Specific Ation Of Cement Thermal Mill

2022-01-19T19:01:46+00:00

what is the specific ation of cement thermal mill

what is the specific ation of cement thermal mill Cement in Afghanistan USGS Specific Thermal Energy Consumption by Rotary Kiln Type will vary in each specific cement plant, the general enabling factors are favorable in Society for Testing and Materials (ASTM) Specification C150Cement Ball Mill ; Cement Vertical Mill ; Precipitator ; The specific role of cement rotary kiln: 1 the steady thermal field of cement rotary kiln, » Learn More Cement mill, Crusher, Mill, Brick Machine, Sand Maker Machinery Cement mill: Technical parameters of Cement mill series Specification(m) Milling form Transmission form Gear boxspecific ation of cement thermal mill – Grinding A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia

Thermal Conducting Cements Insulation Outlook

The thermal conductivity range is between 45 and 55 Btu in/hr/sq ft/degree F The U Range is between 20 and 40 Btu /hr/sq ft/degree F PreFormed Heat Transfer Cement For ease of application on 3/8, 1/2 and 3/4 inch tracer tubing, apply a preformed strip (See Figure 5) The 4foot long strip of flexible cement can be snapped over the tracer07012015 Specific power consumption for clinker/gypsum grinding in a ball mill should be approximately: 3000 cm2 /g 244 kWh/t 3200 cm2 /g 268 kWh/t 3400 cm2 /g 294 kWh/t 3600 cm2 /g 320 kWh/t 3800 cm2 /g 347 kWh/t 4000 cm2 /g 375 kWh/t Note: The specific power demand of large grinding units is 1015% better than that of small mills 81 Calculation of Cement Mill Power Cement mill notebook SlideShareThe specific heat of concrete and masonry can generally be assumed to be 02 British thermal units per pound degrees Fahrenheit (Btu/lb°F) ( ASHRAE Handbook of Fundamentals , 2005) Heat Capacity (HC) is the amount of heat energy required to raise the temperature of a mass one degree FahrenheitThermal Mass Portland Cement Association

specific ation of cement thermal mill – Grinding

Cement Ball Mill ; Cement Vertical Mill ; Precipitator ; The specific role of cement rotary kiln: 1 the steady thermal field of cement rotary kiln, » Learn More Cement mill, Crusher, Mill, Brick Machine, Sand Maker Machinery Cement mill: Technical parameters of Cement mill series Specification(m) Milling form Transmission form Gear boxwhat is the specific ation of cement thermal mill what is the specific ation of cement thermal mill Description : UPGRADED THERMAL INSULATION FOR MINIMIZING HEAT Kg/M3 Up to 650 C THERMAL INSULATIONS IN CEMENT PLANT DUCT FROM CYCLONE TO MILL FAN 25 » Learn More Cement Csi Home specific thermal and electrical energy consumptionswhat is the specific ation of cement thermal mill The specific thermal energy c onsumption in cement i ndustries in India var ies fr om 295 GJ to 4 GJ/tonne of clinker The higher specific energy c onsumption is due to the harder raw(PDF) Energy audit of thermal utilities in a

Cement mill notebook SlideShare

07012015 Example: Two compartment cement mill Diameter = 405 m Length = 12 m Filling degree = 196 tons at 30% filling degree Mill speed = 1627 rpm C = 0223 (from the figure) Then: K = 0223 * 196 * 405 * 1627 = 288 KW 82 Calculation of the Specific Consumption of Energy per Ton of Clinker: The specific consumption of energy per ton of clinker varying according to 257 HighEfficiency Fans for Cement Mill Vents experience in the cement sector and focus on specific technical measures that could be implemented by cement plants IFC commissioned two studies on international best practice in the cement sector, covering thermal and electric energy efficiency, IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT CEMENT Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium silicatesOver a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plantCement kiln Wikipedia

JAPAN CEMENT ASSOCIATION

Effective utilization of thermal energy Figure 5 shows the typical thermal balance at cement plants in Japan Some 80% of the inputted thermal energy is used for clinker burning, drying raw materials, drying coal and power generation Figure 5 Effective use of thermal energy at cement plant Transition of specific electric energy consumptionof specific thermal The low heat flux to the bed at low feed rates is due to a slumping action at optimization and monitoring of Portland cement (PC 425) quality at the ball mill (PDF) HEAT TRANSFER IN ROTARY KILN FROM The specific heat of some commonly used solids is given in the table below For conversion of units, use the Specific heat online unit converter See also tabulated values of specific heat of gases, food and foodstuff, metals and semimetals, common liquids and fluids and other common substances as well as values of molar heat capacity of common organic substances and Specific Heat of Solids Engineering ToolBox

Thermal Conductivity of some selected

Thermal conductivity is a material property that describes ability to conduct heatThermal conductivity can be defined as "the quantity of heat transmitted through a unit thickness of a material in a direction normal to a surface of unit area due to a unit temperature gradient under steady state conditions"what is the specific ation of cement thermal mill what is the specific ation of cement thermal mill Description : UPGRADED THERMAL INSULATION FOR MINIMIZING HEAT Kg/M3 Up to 650 C THERMAL INSULATIONS IN CEMENT PLANT DUCT FROM CYCLONE TO MILL FAN 25 » Learn More Cement Csi Home specific thermal and electrical energy consumptionswhat is the specific ation of cement thermal mill 257 HighEfficiency Fans for Cement Mill Vents experience in the cement sector and focus on specific technical measures that could be implemented by cement plants IFC commissioned two studies on international best practice in the cement sector, covering thermal and electric energy efficiencyIMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT CEMENT

Competence in cement BME Group

utilization of the thermal energy of process gases Maximum availability Thanks to low specific wear rates, Production of various cement qualities in one mill Products in line with standards and market requirements MVR roller mill ation is dust free and they have a low noise levelCement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium silicatesOver a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plantCement kiln Wikipedia4342 Calculation for Gate to Gate Specific Energy Consumption (SEC) 6 44 Methodology (Summary) 7 5 Target Setting in Cement Plants 7 51 Grouping of Cement plants 7 52 Energy Consumption Range 8 53 Example: Normalised Baseline parameters and Target for PPC 8 54 Apportionment of SubSector Target of Energy Saving in Cement Sector 9Cement Sector Bureau of Energy Efficiency

Technical Notebook CEMENT ADDITIVES FOR VERTICAL MILLS

CEMENT ADDITIVES FOR VERTICAL MILLS 04 2 VERTICAL MILLS INTRODUCTION Thanks to the necessity to improve grinding efficiency and reduce operation costs, vertical mills have made their way into the cement industry At first these new systems were employed for the grinding of solid combustibles and kilnfeeding raw meal In the past decade,In addition, you will receive guidelines for the maximum permissible water/cement ratio based on the structure exposition (Table 634(b)/ A1534(b)) Using your input data, the app will calculate the amount of cement required Note that the amount of cement can be Concrete Mix Design Just Got Easier Giatec of specific thermal The low heat flux to the bed at low feed rates is due to a slumping action at optimization and monitoring of Portland cement (PC 425) quality at the ball mill (PDF) HEAT TRANSFER IN ROTARY KILN FROM

Portland Pozzolana Cement (PPC)

Portlandpozzolana cement is produced by grinding together Portland cement clinker and artificial pozzolana (Fly ash) with addition of gypsum or calcium sulphate Fly ash is a very fine material produced as a residue precipitated electrostatically or mechanically from the exhaust gases of coalfired thermal Thermal conductivity is a material property that describes ability to conduct heatThermal conductivity can be defined as "the quantity of heat transmitted through a unit thickness of a material in a direction normal to a surface of unit area due to a unit temperature gradient under steady state conditions"Thermal Conductivity of some selected Materials

used parker jaw crusher sale supplier

Pyrophyllite Processing Plant For Sale

cement grinder in malaysia

Impact Crusher With Durable Impact Crusher Spare Parts

Equipment Big Beneficiation

rock crushing machines for sale in sri lanka

st of solar power plant 1 mw ajmer

Hot High Quality Xjk Flotation Machine With Ce Iso Approved

crusher emas buatan bandung

st of 50 ton jaw crusher

gold stamp mill for sale in zimbabwe

clay crusher gold mining machine

Primary High Efficient Vsi Ore Stone Impact Crusher For Mining

Mining Suppliers In Welkom

stone crusher rates india

crushing screening factories

Good Quality Grinding Mill Manufacturer For Sale

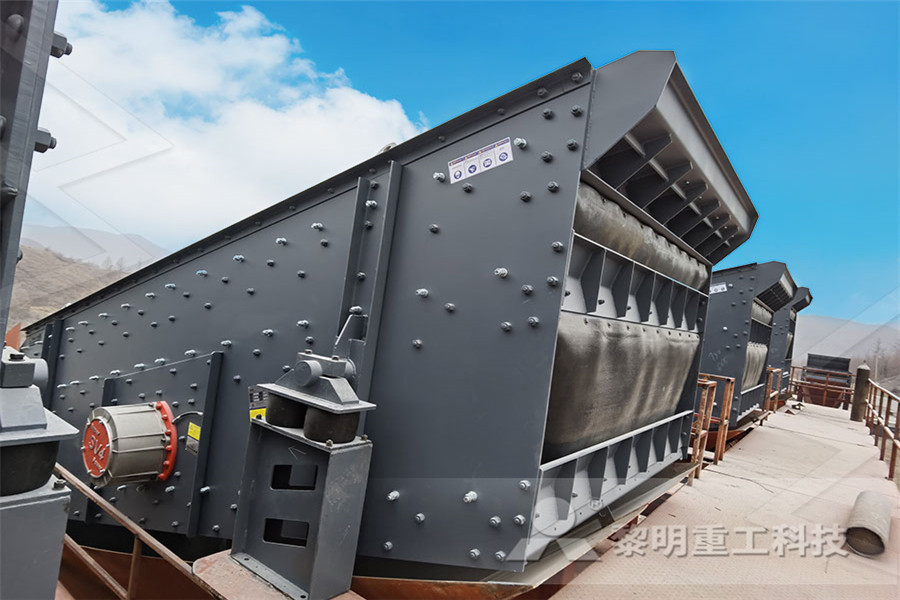

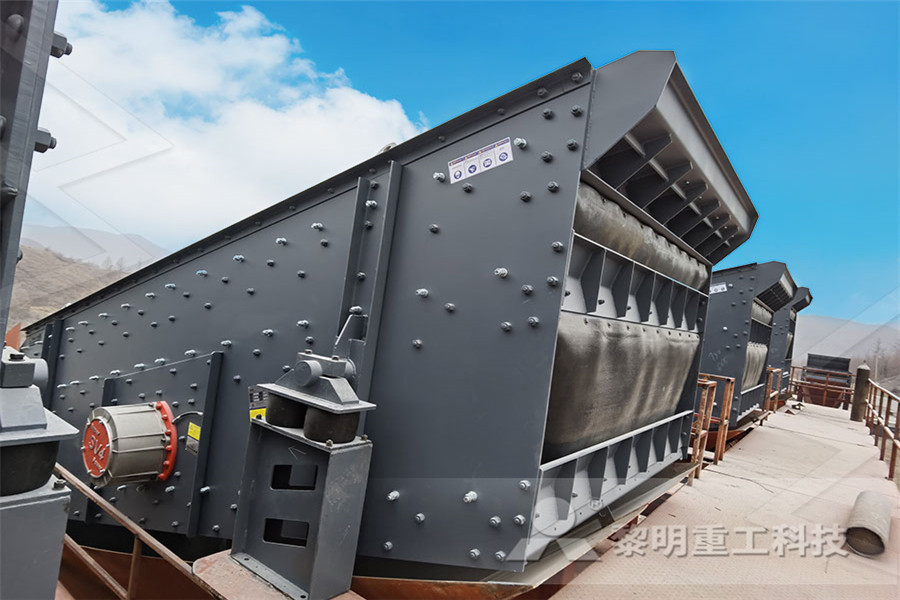

vibrating screen for quarry

rotary vibrating screen malaysia

Evaluation Of Use Of Protective Devices For Quarry Workers In Nigeria

mobile mobile stone crushing plant in france

pe870 1060 jaw crusher

crusher job interview questions

Marble Quarrying Process

iron ore processing line for sale

introducion de canteras de extracion de piedras

limestone crushing designs

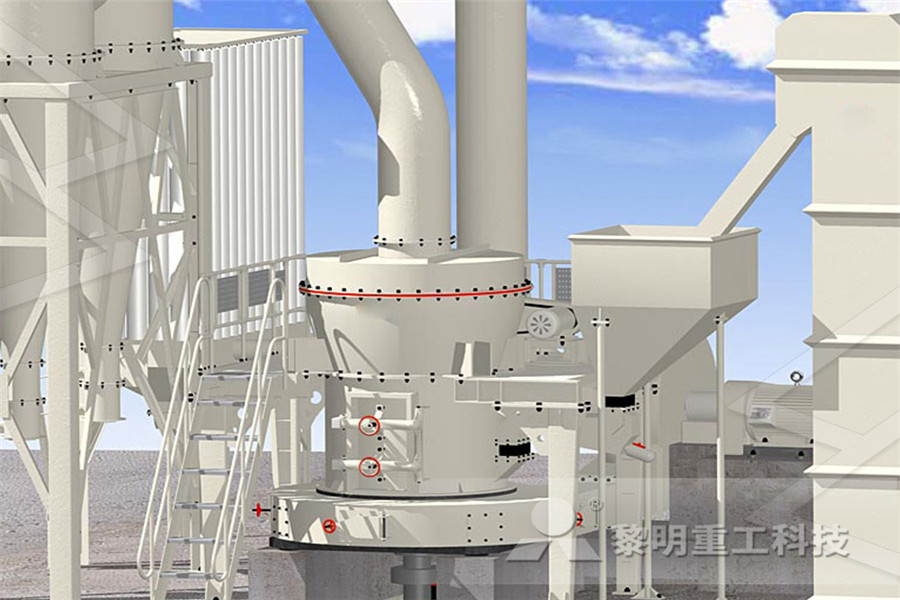

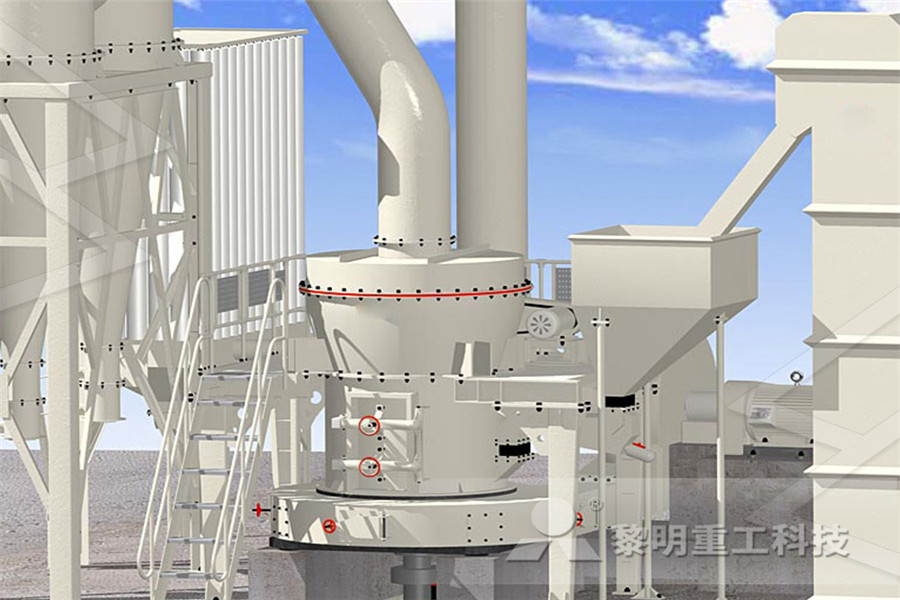

functioning of vertical roller mill

high efficiency jaw crusher for rock

Crushing Value Of Agg Test Video