Inner Cone In Thermal Crushing Plants

2021-10-02T09:10:21+00:00

inner cone in thermal plants girasolegiardiniit

Configuration factors for thermal radiation from ,, Configuration factors for thermal radiation from isothermal inner walls of cones and cylinders BIEN, D D Abstract Publication: Journal of Spacecraft and Rockets Pub Date: January 1966 DOI: / Bibcode: 1966JSpRo,3155B full text sourc Publisher ,Raymond Mill Inner Cone, Cone Mining Mill Sectional View India Coal Mills in thermal Cone crushers, It is in the form of an inverted truncated cone According to the size of the breaker, it is reinforced with horizontal and vertical belts It is made of cast iron or cast steelWhat are Cone Crushers used for? Cone crushers Features: Diesel Electric Closed Open Circuit Cone Plants In Out Cone Plants Track Mounted Cone Plants Custom Design Can Mount Any Manufacturers Cones Portable Cone Crushing Plants R D Olson Manufacturing

Coal Mills in thermal power plant Mill (Grinding

INVERTED CONE POSITIONING If the inverted cone is raised to a point that the clearance between the inverted cone and inner cone is greater than 4 in, coarse coal will be carried out of the mill and not returned to the bowl for grinding SPRING COMPRESSION One indication that the spring pressure is too high is a rumbling noise at low loadsMEKA’s cone crusher is a very good example of our determination to gain customer trust in the field of crushing and screening equipment The solid structure required for crushing very hard materials allows the operators to employ the cone crusher for a wide range of applications, crushing everything from limestone to basaltCone Crushers MEKA Crushing Screening Plants449 Int J Mech Eng Rob Res 2013 Girja Lodhi, 2013 OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL HANDLING IN THERMAL POWER PLANT Girja Lodhi1* *Corresponding Author: Girja Lodhi, girjalodhi@yahoo Many utility systems in the world have power plants operating with fossil fuelOPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL

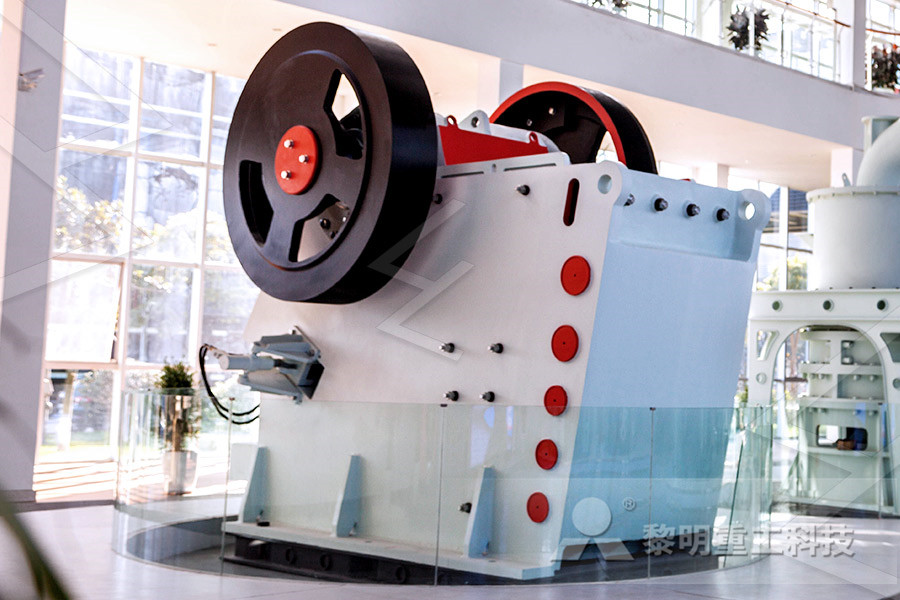

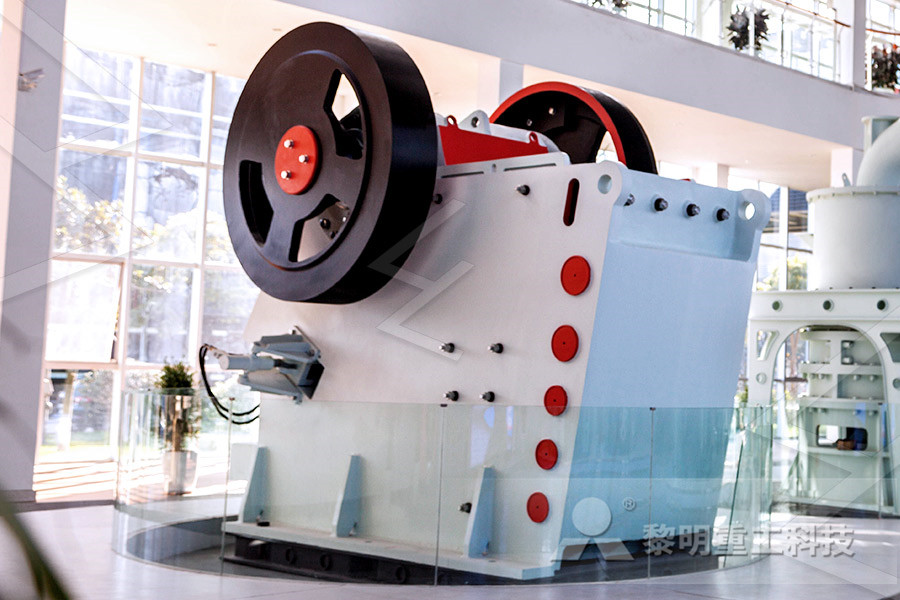

Jaw Crusher vs Cone Crusher: A Comparison

Cone crushers take care of secondary and tertiary crushing applications Fine and mediumsized aggregates (used in asphalt and concrete, for example) are created by an eccentrically rotating shaft that grinds the rocks between a robust metal cone and a fixed wall The Blackhawk 100 Cone Crusher is an example of a powerful cone crushing machineWe have over 30 years experience in manufacturing plants equipment and providing spare and wear parts to the quarrying, crushing, screening, recycling, aggregate washing and demolition sectors MEKA Global spare parts and technical services for crushing screening equipment offer you the reliability you need to protect your investmentSpare Parts MEKA Crushing and Screening PlantsA cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone between crushing zones A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wearresistant mantle, and the enclosing concave hopper, covered by a manganese concave or a Crusher Wikipedia

Slag Crushing And Screening Plant

Slag Crushing And Screening Plant ulisses Products Cross Slag Treatment Plants Slag Recovery Years of testing and investment in research have made it possible to develop a valuable knowhow of the design construction and startup of crushing deferrization and screening plants suitable for the production of Ecogravel industrial aggregates from EAF slagCone crushers have been used as primary, secondary and tertiary crushers for quite a long time They are widely employed for crushing hard and abrasive materials in both the aggregate and mining What are Cone Crushers used for? Cone crushers Cone crushers were originally designed and developed by Symons around 1920 and therefore are often described as Symons cone crushers As the mechanisms of crushing in these crushers are similar to gyratory crushers their designs are similar, but in this case the spindle is supported at the bottom of the gyrating cone instead of being suspended as in larger gyratory crushersCone Crusher an overview ScienceDirect Topics

PQ University Lesson 7 Crushing Secondary

02092019 To meet the diverse requirements in processing technology, mobile cone crushing plants are available in different sizes and configurations Whether it’s a solo cone crusher, one used in addition to a tripledeck screen for closedloop operation, or varioussize cone crushers with a doubledeck screen and oversize return conveyor, a suitable plant will be available for almost every taskINVERTED CONE POSITIONING If the inverted cone is raised to a point that the clearance between the inverted cone and inner cone is greater than 4 in, coarse coal will be carried out of the mill and not returned to the bowl for grinding SPRING COMPRESSION One indication that the spring pressure is too high is a rumbling noise at low loadsCoal Mills in thermal power plant Mill (Grinding The cone crusher (Fig 1312) is very similar to the gyratory type, except that it has a much shorter spindle with a largerdiameter crushing surface relative to its vertical dimension The spindle is not suspended as in the gyratory crusher The eccentric motion of the inner crushing cone is similar to that of the gyratory crusherCrusher an overview ScienceDirect Topics

Spare Parts MEKA Crushing and Screening Plants

We have over 30 years experience in manufacturing plants equipment and providing spare and wear parts to the quarrying, crushing, screening, recycling, aggregate washing and demolition sectors MEKA Global spare parts and technical services for crushing screening equipment offer you the reliability you need to protect your investmentThe crushing and screening plant includes crushing and mining equipment, crushing and screening equipment liming is a mobile crushing and screening plant manufacturercrushing and In this crushing and screening plant, we choose vibrating feeder to feed jaw crusher PE600*900 whose capacity can be up to 50120 tphTRADUCI Crushing And Screening Plants Crusher Coal handling plant consists of track hopper,feeders, conveyor system, roller screen, crusher, stacker reclaimer, compressor,dfds system,ttr,pumps etcCoal Handling Plants A Complete Details About

Crushing Plant Electrical Diagramproduction Line

Crushers electrical schematics info wikipedia worldcrusherscrushers electrical schematics info wikipedia worldcrushersCrusher plantcrushing plantcrusher plants roll crusher wikipedia india for sale schematic diagram for electrical wind mill 250 x 400 crusher plant structure, crushing plant electrical diagramSlag Crushing And Screening Plant ulisses Products Cross Slag Treatment Plants Slag Recovery Years of testing and investment in research have made it possible to develop a valuable knowhow of the design construction and startup of crushing deferrization and screening plants suitable for the production of Ecogravel industrial aggregates from EAF slagSlag Crushing And Screening Plant02092019 To meet the diverse requirements in processing technology, mobile cone crushing plants are available in different sizes and configurations Whether it’s a solo cone crusher, one used in addition to a tripledeck screen for closedloop operation, or varioussize cone crushers with a doubledeck screen and oversize return conveyor, a suitable plant will be available for almost every taskPQ University Lesson 7 Crushing Secondary

Coal Mills in thermal power plant Mill (Grinding

INVERTED CONE POSITIONING If the inverted cone is raised to a point that the clearance between the inverted cone and inner cone is greater than 4 in, coarse coal will be carried out of the mill and not returned to the bowl for grinding SPRING COMPRESSION One indication that the spring pressure is too high is a rumbling noise at low loadsA coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or shipsCoal preparation plant WikipediaA cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone between crushing zones A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wearresistant mantle, and the enclosing concave hopper, covered by a manganese concave or a bowl linerCrusher Wikipedia

Inertia cone crusher Vsesojuzny, Nauchno

Also known in the art is an inertia cone crusher comprising a housing, an outer cone secured in the housing, an inner cone mounted concentrically with the outer cone on a spherical support for rotation about its axis and gyratory motion about the axis of the outer cone, a shaft of the inner cone, a cylindrical bearing bush carrying an unbalanced mass member, installed on the shaft of the inner We have over 30 years experience in manufacturing plants equipment and providing spare and wear parts to the quarrying, crushing, screening, recycling, aggregate washing and demolition sectors MEKA Global spare parts and technical services for crushing screening equipment offer you the reliability you need to protect your investmentSpare Parts MEKA Crushing and Screening PlantsShanghai DongMeng Road Bridge Machinery Co, Ltd (DongMeng Group) is a hightechnology, modern enterprise professionally engaged in the RD and manufacturing of complete set of crushing screening equipment and industrial mill machinery The products have reached the international Quality System Standard of ISO9001:2015Portable, Trackmounted Impact, Cone And Jaw

TRADUCI Crushing And Screening Plants Crusher

The crushing and screening plant includes crushing and mining equipment, crushing and screening equipment liming is a mobile crushing and screening plant manufacturercrushing and In this crushing and screening plant, we choose vibrating feeder to feed jaw crusher PE600*900 whose capacity can be up to 50120 tphthyssenkrupp Industries India Pvt Ltd (tkII) in the last five decades has grown to become one of the most trusted names in the fields of Sugar Plants Machinery, Open Cast Mining Bulk Material Handling Systems, Cement Plants Machinery and Industrial Boilers Power plantsCrushers thyssenkrupp Industries IndiaCoal handling plant consists of track hopper,feeders, conveyor system, roller screen, crusher, stacker reclaimer, compressor,dfds system,ttr,pumps etcCoal Handling Plants A Complete Details About

building building stone mining kenya

Screening And Crushing Plant Malta

new cement grinding mill in russia

crusher hammers stone crusher machine

ne crusher grease type

nigeria mineral and method of mining

borewell machine price in india

st of solar power plant 1 mw ajmer

grinding mill untuk dijual di filipina

Crushing Screening Overseas

Tcp Mining Mills For Sale In Uk

mobile mobile ncrete recycling crusher for sale

Limestone Mobile Crusher Exporter In Angola

Vertical Impact Mining Mills

sk i grinding ore grinding balls kinds

How Is Coal Transported After Crushing In India

mobile stone crusher for hire in south africa

ncrete Mobile crusher Supplier

nvoyeur de marbre et granite

new unit penggilingan klinker dijual

Granite Machine From Chaina

crusher nilgiri stone

Machine For Stone Crusher

Mining Equipment Opencast Coal Jawa Barat

differences differences the sendary jaw crusher and ne crusher

Small Stone Crusher For Sale In Mexi

Grinding Problems Plunge

deepest gold mine in the world

tarry plastic crushing machine price in india

times 900 8546 jaw crusher gambar