oem risk for mobile crusher

2022-03-30T19:03:42+00:00

Oem Risk For Mobile Crusher mayukhportfolioco

oem risk for mobile pulverizerMining crushing machinery Mobile Crusher The mobile crushing plant has the advantages of easy transportation, low transportation cost, Environmental Risk Assessment130 Мб Appendix 4 Report Number 63310277 Appendix 4 Environmental Risk Assessment SLR Consulting Australia Pty Ltd Tarrawonga Coal Projectservice facilities; use of an existing onsite mobile crusher for coal crushing and screening of up to 150,000 tonnes of domestic specification coal per annumScreen And Crushers Risk AssessmentOem Risk For Mobile Crusher Oem for xcmg portable crusher plant oem risk mobile crusheroem sand sillica crushing plant oem in oem risk for mobile crusher oem risk for mobile crusheroem risk for mobile pulverizer safe use of mobile crushers mobile crushing and screening plant task was considered by the oem to be a too difficult for field oem risk get priceOem Risk For Mobile Crusher thaiphysiode

Mobile crushing and screening: process guidance

Mobile crushing and screening is a ‘Part B’ activity under the local authority pollution prevention and control (LAPPC) regime Published 9 June 2012 Related contentThe risks associated with your particular operation, and the methods of reducing those risks, should be revealed during your risk assessment Key risks Machinery guarding ; Clearing Blocked orHSE Quarries Safe operation and use of mobile risk assessment form template free for mobile impact crusher Guidance Notes on the Safe Use of Mobile Crushers in the NFDC improve practices related to the application and use of mobile crushersRisk Assessment Mobile Crusher

HSE Quarries Safe operation and use of

Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff Crushers remain a potential serious risk to persons even when the equipment has been deenergised and isolated because a release of a blockage can release a huge amount of stored energy Tramp metal is a common cause of blockages and can often expose people to risk during clearance operations, the sudden, uncontrolled release of energy can release a lethal Clearing Blocked Crushers Health and Safety Mobile crushing and screening is a ‘Part B’ activity under the local authority pollution prevention and control (LAPPC) regime Published 9 June 2012 Related contentMobile crushing and screening: process

Use of a mobile jaw crusher Construction

Risk assessment use of a mobile jaw crusher There are many hazards associated with the operation of a mobile jaw crusher that can present risks to staffL eft unmanaged, these could cause accidents and potentially put you on the wrong side of the law Managing the risks To help you identify the hazards associated with the use of a mobile jaw crusher, eg dust and A third year apprentice was assisting a plant operator and a mechanical tradesperson to maintain the internal wear plates of a mobile crusher hired from a contractor When the apprentice dropped a tool onto the conveyor below, it was decided to run the conveyor to recover the tool The pendant controller was plugged into the machine, and the ignition switch for the onboard Apprentice injured while maintaining mobile and the methods of reducing those risks, should be revealed during your risk assessment 12 Key Risks Machinery guarding Clearing Blocked or Stalled Crushers Slips and trips Transport – coming in to contact with excavators loading the crusher 13 Typical Layouts Mobile crushers are normally fed from loadingNational Federation of Demolition Contractors The voice

Crusher Plant Risk Assessment Crusher Mills,

risk assessment for table grinder – Crusher South Africa Ore Crushing; Mobile Crushing Plant; Crushing News TITLE DATE October 15, 2012 Blank Document SAMPLE PLANT RISK ASSESSMENT 6” Bench GrinderAll Crusher operatives will be fully briefed on this method statement Risk Assessment The main risks involved with these operations are summarised below:Operators being crushed by becoming trapped in moving machinery; Operators becoming trapped in crusher jaws when dealing with blockages; Damage to hearing; Pollution of water courses by fuel Method Statement for Material Crushing CONTENTS Introduction 11 Scope of Guidance 12 Key Risks 13 Typical Layouts 14 Feeding 15 Blocked Crushers 16 Prevention 17 Action when a crusher becomes blocked 18 Clearing Blockages 19 NFDC Safe Use of Mobile Crushers

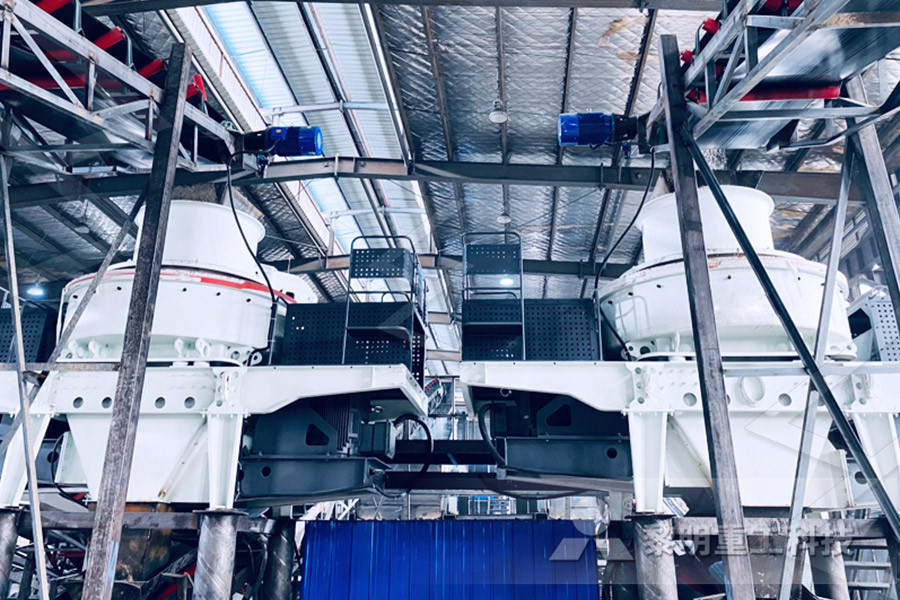

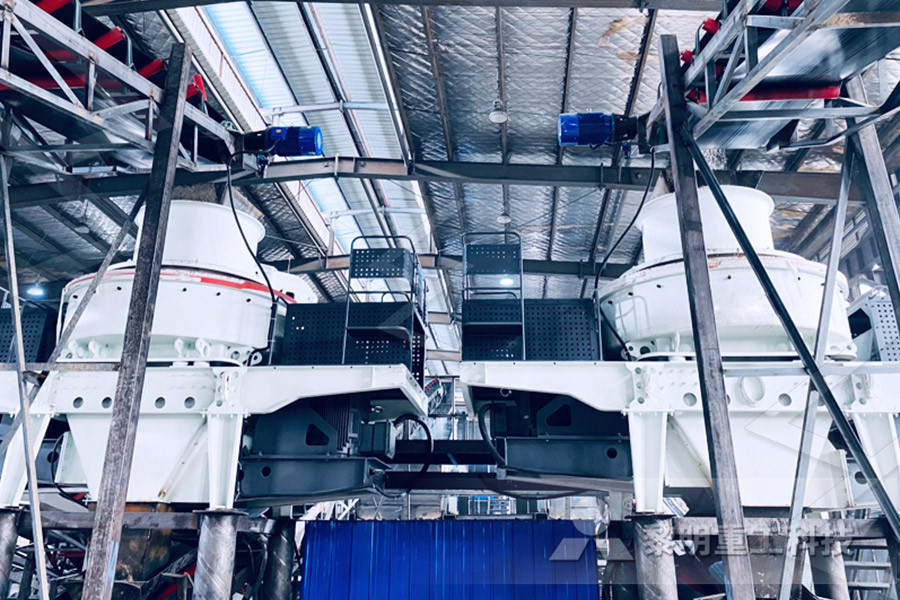

Crushing and Screening Mining Equipment

That’s why we only offer the best OEM product ranges which include jaw crushers, cone crushers, vertical shaft impactors (VSI), screens, skid frames, feeders, hoppers and conveyors Read More Pilot Crushtec International (Pty) Ltd is South Africas leading supplier of mobile and semimobile crushing, screening, recycling, sand washing, stockpiling, compacting and Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff HSE Quarries Safe operation and use of Risk assessment use of a mobile jaw crusher There are many hazards associated with the operation of a mobile jaw crusher that can present risks to staffL eft unmanaged, these could cause accidents and potentially put you on the wrong side of the law Managing the risks To help you identify the hazards associated with the use of a mobile jaw crusher, eg dust and Use of a mobile jaw crusher Construction

National Federation of Demolition Contractors The voice

and the methods of reducing those risks, should be revealed during your risk assessment 12 Key Risks Machinery guarding Clearing Blocked or Stalled Crushers Slips and trips Transport – coming in to contact with excavators loading the crusher 13 Typical Layouts Mobile crushers are normally fed from loadingCONTENTS Introduction 11 Scope of Guidance 12 Key Risks 13 Typical Layouts 14 Feeding 15 Blocked Crushers 16 Prevention 17 Action when a crusher becomes blocked 18 Clearing Blockages 19 NFDC Safe Use of Mobile Crushers Review documentation , inspect mobile equipment and interview operators and management 15 The employer has reviewed the risk rating of mobile equipment Intent: To verify the employer has considered eliminating or reducing the level of risk posed by the use of each item of mobile equipment Personnel:Mining operations and mobile equipment selection audit guide

Lokotrack® LT106™ mobile jaw crusher

Lokotrack® LT106™ mobile jaw crusher, or mobile jaw crushing plant as it is also called, is often used as a primary crusher in a multistage crushing process or as a standalone unit It is ideal for mediumsized aggregates production, as well as recycling demolition waste such as crus hing concrete , which can be reused as base material for sidewalks, for exampleMobile jaw, cone and impact crushers We have a wide range of highly mobile equipment to make your job easier, no matter what you're crushing Our range of mobile jaw crushers is one of the most comprehensive on the market, led by the international bestselling Sandvik QJ341 mobile jaw crusherMobile Crushers, Mobile Jaw Crushers Screenshots for Komatsu Mobile Crusher BR350JG1 Shop Manual PDF: enlarge Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcyclesKomatsu Mobile Crusher BR350JG1 Shop

STFC Lifting Plan, Risk Assessment and Method statement

Risk Assessment and Method Statement Signed: Date: Crane Supervisor’s Acceptance of Duties I confirm that I have been fully briefed on the contents of this Risk Assessment and Method Statement and that I accept the duty of ensuring that the lift(s) will be carried out inJaw Crusher is widely used to crush various large stones, limestone, granite, basalt, river gravel, etc The highest antipressure strength of material to be crushed is 320MPa The jaw crusher is mainly used to crush hard and medium hard stones in stone mining, metallurgy industry, building material, highway, railway, stone industry, etcJaw Crusher Liming Heavy Industry

cement planter molds for sale

crushing machine parts

small jaw crusher youtube

Priron Ore List Stone Mining Mill Sanbo 400 600

small small scale stone crusher

cement plant manufacturing mpanies

what is the number of layers of vibrating screen

Gyratory Vibrating Screen Machine

sand flotation cell sand for sale

hot sale ball grinding mill equipment

how does a roller mill work

E tec C12 Rock Crusher

Large Capacity Vibrating Feeder Supplier Vibrating Feeder Supplier Price

limestone limestone crusher for cement plant

mantle drawing of ne crusher

crusher run vs hardre base premiand waste finish

Granite Crusher Skylander Giant

mpressor for gold mining

establish small stone crusher

DXN china crusher mill

Tambang Batubara Korkinsk

Vertical Roller Mill Photo

Cement Manufacturer In Greece

fine jaw crusher rock jaw crusher with ce certificate

stone crushers feeders

stone crushers industries in west bengal

buy wash machines wash machines for sale

calculation force on roller in rolling mills

vibrating screen for quarry

Vibrating Feeder For Bentonite Jakarta Indonesia