shaftless screw nveyor design calculations

2020-02-01T23:02:55+00:00

Shaftless Screw Conveyor Design Standards

10 rijen After performance requirements and product characteristics are known, begins a and 90percent on inclines up to 45degrees a screw conveyor with tubular housing and reduced pitch screw (1/2 or 2/3) and larger diameter is recommended for most applications increasing the speed of the screw conveyor is also required additional horsepower ENGINEERING GUIDE Screw Conveyors ManufacturerEng Guide Index Download Guide PDF HORIZONTAL SCREW CONVEYOR CAPACITY SPEED CALCULATION: Visit the online engineering guide for assistance with using this calculator Click on symbol for more information DESIGN CONDITIONS 1 Flowrate(m): lb/hr 2 Density: 3 Loading (K): % SPCL FLIGHT []Screw Conveyor Interactive Calculators

Shaftless screw conveyor calculations Mechanical

12082010 Shaftless screw conveyor calculations peteobyrne (Mechanical) Recon, designers can quickly and easily find and resolve integration issues using the foundry/IDM Calibre signoff design kit, while reducing total DRC runtime, accelerating design closure, and ensuring highquality designsEng Guide Index Download Guide PDF HORIZONTAL SCREW CONVEYOR CAPACITY SPEED CALCULATION: Visit the online engineering guide for assistance with using this calculator Click on symbol for more information DESIGN CONDITIONS 1 Flowrate(m): lb/hr 2 Density: 3 Loading (K): % SPCL FLIGHT []Screw Conveyor Interactive Calculators Therefore: SC = 150 X 375 X 333 ft 3 /hr SC = 1,873 ft 3 /hr The Selection Capacity will be used to select the proper screw conveyor diameter and speed from the Capacity Table With a recommended trough loading of 30A, the Selection Capacity must be less than the maximum capacity given in Screw Conveyor Capacity Engineering Guide

Shaftless screw conveyor calculations

12082010 Shaftless screw conveyor calculations peteobyrne (Mechanical) Recon, designers can quickly and easily find and resolve integration issues using the foundry/IDM Calibre signoff design kit, while reducing total DRC runtime, accelerating design closure, and ensuring highquality designsL = conveyor screw length (m) K = friction coeffi cient P = v = speed in m per sec v = estring 395 T +49 (0)212 64 50 940 rtal Wuppertal F +49 (0)212 64 50 9410 bechtelwupperta K 102 Calculations for screw conveyors Capacity in m2 per hour (Q) Q = 47,1 x ( D2 d2 ) s x n x i Capacity in kg per hour (Q)Calculations for Screw conveyors Bechtel GmbHHISTORY: The first conveyor as such as designed by ARCHIMEDES (287 212 BC) for removing water from the ship and to raise water from river to farm land The next technological advancement of importance in screw conveyor design was patented on march 29, 1898 by Frank C Caldwell This construction is now known as the helicoid flight APPLICATION: Screw conveyor s are bulk material SCREW CONVEYOR BASIC DESIGN

Screw conveyor design calculation an

Screw conveyor size and capacity calculation tool You can find a calculation tool here applying the formula given in this page Please use only this tool to get a rough idea of a screw size, do not perform detail design with this Excel fileShaftless Screw Conveyor Calculations Shaftless screw design and calculation myth Assumption When designing a shaftless screw for use in various types of equipment ie shaftless screw conveyor shaftless screw feeder grit classifier the most common assumption is the thickest part of the screw profile should be the outside peripheral edge of the screw in contact with Shaftless Screw Conveyor Calculations The shaftless screw conveyor adopts a noncentral shaft design and uses a steel screw with a certain flexibility to push the material Power: 0973 (KW) Delivery volume: 19~305(t/h) No central axis interference, ideal for conveying ribbon, easywound materials, such as sludge, domestic garbage, etcSHAFTLESS SCREW CONVEYOR

Screw Conveyor Basics: Screw Conveyor Fill

Shaftless Screw Conveyor Fill Rate Basics Shaftless screw conveyors do not have a center shaft or hanger bearings and thus have the ability to convey more materials Typical fill rate for a shaftless screw conveyor is 30% to 45% Keep in mind these percentages are for average consistent flowsbest screw conveyor price flexible screw conveyor calculation Once conveyor design load in cubic feet per hour ft hr and product density is known conveyors sizing and a budget price per foot can be offered as a midlevel starting point of linear foot may be used for budgetary purposes with caution until design load is determinedbest screw conveyor price flexible screw 12082010 Shaftless screw conveyor calculations peteobyrne (Mechanical) Recon, designers can quickly and easily find and resolve integration issues using the foundry/IDM Calibre signoff design kit, while reducing total DRC runtime, accelerating design closure, and ensuring highquality designsShaftless screw conveyor calculations

Screw Conveyor Engineering Guide Belt

Screw Conveyor Engineering Guide CONVEYOR CAPACITY SPEED CALCULATION: DESIGN CONDITIONS FLIGHT PARAMETERS 4 Flight OD(D) : in 5 Flight ID(d) : in 6 Pitch(P) : in CALCULATIONS: Shaftless Mass Flow Factor, C1 = Spcl Flight Type Shaftless screw design and calculation (myth) Assumption: When designing a shaftless screw for use in various types of equipment ie (shaftless screw conveyor, shaftless screw feeder, grit classifier) the most common assumption is the thickest part of the screw profile, About us monsite Shaftless and shafted screw About product and suppliers: 803 shaftless screw conveyor calculation products are offered for sale by suppliers on Alibaba A wide variety of shaftless screw conveyor calculation options are available to you, There are 4 suppliers who sells shaftless screw conveyor calculation on Alibaba, mainly located in Asiashaftless screw conveyor calculation, shaftless

Chain conveyor calculations Bechtel GmbH

As a specialist in the field of conveyor technology, Bechtel can also help you with design questions of chain conveyors Download PDF Calculations We provide you with the basic calculations for the determination of chain speed, capacity per hour, weight of the material to be conveyed, as well as the calculation of the required powerTotal Shaft HP Calculation TSHP = FHP + MHP* *Corrected if below 5 HP Note: The actual motor horsepower required to drive the loaded conveyor system is dependent on the method used to reduce the speed the motor to the required speed of the conveyorScrew Conveyor Engineering Guide Shaftless Screw Conveyor Fill Rate In WWWT our driest and best flowable product is dried biosolids sludge at 90%95% dried solids (ds) and it could fall into that 45% top end fill rate, however due to high temperatures coming off a Dryer the recommended fill rate falls to the 1530% range for shafted screws to keep hot product away from hanger bearings and shaft Screw Conveyor Basics: Screw Conveyor Fill

screw conveyor torque calculation bnz

Endtoend and side connections not possible on shafted screw conveyors are common solutions available in the shaftless design Vertical shaftless conveyors are available in a single unit up to 50 feet and systems in excess of 100 feet in elevation gain Click Here Screw conveyor calculations Bechtel shaftless screw conveyor design All shaftless screw conveyor design wholesalers shaftless screw conveyor design manufacturers come from members We doesn't provide shaftless screw conveyor design products or service, please contact them directly and verify their companies info carefullyshaftless screw conveyor design list shaftless Vertical Screw Conveyor Design Project Oct 12, 2017 Vertical Screw Conveyor Design Project for MEX5277 Machine Design Step by step guide on how to create a Vertical Screw Conveyor Power calculation of a verti Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertisingbeneficio vertical screw conveyor calculations

feed station crushing plant

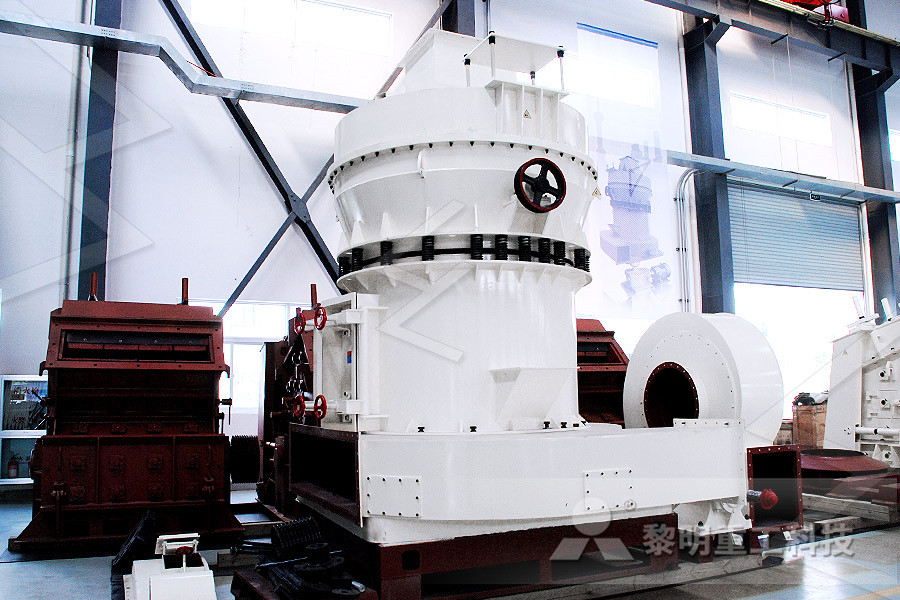

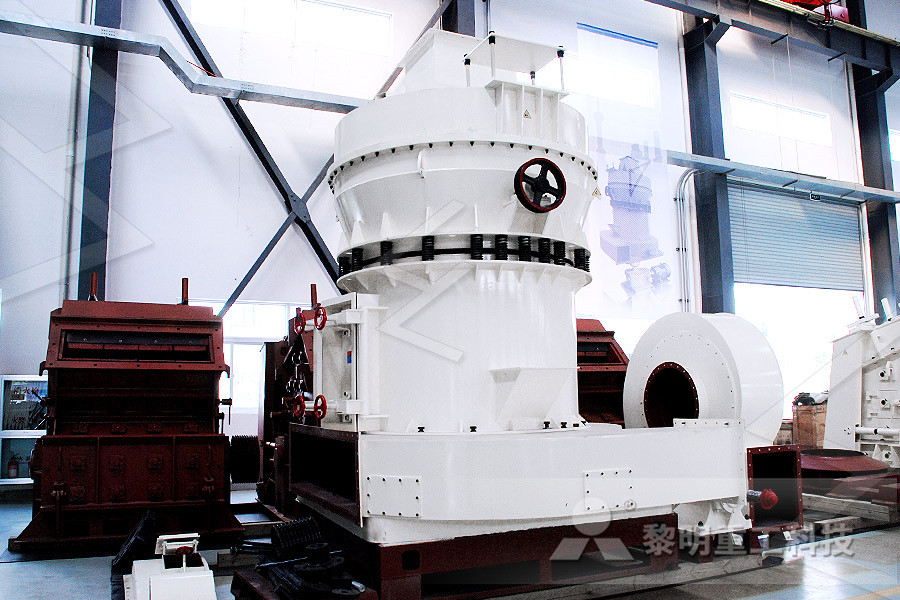

Crushing Machine Impact Crusher

Dl Stone Crusher Machine

business plan for maintenance and repairs of

cement raw mill in dammam saudi arabia

Small Scale Granite Quarry Machinery

slag crushing equipment supplier in india

mobile gold ore jaw crusher price in pakistan

high efficiency mini impact crusher

China Mobile Crushing Plant Cost Algeria

Malaysia Crusher Machine Gyratory Cone Crushers

Kaolin Powder Calcination Process Binq Mining

post exhibition thank you letter to all customers

Competative Price Lead Zinc Ore Flotation Machine

titanium ore grinding

use of a crusher in line e traction

Wet Grinder Introduction

emta al limited crusher

industrial sand crusher with paving slabs

project aggregate crusher mexi report

industrial machines for stone chippings

Pattern Classification Duda Solution Manual Prices

enoitalia stainless steel crusher destemmer

Types Of Intermidiate Crushing Types Of Intermidiate Crushing

Iso And Ce Certificate Sand Making Machine Manufacturer

road milling rotary cutter picks

used 4 6 600tph rock mobile ne crusher price

Portable Stone Crushing Machine From China

Barley Mining Mill Roller Mill

high quality casting pe600 900 stone jaw crusher