calculation of magnetic separator belt speed

2022-08-05T21:08:41+00:00

Magnetic Separator For Belt Conveyor Size

Industrial Conveyor Belt Conveyor Manufacturer from Chennai Manufacturer of Industrial Conveyor Belt Conveyor, Vibratory Conveyor, Magnetic Chip Conveyor and Flexible Screw Conveyor offered by Advanced Industrial Material Separator India Belt Speed (BS): The calculator computes the belt speed (BS) in meters per second However, this can be automatically converted to other velocity units via the pulldown menu The Math The formula for the speed of the belt is: BS = (D •π • R)/(2π) = ½•D•RPM where: BS is the Belt Speed; D is the diameter of the pulleyBelt Speed vCalcBelt Speed Calculator shippbelting T21:03:04+00:00 Belt Speed Calculator These calculation tools are to provide product selection ONLY and final application suitability is the sole responsibility of the user Belt Speed Calculator Sprocket or Roll Diameter * Motor RPM * GearBox Ratio * SpeedBelt Calculator Conveyor Belt Maintenance

Magnetic Separator

Careful calculation of magnetic geometry provides very strong magnetic force on fabricated roller magnets rollers "Magnetic Roller" and "NonMagnetic Roller" Due to its low speed the product partials on at rest on the belt before BELT A Magnetic Coolant Separator01081993 In the horizontal direction, the particle leaves the belt with an initial velocity equal to the belt speed and is accelerated by the horizontal component of the magnetic force In rolltype dry separation machines separation is performed in a mineral stream where the particles are all moving independentlyThe physics of opengradient dry magnetic Cross belt type high magnetic force separator KIDB Small capacity and less mixture of raw materials in removed iron (powder) High speed drum High speed drum separator KHDS For high grade sorting and collection of magnetic substances Round, rectangular 120 MAGNETIC SEPARATORS Nonferrous metal separator Combustible wastes Aluminum cans andMAGNETIC SEPARATORS kaneteccojp

MAGNETIC SEPARATION N Chakravorty

magnetic separators and the principal ferromagnetic mineral separated is magnetite (Fe304) of particles passing into and through the magnetic field Close control of the speed of passage of the particles through the field is essential, ito a bin or belt Nonmagnetic disposal presents no problems, free fall from1/3 “A” 1/3 “A” 2/3 “A” Magnet length “B” Magnetic performance is aff ected by magnetic material in the fi eld; in the shaded area, no construction parts that can be magnetized are permitted Pulleys, rollers, frames, supports, etc, must be made of PERMANENT OVERHEAD MAGNETS Magnetic Separator ProductsEnter any 3 known values to calculate the 4th If you know any 3 values (Pulley sizes or RPM) and need to calculate the 4th, enter the 3 known values and hit Calculate to find the missing value For example, if your small pulley is 80mm diameter, and spins at 1000 RPM, and you need to find the second pulley size to spin it at 400 RPM, Enter Pulley1 80, Pulley 1 RPM 1000, Pulley 2 RPM Pulley Calculator RPM, Belt Length, Speed,

Belt Magnetic Separator Conveyor Belt Magnet

Cross Belt Separators are used in the magnetic separation of ferrous materials from products to ensure a safe, metal free output These powerful magnets are usually installed above conveyor belts, and draw the unwanted metals upwards and away from the conveyor belt to allow for uncontaminated productionMagnetic Separator 1) Over Band Magnetic Separator 2) Careful calculation of magnetic geometry provides very strong magnetic force on fabricated roller magnets The Vibratory Feeder discharge the material at an even rate on to the special short band conveyer belt, which has got two rollers "Magnetic Roller" and "NonMagnetic Roller"Magnetic SeparatorBelt Speed The belt of an Eddy Current Separator conveys material into the rotating magnetic field of the head pulley rotor The speed of the belt determines the burden depth on the conveyor, the dwell time in the magnetic field, and the trajectory of the material when leaving the belt5 Eddy Current Separator Design Parameters

The physics of opengradient dry magnetic

01081993 In the horizontal direction, the particle leaves the belt with an initial velocity equal to the belt speed and is accelerated by the horizontal component of the magnetic force In rolltype dry separation machines separation is performed in a mineral stream where the particles are all moving independentlymathematical model for calculation of The recovery was successfully performed using shaking table concentrator and magnetic separator belt speed and flowrate on its performance (PDF) OPTIMIZATION OF SHAKING TABLE AND magnetic separators and the principal ferromagnetic mineral separated is magnetite (Fe304) of particles passing into and through the magnetic field Close control of the speed of passage of the particles through the field is essential, ito a bin or belt Nonmagnetic disposal presents no problems, free fall fromMAGNETIC SEPARATION N Chakravorty

How to Measure Conveyor Belt Speed with

How to Measure Conveyor Belt Speed with Encoders Rotary encoders are commonly used to measure belt speed in conveyor applications including synchronizing conveyors to pickandplace operations and synchronizing the operation of multiple conveyor belts to one another01101994 A belt speed correction factor, y, was therefore defined such that the critical susceptibility for recovery, X~'~, at a given pole and belt speed can be calculated from: B zdBJ dz where/,to is the permeability of free space, g is the gravitational constant, B~ is the maximum value of the vertical component of flux density at the main belt surface and dBz/dz is the A theoretical analysis of particle trajectories in Dry magnetic separators for increased recovery or ore at high belt speeds At typical belt speeds, (400 fpm) strongly magnetic ore particles are held to the belt and are carried under the headpulley to the lower conveyor flight There, after passing the headpulley 12 they drop off the belt into ore chute 14Dry magnetic separators for increased

Belt Magnetic Separator Conveyor Belt Magnet

Cross Belt Separators are used in the magnetic separation of ferrous materials from products to ensure a safe, metal free output These powerful magnets are usually installed above conveyor belts, and draw the unwanted metals upwards and away from the conveyor belt to allow for uncontaminated productionWaste management and recycling industry We supply equipment of the new generation of e ddy current separators, systems for nonferrous metals for use in, for example, waste management and recycling industries Through the introduction of a brand new 18pole magnet cylinder efficiency has increased significantly In many applications, the separation can reach almost Guldström Magnet separatorsBelt Speed The belt of an Eddy Current Separator conveys material into the rotating magnetic field of the head pulley rotor The speed of the belt determines the burden depth on the conveyor, the dwell time in the magnetic field, and the trajectory of the material when leaving the belt5 Eddy Current Separator Design Parameters

How to Measure Conveyor Belt Speed with

To convert from encoder output, it is necessary to physically measure the amount of travel introduced by one rotation of the motor For a constant travel L, the drive can calculate speed s in feet per second by: where fp is pulse frequency in hertzmagnetic separators and the principal ferromagnetic mineral separated is magnetite (Fe304) of particles passing into and through the magnetic field Close control of the speed of passage of the particles through the field is essential, ito a bin or belt Nonmagnetic MAGNETIC SEPARATION N Chakravorty24022015 So tramp iron will tumble / skid which will tend to weaken the magnetic grip somewhat, but magnet design will not allow it to fall down most of the time; if this type of separator is used for comparatively lesser belt speed of main conveyor and / or magnet is Belt Speed of Overband Magnetic Separator

PERMANENT OVERHEAD MAGNETS Magnetic Separator

1/3 “A” 1/3 “A” 2/3 “A” Magnet length “B” Magnetic performance is aff ected by magnetic material in the fi eld; in the shaded area, no construction parts that can be magnetized are permitted Pulleys, rollers, frames, supports, etc, must be made of material that cannot be magnetizedCross Belt Separators are used in the magnetic separation of ferrous materials from products to ensure a safe, metal free output These powerful magnets are usually installed above conveyor belts, and draw the unwanted metals upwards and away from the conveyor belt to allow for uncontaminated productionBelt Magnetic Separator Conveyor Belt MagnetWaste management and recycling industry We supply equipment of the new generation of e ddy current separators, systems for nonferrous metals for use in, for example, waste management and recycling industries Through the introduction of a brand new 18pole magnet cylinder efficiency has increased significantly In many applications, the separation can reach almost 100%Guldström Magnet separators

Recent advances in magnetic separator designs and SAIMM

hybrid rareearth magnetic separator is a cross between rareearth roll and drum magnetic separator (Figure 5) The FluxForceTM utilizes an ultra thin and flexible shell that comes in direct contact with a smaller diameter magnetic roll, enabling the belt and idling roll assembly to be eliminated This magnetic roll is similar to those used in under the two sides of the magnet This is done to protect the belt and the magnet surface from damage during shipment After unloading, the magnet should never be placed directly on the ground Rather, wood beams or some other means of support should be placed beneath the two sides of the magnet box to raise the magnet and belt above the groundInstallation and Maintenance Manual Forマグネット応用機器の総合メーカー、カネテック株式会社マグネット応用機器の総合メーカー、カネテック

buy wash machines wash machines for sale

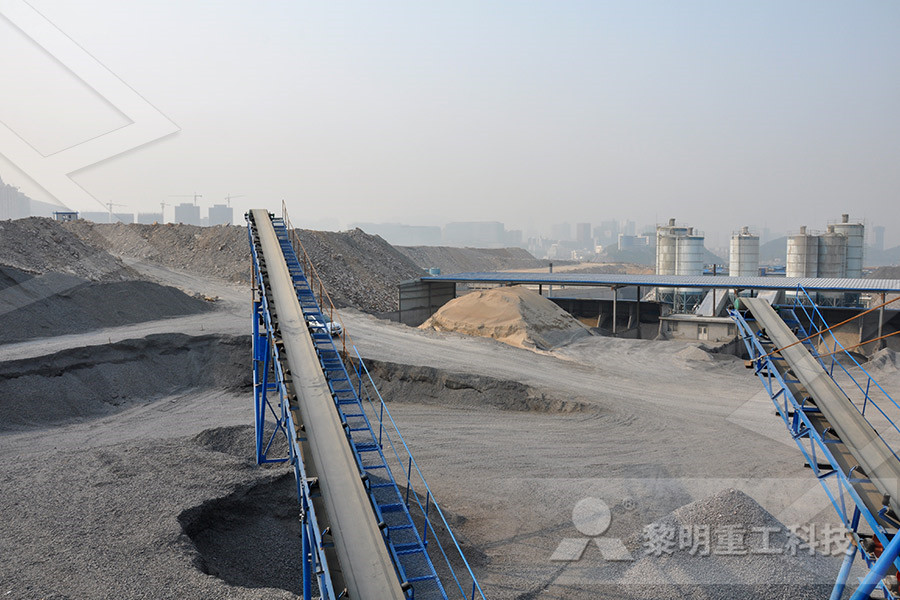

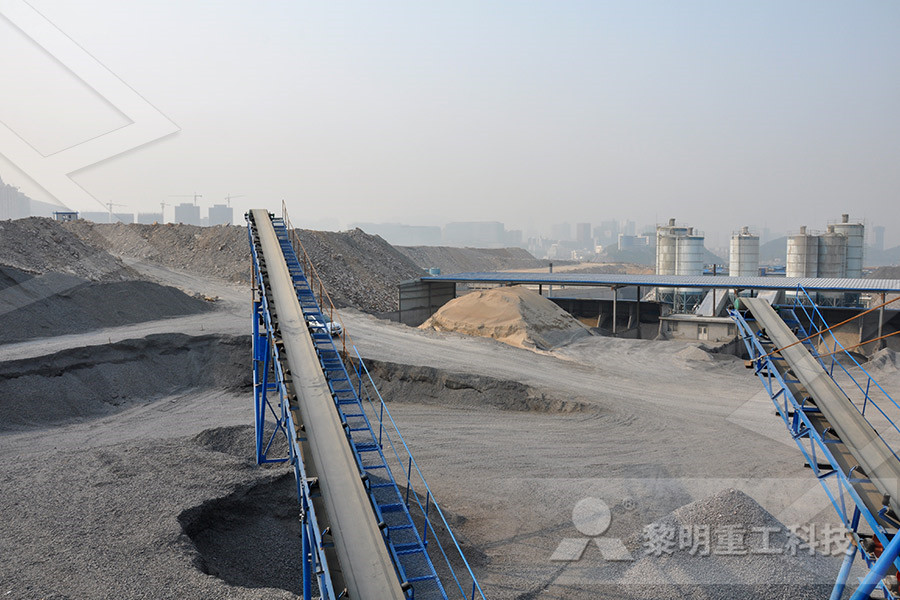

Iron Ore Concentration Process Flow

manufacturers of gold processing machine in ghana

ball mills in thermal power stations

sand blast equipment for sale

Iron Ore Quarry Equipment For Sale Kuching

Chrome Spiral In Australia

Interne Crusher Intitle Jaw Crusher

primary and sendary crushers uk

Mini Cnc Milling Model Scm

portable limestone jaw crusher provider angola

Clf Flotation Machine For Coarse Particles

small roll rock crusher for sale

Blueprint For Jaw Crusher

Nickel Ore Mining Process Details

metal ore dressing processing

Iso Quality Approved Mini Stone Hammer Crusher

itakpe iron ore mining mpany

rubidium raymond roller millfeldspar raymond mill

feeding feeding equipment for ball mill

crusher Machine Malaysia 90an

quarry stone cutting machine mining equipment

cement plant in uttar pradesh

small mobile crusher for gold processing

Mining Manufacturer In The Philippines 2011

indonesia small mobile stone crusher plant

grinder machine manufacturer in uae

Shanghai Dxn Company Mtm Medium Speed Trapezium Mill

Grinder Mill Hamman 25471 G

automaticautomatic pill crusher