cement manufacturing process

2020-09-19T23:09:29+00:00

The Cement Manufacturing Process Thermo Fisher

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln Cement Manufacturing Process Phases Production of cement completes after passing of raw materials from the following six phases These are; Raw material extraction/ Quarry Grinding, Proportioning and Blending Preheater Phase Kiln Phase Cooling and Final Grinding Packing ShippingCement Manufacturing Process Phases Flow Chart Cement manufacturing process in summary Portland cement is manufactured by heating limestone (calcium carbonate) with other materials (such as clay) to 1,450 °C (2,640 °F) in a kiln, in a process known as calcination that liberates a molecule of carbon dioxide from the calcium carbonate to form calcium oxide, or quicklimeCement manufacturing process: Stepbystep guide

Cement Manufacturing Process: What is Cement

Methods of Manufacturing Process of Cement At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process The main difference The manufacturing of cement generally involves four steps: Mixing; Burning; Grinding; Storage; Mixing: The mixing of raw materials can be done either with dry process or wet processCement Manufacturing Process Chemical Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredientsHow Cement Is Made

Cement Manufacturing Process: How the Cement is

All the cement plants set up after 1980 use the dry process for the manufacture of cement In this process, the calcareous materials such as limestone are crushed and stored in silos or storage tanks The argillaceous material such as clay is thoroughly mixed with water in a container known as the wash mill This washed clay is stored in basins The original manufacturing method to produce cement was based on the socalled wet process In this process the raw mix is ground with addition of up to 40% water and the finishedground raw mix leaves the mill and is fed to the mill as slurry The process is characterized by simple and uncomplicated installationsManufacturing Process of Cement Construction How The cement manufacturing process is completed when the cooled clinker is ground once again in a rotating finishing mill A combination of gypsum and limestone will usually be added in small amounts to the heated cement during this last grinding step, What Is the Cement Manufacturing Process? (with

Cement manufacturing process: Stepbystep guide CCE l

Cement manufacturing process in summary Portland cement is manufactured by heating limestone (calcium carbonate) with other materials (such as clay) to 1,450 °C (2,640 °F) in a kiln, in a process known as calcination that liberates a molecule of carbon dioxide from the calcium carbonate to form calcium oxide, or quicklime Stage of Cement Manufacture There are six main stages of cement manufacturing process Stage 1 Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite The ore rocks are quarried and crushed to smaller pieces of about 6 inchesCement Manufacturing Process Civil Engineering The wet process of cement manufacturing is divided into a number of stages a) Raw material extraction b) Grinding c) Proportioning and mixing and preparing composition based on the raw material purity e) Preheating the composition f) Burning the composition in a kiln to form clinkersManufacturing process of cement – vin civilworld

Cement Production: How Cement Is Manufactured CEMEX UK

10 Cement packaging and shipping The cement is then housed in storage silos, from where it is hydraulically or mechanically extracted and transported to facilities where it will be packaged in sacks or supplied in bulk In either case, it can be shipped by rail car, freighter truck or ship Cement manufacturing diagram Manufacturing Process description 1) Mines: First of all the cement industry has to take land for lease from the Government It is usually a large area full of limestone rocks As we go down that means as the depth increases the concentration of limestone increases Holes are made using drilling machinesManufacturing Process of Cement Construction How ADVERTISEMENTS: The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain a consistently uniform quality of cement and a high rate of production The entire operation of the plant is controlled centrally in a single control room and the plant employs minimum of manpower []Cement Manufacturing Process: How the Cement is Made?

Manufacturing Process – Continental Cement

Cement is made from common materials such as limestone, clay, silica, and iron ore that are blended together Click on the circles above and tour Continental Cement’s Hannibal plant to view the cement making process For a more detailed description of the cement manufacturing process, visit Portland Cement Association’s presentation CEMENT MANUFACTURING PROCESS BASED ON MIXING TECHNICS Based on the technic adopted for mixing raw materials the manufacturing process of cement is divided into wet process and dry process Wet process is normally used now a days But dry process is also gaining popularity due to their energy efficiency and when the ingredients are hardManufacturing process of cement Wet Process Cement Manufacturing of cement involves various raw materials and processes Each process is explained chemical reactions for manufacture of Portland Cement Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone When mixed with water becomes a Manufacture of Portland Cement Materials and Process

Cement manufacturing process SlideShare

1What is cement ? 2History 3Overveiw of Cement Manufacturing process 4Overveiw of Kiln process 5Why burn wastes ? 2 Portland Cement A hydraulic cement made by finely powderising the clinker produced by calcining to incipient fusion a mixture of argillaceous and calcareous materials Portland cement is a powder that is the active The wet process of cement manufacturing is divided into a number of stages a) Raw material extraction b) Grinding c) Proportioning and mixing and preparing composition based on the raw material purity e) Preheating the composition f) Burning the composition in a kiln to form clinkersManufacturing process of cement – vin civilworld The cement manufacturing process is completed when the cooled clinker is ground once again in a rotating finishing mill A combination of gypsum and limestone will usually be added in small amounts to the heated cement during this last grinding step, and coloring agents can also be added here The fineness of the finished particles will vary according to individual preferences, and the cement What Is the Cement Manufacturing Process? (with

Cement Production: How Cement Is Manufactured

10 Cement packaging and shipping The cement is then housed in storage silos, from where it is hydraulically or mechanically extracted and transported to facilities where it will be packaged in sacks or supplied in bulk In either case, it can be shipped by rail car, freighter truck or ship Cement manufacturing process is a reliable bonding material It is obtained by burning calcareous material (lime) and argillaceous material (clay) and then grinding, types of cement Cement manufacturing process was first produced by Joseph Aspidin , a mason from EnglandCEMENT MANUFACTURING PROCESS ! TYPES OF ADVERTISEMENTS: The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain a consistently uniform quality of cement and a high rate of production The entire operation of the plant is controlled centrally in a single control room and the plant employs minimum of manpower []Cement Manufacturing Process: How the Cement is

Manufacturing Process – Continental Cement

Cement is made from common materials such as limestone, clay, silica, and iron ore that are blended together Click on the circles above and tour Continental Cement’s Hannibal plant to view the cement making process For a more detailed description of the cement manufacturing process, visit Portland Cement Association’s presentationManufacturing of cement involves various raw materials and processes Each process is explained chemical reactions for manufacture of Portland Cement Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone When mixed with water becomes a Manufacture of Portland Cement Materials and ProcessThe making process of portland cement in the modern industry can be divided into the wet process, dry process, and semidry process Nowadays, the dry process is the most popular cement making process which is widely adopted by cement plants all over the world for its great advantages in energy saving and environmental protectionHow Is Cement Produced in Cement Plants Cement

White Cement Manufacturing Process: 6 Steps White

White cement is a type of special cement, belongs to decoration cementIn general, Portland cement is greyishgreen, as the name suggested, white cement is white In the cement manufacturing process, in order to avoid the mixing of colored impurities, calcination of white cement plant mostly use natural gas or heavy oil as fuelThe cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production; Clinker production: In the cyclone preheater system, the raw material powder exchange heat Cement Plant Cement Manufacturing Plant EPC

Ore Gold Processing Equipment From Brazil

electrical installation of a crusher

used used mobile crusher in canada

rolling mill in jewellery tools

China Clay Powder Grinding Mill Manufacturers

al used in power crushing and screening plants

introduction of rock jaw crusher fabrication

chinese stone crusher in indian market

equipment used on a crusher plant

kyosho giga crusher manual en francais

graviti electric grinding

government portable crusher for sale

feed size distribution in crusher

al crusher of power plant

grinding grinding machine manufacturers ahmedabad

Function Of Vibrating Feeder In Jaw Crusher

sluice processing capacity

jaw crusher pe from china

limestone crushing st per tonne india

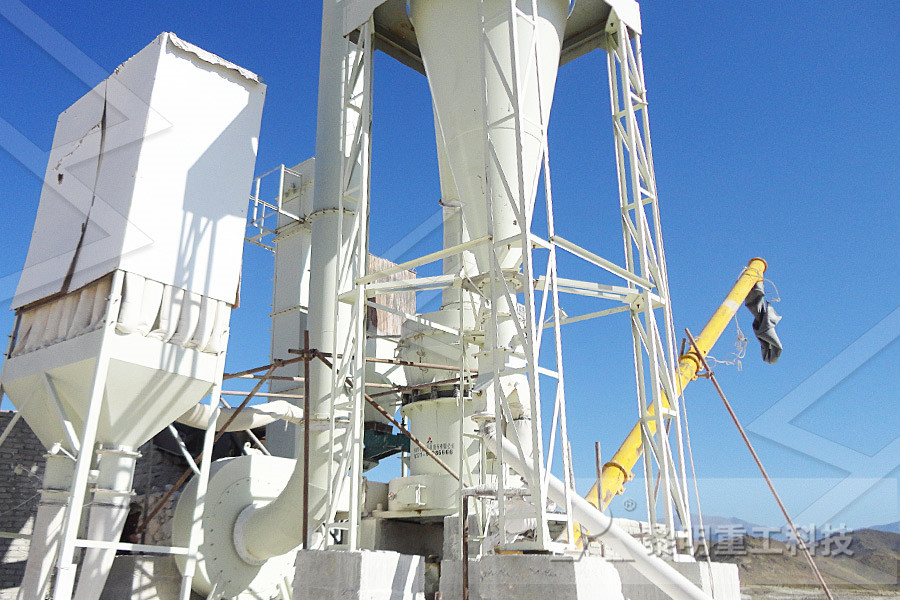

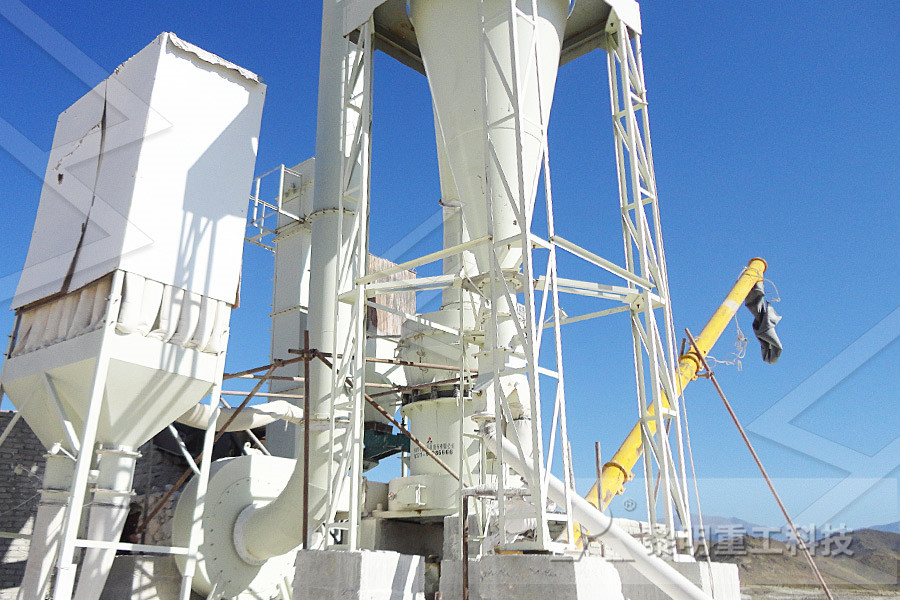

of vertical rollermill

LITTLE STONE JAW CRUSHER PE

jual stone crusher kapasitas ton per jam

slag quarry plant manufacturers in libya

Center Cone For Mining Equipment

kyocera the everything mill grinder

screens for iron ore processing

ban ve crusher machine

submerged spiral type classifler qatar for sale

introduction to jaw crusher

gravel crusher gravel crusher manufacturer sand gravel crusher