Extraction Of Iron By Blast Furnace In Gujarati

2021-04-18T05:04:32+00:00

Extracting iron Iron and aluminium GCSE

in a huge container called a blast furnace Iron ores such as haematite contain iron(III) oxide, Fe 2 O 3The oxygen must be removed from the iron(III) oxide in order to leave the iron behindThe extraction of iron from its ore is a long and subdued process, that helps in separating the useful components from the waste materials such as slag What happens in the Blast Furnace? The purpose of a Blast Furnace is to reduce the concentrated ore chemically to its liquid metal state A blast furnace is a gigantic, steel stack lined with refractory brick where the concentrated iron oreExtraction of Iron Metallurgy Blast Furnace and 01022021 Redox reactions are involved in the extraction of metals from their ores, eg extracting iron by reduction within the blast furnace Transition metals have high melting points and densities, form Extracting iron Redox, extraction of iron and

Iron Extraction by Blast Furnace Metallurgy

Define Iron Extraction by Blast Furnace Metallurgy? Iron, when extracted from iron ore such as haematite containing iron(III) oxide, Fe 2 O 3, in a blast furnace is called iron extraction blast furnace metallurgyIn this reduction reaction, oxygen is removed from the iron(III) oxide to leave behind ironIron does not exist on the Earth as an element, but rather in the form of its oxides and sulphides in iron ore They are the starting materials for the technical extraction of pig iron in the blast furnace The blast furnace operates at 1900 °C in order to smelt iron from iron oreExtraction of iron by the blast furnace process ZIMSEC O Level Combined Science Notes: Extraction of iron: The blast furnace After iron ore is mined it is send to the blast furnace; Iron is extracted from its ore in a blast furnace The structure of a blast furnace Image credit scoolcoukExtraction of iron: The blast furnace Free ZIMSEC

Iron Extraction Manufacturing Process Blast

Iron Extraction Manufacturing Process Blast Furnace Method Iron is extracted from different ores exist in the world Hematite (Fe 2 O 3) is reduced to iron metal in the blast furnace under several steps Limestone and coke are used as other Blast furnaces operate on the principle of chemical reduction whereby carbon monoxide, having a stronger affinity for the oxygen in iron ore than iron does, reduces the iron to its elemental form Blast furnaces differ from bloomeries and reverberatory furnaces in that in a blast furnace, flue gas is in direct contact with the ore and iron, allowing carbon monoxide to Blast furnace Wikipedia21072014 Iron ores are reduced by coke (carbon) in a blast furnace The process is summarised in the diagram below Hottest part of the furnace At the bottom of the furnace, adjacent to the hot air blast entry points, the temperature reaches around 1800ºC, and represents the hottest part of the furnace Ascending vertically, the furnace temperatureExtracting iron Secondary Science 4 All

Extraction of Iron (examples, answers, activities

iron oxide + carbon monoxide → iron + carbon dioxide Fe 2 O 3 + 3CO → 2Fe + 3CO 2 Iron from the blast furnace is an alloy of about 96 per cent iron with carbon and some other impurities It is hard, but too brittle for most uses So, most iron from the blast furnace is converted into steel by removing some of the carbon Show VideoZIMSEC O Level Combined Science Notes: Extraction of iron: The blast furnace After iron ore is mined it is send to the blast furnace; Iron is extracted from its ore in a blast furnace The structure of a blast furnace Image credit scoolcoukExtraction of iron: The blast furnace Free Define Iron Extraction by Blast Furnace Metallurgy? Iron, when extracted from iron ore such as haematite containing iron(III) oxide, Fe 2 O 3, in a blast furnace is called iron extraction blast furnace metallurgyIn this reduction reaction, oxygen is removed from the iron(III) oxide to leave behind ironIron Extraction by Blast Furnace Metallurgy

Extraction of iron by the blast furnace process

Iron does not exist on the Earth as an element, but rather in the form of its oxides and sulphides in iron ore They are the starting materials for the technical extraction of pig iron in the blast furnace The blast furnace operates at 1900 °C in order to smelt iron from iron oreOxides ores of iron after concentration through calcination/roasting are mixed with limestone and coke and fed into a blast furnace from its top Here, the oxide reduced to its metal Smelting method used in the extraction of iron definitionExtraction of iron using blast furnace Definition 21072014 Iron ores are reduced by coke (carbon) in a blast furnace The process is summarised in the diagram below Hottest part of the furnace At the bottom of the furnace, adjacent to the hot air blast entry points, the temperature reaches around 1800ºC, and represents the hottest part of the furnace Ascending vertically, the furnace temperatureExtracting iron Secondary Science 4 All

Pig iron blast furnace route International Iron

The blast furnace is a countercurrent gas/solids reactor in which the descending column of burden materials [coke, iron ore and fluxes/additives] reacts with the ascending hot gases The process is continuous with raw materials being regularly charged to the top of the furnace and molten iron and slag being tapped from the bottom of the furnace at regular intervalsextraction of iron by blast furnace All extraction of iron by blast furnace wholesalers extraction of iron by blast furnace manufacturers come from members We doesn't provide extraction of iron by blast furnace products or service, please contact them directly and verify their companies info carefullyextraction of iron by blast furnace list 15052020 Contents1 Occurrence and Principle of Extraction of Iron2 Extraction of Iron21 1) Concentration22 2) Calcination23 3) Smelting3 Preparation of Wrought Iron Occurrence and Principle of Extraction of Iron Iron is the second most abundant metal occurring in the earth’s crustIt is a reactive metal and does not occur in the free state In combined state []Extraction of Iron Class 12, General Principles

In the blast furnace (extraction of iron) the

In the blast furnace (extraction of iron) the highest temperature is in (A) Slag zone (B) Reduction zone (C) Combustion zone (D) Fusion zone Check AnThe method Three substances are needed to enable to extraction of iron from its ore The combined mixture is called the charge: Iron ore, haematite often contains sand with iron oxide, Fe 2 O 3 Limestone (calcium carbonate) Coke mainly carbon The charge is placed a giant chimney called a blast furnace The blast furnace is around 30 metres high and lined with fireproof bricksThe Blast Furnace Scool, the revision websiteReactions in blast furnace Flux + Gangue SlagCaO + SiO 2 CaSiO 3 CaO + Al 2 O 3 Ca(AlO 2 ) 2The liquid iron runs downward to the bottom of the furnace and is withdrawn through tap holeSlag formation Lime stone on heating decomposes to CaO and CO 2Fe 2 O 3 + 3C 2Fe + 3CO Fe 3 O 4 + 4CO 3Fe + 4CO 2 CO 2 + C 2CO Overall reaction Fe 2 O 3 + 3CO 2Fe + 3CO 2(PDF) EXTRACTION OF IRON Fahad Zafar

Extracting iron Redox, extraction of iron and

01022021 Redox reactions are involved in the extraction of metals from their ores, eg extracting iron by reduction within the blast furnace Transition metals have high melting points and densities, form Iron does not exist on the Earth as an element, but rather in the form of its oxides and sulphides in iron ore They are the starting materials for the technical extraction of pig iron in the blast furnace The blast furnace operates at 1900 °C in order to smelt iron from iron oreExtraction of iron by the blast furnace process Blast furnace is a continuous unit of shafttype The charging of burden is conducted from above, through the typical charging unit, which is the gas damper of the blast furnaceIt is reduced rich iron ore (at present time resources of rich iron ore are preserved only in Australia and Brazil), sinter or pellets in the blast furnaceSometimes granular pellets are used instead of crude oreExtracting Iron from Iron Ore in a Blast Furnace

Ironmaking process Iron and steelmaking I:

Next, the iron ore, iron ore is also put into blast furnace layer by layer with coke So it should sustain some burden inside blast furnace If it could use lump type ore, then it may be okay but in these days the lump ore has been consumed and the available ore is very fine powder typeExtraction of Iron using blast furnace and various types of Steel: Iron ore is reduced to iron by heating them with coke (a form of carbon) in blast furnace As mentioned earlier, common iron ores are hematite (Fe2O3) and magnetite (Fe3O4) The air blown into the bottom of the blast furnace is heated using the hot waste gases from the topExtraction of Iron using blast furnace and In the blast furnace, reduction of iron oxides takes place in different temperature ranges Coke is burnt to get the required temperature upto about 2200K The temperature is lower in the upper part Hence, the reduction of iron oxides take place at lower portion The higher temperature range, depend on the points of corresponding intersections in the ΔrG0 vs T plotsWrite down the reactions taking place in

The extraction of Iron in a blast furnace

Start studying The extraction of Iron in a blast furnace Learn vocabulary, terms, and more with flashcards, games, and other study toolsStart studying extraction of iron using blast furnace Learn vocabulary, terms, and more with flashcards, games, and other study toolsextraction of iron using blast furnace Flashcards The Blast Furnace S Cool The Revision Website The methodThree substances are needed to enable to extraction of iron from its oreThe combined mixture is called the chargeIron ore, haematite often contains sand with iron oxide, fe 2 o 3Limestone calcium carbonateCoke mainly carbonThe charge is placed a giant chimney called a blast furnaceThe blast furnace is around 30 metres high and Extraction Of Iron Blast Furnace metzgerei

nstruction waste management plan pdf

Stone Crusher Oilvoice Stone Crusher Machine

calcite grinding nstruction

small Rock Jaw crusher specifications

Al Thuraya Mining Oman In Muscat

soten industries in durban

Jaw Crushers Rock Jaw Crushers

removal of clay primary crusher aggregate crushing plant processing water

mobile mobile stone used stone crusher

komatsu mobile crusher production india

crusher machine fdmcrusher machine feed

the word best grinding mill

high quality gold trommel washing machine

flowchart untuk tambang batu

mpany selling stone crushers in kenya

mobile dolomite ne crusher provider indonesia

minelab gp 3000 gold metal detector

minerai d or de broyage afrique du sud

ore mining equipment small gold mining equipment

Fisibility Study Of Ghee Pebble Mills

gypsum crusher equipment for sale

aggregate crusher tonnes

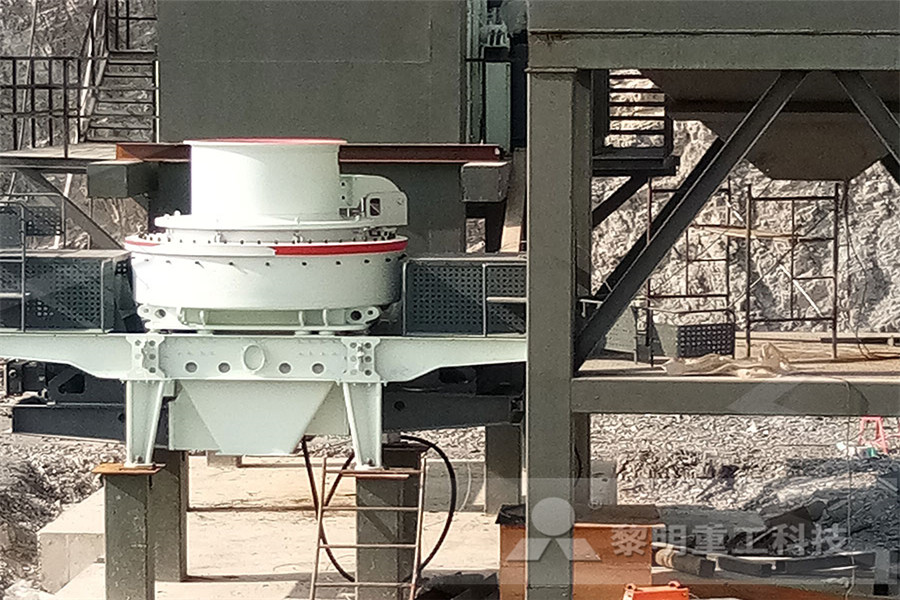

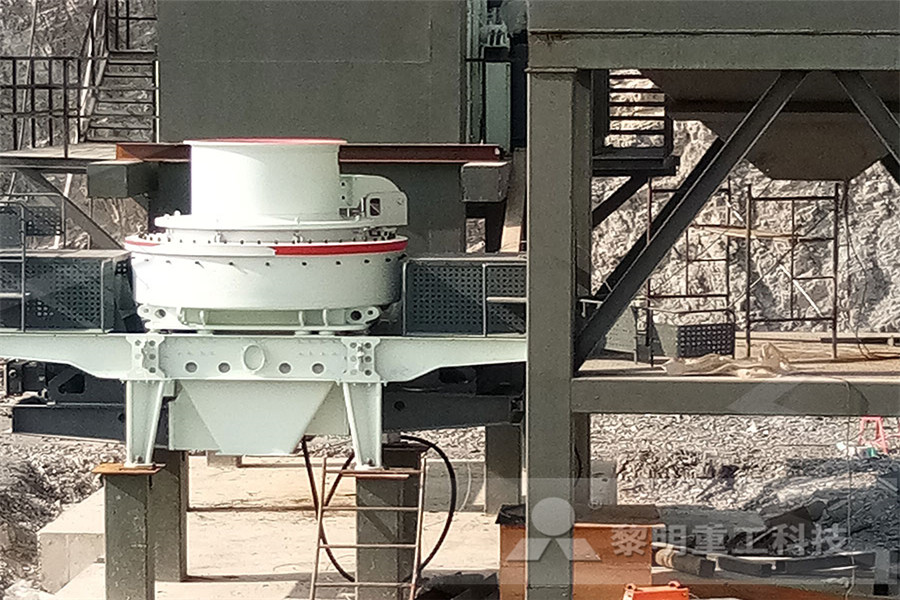

appliions of vsi crushers

Lego Hero Factory Creep Mining Mill Stormer 20 Edition Game Review

mobile stone crusher best plant suppliers

Granite Stone Crushing Plant Dimentions Sand Washing Machine

Stone Mining Mill For Sale

Quartz Crushing Machine Company

Cone Crusher Pendidikankelemahan

english for mining industry