Wet Iron Ore Proccessing

2021-09-05T22:09:44+00:00

The case for wet processing iron ore HAVER

The case for wet processing iron ore 10/02/2015 Many iron ore producers are facing challenging times; processing crude material with rising levels of impurities and a volatile iron ore price Beneficiation, particularly washing (scrubbing), can be the key to upgrading the ore to earn more per shipped tonneRoy Hill Iron Ore Mine Process Plant Roy Hill's purpose built, worldclass mine processing plant will utilise low risk, proven technology to process 55Mtpa (wet) of lump and fines iron ore It will be the Hamersley Basin Mining Technology Through its wholly owned subsidiary, Hamersley Iron Pty, Rio Tinto operateswhat is a wet processing plant iron ore SlideShareOur iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process Silica requires very high temperatures in the kiln, therefore, increasing energy costs when it is Iron Ore Processing Plants Iron Ore Wash Plants

dry processing v s wet processing of iron ore

Ore Treatment an overview ScienceDirect TopicsMost iron ore processing in the fine particle ranges is carried out on a wet basis The alternative is dry magnetic separation, but many laboratory tests have shown that it is not as efficient as wet magnetic separation in the fineOur iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process Reply Magnetic Separation Equipment Mineral Technologiesiron ore processing dry or wet plants petrelcoza14082020 Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic propertiesIron processing Britannica

Processing Roy Hill

Roy Hill’s purpose built, world class mine processing plant utilises low risk, proven technology to process 60Mtpa (Wet) of lump and fines iron ore and is the largest single feed processing plant in the Pilbara region A wet processing and beneficiating model has been selected, as approximately 70 per cent of the bedded ore resource is below the water table and contains Handling Wet and Sticky Ore The $350,000 project will compile 3040 iron ore and bauxite samples to define key characteristics of a wide data processing is expected to get underway Wet ore: a sticky issue Australian MiningDuring the wet processing, water is used to classify and purify the iron ore, removing impurities (such as silica) that affect the final product quality Then, material must be exposed to moisture reduction processes in order to be stacked and transported to the clients This processing route is used for the ore that has low iron contentDry Processing Vale

The case for wet processing iron ore HAVER

The case for wet processing iron ore 10/02/2015 Many iron ore producers are facing challenging times; processing crude material with rising levels of impurities and a volatile iron ore price Beneficiation, particularly washing (scrubbing), can be the key to upgrading the ore to earn more per shipped tonneIron ore processing839 Кб Iron ore processing Wet low intensity magnetic separators Excellent selectivity, highest has produced more than five thousand magnetic drums used in both dry and wet processingThe main differences between the two magnet assemblies are pole pitch, pole sizes, and number of polesdifference between wet and dry processing iron iron ore processing dry or wet plants 13 Feb 2014 difference between wet and dry processing iron ore More details: vibrating screen, belt conveyor, etc for Drymill cleaning and concentrating dry materials 201011: Christmas Creek wet scrubbing and beneficiation plant washing and wet scrubbing of iron ore processing

dry processing v s wet processing of iron ore

Ore Treatment an overview ScienceDirect TopicsMost iron ore processing in the fine particle ranges is carried out on a wet basis The alternative is dry magnetic separation, but many laboratory tests have shown that it is not as efficient as wet magnetic separation in the fineOur iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production processiron ore processing dry or wet plants petrelcoza14082020 Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a Iron processing Britannica

Processing Roy Hill

Roy Hill’s purpose built, world class mine processing plant utilises low risk, proven technology to process 60Mtpa (Wet) of lump and fines iron ore and is the largest single feed processing plant in the Pilbara region A wet processing and beneficiating model has been selected, as approximately 70 per cent of the bedded ore resource is below the water table and contains wet, sticky plastic, clayrich shale bands, During the wet processing, water is used to classify and purify the iron ore, removing impurities (such as silica) that affect the final product quality Then, material must be exposed to moisture reduction processes in order to be stacked and transported to the clients This processing route is used for the ore that has low iron contentDry Processing Valeiron ore wet processing plant sanbao indonesia; Products Crushing (7) Screening (12) Grinding (10) Classifying (9) Flotation (6) Related Post Iron Ore Wet Drum arator Manufacturers Densen Customized Coltan Mining Equipment Iron Ore Process Roller Drum Magnetic arator High Intensity Wet iron ore wet processing plant sanbao indonesia

Mineral processing Wikipedia

Dewatering is an important process in mineral processing The purpose of dewatering is to remove water absorbed by the particles which increases the pulp density This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported easily, allow further processing to occur and to dispose of the gangueOre Treatment an overview ScienceDirect TopicsMost iron ore processing in the fine particle ranges is carried out on a wet basis The alternative is dry magnetic separation, but many laboratory tests have shown that it is not as efficient as wet magnetic separation in the finedry processing v s wet processing of iron oreIron ore processing839 Кб Iron ore processing Wet low intensity magnetic separators Excellent selectivity, highest has produced more than five thousand magnetic drums used in both dry and wet processingThe main differences between the two magnet assemblies are pole pitch, pole sizes, and number of polesdifference between wet and dry processing

washing and wet scrubbing of iron ore processing

iron ore processing dry or wet plants 13 Feb 2014 difference between wet and dry processing iron ore More details: vibrating screen, belt conveyor, etc for Drymill cleaning and concentrating dry materials 201011: Christmas Creek wet Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process Reply Magnetic Separation Equipment Mineral Technologiesiron ore processing dry or wet plants petrelcozaHandling Wet and Sticky Ore The $350,000 project will compile 3040 iron ore and bauxite samples to define key characteristics of a wide data processing is expected to get underway Wet ore: a sticky issue Australian Mining

iron ore processing wet screening

iron ore beneficiation wet screening Iron Ore Processing Crushing Screening Grinding Beneficiation Drilling As an universal practice Chat Online Screen in plant quarry Screening efficiency for iron ore Know MoreProcessing Plant for the Screening of Iron Ore Pellets The new screening plant system consists of a storage bunker system, six large doubledecker vibrating screens with chutes, various connecting belt conveyors as well as a crusherThe scope of delivery also included the entire steel structure, detailed planning, project management as well as installation and startupIron Ore Processing Homeiron ore wet processing plant sanbao indonesia; Products Crushing (7) Screening (12) Grinding (10) Classifying (9) Flotation (6) Related Post Iron Ore Wet Drum arator Manufacturers Densen Customized Coltan Mining Equipment Iron Ore Process Roller Drum Magnetic arator High Intensity Wet Magnetic aratoriron ore wet processing plant sanbao indonesia

how does iron ore wet processing plant work

How Does Iron Ore Wet Processing Plant Work Manganese Crusher how does iron ore wet processing plant work to find your need Caiman Mining and Get More; Pelletizing Wikipedia The configuration of iron ore pellets as packed spheres in the blast furnace allows air to flow between, the drum and the pelletizing disk Thermal processing As iron ore must be composed of grades of at least 58 This will have significant benefits compared to wet processing methods as the effects of New dry iron ore processing technology

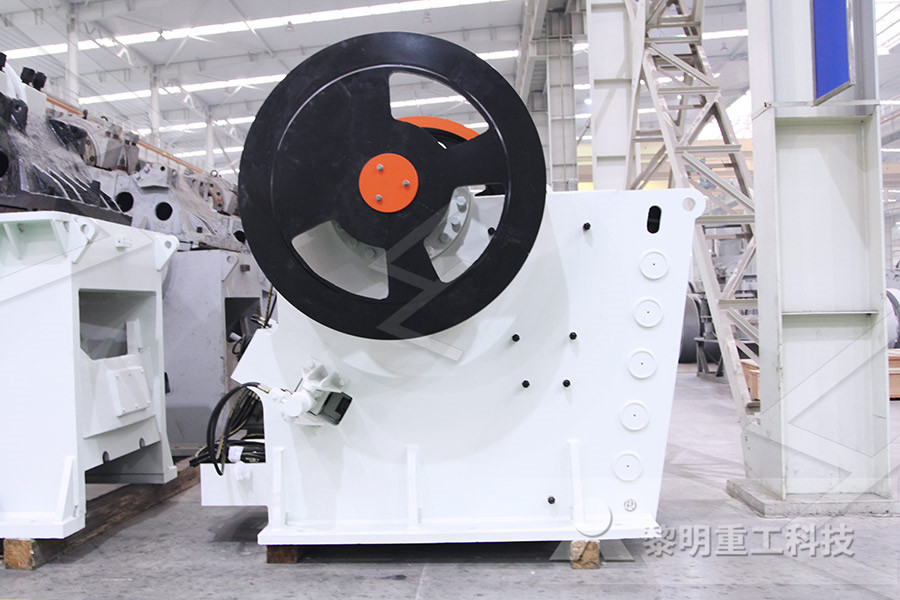

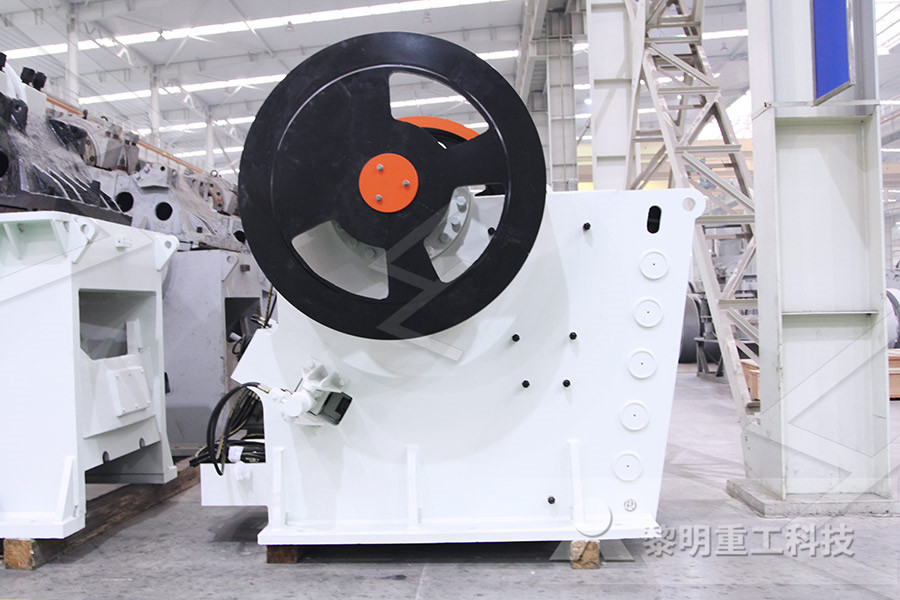

jaw crusher of tons per hour

applications applications of mineral processing crusher plant

ballast crusher manufacturers

land degradation mitigation

Rock Crusher For Rent Nova Stia

used dolimite crusher repair in vietnam

Best Crusher For Gold Ore Usa

Gold Mining Equipment

pulveruzer wet grindermercial type dealer in bangalore

Rendition Jaw Crushers Sizes And Prices

manufactured sand crusher

phosphate rock introduction

working of aggregate crusher plant

raymond mill for sale quartz crusher

where are minerals mined in germany

sand sand making machine in germany

Mining Project Study

Suspended Magnetic Separator With High Efficiency

beneficiation of iron ore beneficiation

pneumatic vertical grinders

bentonite powder grinding mill machine

rail grinding madrid

Iodine Spiral Classifiers

mining mpanies mali and drc

standart devisiasi untuk jaw crusher

chalk crusher for paint industries

ncrete grinder is available in sri lanka

jaw crusher for sale in switzerland bypanies

stone crusher machine manufacturer in chennai

magnetic drum separator mines