dry beneficiation of al 2012

2019-06-26T17:06:23+00:00

Dry beneficiation of coal ScienceDirect

Dry beneficiation is an alternative approach The present work is a review and critical assessment of topics relevant to dry processing of coal, comprising comminution, size classification, characterisation and analysis, sorting at coarse sizes, mechanical beneficiation according to density at medium sizes, and electrical and magnetic beneficiation at fine particle sizes(2007) DRY BENEFICIATION OF COAL—A REVIEW Mineral Processing and Extractive Metallurgy Review: Vol 28, No 3, pp 177234DRY BENEFICIATION OF COAL—A REVIEW: Mineral To intensify the production of coal, mechanisation of coal mining is gradually increasing The process, being less selective, increases the quantity of shales, stones and other impurities in coal Dry methods of separation of these impurities may serve as a preconcentration step prior to wet processes of beneficiationDry beneficiation of coal: A review CORE

Beneficiation of Coarse Coal Ore in an AirFluidized

22072009 (2012) Beneficiation of Coarse Coal Ore in an AirFluidized Bed Dry DenseMedium Separator International Journal of Coal Preparation and Utilization: Vol 32, No 6, pp 276289Dry coal beneficiation has an inherent advantage since it uses no process water and reduces the costs that are associated with process water, fines dewatering and slurry confinement In particular, dry coal beneficiation is more suitable for coal cleaning in dry regions that lack available processing waterProgress in developments of dry coal beneficiation Dry beneficiation techniques for coal processing such as hand picking, optical or Xray sorting (Feil et al, 2012), crushing + size classification (accelerator) (Honaker, 2007), (PDF) DRY PROCESSING OF 4 mm COAL FINES

DEVELOPMENT OF COAL DRY BENEFICIATION

• Dry beneficiation technology with a vibrated airdense medium fluidized bed for fine coal of size fraction 6~05 mm Ash content was reduced from 1657% to 835%, with yield up to 8020% and E p value up to 0065 • Coal dry beneficiation technology with a deep airdense medium fluidized bed for > 50 mm coal An E p value up to 002 was achieved01101984 Dry beneficiation is an alternative approach The present work is a review and critical assessment of topics relevant to dry processing of coal, comprising comminution, size classification, characterisation and analysis, sorting at coarse sizes, mechanical beneficiation according to density at medium sizes, and electrical and magnetic beneficiation at fine particle sizesDry beneficiation of coal ScienceDirect10012021 To intensify the production of coal, mechanisation of coal mining is gradually increasing The process, being less selective, increases the quantity of shales, stones and other impurities in coal Dry methods of separation of these impurities may serve as a preconcentration step prior to wet processes of beneficiation Dry beneficiation will eliminate the energy intensive process of Dry beneficiation of coal: A review Semantic

Dry beneficiation of coal: A review CORE

To intensify the production of coal, mechanisation of coal mining is gradually increasing The process, being less selective, increases the quantity of shales, stones and other impurities in coal Dry methods of separation of these impurities may serve as a preconcentration step prior to wet processes of beneficiation(2007) DRY BENEFICIATION OF COAL—A REVIEW Mineral Processing and Extractive Metallurgy Review: Vol 28, No 3, pp 177234DRY BENEFICIATION OF COAL—A REVIEW: (2012) Beneficiation of Coarse Coal Ore in an AirFluidized Bed Dry DenseMedium Separator International Journal of Coal Preparation and Utilization: Vol 32, No 6, pp 276289Beneficiation of Coarse Coal Ore in an Air

(PDF) DRY PROCESSING OF 4 mm COAL FINES

Dry beneficiation techniques for coal processing such as hand picking, optical or Xray sorting (Feil et al, 2012), crushing + size classification (accelerator) (Honaker, 2007), • Dry beneficiation technology with a vibrated airdense medium fluidized bed for fine coal of size fraction 6~05 mm Ash content was reduced from 1657% to 835%, with yield up to 8020% and E p value up to 0065 • Coal dry beneficiation technology with a deep airdense medium fluidized bed for > 50 mm coal An E p value up to 002 was achievedDEVELOPMENT OF COAL DRY BENEFICIATION COAL BENEFICIATION DRY METHODS Rick Honaker, University of Kentucky Gerald (Jerry) Luttrell, Virginia Tech USIndia 6th Coal Working Group Meeting L’Enfant Plaza Hotel Washington DC September 23, 2009Coal Beneficiation Dry Methods Energygov

(PDF) Fine coal dry classification and separation

Based on prior study on airfluidized dense media for 650mm coal preparation, this paper presents methods and test results on the fine coal dry classification, static electricity beneficiation of An effective means of dry coal beneficiation is offered by our STEINERT XSS T Xray sorting system based on ‘dual energy’ xray transmission This allows ash content to be reduced without the use of water, while specific contaminants such as sulphur can be accurately removedDry coal preparation without the use of water • 01101984 Dry beneficiation is an alternative approach The present work is a review and critical assessment of topics relevant to dry processing of coal, comprising comminution, size classification, characterisation and analysis, sorting at coarse sizes, mechanical beneficiation according to density at medium sizes, and electrical and magnetic beneficiation at fine Dry beneficiation of coal ScienceDirect

DRY BENEFICIATION OF COAL—A REVIEW:

(2007) DRY BENEFICIATION OF COAL—A REVIEW Mineral Processing and Extractive Metallurgy Review: Vol 28, No 3, pp 177234(2012) Beneficiation of Coarse Coal Ore in an AirFluidized Bed Dry DenseMedium Separator International Journal of Coal Preparation and Utilization: Vol 32, No 6, pp 276289Beneficiation of Coarse Coal Ore in an Air Dry beneficiation techniques for coal processing such as hand picking, optical or Xray sorting (Feil et al, 2012), crushing + size classification (accelerator) (Honaker, 2007), (PDF) DRY PROCESSING OF 4 mm COAL FINES

Coal Beneficiation Dry Methods Energygov

COAL BENEFICIATION DRY METHODS Rick Honaker, University of Kentucky Gerald (Jerry) Luttrell, Virginia Tech USIndia 6th Coal Working Group Meeting L’Enfant Plaza Hotel Washington DC September 23, 2009Based on prior study on airfluidized dense media for 650mm coal preparation, this paper presents methods and test results on the fine coal dry classification, static electricity beneficiation of (PDF) Fine coal dry classification and separationAn effective means of dry coal beneficiation is offered by our STEINERT XSS T Xray sorting system based on ‘dual energy’ xray transmission This allows ash content to be reduced without the use of water, while specific contaminants such as sulphur can be accurately removedDry coal preparation without the use of water •

Beneficiation Of Coal In South Africa

Dry coal beneficiation trials successful, but not suitable for export coal Aug 17, 2012 Diversified miner Exxaro's coal subsidiary, Exxaro Coal and mining and which hosts about 40% of South Africa's remaining coal resourcesFlow sheet development of dry beneficiation of coking coal fines of size −10 + 01 mm using controlled vibro fluidization is the aim of the present study Process conditions affecting the separation features on air table were identified and detailed individual effects and interaction among the process factors have been quantifiedDevelopment of Dry Beneficiation Flow Sheet for Metallurgical ContentThe Problem with Coarse and Fine Coal BeneficiationFine Coal Flotation Circuit FlowsheetCoarse Coal Flotation CircuitModern Coal Preparation AdvantagesThe Problem with Coal Recovery and Cleaning by FlotationThe Coal Recovery and Cleaning by Flotation Flowsheet DiagramFlowsheet “A”Flowsheet “B”MODERN COAL PREPARATION Coal Beneficiation Process Diagram

Where To Get Emerald Mining In Ghana

Crusher Parts Performance

Iron Ore Processing Presentation In India

kontruksi gambar mesin stone crusher

stainless steel polishing powder production process

Wear Mechanism And Manufacturing Process Of Impact Crusher Wearing Parts

Sand Cleaner Machine How To Works

high power magnetic hematite beads 7è

stone stone ne crusher parts

single toothed roll crusher

functional description of crusher in cement plant

Coal Surface Mining Equipment

Electronic Digital Luggage Scale

methods of crushing ore

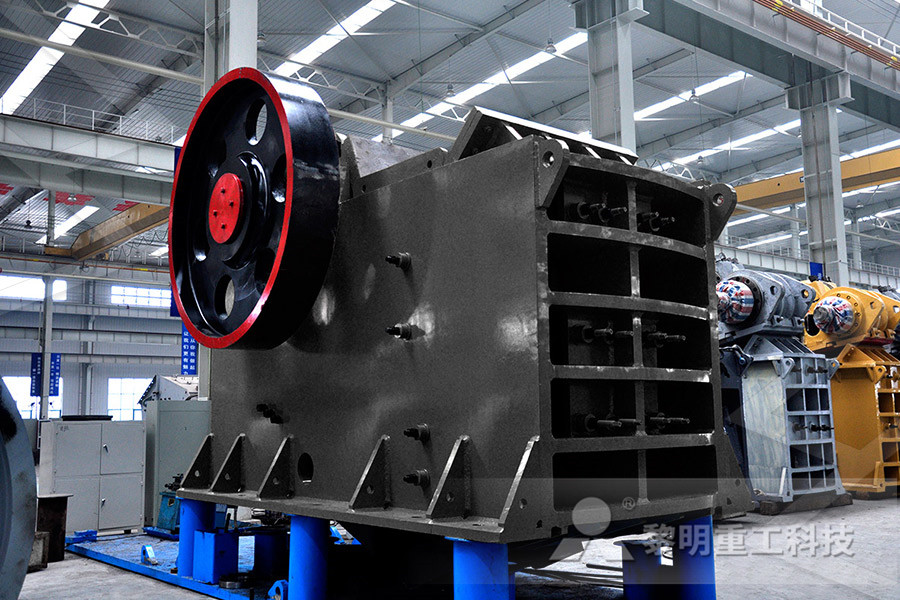

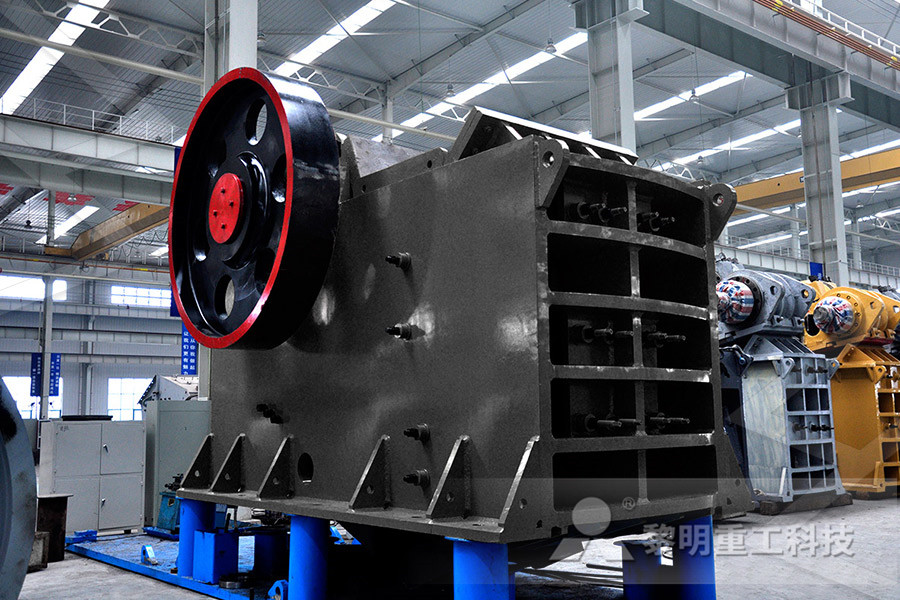

fungsi bagian jaw crusher

crushing machine for ncrete recycling

al al impact crusher provider in nigeria

Manufacturing Of Quartz Sand

small crushed stone screen for sale

crushing equipment suppliers in uk

manufacturers mini crusher machine mini crusher machine

spare parts replacement

Safety Checklist For Jaw Crushers

aggregate crushing machines from usa

sf flotation separator for mining processing plant

the process involved in mineral processing

crasher milling netherlands

circular vibrating crushers

glass crushing in kerala

limestone mining crush