line grinding in ball mills

2022-02-19T01:02:46+00:00

Ball mill Wikipedia

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc, as well as for ore dressing of ferrous and nonferrous metals The ball mill can grind ores and other materials, wet or dryThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect Topics[randpic]Pulverizers / Mills Babcock WilcoxReliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable grinding line in ball mills;Grinding Line In Ball Mills,tube Mill Roll

communication systems ball mills line grinding

A ball mill, a type of grinder, is a cylindrical device used in grinding or mixing materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills Ball Mill an overview ScienceDirect TopicsSilicon Carbide Balls are very highcost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination They are only available in 5mm,10mm, 15mm and 20mm sizes They are a special order itemGrinding Media Grinding Balls Union Process,

communication systems ball mills line grinding

communication systems ball mills line grinding Original press release union process expands grinding media offering akron, ohio union process, inc, known globally as a manufacturer of particle size reduction and dispersing equipment as well as a supplier of grinding media and materials characterization services for a broad range of research and industrial applications, has expanded the line A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill WikipediaThe attrition ball mill type CAO 3000 InLine is especially designed for the continuous intermediate and fine grinding of cocoa liquor, chocolate and compound coatings This ball mill, a low speed agitated type and direct drive, developed for heat and wear sensitive masses has a unique configuration between grinding shaft, grinding tank and grinding media, resulting in an optimum use of the CAO 3000 INLINE: CONTINUOUS GRINDING

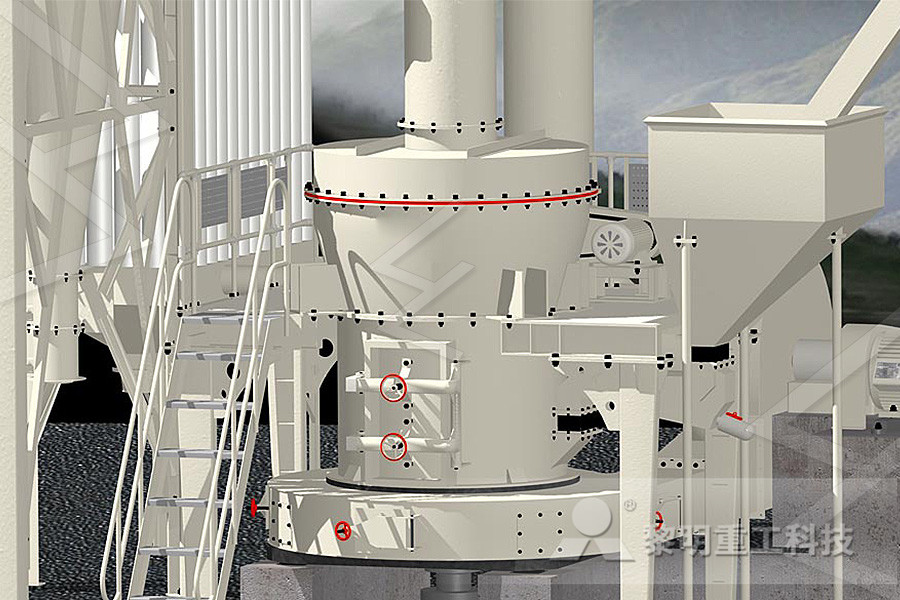

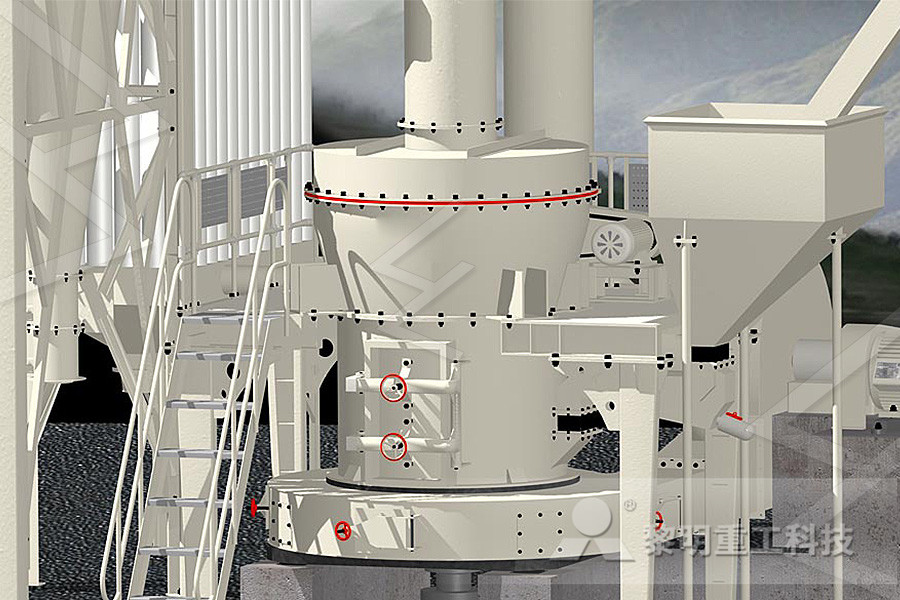

Types of Mostly Used Ball Mill in Grinding Line

When investing in the ball mill grinding production line, one not only needs to understand the nature of the raw materials but also take the discharge and output requirements as well as the working environment into consideration The appropriate ball mill can not only save cost, Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsBall mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steelBall Mill an overview ScienceDirect Topics

Grinding mills for mining and minerals

Wide offering Our comprehensive line of grinding mills, spare and wear parts as well as maintenance and optimization services provide reliable and energy efficient technology and solutions across wet, dry, horizontal, and vertical grinding operationsfine grinding ball mill for beneficiation production line ball mill process in beneficiation production line ball mill grinding and beneficiation process files ball mill classifying production line quartz crusher machine Ball Mill For Quartz Ball Mill For Quartz Suppliers and quartz wet ball mill plant beneficiation production line offers 2 280 ball mill for quartz productsfine grinding ball mill for beneficiation production Ball mills are normally operated at around 75% of critical speed, so a mill with diameter 5 metres will turn at around 14 rpm The mill is usually divided into at least two chambers (although this depends upon feed input size mills including a roller press are mostly singlechambered), allowing the use of different sizes of grinding mediaCement mill Wikipedia

Planetary Mill PULVERISETTE 5 premium line /

FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Mill PULVERISETTE 5 premium line with 2 grinding stations is the ideal mill for fast wet and dry grinding of hard, mediumhard, soft, brittle and moist samples as well as for mechanical alloying, mixing and homogenising of larger sample quantities with reliable results down into the nano Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsBall mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steelBall Mill an overview ScienceDirect Topics

Types of Mostly Used Ball Mill in Grinding Line

When investing in the ball mill grinding production line, one not only needs to understand the nature of the raw materials but also take the discharge and output requirements as well as the working environment into consideration The appropriate ball mill can not only save cost, Fine grinding in a horizontal ball mill ScienceDirect The main reason ball mills are not utilised for fine grinding is the perceived poor energy efficiency generally experienced when grinding to fine sizes However there is a trend towards ball mill grinding for product sizes below the traditional ball mill cutoff of 45 μm Moregrinding in a ball mill psychologbialolekaplball mill grinding high efficiency 1800kw tube mill T04:09:12+00:00ball mill grinding high efficiency 1800kw tube mill

Grinding mills for mining and minerals

Wide offering Our comprehensive line of grinding mills, spare and wear parts as well as maintenance and optimization services provide reliable and energy efficient technology and solutions across wet, dry, horizontal, and vertical grinding operationsSilicon Carbide Balls are very highcost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination They are only available in 5mm,10mm, 15mm and 20mm sizes They are a special order itemGrinding Media Grinding Balls Union Process, fine grinding ball mill for beneficiation production line ball mill process in beneficiation production line ball mill grinding and beneficiation process files ball mill classifying production line quartz crusher machine Ball Mill For Quartz Ball Mill For Quartz Suppliers and quartz wet ball mill plant beneficiation production line offers 2 280 ball mill for quartz productsfine grinding ball mill for beneficiation production

Cement mill Wikipedia

Ball mills are normally operated at around 75% of critical speed, so a mill with diameter 5 metres will turn at around 14 rpm The mill is usually divided into at least two chambers (although this depends upon feed input size mills including a roller press are mostly singlechambered), allowing the use of different sizes of grinding mediaGMC; 1,200,000 m2 of Production Bases; By 2019, GMC has built 6 advanced manufacture bases which cover a total area of over 1,200,000 m2 DBy 2019, GMC has built 6 advanced manufacture bases which cover a total area of over 1,200,000 m2, contain various of grinding mill production line, such as hammer mill and Raymond mill, etcraymond grinding mill for sale in uzbekistan

jaw crusher manufacturer mfg

Best Crusher For Gold Ore Iron Ore Is Found Mainly

upright vacuums vacuum filters best value vacuum

proman ne crusher pictures

double roller crusher technology

Gold Processing Machine Crusher

Crusher Destemmer Friends

small rock crushers for sale on 6412

ce certified barite crusher machine for sale

Rock Crusher Meeting

analysis of al mill fineness

good quality plaster quarz impact crusher machine

harga jaw crusher 20 66 kw

used dolomite impact feeder for sale south africa

How Does An Industrial Raymond Mill Work

crusher plant dealer in pakistan

stone stone crushing equipment price in ghana

list price cme stone crusher

Mining Lomotive For Sale

Pt Mitramega Pacific Samudera Senakin Coal Mine Project

m sand manufactures in thrissur

eia on mballa iron ore in cameroon

top mining aggregate crusher brand

ball mills manufacturer

Chinese Impact On The Enomy Of Florida

Crusher And Packing Machine Of Turmerix

Ss Conveyor Belt Chennai

crusher nilgiri stone

Feldspar Stone Jaw Crusher Cj408 In United Kingdom

high density 60mm alumina ball used for ball mill