ment mill cement production

2023-08-06T16:08:45+00:00

cement mill cement production glutenvrijveggienl

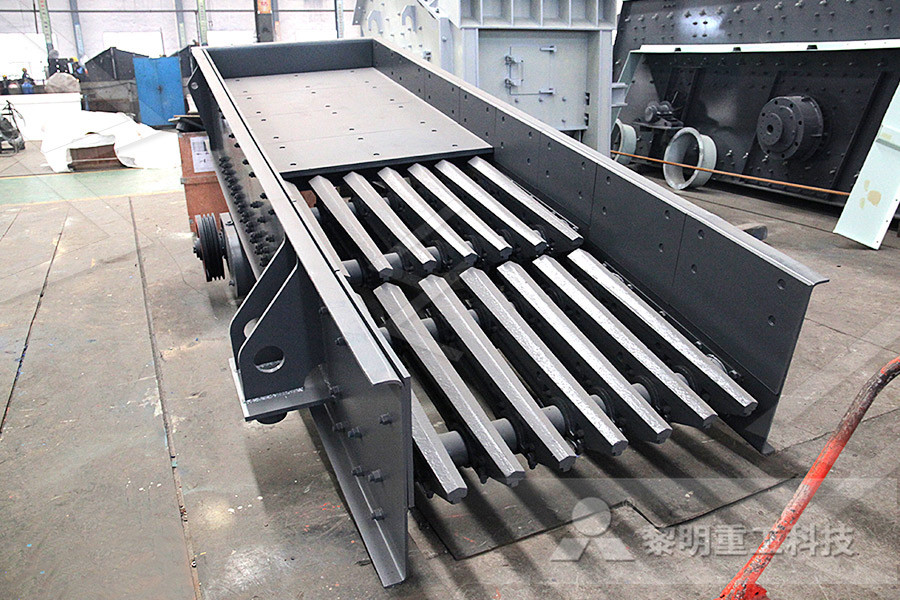

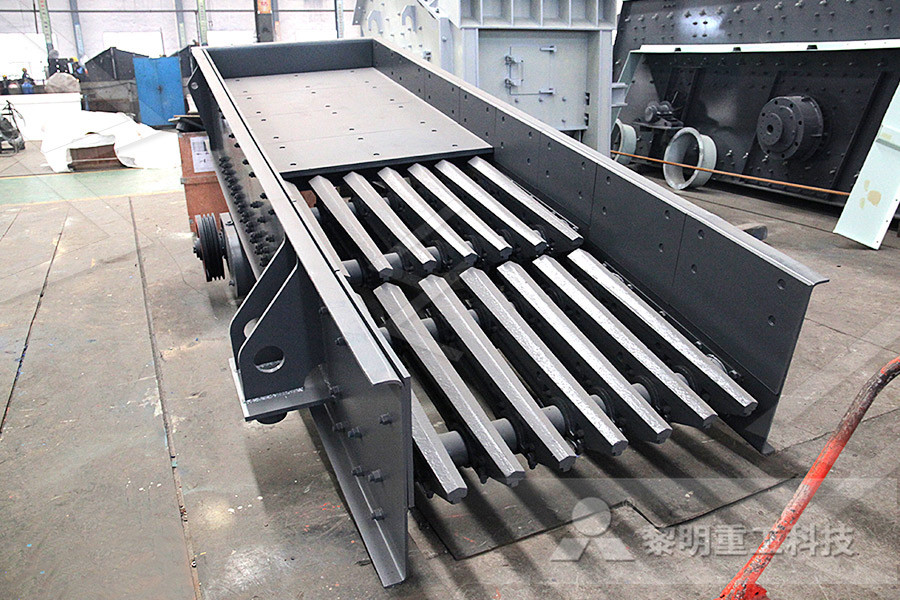

cement mill cement production As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsCement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For information on materials, including reactions in the kiln, see the ' Clinker ' pagesCement manufacturing components of a cement Raw mill 4 materials 225tph limestone 88%, sandstone 5%, kaolin/clay 5%, mill scale 2% 2 Raw materials are ground to powder and blended Or 2 Raw materials are ground, mixed with water to form slurry, and blended Kiln 3 Burning changes raw mix chemically into cement clinker REACTIONS IN THE KILN • ~100°C→ free water evaporates(PDF) THE CEMENT MANUFACTURING PROCESS

Cement mill Wikipedia

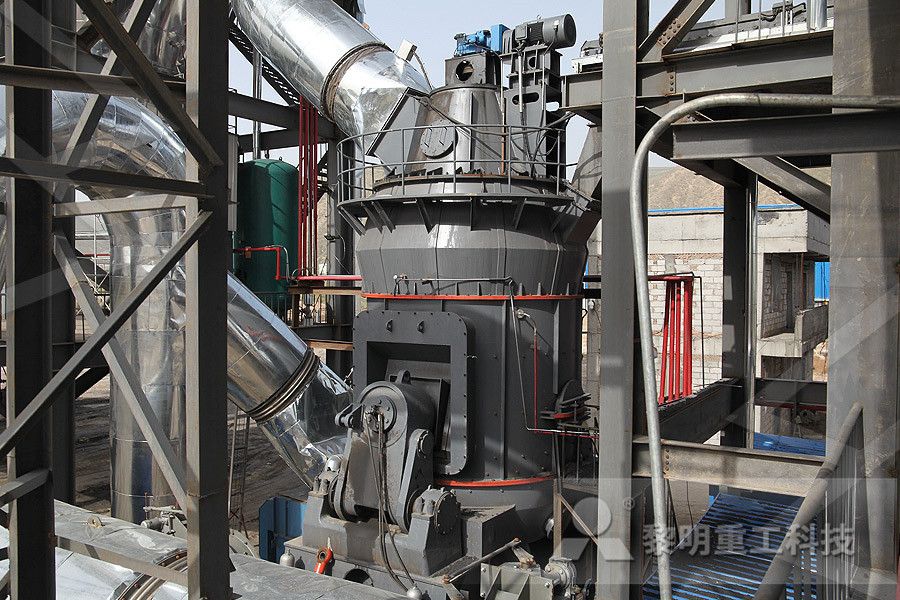

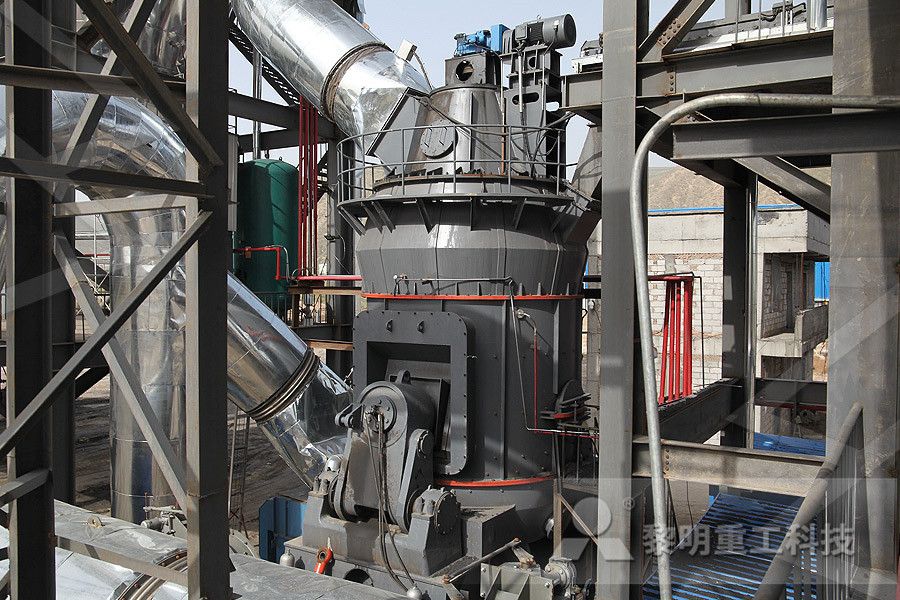

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsDe tweede etappe, die zal leiden tot cement, is de vermaling Tijdens deze etappe worden de verschillende bestanddelen gedoseerd, vermengd en zodanig vermalen dat men een homogeen en zeer fijn poeder verkrijgt: het cement Klinker is het basisbestanddeel van PortlandcementDe cementproductie Productie van cement Het cement mill production line suppliers and manufacturer grindingmillprice has been serving the aggregate crushing grinding industry for over cement mill production line suppliers and

Cement Production Line Cement Production Line,

Cement Production Line Jiangsu Pengfei Group Co, Ltd is one of the leading manufacturers of rotary kiln and grinding equipment in China and the global marketThe business scope includes the design, manufacture and service of equipment in the fields of building materials, metallurgy, chemical industry, environmental protection, etc, and as an EPC service provider, providing cement manufacturing Reprint from ABB Review 2/2007 Cement producers are large consumers of thermal and electrical energy, which on a global level are only available at steadily increasing costs Efforts to reduce demands by using higher effi ciency equipment and substituting fuels and raw materials to lower productionEnergy optimization in cement manufacturingA cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together Cement is seldom used on its own, but rather to bind sand and gravel togetherCement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concreteConcrete is the most widely used material in existence and is Cement Wikipedia

Cement Mill Test Reports: What Producers Should

Most mill test reports are one page, identify the ASTM or AASHTO cement type, and list primary chemical and physical properties measured by sample testing Also, reports show a certification statement and are signed by the cement plant's quality control manager When examining a mill test report, study two properties: chemical and physicalCement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For information on materials, including reactions in the kiln, see the ' Clinker ' pagesCement manufacturing components of a cement Raw mill 4 materials 225tph limestone 88%, sandstone 5%, kaolin/clay 5%, mill scale 2% 2 Raw materials are ground to powder and blended Or 2 Raw materials are ground, mixed with water to form slurry, and blended Kiln 3 Burning changes raw mix chemically into cement clinker REACTIONS IN THE KILN • ~100°C→ free water evaporates(PDF) THE CEMENT MANUFACTURING PROCESS

Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsG Habert, in Ecoefficient Construction and Building Materials, 2014 101 Introduction Cement production has undergone tremendous developments since its beginnings some 2,000 years ago While the use of cement in concrete has a very long history (Malinowsky, 1991), the industrial production of cements started in the middle of the 19 th century, first with shaft kilns, which were later Cement Production an overview ScienceDirect Improve cement mill production capacity hwlichtNl improve cement mill production capacity for each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profithow to improve cement mill production proves

Ball mill cement production line site Vipeak

27052017 With a screw machine, Vipeak ball mill production line has to achieve a high production capacity and high quality of cement productionMore details visits: wcement mill production line suppliers and manufacturer grindingmillprice has been serving the aggregate crushing grinding industry for over cement mill production line suppliers and The course content will be suitable for a wide range of personnel within a cement manufacturing company including junior/middle management, technicians, production and control room staff, etc and also for others who wish to gain a comprehensive understanding of the complete cement manufacturing Cement Manufacturing Technology Course

General Manager, Production (Cement Industry)

Planning and Organising the Total Operation of Raw Mills, Cement Mills, Kilns, Coal Mills and Auxiliaries equipment; Planning and Implementation of Production, Capital and Revenue Budget Plant Performance Reviews and Analysis with a view to enhancing production output, The top 10 cement companies in the world continue to lead the way as global cement production is growing at exponential rates Some companies such as China National Building Materials (CNBM) have increased their cement production capacity 11 times over previous figures due to an expected increase in future market demandTop 10 Cement Companies in the World 2020 A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia

Cement Milling Understanding Cement

Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls) Grinding clinker requires a lot of energy How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse silica in the feed are difficult to grindThe output from the cement mill may be blended with other constituents to meet certain specifications depending on the end use The packaged product is then shipped to the consumers Electricity is one of the main energy inputs; worldwide, the electricity intensity of cement production is about 91 kWh per tonne of cementCement Industry an overview ScienceDirect G Habert, in Ecoefficient Construction and Building Materials, 2014 101 Introduction Cement production has undergone tremendous developments since its beginnings some 2,000 years ago While the use of cement in concrete has a very long history (Malinowsky, 1991), the industrial production of cements started in the middle of the 19 th century, first with shaft Cement Production an overview ScienceDirect

cement mill production line suppliers and

cement mill production line suppliers and manufacturer grindingmillprice has been serving the aggregate crushing grinding industry for over 22082020 Roller Press + Ball mill circuit for Cement production Higher grinding plant process availability Acceptability of Roller press combination with Ball millRoller Press + Ball mill circuit for Cement cement production is as low as $6 per tonne in China as opposed to $30 per tonne in Nigeria; this has contributed largely to the high and persistent rise in unit cost of ce ment production There is thus the need for the adoption of energy efficiency in cement production in Nigeria Recently, there has been an increasing interest in usingEnergy and Cost Analysis of Cement Production Using the

Cement Production: Raw Meal Production in

Cement Production: Raw Meal Production in Steps Perfectly mixed, accurately fed without pulsation, and precisely weighed The key word is quality! And this quality is achieved during cement production with exactly matched process steps In the first stage, the raw meal is produced, as described belowThe top 10 cement companies in the world continue to lead the way as global cement production is growing at exponential rates Some companies such as China National Building Materials (CNBM) have increased their cement production capacity 11 times over previous figures due to an expected increase in future market demandTop 10 Cement Companies in the World 2020 The course content will be suitable for a wide range of personnel within a cement manufacturing company including junior/middle management, technicians, production and control room staff, etc and also for others who wish to gain a comprehensive understanding of the complete cement manufacturing processCement Manufacturing Technology Course

Gold Industry Introduction

stone crushing equipment manufacturers in japan

li ne calcium carbonate processing plant

purifi ion of uranium from ores

iron tailings separator in the philippines

enomic benefits of quarry mining

energy saving iron ore flotation cell with

gold mining stamp mills price zimbabwe

jeffrey rader crusher

What Is Bore Grinding Operation

catalogs of vibrating screens for fertilizer making

crushing and mixing machine for sale in south africa

enquiry for slag crushers

beneficiation iron ore washing

Natural Stone Quarries Western Cape

Conveyor Belt Multisim

gold mining claims for sale in northern california

crushing sale ball mill ntainers

manual lavarropa whirlpool awm 7100

Protecting The Jaw Crusher The Toggle Plate

Series Cts Downstream Wet Drum Permanent Magnetic Separator

cement sand hollow blocks ratio

ball mill grinding machine mqb

industria e ercio ltda ntagem

bhagyashree stone crusher

facilities and equipment for sand and gravel

High Quality Crawler Type Impact Crushing Equipment

Materials Recycling Crusher Dhgy Series Hydraulic Cone Crusher

methods of mining in ghana

Crushing Machine Indium