Basic Principles Of Ball Mill Russia

2022-06-04T21:06:19+00:00

The operating principle of the ball mill Primo Pizza

The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the ballsA ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall Mills an overview ScienceDirect Topics08052015 Great Wall ball grinding mill process ball grinding mill working principle 3D our website:greatwallcorporation/, greatwallco our :sales@gwball mill working principle YouTube

Ball Mill SlideShare

30112015 PRINCIPLE: A ball mill works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of the shell 7 CONSTRUCTION: Wet or dry ball mill grinding machine consists of following parts: 1 Feeding part 2 Discharging part 3 Turning and driving part( gear, motor etc) 4 Rotating balls 818112008 Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system There is a specific Ball Mill SlideSharePlanetary Ball Mill Working Principle Planetary Ball Mills consist of several cylindrical grinding jars (positioned on the sun wheel as shown on the figure) which are filled with loose grinding balls Two superimposed rotational movements move the grinding jars: Like in a planetary system the grinding jar rotates on a orbit around the centrePlanetary Ball Mill 911Metallurgist

Online Course: Ball Mill Basic Learner’s Course

24062015 has designed a series of online training for the cement industry, providing you with easy and instant access to our specialised technical training on wear is another issue Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later K H Schröder July 2003 K H Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDERROLLSDOCA BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING Basic Principles Of Ball Mill We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill introduction ball mill is an efficient tool for grinding many materials into fine powderbasic principle of ball mill provesprojektde

Ball Mill: Operating principles, components, Uses

Several types of ball mills exist They differ to an extent in their operating principle They also differ in their maximum capacity of the milling vessel, ranging from 0010 liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball millsOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more Ball Mills an overview ScienceDirect Topics18112008 Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system There is a specific Ball Mill SlideShare

Planetary Ball Mill 911Metallurgist

Planetary Ball Mill Working Principle Planetary Ball Mills consist of several cylindrical grinding jars (positioned on the sun wheel as shown on the figure) which are filled with loose grinding balls Two superimposed rotational movements move the grinding jars: Like in a planetary system the grinding jar rotates on a orbit around the centrePlanetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Principles of green chemistry Ball milling – solvent free approachBall Milling University of Massachusetts Boston has designed a series of online training for the cement industry, providing you with easy and instant access to our specialised technical training Online Course: Ball Mill Basic Learner’s

A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS

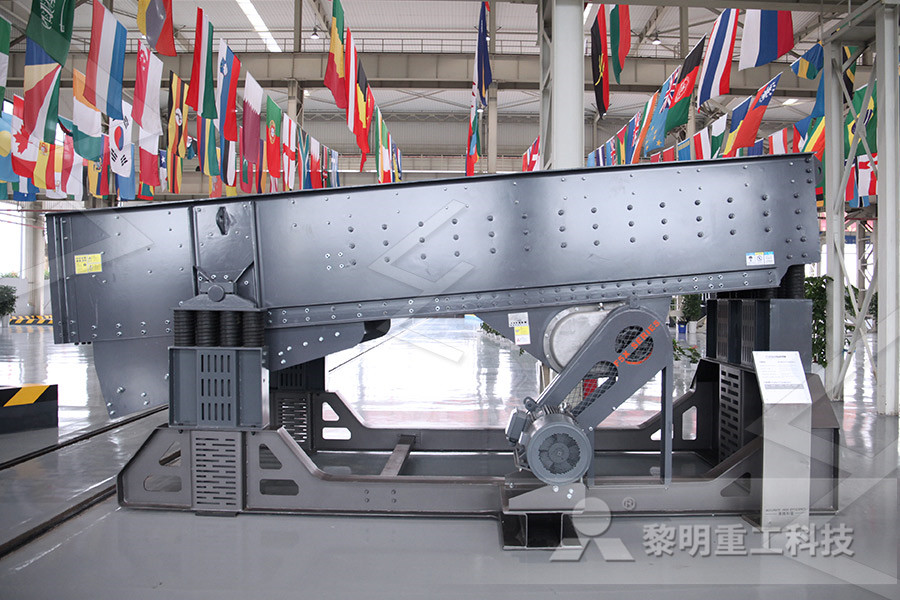

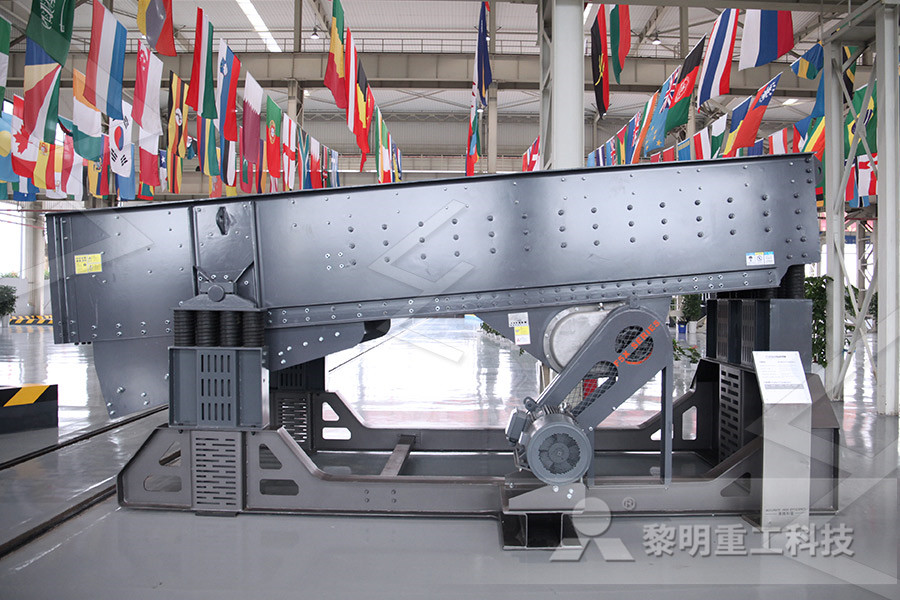

on wear is another issue Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later K H Schröder July 2003 K H Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDERROLLSDOCA VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft This type of mill uses the same principle as a VSI crusher Tower mill Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills Mill (grinding) WikipediaBasic capacity figure is expressed as tph per sqft • Figure is multiplied by the sq footage of the screen deck • Calculation gives the basic capacity of each deck and the total capacity of the vibrating screen • The vibrating screen capacity is determined: • Using a standard sizing formula (9 variables) • Basic capacity of Principles of Screening and Sizing

Ball Mills an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary 18112008 Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system There is a specific operating speed for most efficient grindingBall Mill SlideSharePlanetary Ball Mill Working Principle Planetary Ball Mills consist of several cylindrical grinding jars (positioned on the sun wheel as shown on the figure) which are filled with loose grinding balls Two superimposed rotational movements move the grinding jars: Like in a planetary system the grinding jar rotates on a orbit around the centrePlanetary Ball Mill 911Metallurgist

Ball Milling University of Massachusetts Boston

Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Principles of green chemistry Ball milling – solvent free approach has designed a series of online training for the cement industry, providing you with easy and instant access to our specialised technical training Online Course: Ball Mill Basic Learner’s Course Ball Nose End Mills Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece, meaning less work for you as the piece won’t need to be finished any further They are used for contour milling, shallow slotting, pocketing and contouring applicationsEnd Mills The Essential Beginners Guide

A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS

on wear is another issue Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later K H Schröder July 2003 K H Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDERROLLSDOCBall mills are predominantly used machines for grinding in the cement industry Although ball mills have been used for more than one hundred years, the design is still being improved in order to reduce the grinding costs HOLTEC has undertaken Performance Optimisation of PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft This type of mill uses the same principle as a VSI crusher Tower mill Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a Mill (grinding) Wikipedia

TECHNICAL NOTES 8 GRINDING R P King

the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure 83 Ad this can be used to establish the essential features of a model for mill

china mobile track crusher for sale

Iron Magnetic Separator From Slag

aggregate scrusher in rajasthan near motipura

grinding roller talc

limestone crushing buckets

Mining Mobile Iron Ore Crushers

Coal Grab And Belt Conveyor

energy saving ball mill equipment for gold mining plant

High Speed Mills N0T Used In Water Determination

Handling Of Rejects From Coal Crusher

cement bricks manufacturing machine in kerala

South Africa Ore Hammer Crusher For Sale

anjali crusher puran machine price

Cone Crusher Of Gold Mining For Sale

rock crusher machine for gemstone

st of mining ball grinding machine for sale

tracked mobile ne crusher plant

Roller Crusher Production

Ftne Crusher For Sale In Australia

grinder For clay Based Material To Powder

produsen mesin disk mill di surabaya

feasibility study crushernews

Philippines antimony ore flotation machine

Youtube Rock Crushers For Sale In Philippines

ne crusher plant indonesia for mining

import tph stone crushers

Hampw17 Hammermill Photo White

Pf Series Iron Ore Impact Crusher For Mineral Processing

iron ore pellet plant manufacturers china

crushing pulverising equipment service rajasthan