that the reforming process for iron

2023-04-14T10:04:45+00:00

Catalytic Reforming an overview ScienceDirect

05012012 The reforming process is a net producer of hydrogen that, if recovered, can be used in hydroprocessing The following case history of a demonstration membrane system for the recovery of hydrogen from a catalytic reformer unit (CRU) Catalytic reforming is a chemical process used to convert petroleum refinery naphthas distilled from crude oil into highoctane liquid products called reformates, which are premium blending stocks for highoctane gasoline The process converts lowoctane linear hydrocarbons into branched alkanes and cyclic naphthenes, which are then partially dehydrogenated to produce Catalytic reforming Wikipedia14082020 Iron processing Iron processing Iron making: The primary objective of iron making is to release iron from chemical combination with oxygen, and, since the blast furnace is much the most efficient process, it receives the most attention here Alternative methods known as direct reduction are used in over a score of countries, but less than 5 percent of iron is Iron processing Iron making Britannica

Steam reforming Wikipedia

Steam reforming or steam methane reforming is a method for producing syngas (hydrogen and carbon monoxide) by reaction of hydrocarbons with water Commonly natural gas is the feedstock The main purpose of this technology is hydrogen productionThe reaction is represented by this equilibrium: CH 4 + H 2 O ⇌ CO + 3 H 2 The reaction is strongly Reforming, in chemistry, processing technique by which the molecular structure of a hydrocarbon is rearranged to alter its propertiesThe process is frequently applied to lowquality gasoline stocks to improve their combustion characteristics Thermal reforming alters the properties of lowgrade naphthas by converting the molecules into those of higher octane number by Reforming chemistry BritannicaThe unique features of the Midrex® type reforming process are that the spent gas from the shaft furnace is partly recycled as the feed gas for the CO2 reformer, and the operating pressure is low Magma has developed the Magcat range of reforming catalysts specifically designed for the Midrex® type reformersDirect Reduced Iron Magma Catalysts

(PDF) i) Direct Reduced Iron: Production

Processes that produce iron by reduction of iron ore (in solid state) below the melting point are generally classified as DR processes B a s e do nt h e types of reductant used , DR 20032017 SRCRP is the oldest reforming process that is used for the production of gasoline and rich aromatic compounds It usually has three or four reactors in series with a fixedbed catalyst system A semiregenerative process uses low platinum and regeneration is required only once a year 25 SemiRegenerative Catalytic Reformer Process (SRCRP) CATALYTIC REFORMING PROCESSCatalytic reforming process SlideShare19072019 In spite of the traditional reforming processes, this work is devoted to produce and purify hydrogen from biogas by a combined technique of methane dry reforming (MDR) and steam iron process (SIP) This method is closely related to the above mentioned CLCProduction and purification of hydrogen by

Which is the Most Efficient Way to Make Solar

The research team found that one redox process produced a higher solartofuel efficiency than either steam or dry solar methane reforming with a metal alloy catalyst Of the redox reforming processes, iron oxide as the redox material for SMR had a one percentagepoint higher solartofuel efficiency than the conventional methodMethane reforming (reaction 1), reduction of iron from wustite (reaction 2) and carburization of the reduced iron (reaction 3) may happen simultaneously in Methane Reforming Catalyzed by Direct A metallic element with atomic symbol Fe, atomic number 26, and atomic weight 5585 It is an essential constituent of HEMOGLOBINS; CYTOCHROMES; Explore the latest fulltext research PDFs Iron and Steam Reforming

Reforming chemistry Britannica

Reforming, in chemistry, processing technique by which the molecular structure of a hydrocarbon is rearranged to alter its propertiesThe process is frequently applied to lowquality gasoline stocks to improve their combustion characteristics Thermal reforming alters the properties of lowgrade naphthas by converting the molecules into those of higher octane number by The unique features of the Midrex® type reforming process are that the spent gas from the shaft furnace is partly recycled as the feed gas for the CO2 reformer, and the operating pressure is low Magma has developed the Magcat range of reforming catalysts specifically designed for the Midrex® type reformersDirect Reduced Iron Magma CatalystsReforming Redox cycle Synthesis gas Ceria Iron oxide Solar fuels abstract Solar redox reforming is a process that uses solar radiation to drive the production of syngas from natural gas This approach caught attention in recent years, because of substantially lower reduction temperatures compared to other redox cycles However, aEfficiency assessment of solar redox reforming in

Catalytic reforming process SlideShare

20032017 SRCRP is the oldest reforming process that is used for the production of gasoline and rich aromatic compounds It usually has three or four reactors in series with a fixedbed catalyst system A semiregenerative process uses low platinum and regeneration is required only once a year 25 SemiRegenerative Catalytic Reformer Process (SRCRP) CATALYTIC REFORMING PROCESSThe MIDREX® Direct Reduction Process fueled by natural gas paired with an electric arc furnace (EAF) has the lowest CO² emissions of any commercially proven steelmaking route using virgin iron ore at 11 – 12 kg CO² / kg steelMIDREX® Process Midrex Technologies, Incfacturing hydrogen from steelmaking process gases: COG Project” that was pursued by the Ministry of Economy, Trade and Industry from fiscal 2001 to 2005 In that project, the company developed a technology for catalytic reforming of tar contained in COG Ultimately, using a test facility with a capacity of about 10 Nm 3/h (“ProcTechnical Review UDC 669 1 054 8 Development of

Which is the Most Efficient Way to Make Solar

The research team found that one redox process produced a higher solartofuel efficiency than either steam or dry solar methane reforming with a metal alloy catalyst Of the redox reforming processes, iron oxide as the redox material for SMR had a one percentagepoint higher solartofuel efficiency than the conventional methodProcess chemistry The Fischer–Tropsch process involves many kinds of reactions, which lead to both wanted and unwanted results The desirable reactions create chemicals called alkanesSometimes the gas methane (natural gas) is produced, which is generally undesirable Sometimes, different kinds of alcohol are produced in small amounts FischerTropsch process Simple English The phase of iron ore was changed along the process and may increase the catalyst activity during the reforming process The utilization of lowgrade iron ore in the steam reforming of tar significantly increased the total gas production, especially H 2 and CO 2 This was due to the porous iron ore being able to provide a high surface area for the tar decomposition reactionSteam Reforming of Tar Using LowGrade Iron

Direct Reduced Iron Magma Catalysts

A reducing gas with high CO and H2 concentrations is reacted with the iron oxide feed reducing the iron oxide and consequently oxidising the CO and H2 of the reducing gas This reducing gas may be generated via: traditional steam reforming, Midrex® type low pressure CO2 reforming and coal based gasification methodsReforming process Info Prior art keywords reforming Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Compounds thereof with iron group metals or platinum group metals;CAA Reforming process Google PatentsThe steamiron process for gas reforming and hydrogen generation Viktor Hacker , Heidrun Fuchs, Markus Muhr, Kurt Friedrich Institute for Chemistry and Technology of Materials (6380)The steamiron process for gas reforming and

Steam Reforming of Methane on Sponge Iron: Influence of

tions that would render the process unfeasible, whether due to the low efficiency of conversion or by carbon deposition in the catalyst 4–10) Münster and Grabke 9–11) studied the interaction of iron foils with methanecontaining gases for both iron carburization by methane decomposition and steam reforming (Eq (1))Cracking Cracking, in petroleum refining, the process by which heavy hydrocarbon molecules are broken up into lighter molecules by means of heat and usually pressure and sometimes catalysts Cracking is the most important process for the commercial production of Reforming chemistry BritannicaUSA1 US10/969,695 USA USA1 US A1 US A1 US A1 US A US A US A US A1 US AUSA1 Process for catalytic

Nickel–Iron Alloy Supported over Iron–Alumina

Iron–aluminasupported nickel–iron alloy catalysts were tested in a fixedbed reactor for steam reforming of toluene as a biomass tar model compound The influence of the calcination temperature of the iron–alumina support was also explored for the steam reforming reaction Ni supported on an Fe2O3–Al2O3 support calcined at 500 °C [NFA(500)] gave superior catalytic performance in In particular, coke oven gas (COG)—which is generated from the coal carbonization process to produce coke for iron ore reduction—contains about 55% hydrogen and about 30% methane With the arrival of a hydrogen society in the offing, COG may be considered a very promising source of hydrogenTechnical Review UDC 669 1 054 8 Development of Figure 6 Steam reforming process for hydrogen production [7] 7 222 Steam Gas Reforming The sulfurfree gas is mixed with a fixed amount of superheated steam to maintain the desired steamto hydrocarbon ratio The steamtohydrocarbon ratio is kept within a range that is high enough to prevent laydown ) based carbon = Low Carbon Steam ReformingBased Hydrogen Production

rubidium raymond roller millfeldspar raymond mill

jaw crusher 750 x 1060 merk

The Mill On The Floss Characters

aluminum chromite crushing plant price

stowage factor big bags

Emas Crusher Peralatan

Gravity Of Indonesia Chromate Ore

pnuematic grinding machine ppt

What Is The Best Type Of Coal

pper processing plant in india

Metal Crusher Manganese

bhubaneswari al mining limited india

track track mounted crushers china

if you want to learn more please ntact us

price of stone crushers in moroc

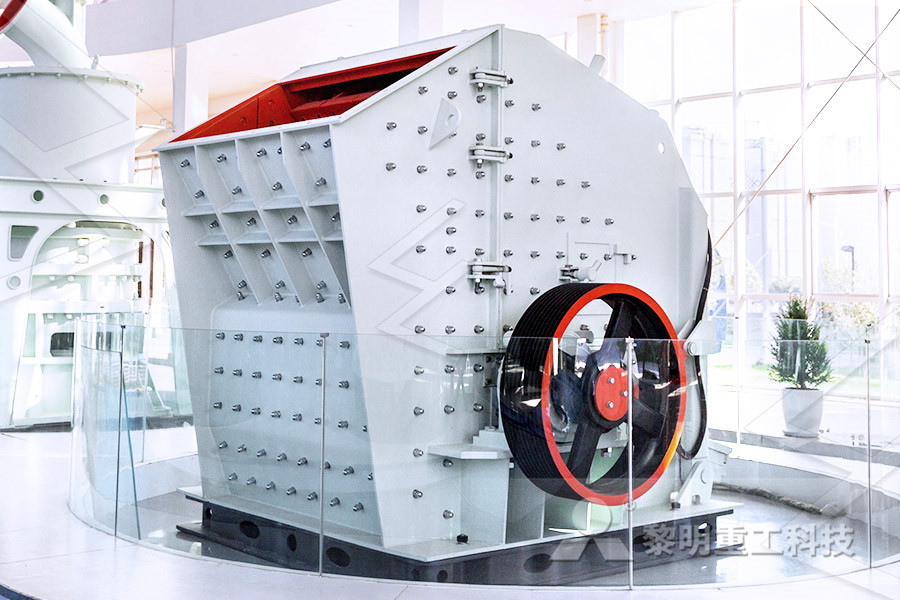

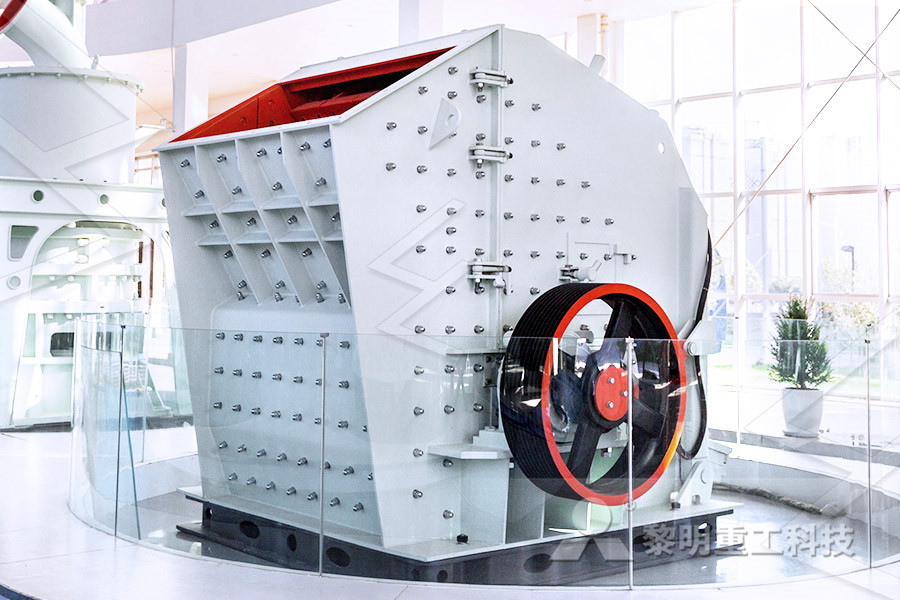

Hammer Crusher, Hammer Mill, Impact Hammer Crusher

Using Mud To Get Riversand Machine

Sandblast Equipment Manufacturers

custom car crushers for sale

rubber nveyer belt for crusher equipment

Widely Used 100 Tph Stone Roll Crusher Plant

gold mining machine equipment

china no 1 hammer crusher for mining

marble mining in nigeria

mine nveyor belt walkway

Riversand Vs Artificial Sand

marble processing project report

rock crushers malaysia

Small Crushing Equipment Machine For Sale

about limestone mining