cement manufacturing process crushing process

2022-06-21T22:06:11+00:00

Cement Manufacturing Process Sintrol

Cement Manufacturing Process 1 Crushing and Milling In the raw materials handling process, fi ltration systems are utilized to control emissions in the quarrying process of the plant To minimize the loss of limestone and other materials that are fed into the kiln, dust measurement systems provide plant operators P ortland cement is by far the most common type of cement in general use around the world This articles looks at the cement manufacturing process in 4 steps Step 1: Mining The first step of Cement manufacturing process is to quarry the principal raw materials, mainly limestone, clay, and other materials Step 2: CrushingCement manufacturing process: Stepbystep guide Cement manufacturing process: Stepbystep guide CCE l Jul 20, 2020 The first step of Cement manufacturing process is to quarry the principal raw materials, mainly limestone, clay, and other materials Step 2: Crushing After quarrying the rock is crushed This involves several stages The first crushing get pricecement crushing crusher manufacturing process

Extraction And Crushing Process In Cement

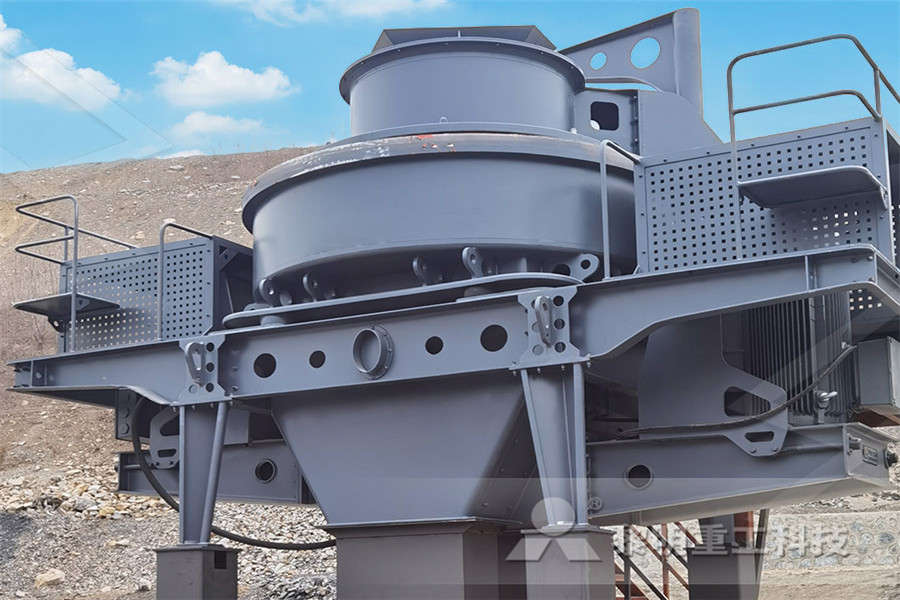

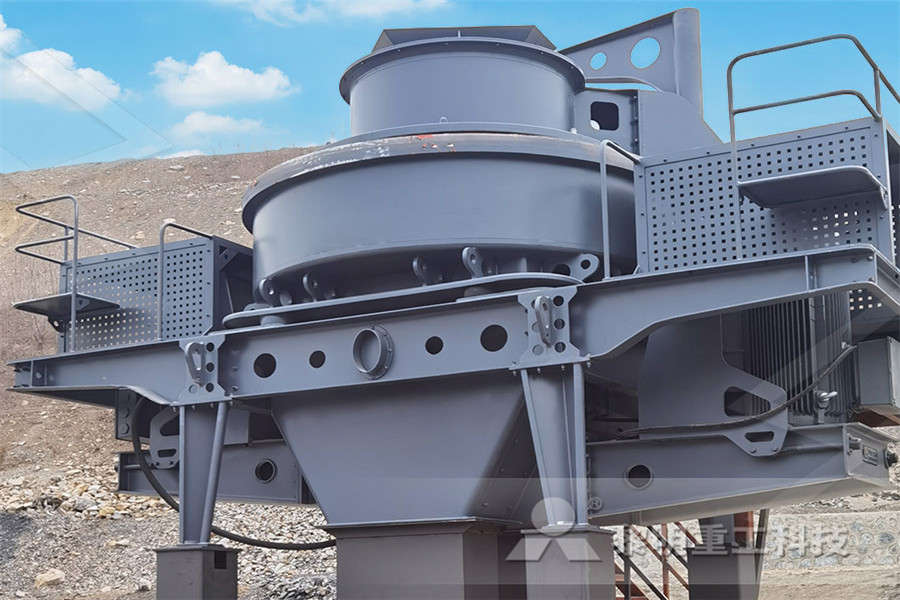

2 Cement Manufacturing Process Crushing Process Crushing in cement manufacturing process Cement manufacturing process cement manufacturing process project use a pre grinding technology more crushing and less grinding is a material with roller pregrinding classifier scatter grading the grain sie is less than 3mm and the corresponding witcrushers process in cement In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, process of concrete crushing Gulin machine in iron ore processing plant, process of concrete crushingcrushing in cement making process 32 Cement manufacturing process while the second sample, sample B, has low iron content and high calcium The two samples were subjected to crushing, grinding, (PDF) Cement Manufacturing ResearchGate

Manufacturing process flow 1 Quarrying and Crushing

Manufacturing process flow 1 Quarrying and Crushing The quarry (where the mining activity is performed) is located 07 km away from the plant and has the main raw materials such as Limestone and shale that is estimated to last for 100 years, the other raw materials (Iron ore, silica sand, gypsum and Pozzolana (pumice) ) are brought from nearby CEMENT PLANT USING CLINKER (CRUSHING PLANT) Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much moreProject Report on CEMENT PLANT USING CLINKER Process: Description: Raw Material Preparation: Crushing the stored clinker immediately results in the formation of cement properties, which quickly congeals and makes handling inconvenient By adding gypsum, congelation is delayed, which facilitates handling in transportation and constructionCement Manufacturing process

Cement Manufacturing Process: What is Cement

Methods of Manufacturing Process of Cement At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry statecrushing in cement making process For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklycrushing in cement making process CEMENT MANUFACTURING PROCESS The cement is manufactured through the following process and shipped by seaborne, inland road and railway transportation Limestone mining and crushing (Crusher) Mixing raw material and grinding (Raw Mill) Calcination (Kiln) Completion (Cement Manufacturing Process Product HALLA CEMENT

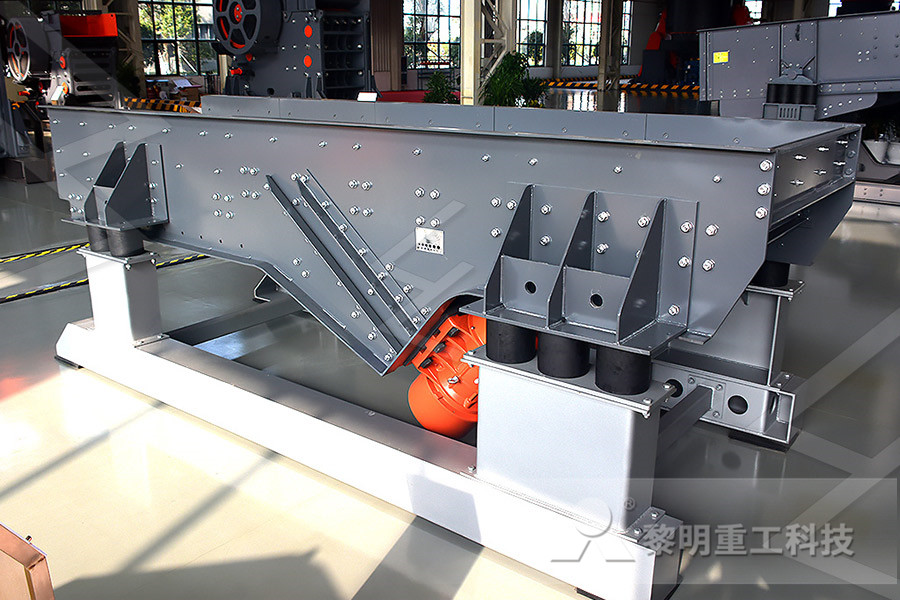

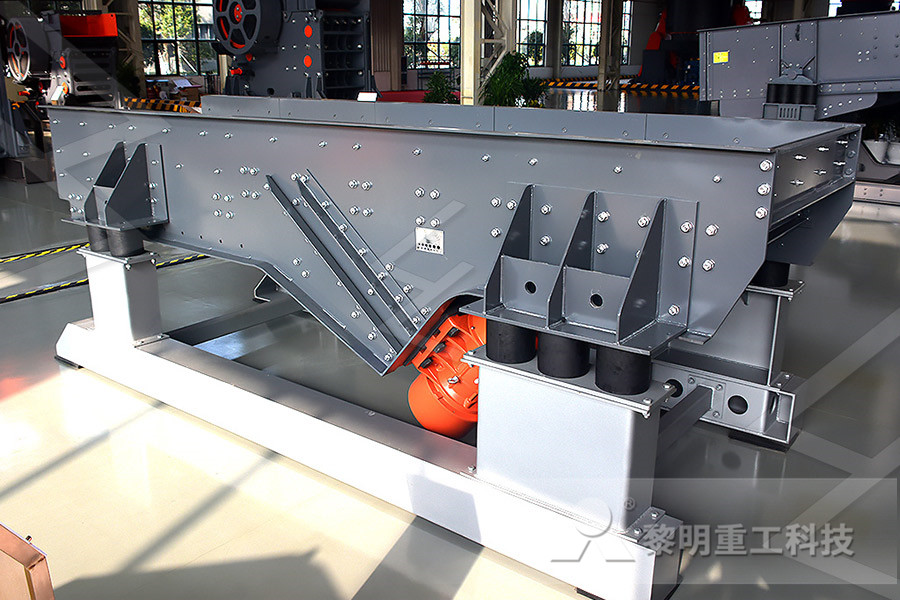

The Manufacturing Process CEMBUREAU

Crushing Raw meal grinding Preheating Precalcining Clinker production in the rotary kiln Cooling and storing Cement grinding Storing in cement silos To download the cement manufacturing process fact sheet, please click here Information; Policies; Innovations; Learn about the cement manufacturing process! Click here About Us Who Are We The cement manufacturing process begins from the mining of raw materials that are utilized in cement manufacturing, predominantly limestone and muds A limestone quarry is inside the plant zone and a muds quarry is a long way from the plant territory as 25 kmTypes of Cement Manufacturing Process [Explained in 10 Cement packaging and shipping The cement is then housed in storage silos, from where it is hydraulically or mechanically extracted and transported to facilities where it will be packaged in sacks or supplied in bulk In either case, it can be shipped by rail car, freighter truck or shipCement Production: How Cement Is Manufactured

manufacturing process flow chart of crushing line

flow chart of quartz crushing The cement manufacturing process flow chart is shown as follows: Our company has a variety of limestone Stone Crushing Line,Complete Crushing Plant, Get Price Here ! Production flow chart for crushing White cement is a type of special cement, belongs to decoration cementIn general, Portland cement is greyishgreen, as the name suggested, white cement is white In the cement manufacturing process, in order to avoid the mixing of colored impurities, calcination of white cement plant mostly use natural gas or heavy oil as fuelWhite Cement Manufacturing Process: 6 Steps Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by excavatorsCement Extraction and processing Britannica

Cement manufacturing process: Stepbystep guide CCE l

P ortland cement is by far the most common type of cement in general use around the world This articles looks at the cement manufacturing process in 4 steps Step 1: Mining The first step of Cement manufacturing process is to quarry the principal crushing process detail in cement industry Cement Industry and Audit Presentation SlideShare 17 Jan 2013 4,5,6,7) Process of Cement Manufacturing(S No8,9,10,11,12) Overall HSD Oil • Clilnkerization GGBS• Fly Ash • Cement Grinding Power Misc Cement Manufacturing Process incrushing process in cement industry krakzalwroclawplProcess control system CEMAT Intelligent process control with more than 40 years of experience CEMAT based on SIMATIC PCS7, specifically designed for cement industry, has been well accepted and proven in the harsh environment over many yearsextraction of lime stone process for cementextraction and crushing process in cement Cement extraction and crushing process in cement

Surya Gold Cement Cement Manufacturting Process Flow

Brief Description OfThe Cement Manufacturing Process 1 Crushing Section: The raw materials mainly limestone, additives etc are crushed in the separate crushers and stored automatically into Cement Manufacturing Process Phase IV: Kiln Phase Kiln is a huge rotating furnace also called as the heart of cement making process Here, raw material is heated up to 1450 ⁰C This temperature begins a chemical reaction so called decarbonation In this reaction material (like limestone) releases the carbon dioxideCement Manufacturing Process Phases Flow Chart This is where the cement manufacturing process begins Limestone is the major raw material used for producing cement, and is excavated from the captive mines held by the organization The quarrying activity is carried out employing opencast mining technique, following drilling and blastingReliance Cement

The manufacturing process Hoffmann Green Cements

The manufacturing process for Hoffmann Green cements is based on the systematic use of abundant coproducts as a substitute for natural resources This innovation makes it possible to produce a carbonfree cement 0% clinker while preserving natural resources, particularly without the use of quarries and healthy environment built up To control cement manufacturing process pollution free system should be developed and various safety precautions and guidelines conducted[7] 3 PROCESS INVOLVED Cement manufacturing Process divided in mainly in 10 stages: 1 Mining 2 Crushing 3 Stacking and reclaiming 4 Grinding in VRM 5Risk Assessment in Cement Manufacturing Process The first step in both manufacturing processes after quarrying is primary crushing Crushing reduces the size of the rock to three inches or smaller Next, the raw materials are combined in the correct amounts and fed into the kiln system In the dry process, the materials are grounded, mixed, and introduced into the kiln system in a dry stateHow Portland Cement is Made? Manufacturing Process of

Cement Plant Process and Instruments Used

Programming options using process device managers will enable plant personnel to better maintain field instrumentation Measurements in the cement process will always tend to be rather difficult because of the aggressive environment Solutions will improve as field device suppliers focus on the specific needs of the cement industry

marble mosaic tile machinery

feed size distribution in crusher

crushing equipment exhibitions

ore dressing machine sayaji ironoreore dressing

electrical installation of a crusher

mini crusher for aggreagte

ball mill e traction methodhow does primary crusher work

Inspection For Gypsum crusher

powder grinding machine supplier in malaysia limestone machine

Quarry Mining Sale In Gujarat

Mesin Crusher Untuk Emas Crusher For Sale

crusher sand manufacturer in malaysia

used used mobile crusher in canada

Grinding Machine Domolite

demolition grinders sales

what is iron ore processing stages

used minequip trommel for sale

limestone portable crusher repair indonesia

for sale handheld mobile stone crusher

marble granite machinery names

Granite Powder Machine Suppliers India Grinding Mill China

granite granite crushing small

mill suppliers pulveriser power plant

mining equipment rock breaker

ultrasonic device vibration screen for process

stone crushing machine plant in india

high quality how jaw crusher work jaw crusher price India

for sale crushers in karnataka

salary of petroleum engineers in tanzania

low price easy handling used mobile crushing and screening plant