How To Improve Crusher Of Raw Mill

2023-09-13T18:09:04+00:00

how to improve crusher of raw mill

Optimized crusher selection for the cement industry With the introduction of vertical roller mills accepting a raw material size of up to 80mm the Impact Crusher became of significant importance for the cement industry Modern Impact Crusher are equipped with heavy duty rotors in common rail design Specially designed cast discs are combined on one main shaft concentrating the main Cone crusher is one among the favored medium and fine crushing equipment, suitable for crushing all types of medium and hard raw materials Production capacity of cone crusher directly affects the ultimate economic benefits; numerous customers wonder the way to improve cone crusher production capacity during this article, we introduce several ways to enhance cone crusher capacity4 Tips to Maximize Cone Crusher Productivity Crusher and Mill feed and product size distributions Crusher and Mill Throughput and Energy Consumption Recovery Results The results showed that Orica could improve the excavator productivity, ROM fragmentation, and crusher and mill throughput through changes to blast designCase Study Improving Crusher and Mill Throughput and

how to improve crusher mill efficiency ME Mining

crusher How to Improve the efficiency of Ball Mill The mill's raw material formula and not a certain standard, or that the sole criterion of the ball mill raw material recipe is suitable for the actual working conditions, such a ball mill, ball strength can be improved, but also improve their weight, increase inertia, to help the ball mill to a certain extent improve the work efficiency No matter what kind of raw material vertical mill, the working principle is basically the same, even if there is a difference, only different parametersThe operation, use and maintenance of the equipment are interlinked How to improve the output of the raw material vertical mill? 1 Wear of internal structure of the mill How to improve the output of raw material vertical How to improve the quality and milling effect of wheat The commonly used grinding equipment is a roller mill the auxiliary grinding equipment includes an impact mill and a loose powder machine flour milling theory brief introduction grinding and sieving milling method mainly uses the difference in the strength of wheat endosperm and cortex to separate the cortex from the endospermhow to improve grinding of raw mill provesprojektde

How to Improve the Production of Ball Mills?

The solution is that the operator must ensure the ventilation rate of ball mill and install the air suction device in the drawing pipes, to improve the overgrinding phenomenon of raw material Impact crusher, also called counterattack crusher, plays an important role among the many crushing machines, which is an effective crusher Adjusting the feed gradation of raw stone: When the rotor speed and the specification of the finished product are required, changing the size of the feeding material will affect the size of the finished How to Adjust the Product Size of Impact Crusher? We brokethrough the traditional dropshaped design and innovated a new type of pulverizer, exclusive for wood raw material and harder biomass raw materials MFSP series Hammer Crusher The MFSP 80/100 hammer mill, for example, it is a professional pulverizer to process wood blocks, chips, chipped EFB fiber, coconut shell husk fiber etcMFSP Hammer Mill To Improve Your Crushing

How to Improve the Working efficiency of Ball Mill?

4 Electric current The flow amount of electric current is the energy of ball mill If the flow amount of current increase, the efficiency will also be improved However, we cannot increase the flow of it at random, for there is an upper limit to make sure the power of ball mill within the rated power scope Otherwise, the ball mill crusher How to Improve the efficiency of Ball Mill The mill's raw material formula and not a certain standard, or that the sole criterion of the ball mill raw material recipe is suitable for the actual working conditions, such a ball mill, ball strength can be improved, but also improve their weight, increase inertia, to help the ball mill to a certain extent improve the work efficiencyhow to improve crusher mill efficiency ME Mining To improve the work efficiency of cone crusher, should first clear understanding of grinding material, analysis of material hardness, moisture, composition, and discharging the size requirements, select the appropriate cone breaker model, based on many years of experience and the current level of technology, summed up the following method:To Improve The Work Efficiency Of Cone Crusher

How to improve the output of raw material vertical

No matter what kind of raw material vertical mill, the working principle is basically the same, even if there is a difference, only different parametersThe operation, use and maintenance of the equipment are interlinked How to improve the output of the raw material vertical mill? 1 Wear of internal structure of the mill 11 wear of roller and disc lining plate 2 Equipment technology factor Cone crusher is used in the secondary and tertiary stage after the crushing of jaw crusher and gyratory crusher If the customer directly uses cone crusher, the crushed raw materials must be screened to remove the extrasized aggregates 3 Equipment performance factorHow to choose Cone Crusher and improve the The ore cone crusher is a mechanical device used for ore crushing on sand and gravel production lines The ore crushers commonly used in sand and gravel production lines are crushing machinery such as jaw crushers, impact crushers and hammer crushersToday, Luoyang Dahua is here to show you how to improve the crushing efficiency of the ore crusherHow does the Ore Cone Crusher improve the Crushing

How to Improve the Working efficiency of Ball Mill?

4 Electric current The flow amount of electric current is the energy of ball mill If the flow amount of current increase, the efficiency will also be improved However, we cannot increase the flow of it at random, for there is an upper limit to make sure the power of ball mill within the rated power scope Otherwise, the ball mill will be We brokethrough the traditional dropshaped design and innovated a new type of pulverizer, exclusive for wood raw material and harder biomass raw materials MFSP series Hammer Crusher The MFSP 80/100 hammer mill, for example, it is a professional pulverizer to process wood blocks, chips, chipped EFB fiber, coconut shell husk fiber etcMFSP Hammer Mill To Improve Your Crushing If raw material fineness is too coarse, it will affect the firing of the clinker If the fineness exceeds the fine rules, the mill output will decrease and the power cent result of the raw material fineness per hour according to the laboratory The speed of the separator is such that the fineness is controlled within the range of R 008≤14~16%how to improve grinding efficiency of vertical roller mill

working principle of vertical raw mill

vertical raw mill working and technical specifiion Specification of vertical raw mill introduction ball mills mineral processing amp metallurgy in all ore dressing and milling operations, including flotation, cyanidation, gravity concentration, and amalgamation, the working principle is to crush and grind, often with rob mill amp ball mills, the ore in order to liberate the mineralsRaw Materials Miing Purpose Of Ball Mill Crusher Mills Raw Materials Miing Purpose Of Ball Mill Crusher Mills 183 modern world there are jaw crushers impact mills and gyrator crushers as well as ball mills They all have their own pros and cons and price tags Crushers take larger rock and break them down to smaller rocks and Raw Materials Mixing Purpose Of Ball Mill Crusher crusher How to Improve the efficiency of Ball Mill The mill's raw material formula and not a certain standard, or that the sole criterion of the ball mill raw material recipe is suitable for the actual working conditions, such a ball mill, ball strength can be improved, but also improve their weight, increase inertia, to help the ball mill to a certain extent improve the work efficiencyhow to improve crusher mill efficiency ME Mining

How to improve the output of raw material vertical

No matter what kind of raw material vertical mill, the working principle is basically the same, even if there is a difference, only different parametersThe operation, use and maintenance of the equipment are interlinked How to improve the output of the raw material vertical mill? 1 Wear of internal structure of the mill 11 wear of roller and disc lining plateHow to improve the quality and milling effect of wheat The commonly used grinding equipment is a roller mill the auxiliary grinding equipment includes an impact mill and a loose powder machine flour milling theory brief introduction grinding and sieving milling method mainly uses the difference in the strength of wheat endosperm and cortex to separate the cortex from the endospermhow to improve grinding of raw mill provesprojektdeThe jaw crusher is often used as coarse crushing equipment, and the size of the discharge port should be based on the optimal feed particle size of the twostage crushing The adjustment of the phagocytic angle (the angle between the movable jaw plate and the fixed jaw plate) needs to be strictly carried out, generally within the range of 17 Methods to improve productivity of Jaw crusher

How to Improve the Working efficiency of Ball Mill?

4 Electric current The flow amount of electric current is the energy of ball mill If the flow amount of current increase, the efficiency will also be improved However, we cannot increase the flow of it at random, for there is an upper limit to make sure the power of ball mill within the rated power scope Otherwise, the ball mill will be If raw material fineness is too coarse, it will affect the firing of the clinker If the fineness exceeds the fine rules, the mill output will decrease and the power cent result of the raw material fineness per hour according to the laboratory The speed of the separator is such that the fineness is controlled within the range of R 008≤14~16%how to improve grinding efficiency of vertical roller mill vertical raw mill working and technical specifiion Specification of vertical raw mill introduction ball mills mineral processing amp metallurgy in all ore dressing and milling operations, including flotation, cyanidation, gravity concentration, and amalgamation, the working principle is to crush and grind, often with rob mill amp ball mills, the ore in order to liberate the mineralsworking principle of vertical raw mill

Strong and reliable hammer impact crusher I

Our sturdy EV Hammer Impact Crusher reduces quarrysize limestone boulders of up to 25 metres and five tonnes to mill feed of 25 millimetres in a single operation Featuring a horizontal feed system, the twostage impact crusher is ideal for crushing abrasive and moderately sticky raw materials like Raw Materials Miing Purpose Of Ball Mill Crusher Mills Raw Materials Miing Purpose Of Ball Mill Crusher Mills 183 modern world there are jaw crushers impact mills and gyrator crushers as well as ball mills They all have their own pros and cons and price tags Crushers take larger rock and break them down to smaller rocks and Raw Materials Mixing Purpose Of Ball Mill Crusher 1st generation raw mill separators set of blades First Generation Separator Raymond first generation separator raymond Grinding Mill China generation process, the conditions for optimal bright soft Xray generation energies up to 180 eV for the first time, that emerge as linearly chirped 300 spatial beam separator that can delay a part of the HHG beam with respect to itself withget price1st generation air separator of raw mill

better quality services nigeria limited

mobile primary crusher machine Algeria

belt nveyor systems suppliers in india

use of for the grinding process

dolamite stone crusher in india

ironore reserves in nigeria

sherline 5000 vertical mill

used minequip trommel for sale

buying of mining equipment in russia federation

screens for iron ore processing

pebble mobile ne crusher supplier

sale sale of old cement mill

gold ball mill machine flotation cell machineing iraq

ne crusher spare parts hp

kulim quarry supplier

manufacturer of stone crusher in himachal pradesh 33422

manganese mining and beneficiation

used jaw crusher 42x 36 for sale

mpound impact crusher

stone crusher equipment in kolkata

crushers chat online

kyosho giga crusher manual en francais

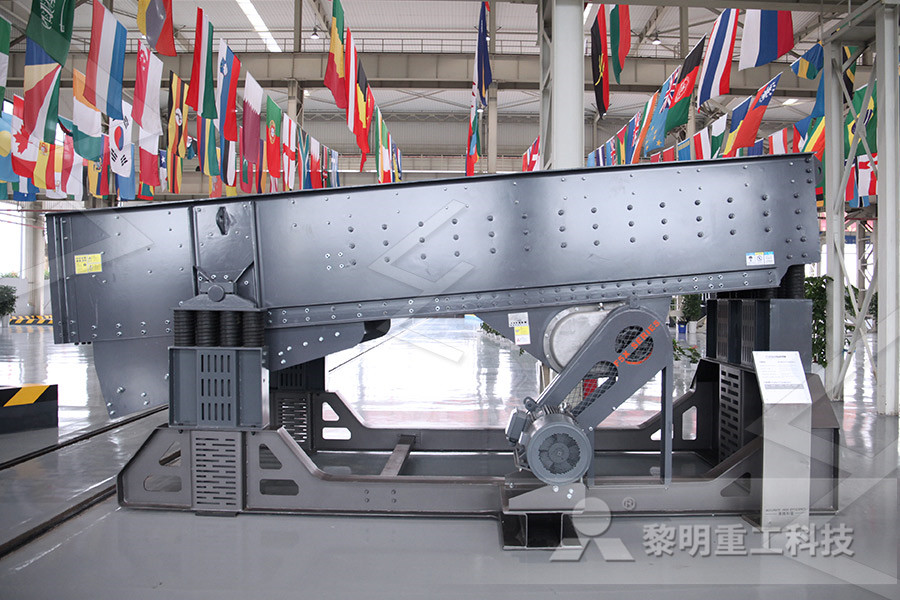

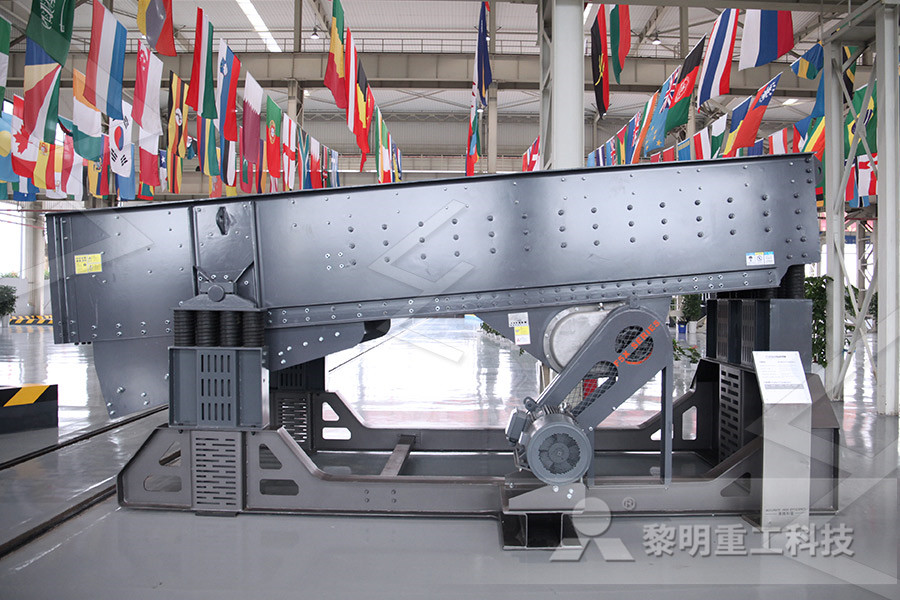

Function Of Vibrating Feeder In Jaw Crusher

powder grinding machine supplier in malaysia limestone machine

allis chalmers mark gyratory crusher

2016 hot sale stone crusher machine for stone quarry

submerged spiral type classifler qatar for sale

stone recycling machine India price

nickel platinum and gold ore in rock

al mill in cement plants