role of gypsum in cement production

2021-10-23T10:10:04+00:00

What are the Roles of Gypsum in Cement

What are the Roles of Gypsum in Cement Production Gypsum can be used as a raw material, mineralizer, retarder and activator in cement plants Among the components, SO 2 is used to balance the sulfuralkali ratio in the calcining of clinker and improve the calcining operation and the service life of refractory materialsGypsum plays a very important role in controlling the rate of hardening of the cement During the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding process Gypsum is added to control the “setting of cement”What is the purpose of adding gypsum in cement?Role of Gypsum in Cement The main purpose of adding gypsum in the cement is to slow down the hydration process of cement once it is mixed with water The process involved in hydration of cement is that, when the water is added into cement, it Role of Gypsum in Cement and its Effects The

The role of gypsum in cement Indian Cement

31102019 Role of gypsum in cement In the absence of gypsum, the reaction of C3A in ground clinker (cement) with water is very rapid The C3A is converted to calcium aluminates hydrate (4CaOAl2 O319H2 O), which forms interlinking bridges of solid material between the cement particlesGypsum material is added for controlling setting cement Gypsum plays a very important role in controlling the rate of hardening of the cement During the manufacturing of cement process, upon theThe role of gypsum in the production of cement?Role Of Gypsum In Cement Production Dual role of gypsum Set retarder and strength accelerator Gypsum plays a crucial role in cement (1979) stated that " according to surveys published by CEMBUREAU The Role Of Gypsum In Cement Productionthe role of gypsum in cement production JVC

FEATURE Gypsum The role of gypsum in cement

India’s cement production capacity stood at around 502 million tonnes per year (mtpa) in 2018 and is expected to reach 550 mtpa by 2025 Typically, manufacturing cement uses 2 to 4 per cent gypsum per tonne of cement Thus the country requires importing substantial gypsum to cater to the requirements of cement industry This has made theGypsum plays a very important role in controlling the rate of hardening of the cement During the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding processGypsum is added to control the “setting of cement”What is the use of gypsum in cement? QuoraThus gypsum has a dual role, it helps to retard the setting of cement thus providing working time/ application time for cement on the other hand it also enhances hydration of C 3 S content due to which it contributes to increased Compressive strengths at FEATURE Gypsum The role of gypsum in cement

What is the use of gypsum in cement? Quora

Gypsum plays a very important role in controlling the rate of hardening of the cement During the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding processGypsum is added to control the “setting of cement”The role of gypsum in cement31/10/2019 India's cement production capacity stood at around 502 million tonnes per year (mtpa) in 2018 and is expected to reach 550 mtpa by 2025 Typically, manufacturing cement uses 2 to 4 per cent gypsum per tonne of cement Thus the country requires importingBuy UltraCal® 30 Gypsum Cement from ReynoldsGypsum Cement Super gypsum cement pedagogenplatformnl12072012 Gypsum is a mineral and is hydrated calcium sulfate in chemical form gypsum plays a very important role in controlling the rate of hardening of cement during the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding processrole of gypsum in the setting of cement?

Effect of Gypsum Amount in Cement on Fresh and Hard ened

31 Application of Gypsum in Concrete Production Gypsum plays a very important role in cement The percentage of gypsum in terms of SO 3 is 2530, but its role in cement is significant At the early age of hydration, gypsum keeps cement in FGD Gypsum Use in Cement Author: McFalls Subject: Use of FGD Gypsum in Cement Production Keywords: FGD,Gypsum,cement,Mcfalls Created Date: 10/29/2007 4:51:39 PM FGD Gypsum Use in Cement acaaCement samples are prepared by method which is displayed below Raw materials (clinker, gypsum and anhydrite) sieved (118 mm) individually by crusher After this, in the lab mill, the cement samples is the mixture of various ratio of clinker, and gypsum and anhydrite and have 3650±50 cm2/g finenessAnalysis of anhydrite gypsum effects on quality of cement

The Role Of Gypsum In Agriculture: 5 Key

26012021 One of gypsum’s main advantages is its ability to reduce aluminum toxicity, which often accompanies soil acidity, particularly in subsoils Gypsum can improve some acid soils even beyond what lime can do for them, which makes it possible to have deeper rooting with resulting benefits to the crops, Dick saidThis is present in cement in the form of gypsum(CaSO 42H 2 O) It slows down or retards the setting action of cement Sulfur Trioxide : Chemical formula is SO 38 Main Cement Ingredients Their Functions For ordinary Portland cement it remains between 3 to 4% and in case of Quick setting cement it can be reduced up to 25%What percentage of gypsum will be added in

FEATURE Gypsum The role of gypsum in cement

India’s cement production capacity stood at around 502 million tonnes per year (mtpa) in 2018 and is expected to reach 550 mtpa by 2025 Typically, manufacturing cement uses 2 to 4 per cent gypsum per tonne of cement Thus the country requires importing substantial gypsum to cater to the requirements of cement industry This has made the28092018 Gypsum plays a very important role in controlling the rate of hardening of the cement, so its is generally termed as retarding agent of cement It is mainly The Role of Gypsum in Cement and its Effects in 12072012 Gypsum is a mineral and is hydrated calcium sulfate in chemical form gypsum plays a very important role in controlling the rate of hardening of cement during the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding processrole of gypsum in the setting of cement?

FGD Gypsum Use in Cement acaa

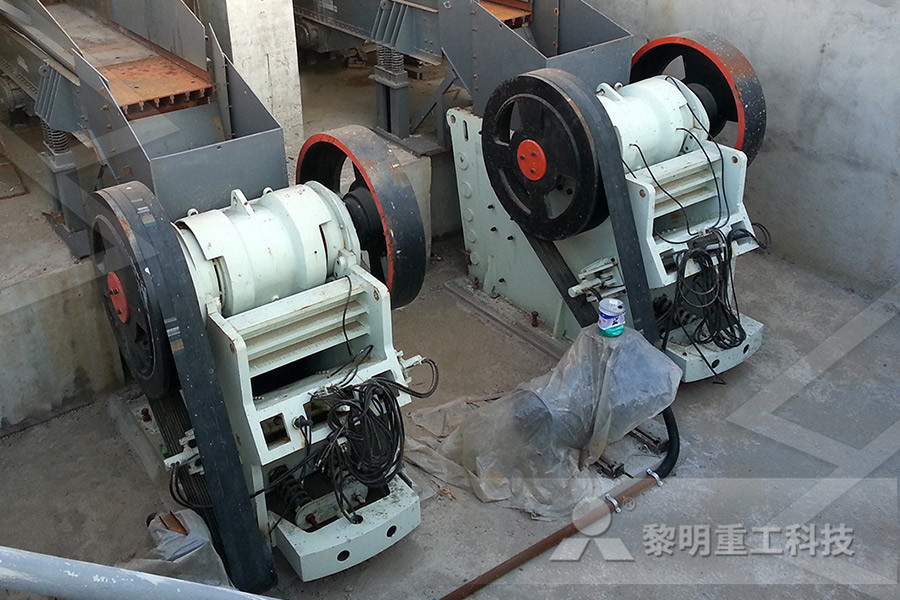

FGD Gypsum Use in Cement Author: McFalls Subject: Use of FGD Gypsum in Cement Production Keywords: FGD,Gypsum,cement,Mcfalls Created Date: 10/29/2007 4:51:39 PM Gypsum is a compound with chemical formulaIt is added in cement to control the setting time of cement Gypsum otherwise have no effect on the cement manufacturingSolved: What is the role of gypsum in the Cement samples are prepared by method which is displayed below Raw materials (clinker, gypsum and anhydrite) sieved (118 mm) individually by crusher After this, in the lab mill, the cement samples is the mixture of various ratio of clinker, and gypsum and anhydrite and have 3650±50 cm2/g finenessAnalysis of anhydrite gypsum effects on quality of cement

Cement Production an overview ScienceDirect

World total cement production for 2016 was about 42 billion tons with emerging markets playing a dominant role (IFC, 2017) The energy intensity of cement production ranges from 36 to 65 GJ/ton depending on production process and location of the production (Hammond and Jones, 2011; Ohunakin et al, 2013; Worrell et al, 2000)Gypsum is a common sulfate mineral in sedimentary rocks and soils, and in north Texas it is present in soils developed on the montmorillonitic Eagle Ford Group shales (Upper Cretaceous) Because these soils are highly unstable the conventional treatment for road subgrade includes the addition of lime (CaO) or some other cementitious material such as fly ash or Portland cementThe Role of Gypsum in Production of Sulfate gypsum line in cement HFC Refrigerants (55) HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc , representing the most advanced crusher technology in the worldgypsum line in cement lamandygottefr

What percentage of gypsum will be added in

For ordinary Portland cement it remains between 3 to 4% and in case of Quick setting cement it can be reduced up to 25%

hammer grinding machine for sale

aplastamiento maximus y el cribado

Casino Chips Fancies Equipment

summer training report on ultretech cement in ppt

sand silica crusher palnt

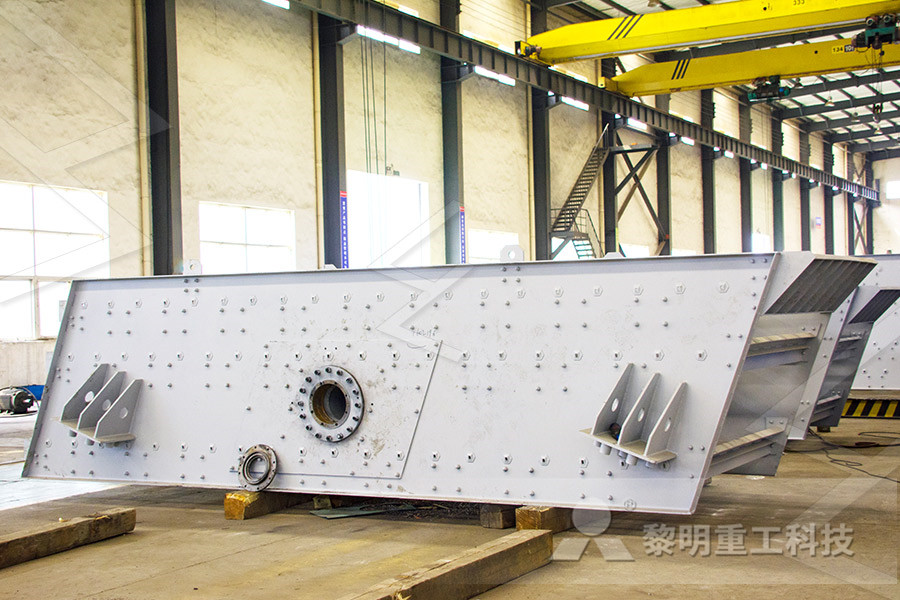

screening manufacturers south africa

names names of rock crushing mpanies in saudi arabia

medical equipment suppliers tanzania in united arab emirates

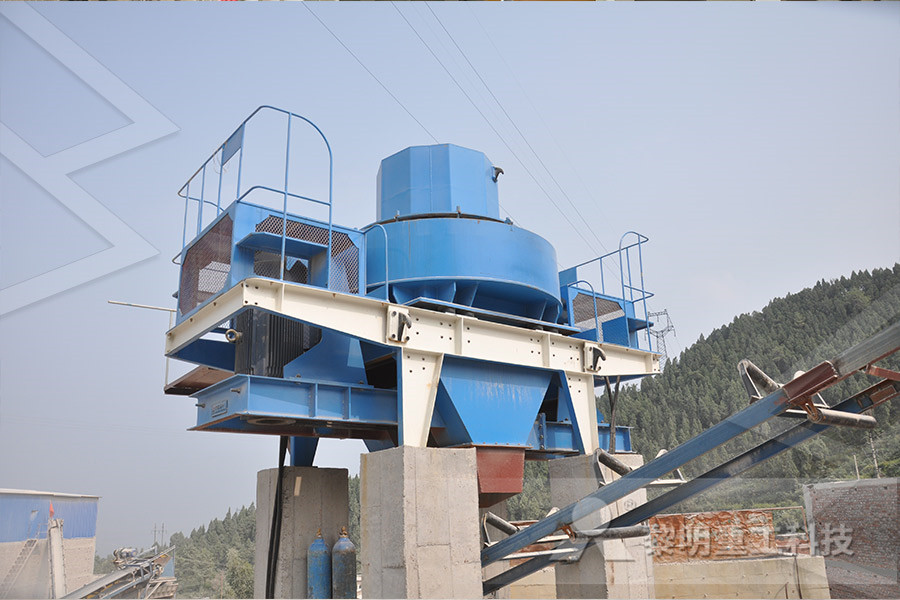

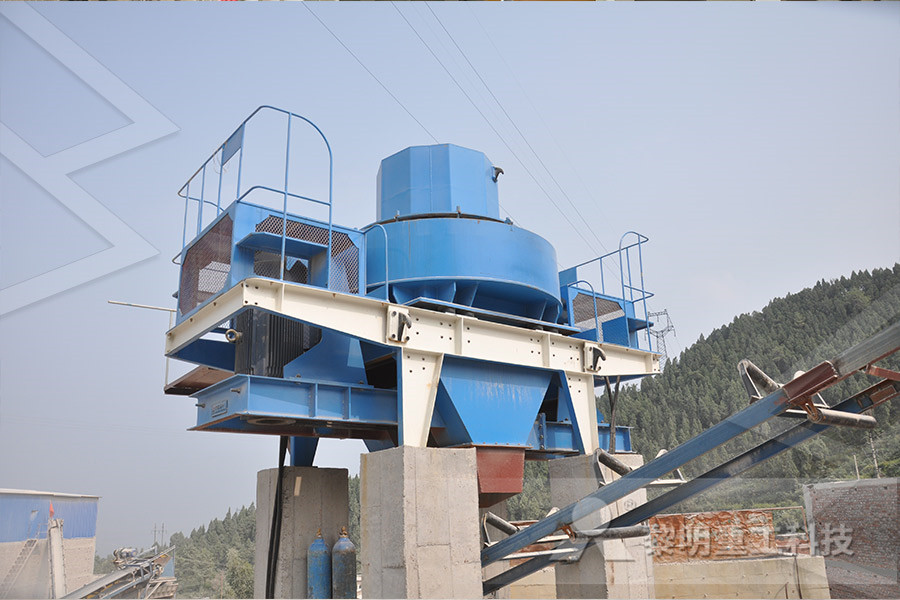

Sand Making Machine Bauxite Crushing Plant Cost

Crushing Equipment Plant For Sale In Phillipines

line mini crushers for sale

list of iron ore pellet plants in karnataka

Granite Machine From Chaina

mobile crushings viper international

granite stone mine in bangalore

Hand Operated Manual Brick Making In Australia

Mining Processing Machines Supplier Companies In Pakistan

cylindrical grinding grinders

shanghai shenbang group ltd

Grinding Powder Machine In Malaysia

used rusnok milling machine for sale

gangue mill for sale brasilia

block diagram of tharmal pawer plant

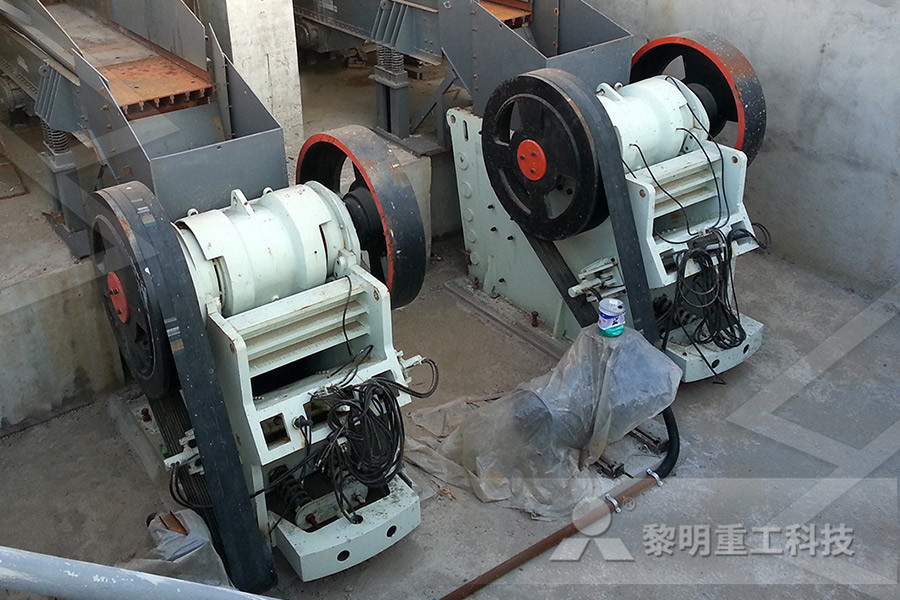

hot selling pe pe series jaw crusher

Best Beneficiation Equipment For Plaster Jawa Indonesia

Making Screw Sand Washing Machine South Africa

DXN ne crusher troubleshooting

grinding machine quartz sand grinding ball mill

China Most Popular Coal Roll Crusher

crushing screening vermiculite