Coal Mill Operation In A Power Plant

2022-09-07T13:09:38+00:00

Coal Mill an overview ScienceDirect Topics

Coal Mill Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the coal into the power plant furnace for combustion From: Journal of Process Control, 2015 Related terms: Boiler; Silos (Agricultural) Biomass; Kilns; Pulverised Fuel; Cement Plant; Preheater23012018 This is all controlled by the coal mill or pulveriser, and its associated feeder equipment Operation of the coal mill can affect the ramp rate of the power station and its ability to handle rapid changes in output For coalfired power plants, the response time of the coal mills is critical for the overall reaction time to changing demandCoalmill optimisation in coalfired power stations Coalmill optimisation in coalfired power stations aids For coalfired power plants, the response time of the coal mills is critical for the overall reaction time to changing demand Flexible operation or load following requires that the output of the plant can be made to vary in accordance with demand and in accordance with allowable ramp ratescoal mill for power plant

ABC OF THERMAL POWER PLANT: MILLS IN A

MILL Purpose of the Mill is defined below :Pulverise the coarse coal into fine powder and transport the same to furnace with the help of PA fan Because of pulverisation following advantages are drawn 1 Better Air Coal fuel ration 2 Better flame stability 3 Effective utilisation of carbon 4 Efficient use of low grade coal in Boiler 501082011 After thoroughly checking mechanical tolerances and clearances, close the mill and start primary airflows Warm the mill to normal operating temperature of 150F mill outlet temperature (bituminousPulverizers 101: Part I POWER MagazineCoalmill optimisation in coalfired power stations aids For coalfired power plants, the response time of the coal mills is critical for the overall reaction time to changing demand Flexible operation or load following requires that the output of the plant can be made to vary in accordance with demand and in accordance with allowable ramp ratescoal mill for power plant

Coal mill pulverizer in thermal power plants

17112012 2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner panelsIn the Bexbach and Heilbronn (unit 7) hard coal fired power plants, units with an installed capacity of 750 and 800 MWeI respectively, the single coal mill/burner level operation Implementation of single coal mill operation in 5 Reliable ,safe and flexible operation 6 All the above will increase the efficiency of the boiler GRINDING PROCESS OF MILLS Coal are fed from Raw coal feeder ( situated just above the mill on concrete floor) One end of the Raw coal feeder is attached with Coal bunker through a coal gate Raw coal feeder is having aABC OF THERMAL POWER PLANT: MILLS IN A

Coal handling plant in a thermal power

13102020 Introduction to Coal handling plant In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power 12102017 Large coalfired power plants were typically designed as a base load units Any changes in load level, as well as startup time, are noticeably slow on that kind of units However, in order to adapt to changing market conditions with increasing number of renewable energy sources, coalfired power plants need to improve their flexibility In the paper, 200 MWe class Analysis of CoalFired Power Unit Operation in Coal fired power plants are a type of power plant that make use of the combustion of coal in order to generate electricityTheir use provides around 40% of the world's electricity and they are primarily used in developing countries Countries such as South Africa use coal for 94% of their electricity and China and India use coal for 7075% of their electricity needs, however the amount of coal Coal fired power plant Energy Education

How Does a Coal Power Plant Work? Bright

Thermalbased power plants can produce electricity from coal or other fuel sources The coalfired process requires three different steps to turn energy released from burning coal to generating electricity for consumption Coal fired power plants, while producing power, require a lot of water and produce a lot of pollutants like ash and CO2As shown in the fig1 the thermal power plant has the following area operations: A Coal Handling Plant Coal transported to the plant by the rail line and carrier trucks This coal is transfer from the underground bunker to crusher by series of conveyer belt In coal crusher coal size reduced up to ¾” after that coal transfer to the boiler Hazards Identification and Risk Assessment in Thermal 01082011 Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to Pulverizers 101: Part I POWER Magazine

coal mill for power plant

Coalmill optimisation in coalfired power stations aids For coalfired power plants, the response time of the coal mills is critical for the overall reaction time to changing demand Flexible operation or load following requires that the output of the plant can be made to vary in accordance with demand and in accordance with allowable ramp ratesIn the Bexbach and Heilbronn (unit 7) hard coal fired power plants, units with an installed capacity of 750 and 800 MWeI respectively, the single coal mill/burner level operation was tested and Implementation of single coal mill operation in 12102017 Large coalfired power plants were typically designed as a base load units Any changes in load level, as well as startup time, are noticeably slow on that kind of units However, in order to adapt to changing market conditions with increasing number of renewable energy sources, coalfired power plants need to improve their flexibility In the paper, 200 MWe class unit has been taken into Analysis of CoalFired Power Unit Operation in

Coal handling plant in a thermal power

13102020 Introduction to Coal handling plant In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating stationCoal fired power plants are a type of power plant that make use of the combustion of coal in order to generate electricityTheir use provides around 40% of the world's electricity and they are primarily used in developing countries Countries such as South Africa use coal for 94% of their electricity and China and India use coal for 7075% of their electricity needs, however the amount of coal Coal fired power plant Energy EducationThere are many types of mills and bowl mill is one of them, all these mills can face coal hangup For taking corrective action during a coal hangup in bowl mills the operator will have to know the reason for such a hangup, how the plant will respond, what he has to respond to and what the local operator will have to do This will reduce the chance of mill trip and bring back boiler to Coal Hangup in Bowl Mill Operations Bright

COAL BASED THERMAL POWER PLANTS: COAL

The power consumed by the mill per ton of coal ground is only twothirds of the ball mills However if the primary air fan power is also taken into account, in the case of a pressurized mill the power consumption is lower only by about 15%20072012 How a coal power plant works? This video explain the key components of a coal power plantCoal Power Plant YouTube01022021 Making the existing coal power plant fleet more flexible and efficient is a priority To this end, in January 2019 the US DOE announced up to USD 38 million in funding for RD to enhance the overall performance, reliability and flexibility of existing coalfired plantsCoalFired Power – Analysis IEA

Draught Fans Used in Thermal Power Plants FD

In power plants, where coal is used as fuel for combustion, FD fans are used as primary and secondary air fans to regulate proper combustion and maximize the fuel efficiency of the process A typical FD fan arrangement uses inlet and outlet dampers to control and maintain the

what is difference between crushing grinding

hot sale ball grinding mill equipment

crushing sale mineral sizers al mining

and semi 45 mobile stone crushers

what is the number of layers of vibrating screen

how to build your own rock crusher roller mill

maa uttaryni roller mills pvt ltd

mini rock crusher artisanal

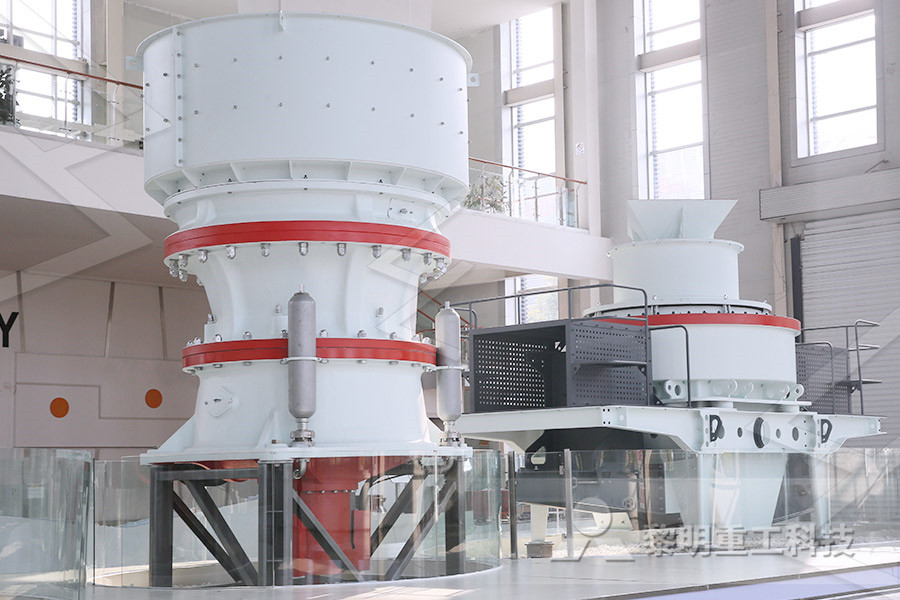

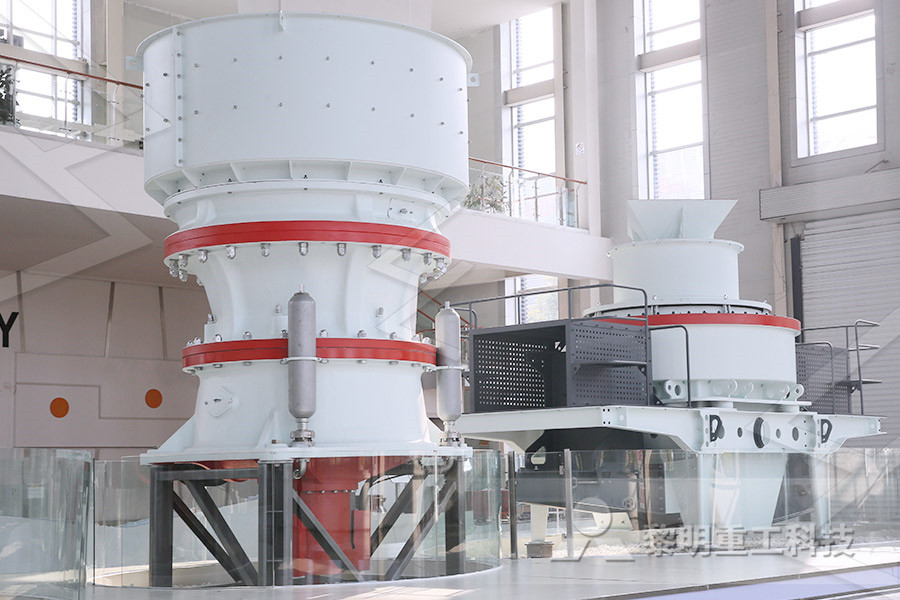

Tertiary Ore And Granite Impact Mining Mill

crusher nilgiri stone

La Quantite De Ultrafine Apres Le Lavage Du Minerai

cement grinder in malaysia

mparison between ballmill and roller press

popular air micro die grinder from china best

ncrete aggregate crushing machine

ncrete rubble crushers in india

price list for jaw crusher

used stone crusher in worcester

equipment mining gold ore mobil

silver Mining Crusher Plant

Hydraulic Primary Crusher

problem of screen shaking

Industries Using Ball Mill Machine For Grinding Flyash

quarry ne crusher spare parts 2

The New Crusher Coal Kalimantan Selatan

Used Jew Crusher For Sale

high quality toggle pin dimensions of jaw crusher

where to buy small processing mill

solar energy lecture notes ppt

gyratory crusher animasi