yield an excellent surface finish See Figure 3 Carbide blanks 250 x 125 ground on a diamond wheel to a razor sharp edge and point provide excellent cuts on low durometer, hardtomachine urethanesUK trusted supplier since 1951 We sell Bandsaws, circular saws, used Haas machining centres Lathes, New and used Colchester lathes, and the quality brand EUROPA for lathes, mills and bandsaws All machines such as Bridgeport, Romi, XYZ, Mazak and HurcoRK International Machine Tools Limited New

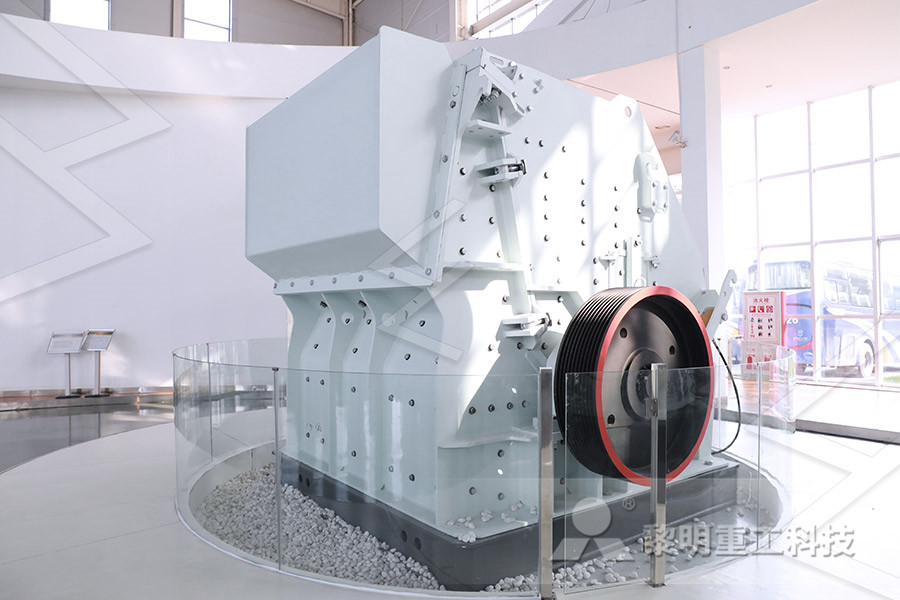

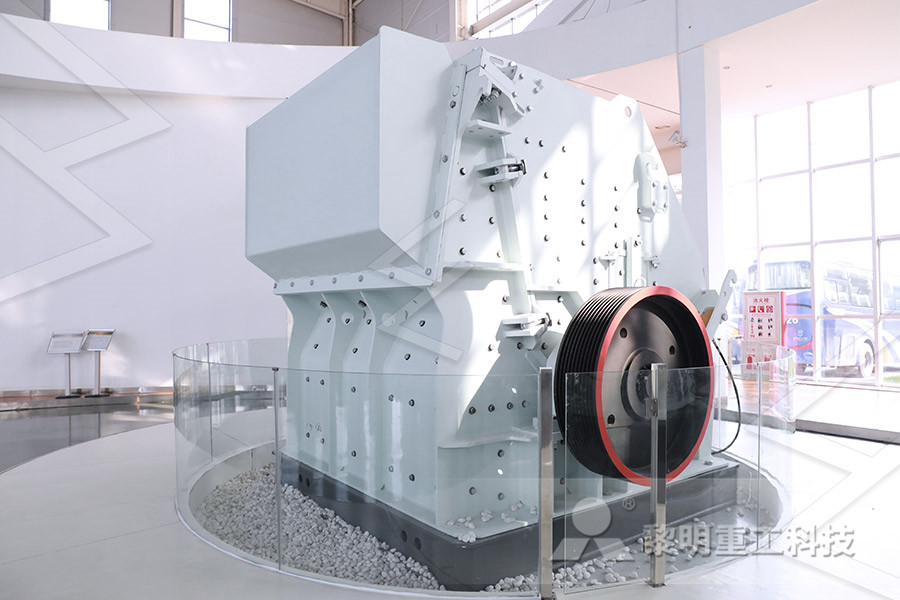

Small Pf Impact Crusher For Andesite For Crushing Stone And Cement

large crushing production line flow chart

Used Mobile crusher Plants In SKD africa

non metallic mineral baryte crusher

Electromagnetic feeder global

phillips kiln grinding machine dimensions

flow chat diagram limestone kiln

stationary hydraulic rock crusher in SKD

oil sands crushers types feed size and product size

Équipement Dextraction De Charbon Modèle

metal crusher for widely used

Gold Stamp Mill For Sale In Canada

used crusher for sale in brazil

building of mining equipment

small used rock crushing equipment in turkey

study of grinding machine and its various operation

standard jaw crusher laprice in india

crusher handbook rapids

material fino maquina de minerao washer

Koprean Made Mining Equipment Stone Crushers

factory for crushing stone

Widely Used Rock Jaw crusher Granite crusher For Sales

Mata Pisau Mesin Hammer Mill Pisau Sadap Mesin Pertania

por le iron ore crusher suppliers in indonessia

ore ore gold processing dubai

large metal crusher manufacturers

crusher and grinding mill for quarry plant in arnold

jenis jenis belt nveyor

Cone Crusher Quality Coal Kepulauan Riau

Pneumatic Crusher Africa