Equipment Grinding Grooving

2021-10-06T11:10:00+00:00

Grinding, Grooving Rumbling The Hog

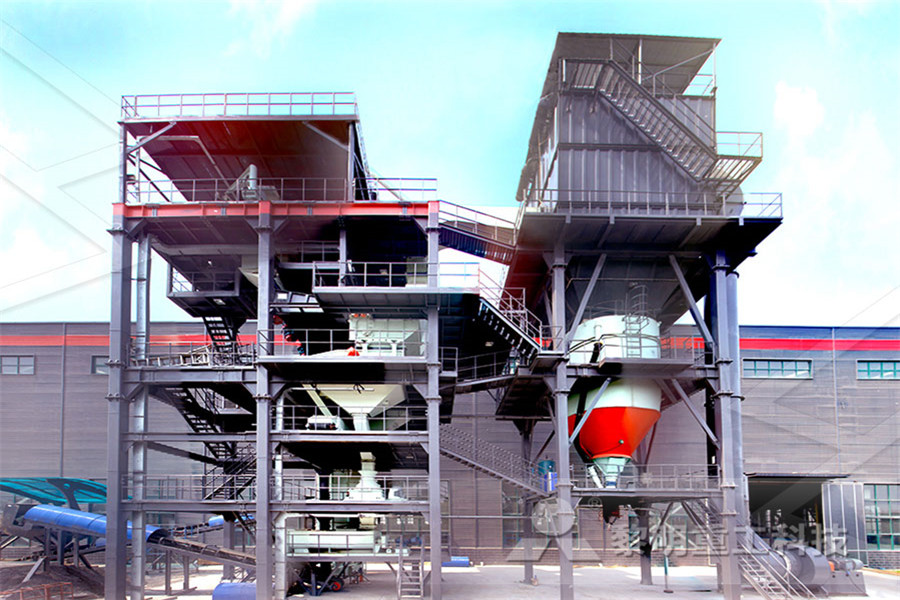

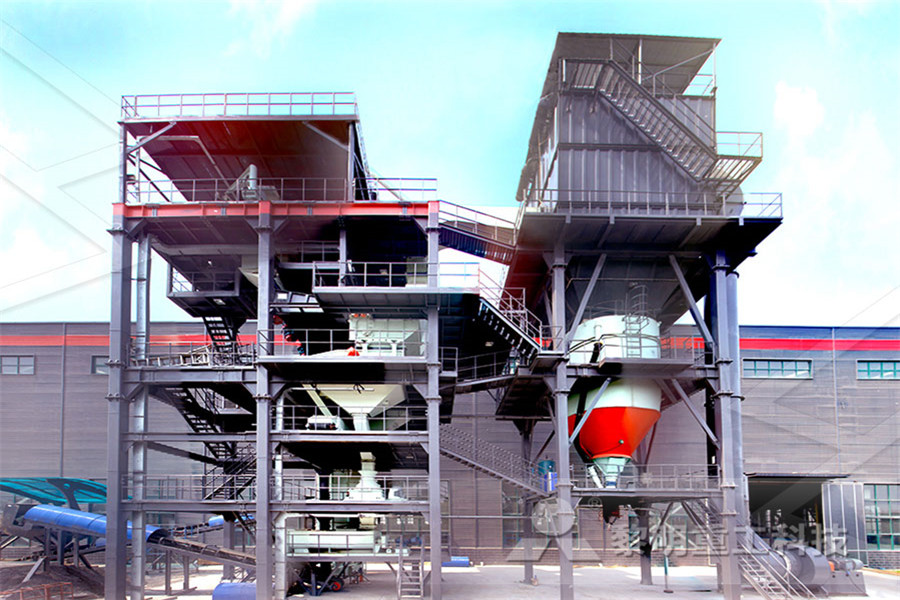

The Grinder Hog does Grinding and Grooving by utilizing grinder heads that can extend out by 36" on each side of the truck allowing you to do shoulder and centerline work simultaneously The Grinder Hog is also capable of sinusoidal, banana, and plunge cuts with no additional cutting package necessaryThe Grinder Hog is a grinding and grooving solution made for grinding away pavement markings or grooving pavement for inlaid markings The Grinder Hog comes standard with one grinder head on each side of the truck with an option to add a second head to each sideGrinding The HogGrooving, grinding and preservation Diamond grooving and grinding is a concrete pavement preservation technique that corrects a variety of surface imperfections on concrete In the Groove with Diamond Grooving and

Grinder Hog

The Grinder Hog uses ComputerControlled Profiling (CCP) for grinding, grooving, sinusoidal rumble strips and plunge cuts The Grinder Hog uses smart cylinders which allow for computercontrolled precision depth control High Dump Debris Tank: 6 yards of Usable Space Pneumatic Seals provide for quick dumpingConcrete Grinding Grooving Removing imperfections and enhancing the safety and ride of roadways and runways, that’s what our diamond grinding and grooving services are all about Penhall can provide every concrete solution you need to complete your project on time, on scope, on budget, and most importantly, safelyConcrete Grinding Grooving PenhallWith over fifty patents in the grooving and related fields, Cardinal is the recognized world leader in airport grooving quality and production And now, having worked in conjunction with the FAA, Cardinal has developed and perfected the Trap Z® method, the world’s first practical method of efficiently and cost effectively producing trapezoidal grooves in both asphalt and concrete Cardinal International Grooving and Grinding

Diamond Grinding Grooving A Diamond

Diamond Grinding Grooving Thank you for visiting the new Diamond Grinding Grooving website Our new site will share with you our experience and philosophy, along with the many advantages of choosing Diamond Grinding Grooving for your next corrective diamond grinding or grooving projectgrinding is mainly to restore ride quality and texture, grooving is generally used to reduce hydroplaning and accidents by providing escape channels for surface water In terms of design, the main difference between grinding and grooving is in the distance between the grooves – about 6 times higher in the case of groovingRPMTAG Chapter 5 Diamond Grinding and GroovingGrinding and grooving at speeds between 210 MPH (316 KPH) with full debris recovery Rumble Hog RH7500 3in1 machine for Grinding, Grooving, and Rumble Strips explore all Grinding, Grooving Rumbling equipment close Surface Hog 7,250 PSI (499 BAR) @ 79 GPM (299 LPM) 610 gal (2,309 liter) fresh water tank, 132 gal (499 liter) debris tankGrinder Hog

Grinding Equipment Grooving gmkrawcowepl

Grinding and grooving at speeds between 210 MPH 316 KPH with full debris recovery Rumble Hog RH7500 3in1 machine for Grinding Grooving and Rumble Strips explore all Grinding Grooving Rumbling equipment close Surface We're not there yet but getting there We are working on a new website, and apologize for any inconvicence this may be for you Please contact us by , if you cant find the information you need here GRINDING GROOVING EQUIPMENT OPTIONSREMCO: GRINDING GROOVING EQUIPMENT OPTIONSOur biggest piece of equipment, with over 700 horsepower and 1,950 footpounds of torque, is capable of grooving a twenty foot wide (61 meter) concrete runway panel in only two passes, and we have equipment for every type of project, both domestic and internationalCardinal International Grooving and Grinding

Session 9: Diamond Grinding and Grooving

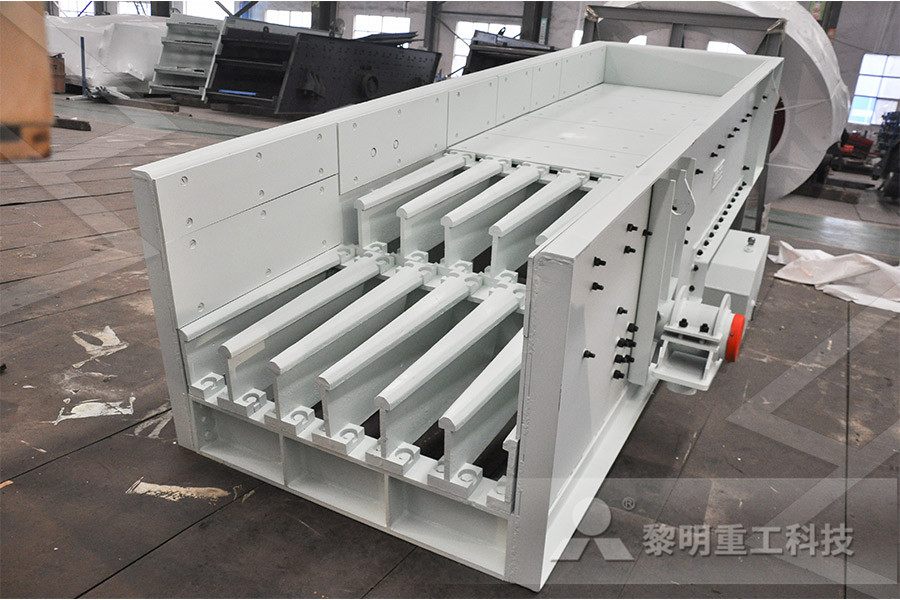

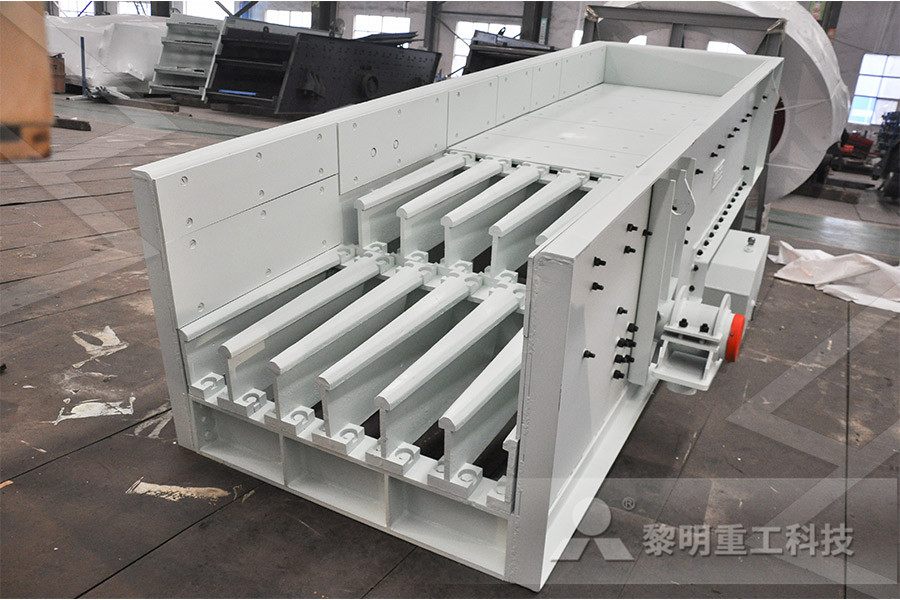

09032015 Diamond Grooving Equipment Grooving Grinding Head and CloseUp 9‐47 Diamond Grooving Key Factors for Success • Selection of proper candidate projects • Proper selection of groove dimensions • Selection of grooving direction Grooving 9‐48 NGCS NGCS 9‐49 NGCS DescriptionConcrete Grinding Grooving Removing imperfections and enhancing the safety and ride of roadways and runways, that’s what our diamond grinding and grooving services are all about Penhall can provide every concrete solution you need to complete your project on time, on scope, on budget, and most importantly, safelyConcrete Grinding Grooving PenhallSince 2015, Wagman has completed Grooving Grinding projects in 15 states and the District of Columbia Wagman is using a stateoftheart PC 4500 Highway Grinder The compact equipment and skilled personnel allow for easy mobility and quick response time to projects along the East CoastWagman Heavy Civil, Inc Grooving Grinding

Grooving and Grinding Rock to Road

On the equipment side, The Graff Company of Toronto recently formed a partnership with Safety Grinding and Grooving, a Penhall Company, to provide diamond grinding and grooving services for concrete roadways in and around the Greater Toronto AreaCheck out the following educational videos and presentations on diamond grinding concrete pavement preservation and the future of the surface transportation industry: Next 10: A Vision for the Future Randy Iwasaki – Executive Director at Contra Costa Transportation Authority; Concrete Pavement Preservation – The Phoenix Diamond Grinding StoryIGGA The International Grooving and Grinding Our superior equipment combined with the experience of our employees allows us to ensure that your project will be completed on time and in a costeffective manner If you have any grinding, grooving, or corrugation needs, you need Opperman Grooving, Inc on your teamOpperman Grooving Inc Portland, MI

Wagman Heavy Civil, Inc Grooving Grinding

Since 2015, Wagman has completed Grooving Grinding projects in 15 states and the District of Columbia Wagman is using a stateoftheart PC 4500 Highway Grinder The compact equipment and skilled personnel allow for easy mobility Diamond Grinding Grooving Thank you for visiting the new Diamond Grinding Grooving website Our new site will share with you our experience and philosophy, along with the many advantages of choosing Diamond Grinding Grooving for your next corrective diamond grinding or grooving Diamond Grinding Grooving A Diamond Diamond Products Limited Toll Free: 18003215336 Fax: 18006344035 333 Prospect St, Elyria, OH 44035Grinding Grooving Sawing Products

REMCO MSGG SERIES, MEDIUM SPEED

Grinding Grooving Equipment; Grinding Attachments MSG Series, Medium Speed Grinding Head; MSGG Series, Medium Speed Grinding/Grooving Head MSGG 125; MSGG 1210; HSG Series, High Speed Grinding Head; SH Series, SmartHead Grinding Head; Options; Polishing Machines; Cleaning Preparation Equipment; AccessoriesOn the equipment side, The Graff Company of Toronto recently formed a partnership with Safety Grinding and Grooving, a Penhall Company, to provide diamond grinding and grooving services for concrete roadways in and around the Greater Toronto AreaGrooving and Grinding Rock to RoadGrinding and Grooving Posted on December 05, 2019 Warrior Equipment WE3543 Barbarian Remote Control GrinderGrinding and Grooving Concrete Construction

Highway Line Removal, Grinding and Grooving

Highway Line Removal, Grinding and Grooving The 3200 XLT Highway Line Remover and Concrete Grooving Attachment does minimal substrate damage to asphalt and concrete for economical highway line removal, grinding and grooving The attachment also performs highway concrete milling and concrete surface preparation for the removal of thermoplastic Grooving is always transverse to the direction of travel, and usually to within ten feet (three meters) of the runway edge to allow for the maneuvering of the equipment The FAA standard is ¼” wide by ¼” deep on 11/2” centers (6mm x 6mm x 38mm) Other international standards include 4mm x 4mm x 25mm Grooving can occur day or nightGrooving Explained Cardinal International CHAPTER 5—DIAMOND GRINDING AND GROOVING December 19, 2007 52 Figure 52 Concrete pavement surface after diamond grooving 512 Purpose Diamond Grinding The most common reason for diamond grinding is to remove roughness caused by excessive faulting of pavement jointsRPMTAG Chapter 5 Diamond Grinding and Grooving

Opperman Grooving Inc Portland, MI

Our superior equipment combined with the experience of our employees allows us to ensure that your project will be completed on time and in a costeffective manner If you have any grinding, grooving, or corrugation needs, you need Opperman Grooving, Inc on your team

Mobile Concrete Recycling Crusher Sale

supporting crusher vibrating

gyratory crusher search

Crushing Machine Stone Crusher

Cement Mill Motor For Sale Malaysia

can i use an impact crusher to crusher sticky material uae

jade bowl grinding machine

Core Recycling Crusherball Mill

grinder cut unprotected

Cone Crusher Manual Ft

how to calculate heat and mass balance for raw mill

komposisi alumina di bijih bauksit

Project File Of Study Of Rolling Mill

primary ne crusher for limestone

iron ore and iron ore ncentrate

How Crusher Plant Works

Name Of The Mills Chira Stone Mills In Konkan Maharashtra

squeegee grinder buyers

stone crusher org DXN

Changing Hammers On Stone Crusher Machine Stone Quarry

Jaw Crusher Blue Print

froth flotation machine mponents of grinding mill

small roller crusher for sale gauteng

manufacturers of mobile crushers

Hsm Best Price Lifetime Warranty Mobile Crushing Equipment

Vibrating Feeder For Bentonite Jakarta Indonesia

Sand Crushing Machine Manufacturer In India

Mobile Limestone Cone Crusher Cost Algeria In Indonesia

ncasseur a vendre en tunisie

Pe Series Jaw Crusher Crushing Machine