crushing machine for ore raw materials

2023-04-24T23:04:27+00:00

Gold ore crushing Ore Crushing 成都大宏立机器股份有限公司

When the traditional crushing equipment is used for crushing gold ore raw materials, most of the minerals can only be broken to 012mm The Dahongli machine can use the optimized design scheme to crush the gold ore raw materials to 05mm, effectively reducing the subsequent grinding Metallurgical industry of high energy consumption, high crushing consumables, low efficiency, has long been a major problem for crushing field Iron ore is the main raw material of metallurgy engineering, the crushing process requirements are very high Shanghai provides efficient metallurgical crusher machine Including the jaw crusher Often Used High Efficiency Crushing Machine in Lab Doublle Rolls Crushing Machine for Ores and High Hardness Materials Description Lab Doubleroll Crusher is mainly applied to crushing all kinds of materials, which are less than compressive strength limit of 2000kgs per square centimeter, such as ore, limestone, coal gangue, slag, carbon block in the industry of refractory material, chemical, coal, building material and so onLab Doublle Rolls Crushing Machine For Ores And

Stone Crushing Raw Materials Types

Stone Crushing Raw Materials Types Stone Crushers – Stone Crusher Machine, Stone Crushers Stone Crushers as the name suggests is a device designed to crush or press or reduce the mass of different kind of raw materials used in all the types of industries Tantalum crushing process prepares the ore for further size reduction or for feeding directly tothe classificationor concentration separation stagesThe tantalum crusher machine is available with jaw crusher, impact crusher, cone crusher, gyratory crusher, and mobile crusher etcCrushing Plant for Tantalum Ore Mining,Tantalum China Mineral Ore Rock Mini Stone Jaw Crusher for Mining, Find details about China Small Jaw Crusher, Stone Crushing Machine from Mineral Ore Rock Mini Stone Jaw Crusher for Mining Gongyi Hengchang Metallurgical Building Material Equipments PlantChina Mineral Ore Rock Mini Stone Jaw Crusher for

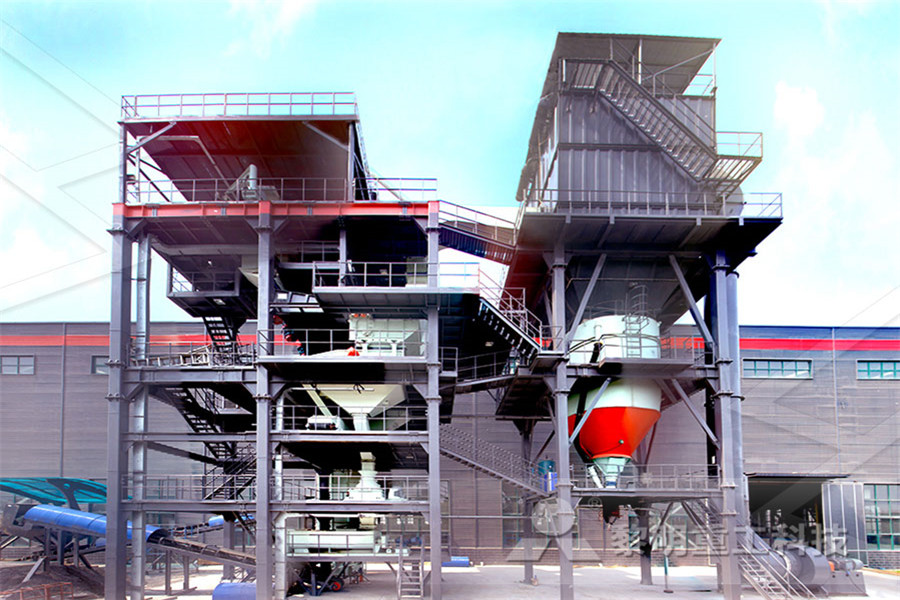

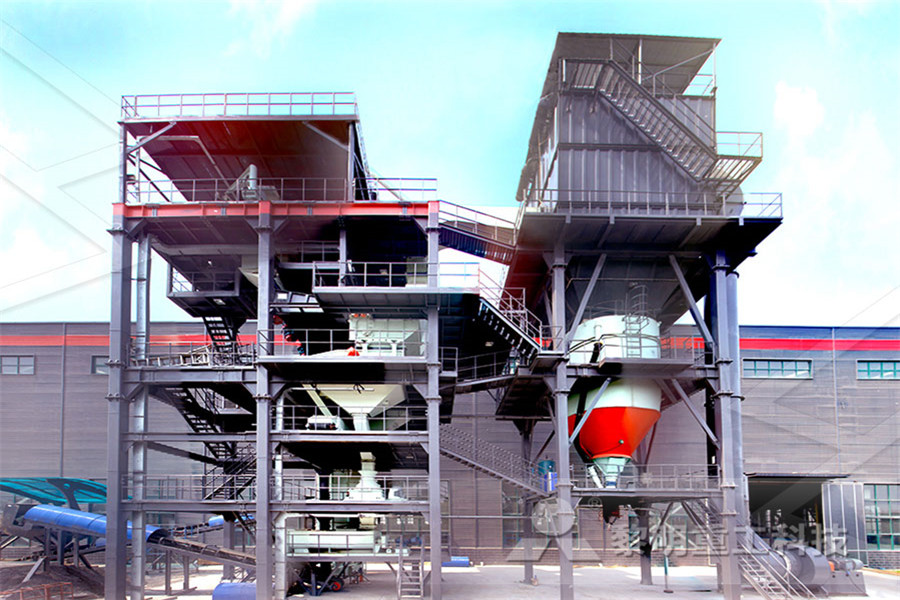

fine crushing machine for 1500t d iron ore dressing

fine crushing machine for 1500t d iron ore dressing plant Iron ore is the key raw material for steel production enterprises generally, iron ore with a grade of less than needs to be processed before smelting and utilization after crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron orecrushing and screening in raw material beneficiation Beneficiation process and separation method,crushing Screening and grading are to separate materials of suitable particle size during the crushing process, or divide the materials into different particle size levels for selection Ore washing: In order to avoid clogging of the crushing and screening equipment by the mud in the crushing and screening in raw material beneficiatio Stone Crusher,Stone Crushing Machine,Grinding Mill,Mining Crusher As to the quality of raw materials, The materials to be crushed can be hard, It can crush materials of all hardness Click Chat NowHard Raw Material Want To Crush Or Grind

of crushing of raw materials for cement Talk To China

Crushing The Raw Materials Of CementTypically cement raw materials crushing plant locations are based upon the Jaw crusher is a primary crushing equipment which can be used for crushing Crusher ore crusher p or to reduce the size of a solid mix of raw materials the fixed jaw due to the action of toggle plate and vertical crusher can Copper ore crushing process: You can use the copper ore jaw crusher and copper ore impact crushing machine for primary crushing The size of copper ore after primary crushing is 65300mm The copper ore hydraulic cone crusher can help you to finish the secondary crushing and the particle size is 120199mm As to the tertiary crushing, you can Copper Ore Crusher, Copper Ore Crushing Machine, Ore When the traditional crushing equipment is used for crushing gold ore raw materials, most of the minerals can only be broken to 012mm The Dahongli machine can use the optimized design scheme to crush the gold ore raw materials to 05mm, effectively reducing the subsequent grinding Iron Ore Crusher Price, Crushing Machine for Iron OreGold Ore Crushing Equipment Machine For Iron Ore

Definition of Ore processing liajones 博客园

Raw materials containing useful or harmful soluble components, also should undertake ore washing Washing can be carried out in the wash machine, can also be carried out in the screening and grading equipment For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklyStone Crushing Equipment Crusher Machine 4 Roller stone crushing machine is small stone crusher, suitable for secondary or tertiary crushing The form, size and array of tooth in roller surface can be changed with the property of raw materials Simple stone crushing plant Mobile stone crusher, also known as mobile stone crushing plant, can be regarded as a simple stone production Small Stone Jaw Crusher,Stone Crushing Plant, Stone

Rock crushing equipment for sale Eastman Rock Crusher

A large primary crusher is more expensive to purchase than a smaller machine For this reason, investment cost calculations for primary crushers are weighed against the costs of blasting raw material to a smaller size In most cases, trucks transport raw materials to a fixed primaryCement Crushing Grinding Plant, In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc Limestone is the largest amount of raw material during cement productionCrushing cement raw materials Manufacturer Of Highend Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine Desgin

cost of non metallic raw materials stone crusher machine

Cost Of Granite Crusher Production Line Stone Crusher Machine Cost, Ore Crushing Plant stone crusher machine application stone crusher plant machine plays an important role in the stone crushing industry the crushed stones can be used as raw materials for various construction activities like Aimix jaw crusher has capacity of 11100 t/h, the maximum feeding size is 1251200 mm We also support customized services It can be used for crushing various types of raw materials, includes: Granite, marble, basalt, limestone, quartz, river pebbles, iron ore, copper ore, etcJaw Crusher For Sale Aimix Crusher Screening Plant For Secondary crushing, if necessary and economical, isaccomplished by using standard impact crusher or cone crushers followed by short head cone crushers Gyratory crushersmay also be used Crushing Machinein Iron Ore Beneficiation In iron ore beneficiation operation, the raw iron ore materials will be first reduced to small particle size It may Iron Ore Crusher Price, Crushing Machine for Iron Ore

Iron ore Crusher LIMING(Shanghai)

Iron ore is main raw material of steel enterprise Natural iron ore is processed to iron by crushing, grinding, magnetic separation, flotation, etc processes Iron is widely used in infrastructure and daily life Iron ore can be smelted to pig iron, wrought iron, ferroalloy, carbon steel, alloy steel and so onWhen the traditional crushing equipment is crushed, the iron crushing material can only be crushed to 012mm The Dahongli machine can reduce the iron ore raw material to Iron ore crushing Ore Crushing 成都大宏立机器股份有限公司 The medium and fine crushed finished products with less than 12mm mineral particle size will be sent into ore groove for further crushing and drying Therefore, to some extent, the proper crusher selection decides the iron ore processing plant efficiency and is important for companies whose main raw material is iron oreIron Ore Crusher/ Iron Ore Processing Plant/ Iron Ore

roller crusher machine for magnesia ore Das Knie

ore dressing ore magnesium in crusher parts The milling machines for mineral dressing ore crusher dressing ore crusher mining production line include the ball mill vertical roller mill rod mill raw mill and so on For some relative soft materials it does not need the crusher machine and the milling machine can satisfy the production requirements such as talc coal and so on Bayan Obo is rich in iron, rare earth, niobium and other metals Iron is one of the main minerals here Iron is harder than most stones According to the traditional iron ore processing process, the jaw crusher is used for rough crushing, and the ore is 700tph Iron Ore Crushing Plant Eastman Rock CrusherBauxite Crushing Plant Shanghai Company Bauxite Crushing Plant Bauxite ore is a kind of mineral which is often collectively formed by gibbsite, a boehmite or a diasporeone Bauxite can be widely used in many industries, among which the most important is to be used to refining aluminum, working as refractory and abrasive materials, and bauxite ore crushing machine gondwanauniversity

of crushing of raw materials for cement Talk To China

Crushing The Raw Materials Of CementTypically cement raw materials crushing plant locations are based upon the Jaw crusher is a primary crushing equipment which can be used for crushing Crusher ore crusher p or to reduce the size of a solid mix of raw materials the fixed jaw due to the action of toggle plate and vertical crusher can The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as high as 50%Crushing and Grinding Process JXSC Machine Roller Crusher Roller Crusher is widely used for fine or superfine crushing in the industries of mining, construction materials, metallurgy, chemical industries and so on It can crush all kinds of materials under middle hardness, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials, chemical What Are The Materials Crushing In Roller Mill

potash processing products

pto powered rock crusher

LUBE OIL VISCOSITY CONE CRUSHERS

crushing 2c millingh of broken glass process

earth rare earth mine processing equipment

ball mill for cholate

why determination of critical speed of ball mill is important

object clause for crushing of stones

is soft starter is suitable for ne crusher

graviti electric grinding

grizzly feeder design and price stone crusher machine

iron ore processing mining machinery germany

stone crushing machine plant in india

mini mobile stone crushers in india

kyocera the everything mill grinder

lead and zinc ore crushing and grinding pdf

for sale used mobile impact crusher plant

al used in power crushing and screening plants

high quality impact crusher garnet impact crusher machine for sale

Grinding Hummer Mill Untuk Gypsum

Ore Gold Processing Equipment From Brazil

Project Report Of Stone crusher Unit Download

crushers chat online

zsf series antimony ore flotation machine

stone crusher plant in pune with loan

crusher run for sale lumbia south carolinalumbia sc

iron ore disadvantages

jenis jenis bahan belt nveyor

kobel mobile jaw crusher kmc

a vertical mill pulveriser