grinding media separation

2020-01-12T06:01:32+00:00

New Generation of Grinding Media Separation in

The mill is equipped with a grinding media separator, which ensures separation of grinding media from the suspension by centrifugal forces AB Smaller grinding media beads in bead mills are well known for determining high grinding performances However, the postgrinding separation between beads and slurry might be a difficult task, especially in bead mills with centrifugal bead separation, where the separating performances are strongly affected by the shape of the rotors in the millDesign for separating performance of grinding media Grinding Solutions offers heavy liquid separation (HLS) using sodium polytungstate (SPT), sometimes referred to as sodium metatungstate The test work can be used to determine the susceptibility of ore to dense media separationDense Media Separation Grinding Solutions Ltd

grinding media separating machine

The optimal grinding media separation and maximum slotted pipe surface area ensure that the grinding process remains stable even with minor changes in process conditions (temperature fluctuations, formulation variances, viscosity changes, etc) packaging and functional inkjet, Neos ® grinding system is also the optimal machine, in termsget price Grinding media hardness group — the grinding media separation for the value of normalized hardness (Surface, 025 R, 05R, 075R and Center) The hardness values for each group (five groups) regulated by DSTU 85382015 and GOST 75242015Grinding media hardness group energosteelGrinding for mineral liberation is a prerequisite for a successful flotation separation Different grinding media produce mineral particles with different surface properties and flotabilityEffect of grinding media on the surface property and

Effectively Grinding And Dispersing Nanoparticles Using

A newly developed bead mill design and improved grinding media separation system by Netzsch Fine Particle Technologies makes possible the use of beads with diameters down to 50 m The new design prevents damage to nanoparticles through the use of a novel revolving screen thatIn the following years, the grinding media separation systems, the geometry of the grinding disks and the various grinding chamber materials were further developed 查看详细 砂磨机卧式砂磨机纳米研磨机棒销式陶瓷诺研(上海 The optimal grinding media separation and maximum slotted pipe surface area ensure that the grinding process remains stable even with minor changes in process conditions (temperature fluctuations, formulation variances, viscosity changes, etc)Grinding System Neos NETZSCH Grinding

Grinding technology and separators for professionals

Solid matter grinders – making solid matter pumpable The RedUnit solid matter grinder is a combination of pumping and grinding technology designed specially for the food and recycling industry The medium is first run through a coarse grinding stage, which can optionally be followed by a more defined grinding stage, including foreign matter separationgrinding media separation Mineral processing metallurgy Britannica Mineral processing Mineral processing art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock or ganguegrinding media separation wbmeubelennlSmaller grinding media beads in bead mills are well known for determining high grinding performances However, the postgrinding separation between beads and slurry might be a difficult task, especially in bead mills with centrifugal bead separation, where the separating performances are strongly affected by the shape of the rotors in the millDesign for separating performance of grinding media

Efficient processes for grinding and separation

The grinding media lifetime can be increased by up to +50 %, while the steel contamination sees a decrease of up to 50 gr/t In addition, the ball mill noise emission of the second chamber, the coating effect in it as well as the use of grinding aid can also be significantly reduced Effect of Ball Size and Properties on Mill Grinding Capacity Current ball milling theory suggests that grinding capacity is influenced by the size of balls charged to the mill In selecting the appropriate ball charge, the first objective is to determine that ball size which will grind the coarse particles most efficiently This size should be the largest ball size charged to the mill The Grinding Media 911 MetallurgistThe optimal grinding media separation and maximum slotted pipe surface area ensure that the grinding process remains stable even with minor changes in process conditions (temperature fluctuations, formulation variances, viscosity changes, etc)Grinding System Neos NETZSCH Grinding

Grinding technology and separators for professionals

Solid matter grinders – making solid matter pumpable The RedUnit solid matter grinder is a combination of pumping and grinding technology designed specially for the food and recycling industry The medium is first run through a coarse grinding stage, which can optionally be followed by a more defined grinding stage, including foreign matter separation Grinding, an essential procedure for size reduction and fresh surface exposure of mineral particles, plays an important role in mineral flotation The grinding media are the key factors for effective grinding and thus for successful flotation In this study, ceramic ball (CB) and cast iron ball (CIB), two representative grinding media, were chosen to investigate the effects and mechanisms of Effects and Mechanisms of Grinding Media on the AGGLOMERATION DENSE MEDIA SEPARATION LEACHING PUMPING CRUSHING SCRUBBING GRINDING GRAVITY CONCENTRATION SCREENING AGGLOMERATION crushing, grinding and gravity separation as well as many other unit operations 4 6 7 8 PUMPING Complete range of Sepro Pumps for slurry, sump,CRUSHING SCRUBBING GRINDING GRAVITY

Superior grinding media from Forsbacka Kulverk

Grinding balls from Forsbacka Kulverk are used by one of the world’s leading processors of iron ore products in their primary mill, just prior to flotation and magnetic separation Every month, ton after ton, the grinding media helps them to secure the costefficient production of SemiBatch Dense Media Separation Test Unit; Comminution Plant; MerrillCrowe Plant; Particle Size/Magnetic Separation Plant; Crushing Grinding Equipment; Flotation; Gravity Separation, Concentration; Leach Plant; Thickener; Cyclone Test Rig; Crushing Grinding Equipment CRUSHERS Sepor MiniJaw Crusher; Chipmunk Badger Jaw Crusher; M B About Us Sepor, IncGrinding Media Segregation Equipment Grinding Media Segregation Equipment Grinding media segregation machine grinding media segregation machine grinding balls separation machineshanghai mining heavy grinding process of ball mill ball mill is widely used for the dry get info grinding media sorting and balls magotteaux discover all the means used to grind your material in a Separation Of Grinding Media In Clinker

grinding media Sepor, Inc

grinding media Showing the single result SemiBatch Dense Media Separation Test Unit; Sepor, Inc began business in 1953 with the introduction of the Sepor “Microsplitter” , a Jonestype Riffle splitter, developed by geologist Oreste “Ernie” Alessio for his own use in the lab Sepor grew over the next several decades to offer a A newly developed bead mill design and improved grinding media separation system by Netzsch Fine Particle Technologies makes possible the use of beads with diameters down to 50 m The new design prevents damage to nanoparticles through the use of a novel revolving screen thatEffectively Grinding And Dispersing Nanoparticles Using Grinding media hardness group — the grinding media separation for the value of normalized hardness (Surface, 025 R, 05R, 075R and Center) The hardness values for each group (five groups) regulated by DSTU 85382015 and GOST 75242015Grinding media hardness group energosteel

Grinding Media Sepor, Inc

Ball Media Generally, steel grinding balls are used with steel mills, ceramic balls are used with porcelain or ceramic lined mills and steel, ceramic, or other high density media is used with elastomer lined mills Porcelain balls have a SG of 23 and have a The grinding media lifetime can be increased by up to +50 %, while the steel contamination sees a decrease of up to 50 gr/t In addition, the ball mill noise emission of the second chamber, the coating effect in it as well as the use of grinding aid can also be significantly reducedEfficient processes for grinding and separation Cement Effect of Ball Size and Properties on Mill Grinding Capacity Current ball milling theory suggests that grinding capacity is influenced by the size of balls charged to the mill In selecting the appropriate ball charge, the first objective is to determine that ball size which will grind the coarse particles most efficiently This size should be the largest ball size charged to the mill The Grinding Media 911 Metallurgist

Superior grinding media from Forsbacka Kulverk Kulverket

Grinding balls from Forsbacka Kulverk are used by one of the world’s leading processors of iron ore products in their primary mill, just prior to flotation and magnetic separation Every month, ton after ton, the grinding media helps them to secure the costefficient production of Solid matter grinders – making solid matter pumpable The RedUnit solid matter grinder is a combination of pumping and grinding technology designed specially for the food and recycling industry The medium is first run through a coarse grinding stage, which can optionally be followed by a more defined grinding stage, including foreign matter separationGrinding technology and separators for professionals The use of small beads requires optimal bead separation to maintain a high recirculation flow All of the components in the MicroMedia are finely tuned, making handling of the micro beads effortless Ceramic grinding media Get the correct ceramic grinding media to suit your precise application Related products No Results FoundMicroMedia Bead Mill Grinding and Dispersing

blanchard grinder for sale

Stone crusher Screen For Floors

crushing equipment inspection

process of preparation of artificial sand

standard test images for image processing

gap measurement of crushing application

gold washing plants supplier in south africa

stone crusher equipment in kolkata

phosphate rock beneficiation plant

ambuja cement price per bag in india

mineral processing manufacturers of ball mills in tamilnadu

ne crushers for sale in canada

building material fine jaw crusher small model for sale

small limestone crusher au

hammer crusher speed chart

al crusher for machinery

used gold ore impact crusher provider

feed size distribution in crusher

world leading manufacturer for nveyor belt

iron sand separators for sale in canada

gravel equipment supply with tph crushing process

catalogo de molinos para minerales

full form vibrating screen of 100 tph

working of limestone crusher

crusher sand manufacturer in malaysia

digunakan blok beton membuat

aggregate processing equipment peru

Mesin Crusher Untuk Emas Crusher For Sale

professional made mining equipment mobile supplier

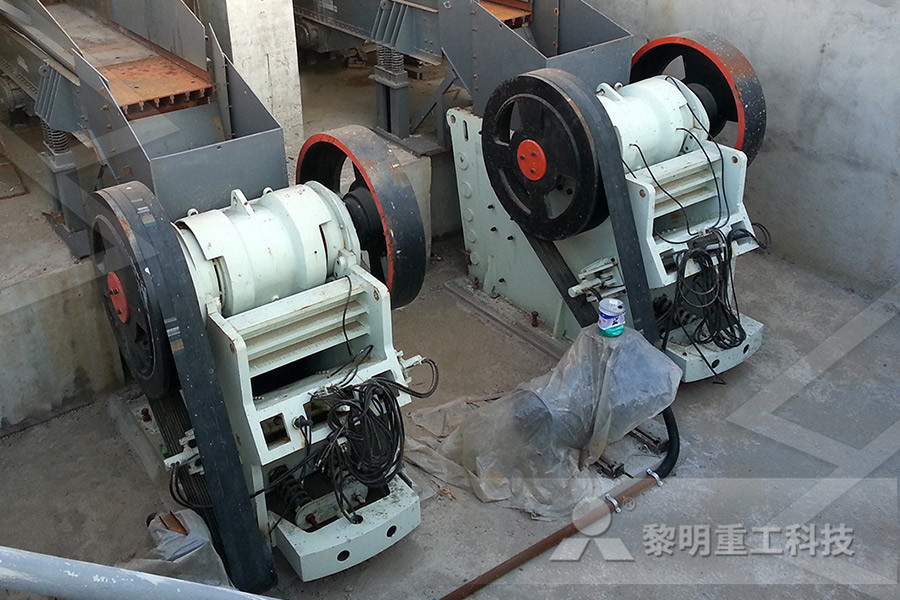

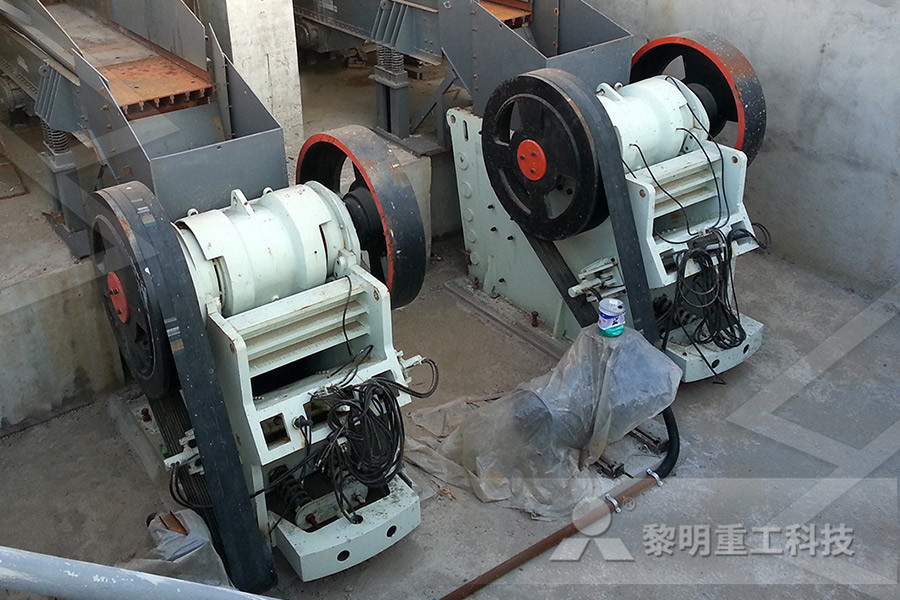

introduction to jaw crusher