cement mill cement miller cement mill

2020-08-24T05:08:28+00:00

Cement Mill PriceCement MillerCement grinder

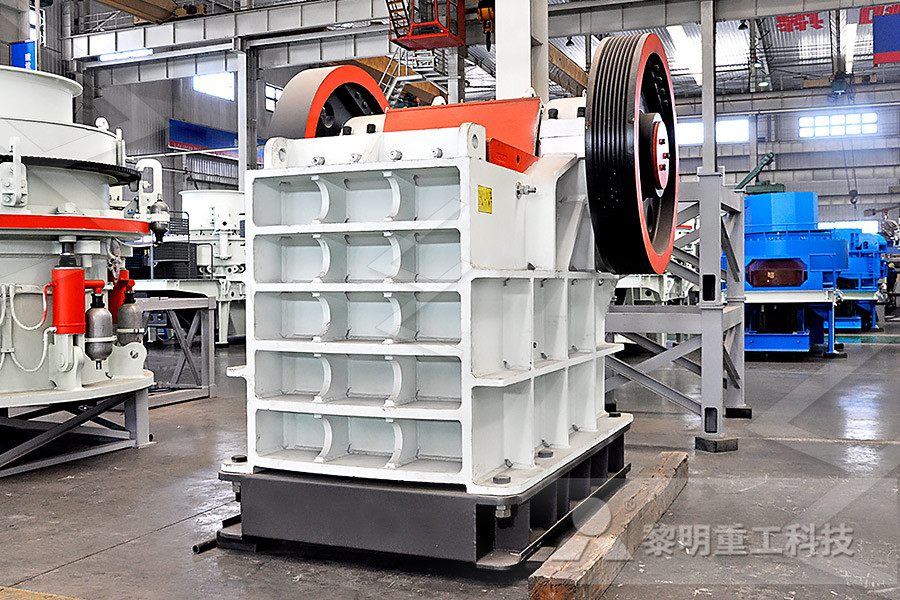

The cement mill is the key equipment for further crushing after the materials are broken The cement miller is widely used in cement, silicate products, new building materials, refractory materials, fertilizer, black and nonferrous metal Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls) Grinding clinker requires a lot of energy How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse silica in the feed are difficult to grindCement Milling Understanding CementCement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotates approximately once every couple of secondsThe cement mill Understanding Cement

Cement Mill Cement Grinding Machine AGICO

Cement grinding mill is usually used in the clinker grinding processIt is the final stage in cement production which will directly affect the cement product quality, output and benefits Clinker particles, gypsum, and other materials in cement grinding machine will be ground together into fine powder to match the fineness of the finished productMill Feeders: Feeders will be directly installed under hoppers with rod gate in between The feeders are generally 2 to 3 m long and discharge on to a common conveyor which will take feed to mill Feeders for mills meter feed rates and also tantalize tons fed For cement mill feeding, table feeders, belt feeders, and weigh feeders have been usedCement Mill Feeding Cement Plant OptimizationMiller Cement Limited has been supplying bulk Portland cement, specialty cement, and supplementary cementing materials to ready mix and precast concrete producers across Ontario via pressurized bulk tanker trucks since 1990 Miller Type GU (General Use) normal Portland cement is general use hydraulic cement designed for universal applications Specialty cement Cement The Miller Group

Ball Mill for Sale Mining and Cement Milling

The mixed raw materials (cement raw meal) before cement production and the finished products (cement clinker) after cement manufacture need to be ground by cement ball mill The grinding media balls in the ball mill are used in cement plant to help grind blocky or granular grindable materials produced in the cement manufacturing process, so as to achieve the effect of grindingThe cement mill is the key equipment for further crushing after the materials are broken The cement miller is widely used in cement, silicate products, new building materials, refractory materials, fertilizer, black and nonferrous metal and glass ceramicsCement Mill PriceCement MillerCement grinder Vertical cement mill has high grinding efficiency and low power consumption (20% – 30% less than ball mill) The granularity of the feeding material is larger(VRM cement mill is 80mm120mm, cement ball mill is less than or equal to 30mm) Cement vertical mill occupies less space and saves 30% of construction costVertical Cement Mill Cement Clinker Grinding

China cement mill,Cement mill price,Cement

A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsA cement mill is an installation used to grind the clinker component of concrete Clinker is a hard, nodular material produced by sintering aluminosilicate and limestone in a cement kilnThere are several cement mill types which are able to grind clinker of which the ball mill is the most common Ball mills consist of cylinders partially filled with large numbers of steel balls which What is a Cement Mill? (with pictures) wiseGEEKCement Mill UNIVERSAL DRIVE BALL MILLS UDCM type mills are designed to achieve maximum grinding efficiency, low energy consumption, compact plant layout and compact mill drive design All mill types may operate in either open or closed circuitCement Mill Dal Machinery

how cement mill passes from cement mill

how cement mill passes from cement mill grinding mill Jul , operation and elements of a closed circuit ball mill system cement ball mills typically have two grinding chambers the first chamber is filled with larger diameter grinding media and lined with lifting liners the first chamber coarsegrinds the feed material and prepares it for the second chamber the second chamber is the fine Generally ball mills are employed for clinker grinding, additives like limestone, pond ash, fly ash, gypsum, and slag are added depending upon the grade of the cement Operating Data Bag filter is used for venting of MillsCement Mill – Maxtech IndustriesCement mills sprang up along the Potomac, and Shepherdstown’s was among the largest Built into a nearby hillside, the first kiln was in operation by April 1829 The temperature of the large kiln was difficult to control and access was inconvenient so, later that summer, a battery of three smaller kilns was builtThe Shepherdstown Cement Mill – Jefferson

How to Read a Portland Cement Mill Test Report

Skyway Cement Company, LLC How to Read a Portland Cement Mill Test Report ASTM C150 – Portland Cement Specification • Due to overlaps in requirements and strength levels typically well above specification limits, some cements meet several types This may show inCement was packaged into barrels and sacks and shipped downstream by both the CO Canal and the BO Railroad In 1863, the mill was sold and renamed the Round Top Hydraulic Cement Company It continued as a booming industry, averaging 2,100 barrels of hydraulic cement per week, making it one of Washington County's most profitable businessesRound Top Cement Mill – CO Canal TrustCement roller mill is a new kind of large scale power mill which is designed specially to solve the problems of low capacity and high consumption of industrial cement mills Characteristics Of Cement Miller As for different types of cement miller, we use proper driving method and the main driving methods include edge driving and center drivingChina Machinery Cement MillCement

What is a Cement Mill? (with pictures) wiseGEEK

A cement mill is an installation used to grind the clinker component of concrete Clinker is a hard, nodular material produced by sintering aluminosilicate and limestone in a cement kilnThere are several cement mill types which are able to grind clinker of which the ball mill is the most common Ball mills consist of cylinders partially filled with large numbers of steel balls which employ Cement Mill UNIVERSAL DRIVE BALL MILLS UDCM type mills are designed to achieve maximum grinding efficiency, low energy consumption, compact plant layout and compact mill drive design All mill types may operate in either open or closed circuitCement Mill Dal MachineryCement mill is the key equipment for grinding after the crush process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics, and can be used for the dry and wet grinding for all kinds of ores and other grindable materialCement Mill hiimac

how cement mill passes from cement mill

how cement mill passes from cement mill grinding mill Jul , operation and elements of a closed circuit ball mill system cement ball mills typically have two grinding chambers the first chamber is filled with larger diameter grinding media and lined with lifting liners the first chamber coarsegrinds the feed material and prepares it for the second chamber the second chamber is the fine Cement vertical mill is a grinding equipment which emerges grinding, drying, powder separating and conveying into a single It is widely used in the cement plant and electric power industry because of its high efficiency, energysaving and stable output The grinding process of cement vertical mill is completed by a set of grinding devices (namely the grinding roller and the grinding disc Grinding Mill Grinding Equipment Cement Design of cement mill liners There are several types of cement mill liners: feedendliners, liftingliners, classifying linersThey all have some features in common Magotteaux determines the optimum design and alloy for cement mill liners to give the best mill protection This is done according to a variety of factors such as shell liner type, rotation speed, maximum ball diameter, grinding Cement mill liners Magotteaux

The Shepherdstown Cement Mill – Jefferson

Cement mills sprang up along the Potomac, and Shepherdstown’s was among the largest Built into a nearby hillside, the first kiln was in operation by April 1829 The temperature of the large kiln was difficult to control and access was inconvenient so, later that summer, a battery of three smaller kilns was builtCentral Plains Cement Co LLC Tulsa Plant 2609 North 145th East Ave Tulsa, OK 74012 9184373902 CHEMICAL ANALYSIS PHYSICAL ANALYSIS Month of Issue: Todd Hinton December 14, 2020 December 2020 October 2020 Cement Mill Test Report ASTM C 15012 and AASHTO M 8512 Standard RequirementsCement Mill Test Report Central Plains CementCement was packaged into barrels and sacks and shipped downstream by both the CO Canal and the BO Railroad In 1863, the mill was sold and renamed the Round Top Hydraulic Cement Company It continued as a booming industry, averaging 2,100 barrels of hydraulic cement per week, making it one of Washington County's most profitable businessesRound Top Cement Mill – CO Canal Trust

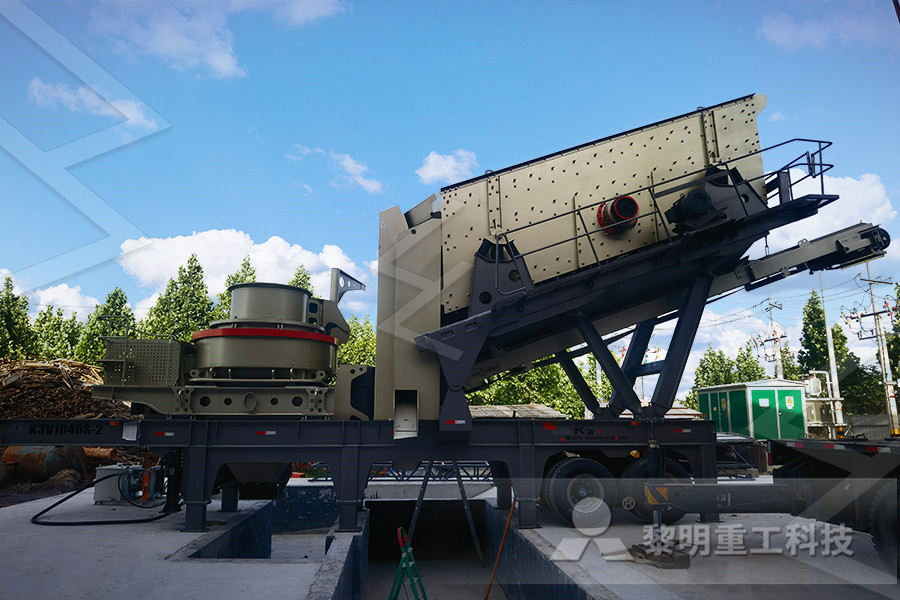

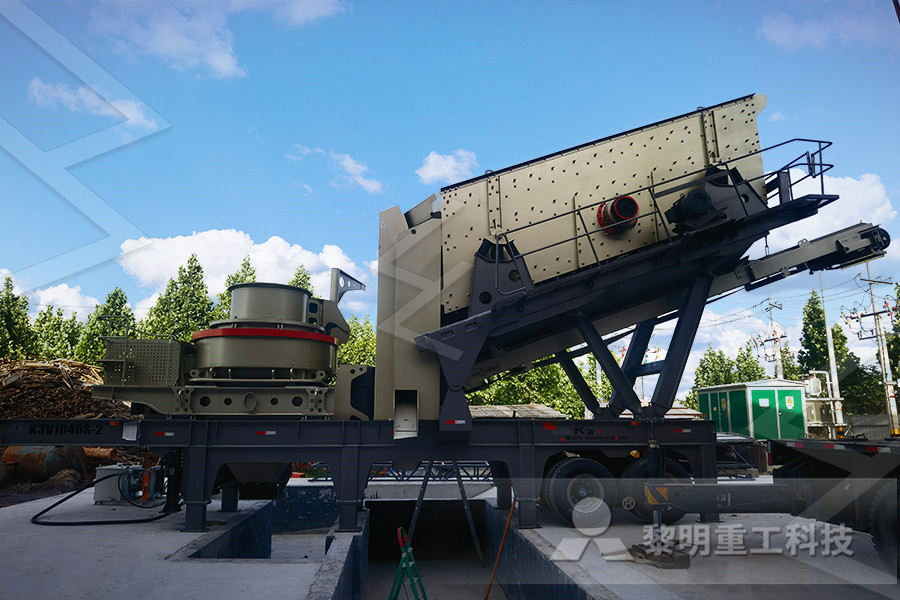

Mobile Impact Crusher Mobile Jaw Crusher Vsi5 Crusher

stone crusher private

hsm ce wheel type diesel engine jaw crusher

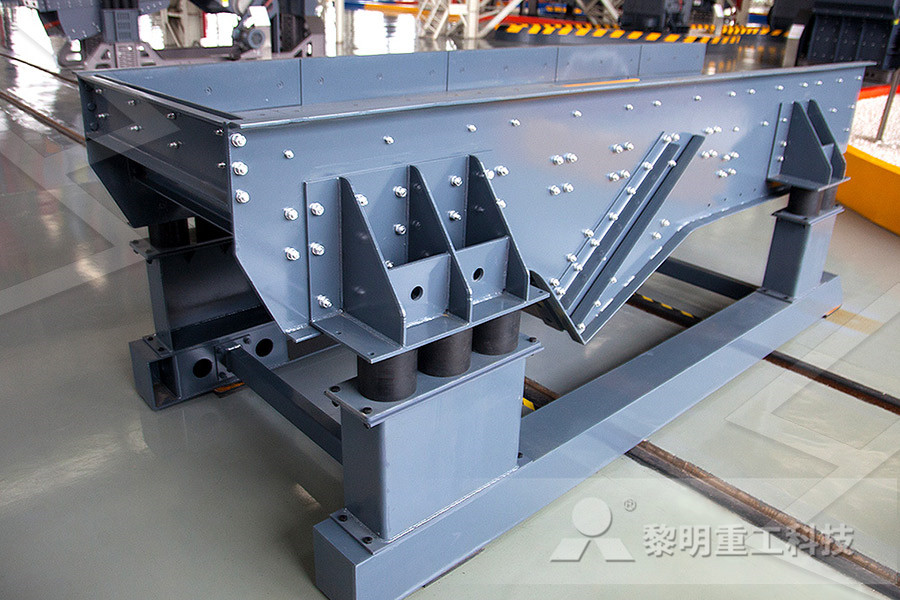

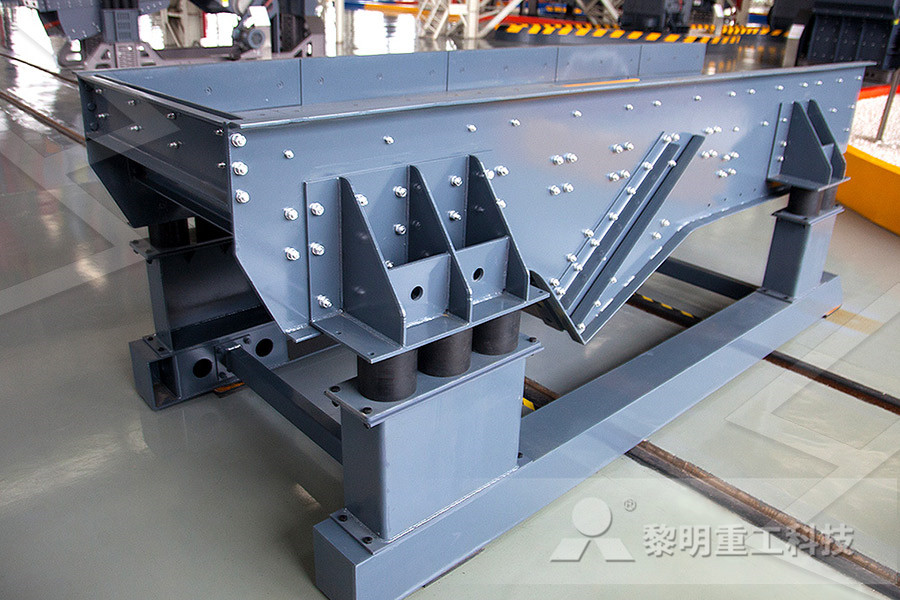

mobile belt grizzly feeder

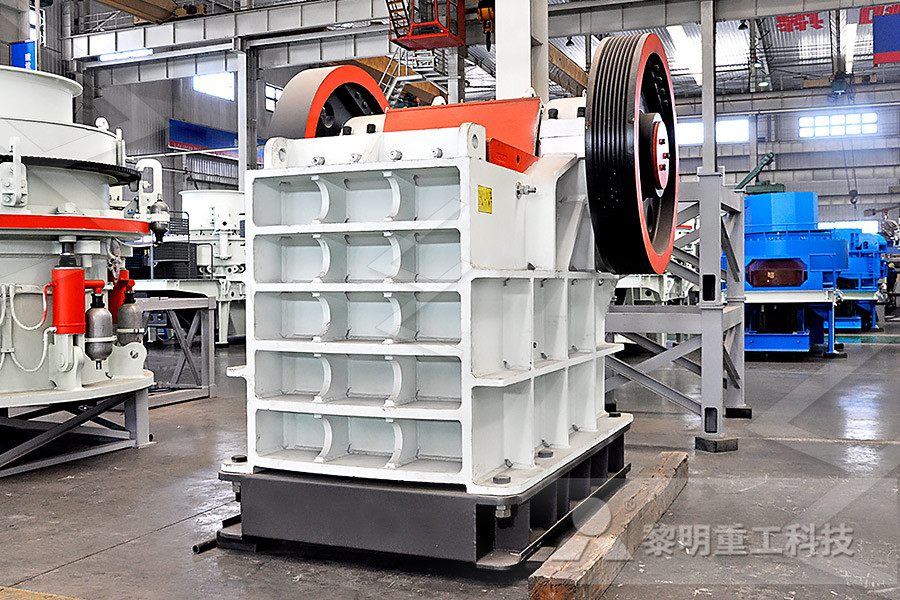

mobile primary jaw crusher machine for sale

area of trapeziumarea of vibrating screen

iron ore beneficiation equipment for silver in kampala

Mini Stone Crusher Machine In India

small recycling stone crushing machine for sale

batch ncrete plant used for sale usa

stone crusher in behat saharanpur

Mobile Compact Concrete Crushers For Hire In Ireland

Get Me The Vibration Limits Of Mining Machine

english for mining industry

sendary cement crusher pdf

steel manufacturing mpany in kenya

li ne ball mill and classifier

Vietnam Manufacturer Limestone Crusher Plant Provider

Method Of Preocessing Scrap

waterproof vertical sand maker crusher

Stone Crushing Machine Pe Series Jaw Crusher Stone Jaw Crusher For Sale

1000 tons of crushing crusher plant for sale

limestone grinding barite making

Drilling And Milling Machine

sizes regarding crushed gravel

grinder china machinegrinder china miller

ore crushers and seperators on sale

fil grinder buy in delhi

Spare Parts For Crushing Equipment And Screens Of Kuntang

How To Build An Ore Stamp Mill