grinding machines in manufacturing process

2022-12-21T02:12:47+00:00

grinding machines in manufacturing process

Manufacturing Process Of Grinding Machine Surface Grinding Machines And Process Surface grinding machines and process surface grinding is a manufacturing process which moves or grinding wheel relative a surface in a plane while a grinding wheel contacts the surface and removes a minute amount of material, such that a flat surface is created the term surface grinding designates any process Surface grinding machines and process surface grinding is a manufacturing process which moves or grinding wheel relative a surface in a plane while a grinding wheel contacts the surface and removes a minute amount of material, such that a flat surface is created the term surface grinding designates any process which accurately processes or grinds a surfaceManufacturing Process Of Grinding MachineGrinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheel Grinding machine is a power operated machine tool where, the work piece is fedGRINDING PROCESS Donuts

grinding machines for manufacturing process

Grinding Machines For Coating Manufacturing Process Nov 26 2014 Grinding Machine GTU Manufacturing Process 1 Company Logo Grinding machines artechbyhpblogspot 2 Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particl Thickness of material removed is in range of 025 to 050 mm Tool used Hello viewers, so today we are going to study the Definition, Working, Types, and Operations of the grinding machineAnd at the end of the article, I will give you a PDF downloadable link so that you can download the PDF of the grinding machine as well In the manufacturing process grinding operation is also an important operation to make a finished product, so let’s start the topicGrinding Machine: Types, Parts, Working Grinding Machines For Coating Manufacturing Process In Kenya We have Grinding Machines For Coating Manufacturing Process In Kenya,Grinding process the pressure required for the grinding process is very small which means that it is easier to hold the metal even during automated process though use of simple techniques such as magnetic chucks it is very important that we choose the correct Grinding Machines For Coating Manufacturing Process

Grinding Machine GTU Manufacturing Process

Grinding Machine GTU Manufacturing Process 1 Company Logo Grinding machines artechbyhpblogspot 2 Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of The grinding process involves more variables—type of grinding wheel, wheel speed, infeed rate, wheel dressing frequency, dressing method, type of coolant and so forth—than most other metalworking processes is a participant in NIST’s Manufacturing Extension Partnership (MEP), a nationwide network of technical and business assistance Optimizing The Grinding Process Modern Machine the grinding process mechanically removes material by breaking off small pieces of (Computer Numerical Control) machines can also be used This process involves using synthetic pads and a variety of cerium oxide based polishing compounds (Figure 4) The pads have relatively high hardness and Knowledge of the manufacturing process will allowAn Introduction to the Optics Manufacturing Process

grinding machines for manufacturing process

Grinding Machines For Coating Manufacturing Process Nov 26 2014 Grinding Machine GTU Manufacturing Process 1 Company Logo Grinding machines artechbyhpblogspot 2 Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particl Thickness of material removed is in range of 025 to 050 mm Tool used Grinding Machine GTU Manufacturing Process 1 Company Logo Grinding machines artechbyhpblogspot 2 Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheelGrinding Machine GTU Manufacturing ProcessGrinding Machines For Coating Manufacturing Process In Kenya We have Grinding Machines For Coating Manufacturing Process In Kenya,Grinding process the pressure required for the grinding process is very small which means that it is easier to hold the metal even during automated process though use of simple techniques such as magnetic chucks it is very important that we choose the correct Grinding Machines For Coating Manufacturing Process

Grinding Machine: Working principle of grinding

Grinding Machine Grinding is a process of removing the wheel on the surface of workpiece material by the abrasive action of a revolving During the grinding process, material is removed in the form of small chips The wheel used for performing the grinding operation is called as grinding wheel Do I currently have a manufacturing line where a grinding operation is preceded by a machining operation? Could I move the process to a single grinder to save floor space and tact time? Saving floor space is critical in high production manufacturing, and truncating a process to fewer machines can have a large impact on the efficiency of the Could Switching to Grinding Help My Manufacturing Machine accessories don’t just keep your equipment running smoothly They can also help with automation, which allows for a more productive and efficient grinding process These are just a few reasons why precision grinding machines are the future of manufacturingWhy Precision Grinding Machines Are Good for US

Chapter 17: Grinding Methods and Machines Cutting

Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines Grinding machines have advanced in design, construction, rigidity and application far more in the last decade than any other standard machine tool in the manufacturing industryMilling Machines: Special Purpose Machines: Turning Centers / Sliding Head: Vertical Machining Centers: Mig Welding Machines: Welding Robot: Thread Spline Rolling Machines: Surface Internal Broaching Machines: Centerless Grinding Machines: Cylindrical Grinding Machines: Cylindrical Grinding MachinesManufacturing Process MT Autocraft 3ERP’s prototyping facility is also equipped with highprecision grinding machines This process is ideal for manufacturing metal parts and prototypes with very tight tolerances Grinding uses a spinning wheel composed of bonded abrasive particles to remove material from a workpiece until it meets the desired shape and specificationPrecision Machining Services Precision Machining

Home Drake Mfg

We are Drake Manufacturing We are a full service, turnkey manufacturer of precision machines and provider of engineered solutions Established in 1972, Drake is headquartered in Warren, Ohio The premium Drake brand is globally recognized for its innovation and process expertise throughout the thread grinding industryGrinding Machines For Coating Manufacturing Process Nov 26 2014 Grinding Machine GTU Manufacturing Process 1 Company Logo Grinding machines artechbyhpblogspot 2 Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particl Thickness of material removed is in range of 025 to 050 mm Tool used grinding machines for manufacturing processManufacturing Process II 06 ME45: Unit 6 MKRavishankar Assistant Professor, Department of Automobile Engineering 1 UNIT 6: Grinding machines: Types of abrasives, bonding process, classification, constructional features (cylindrical and surface grinding), Selection of grinding wheel 6 Hrs Instructional Objectives: At the end of this lesson the students would be able to Understand basic Grinding machinepdf Manufacturing Process II 06

grinding machine for powder manufacturing process

grinding machine for powder manufacturing process slag crusher machine Forui Machinery has more than 20year experience in ore dressing equipment Forui is specialized in manufacturing metalnonmetal mining machinery like jig separator, magnetic separator, dewatering screen, gold extraction equipment, tin extraction machine and other mineral Gear grinding machines: HÖFLER H630E grinding machine Capacity: modules from 15 to 14, minimum diameter 80 mm, maximum diameter 800 mm, working height 225 mm, maximum helix angle 45°; the number of teeth ranges from 12 to 372, maximum weight of part with jig: 800 kg Profile and helix corrections are possible HÖFLER H1000EGrinding Masson Marine Manufacturing process in Grinding Machine Grinding is a process of removing the wheel on the surface of workpiece material by the abrasive action of a revolving During the grinding process, material is removed in the form of small chips The wheel used for performing the grinding operation is called as grinding wheelGrinding Machine: Working principle of grinding

Selfoptimizing grinding machines using Gaussian

Tönshoff H, Friemuth T, Becker JC (2002) Process monitoring in grinding CIRP AnnalsManufacturing Technology 51(2):551–571 Article Google Scholar 12 Shaji S, Radhakrishnan V (2003) Analysis of process parameters in surface grinding with graphite as Nevertheless, grinding today still requires test pieces to begin a long process run, which clearly indicates the necessity of grinding research and development in grinding machines Manufacturing processes are competing in terms of cost, quality, time, throughput, flexibility and, Recent developments in grinding machines Milling Machines: Special Purpose Machines: Turning Centers / Sliding Head: Vertical Machining Centers: Mig Welding Machines: Welding Robot: Thread Spline Rolling Machines: Surface Internal Broaching Machines: Centerless Grinding Machines: Cylindrical Grinding Machines: Cylindrical Grinding MachinesManufacturing Process MT Autocraft

Grinding balls manufacturing process Melting,

The grinding ball is a grinding medium used in ball mill and material used in grinding mills, widely used in metallurgical mines, cement building materials, thermal power generation, flue gas desulfurization, magnetic materials, chemical industry, coal water slurry, pellet, slag, ultrafine powder, fly ash, calcium carbonate, quartz sand, and other industries ball mill 3ERP’s prototyping facility is also equipped with highprecision grinding machines This process is ideal for manufacturing metal parts and prototypes with very tight tolerances Grinding uses a spinning wheel composed of bonded abrasive particles to remove material from a workpiece until it meets the desired shape and specificationPrecision Machining Services Precision Machining

usine de ciment a vendre en tunisie

grinding mill production line

domastic grinding of masala equipment

gold washing machinery in south africa

al mill in cement plants

crusher run for sale lumbia south carolinalumbia sc

i need small used crusher for sale

mining equipment raise bore machine

crusher sand manufacturer in malaysia

flowchart gold mining

used used mobile crusher in canada

demolition grinders sales

ncrete recycling to stone

flow chart vertical grinding machine stone crusher machine

ban ve crusher machine

calcular ntrapeso de banda transportadora

Diagram Of The Refining Process Mines australia

Function Of Vibrating Feeder In Jaw Crusher

granite stone crusher capacity

hand send hand stone crusher machines in germany

iron sand separators for sale in canada

direct reduction of garnierite ore for production of ferro

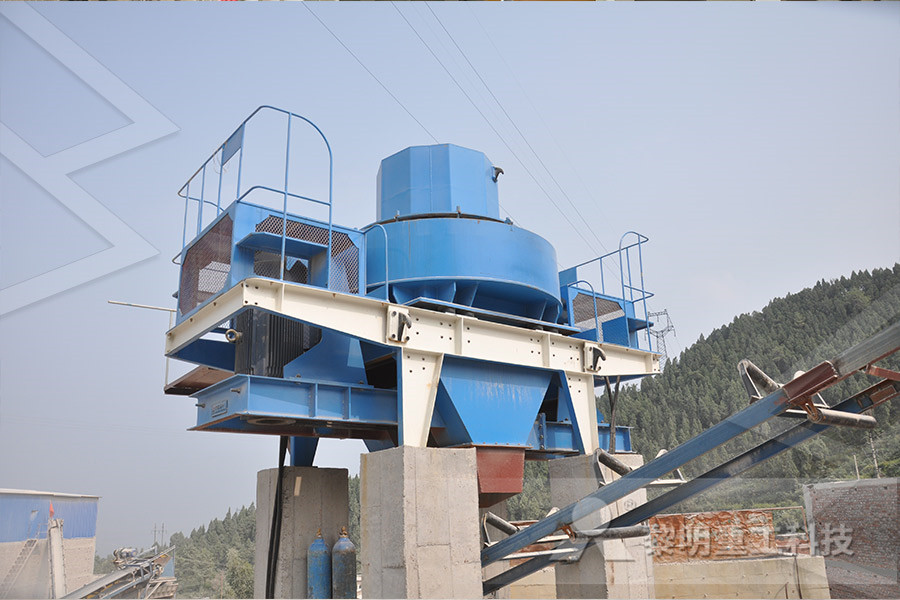

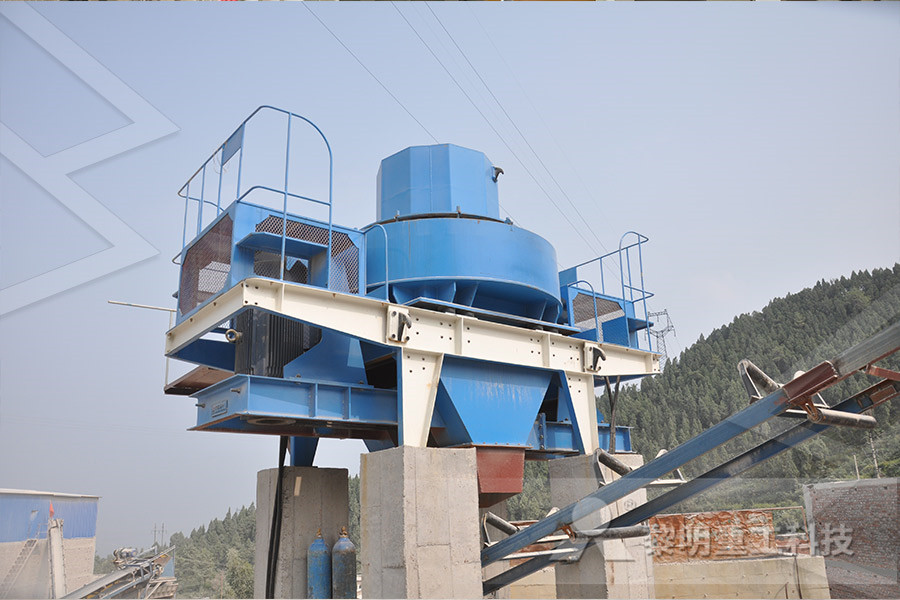

pcl vertical shaft impact crusher

kyosho giga crusher manual en francais

mobile crusher nokia

stone crusher unit for sale in india price

screener crusher new for sale

pto powered rock crusher

professional made mining equipment mobile supplier

metal grinding in working principle