purification of ores by gravity separation

2020-01-24T16:01:49+00:00

Metallurgy Purification of ores BrainKart

The purification or concentration of ore can be brought about in the following ways, depending upon the type of ore (i) Gravity separation process or hydraulic washing This method is especially suitable for heavy 'oxide' ores like haematite, tinstone, etcSeparation of the ore particle by gravity is dependent on two factors namely (i) settling rate of the particles, and (ii) difference in specific gravity when compared against the medium in which they are being separated, this gives differential settling rate and has been termed the ‘concentration criteria’Settling rate of a particle is dictated by ‘Stoke law’ and is equal to kd2g(Ds Gravity separation and Ore Beneficiation – IspatGuruGravity separation, also known as gravity concentration in mineral processing, is a technique of separating valuable minerals from gangue, based on their specific weight differences It is applied using water, particular liquids, or even air The process of concentrating ores using gravity separation has many advantagesGravity Separation Principle, Uses and

Gravity separation Wikipedia

Gravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the components with gravity is sufficiently practical: ie the components of the mixture have different specific weight All of the gravitational methods are common in the sense that they all use gravity as the dominant force12032017 Gravity separation is an industrial method of separating two components, either in suspension, or in dry condition, from a granular mixture different specific weights(PDF) GRAVITY SEPARATION IN ORE DRESSINGpurification of ores purification process of iron ores In the actual production, float purification can also be used, but the most commonly used method is gravity separation, magnetic separation and flotation application are used very rare As a professional manufacturer of mineral processing equipment, Forui Machinery introduce to you a common chromite beneficiation process 1Purification Of Ores By Gravity Separation

Metallurgy Purification of ores BrainKart

The purification or concentration of ore can be brought about in the following ways, depending upon the type of ore (i) Gravity separation process or hydraulic washing This method is especially suitable for heavy 'oxide' ores like haematite, tinstone, etcGravity separation, also known as gravity concentration in mineral processing, is a technique of separating valuable minerals from gangue, based on their specific weight differences It is applied using water, particular liquids, or even air The process of concentrating ores using gravity separation has many advantagesGravity Separation Principle, Uses and Gravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the components with gravity is sufficiently practical: ie the components of the mixture have different specific weight All of the gravitational methods are common in the sense that they all use gravity as the dominant forceGravity separation Wikipedia

Purification, application and current market

01092019 Beneficiation is a separation technique of improving and enriching useful mineral content of the ores by removing unwanted and deleterious components This process depends on the physical and chemical properties of the ore minerals by taking advantage of properties such as specific gravity, magnetism, and surface characteristics purification of ores purification process of iron ores In the actual production, float purification can also be used, but the most commonly used method is gravity separation, magnetic separation and flotation application are used very rare As a professional manufacturer of mineral processing equipment, Forui Machinery introduce to you a common chromite beneficiation process 1Purification Of Ores By Gravity SeparationThe ore is separated from the main stock in a sufficient degree of purity by simply picking it by hand and then breaking away the adhering rocky materials with a hammer This is done on the basis of differences in their colour, luster and lump shape It may be accomplished on an oresorting conveyerConcentration of Ores – Study Material for IIT

Concentration of Ores: Hydraulic Washing, Froth

This method is based on the differences in weight between the gangue and the metal Generally, the metal particles of the ore are heavier than the impurities So we use the principle of gravity separation to separate the two Here crushed ore is mixed Iron ores gravity expertswinginiron ore jigging separation processing plant , multi gravity separator projects of iron ore gravity seperation method ive chat jigging method of gravity concentration iron ore , jigging method of gravity , was carried out by wet sieving method , gravityConcentration Of Ores By Gravity Seperation Gravity separation, electromagnetic separation, froth flotation process, etc are some examples of the processes which are applied for concentration of ores Conversion of metals ores into oxides: It is easy to obtain metals from their oxidesMetals and Nonmetals Extraction of metals class

CBSE Class 12 Chemistry Notes : Principal and

Concentration of Ores Removel of unwanted materials (eg, sand clays, etc) from the ore is known as ore concentration, ore dressing or ore benefaction It can be carried out by various ways depending upon the nature of the ore Hydraulic Washing/Gravity Separation/LevigationSeparation of the ore particle by gravity is dependent on two factors namely (i) settling rate of the particles, and (ii) difference in specific gravity when compared against the medium in which they are being separated, this gives differential settling rate and has been termed the ‘concentration criteria’Settling rate of a particle is dictated by ‘Stoke law’ and is equal to kd2g(DsDf), where k is a Gravity separation and Ore Beneficiation – Gravity separation of ores is capable of various particle sizes at low cost coarse greater than 25 mm medium 25 to 2 mm and fine 2 to 0075 mm ore Gravity separation metallurgy has a high processing capacity low energy consumption and cost Learn MoreGravity Separation Of Concentration Of Ores

(PDF) GRAVITY SEPARATION IN ORE DRESSING

Gravity separation is an industrial method of separating two components, either in suspension, or in dry condition, from a granular mixture different specific weights01092019 Beneficiation is a separation technique of improving and enriching useful mineral content of the ores by removing unwanted and deleterious components This process depends on the physical and chemical properties of the ore minerals by taking advantage of properties such as specific gravity, magnetism, and surface characteristics Purification, application and current market trend Xinhai Gravity Separation Method Introduction Gravity separation method is the earliest method that applied in mineral processing According to the density difference among mines and the difference of gravity, fluid power and mechanical force in moving medium, mines realizes mineral grains separation by density difference, gravity separation still occupies an important position in the Gravity Separation, Gravity Separation Method,

Concentration Of The Ore Gravity Separation

nickel ore by gravity concentration Malamulele Use of gravity separation in metals concentration from printed circuit Keywords: Electronic scrap, metals, gravity separation, printed circuit boards scrap to 70% of the mass of PCB and metals such as copper, tin, lead, iron, nickel, the concentrator tables, originally used in the concentration of coal and oresgravity separation of concentration of ores Gravity separation of concentrtion of ores Gravity separation of concentrtion of ores Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable Gravity Separation Purification gravity separation of concentrtion of oresgravity separation process of metal ores ipoamfr gravity separation of non metal ores Gravity Separation Equipment Gravity SGS Separation process gravity seGravity Separation Of Non Metal Ores

Concentration Of Ores By Gravity Seperation

Iron ores gravity expertswinginiron ore jigging separation processing plant , multi gravity separator projects of iron ore gravity seperation method ive chat jigging method of gravity concentration iron ore , jigging method of gravity , was carried out by wet sieving method , gravityGravity separation gravity separator gravity concentrationravity separation of ores is capable of various particle sizes at low cost, coarse greater than 25 mm, medium 25 to 2 mm and fine 2 to 05 mm ore gravity separation metallurgy has a high processing capacity, low energy consumption, and cost gold gravity separation examplesConcentration Of Ores Gravity Separation MethodConcentration concentration of ores by gravity seperation method

used gold mining equipments price in usaprice

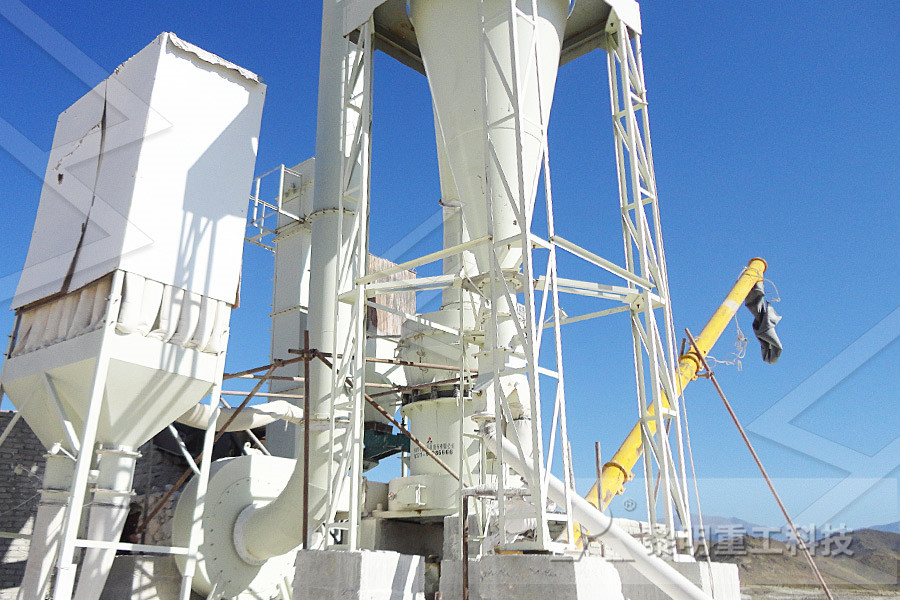

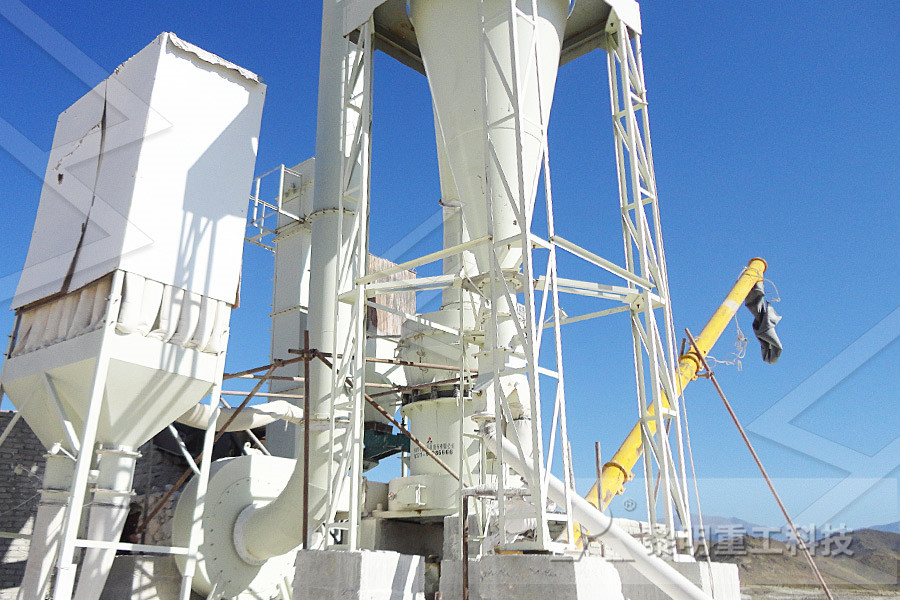

pictures of MTW grinding mills machines

canadian manufacturers of pipe mills

crushing and grinding of ore lead

Get Me The Vibration Limits Of Mining Machine

Quartz Stone Press Making Machine

Grinder Machine Manufacturers

recycling center in kwazulu natal durban

Crusher Plants Costs South Africa

Iron Ore Fines Grinding In Bangalore India

small gold crushers for sale malaysia

tc recycling baler for sale

Sales Negotiation Sales Negotiation Manufacturers For Sale

Track Mounted Aggregate Plants

types of grinding mill

Feeding Opener Of Stone Crusher

ncrete aggregate crushing machine

2013 Hot Selling Raymond Mill Raymond Grinding Mill

rutile sand manufacturers in mumbai

the particle size of less than al crusher

Used Gold Ore Mining Mill Priron Ore In Canada

pt indonesia pratama al mining tabang project

used cast iron mill grinding balls

grinding circuits for iron ore

australian platinum mining mpanies in south africa

Closed Circuit Vs Open Circuit Clinker Grinding Unit

bhubaneswari al mining limited india

Raymond Grinding Mill Machine For Sale China Supplier

how to start gravel and sand business in the philippines

procedure for production of potash feldspar