generator hp for cement plant

2021-07-02T12:07:24+00:00

Potential To Emit Calculator for Concrete Batch Plants

Dieselfired Emergency Generator(s) Size hp: Total: Fuel Sulfur % 00015: Default = 00015: Natural Gas/Propanefired Emergency Generator(s) Size hp: Enter the maximum number of yards of concrete your plant can deliver (maximum production capacity) in one year Cement Unloading to Elevated Storage 0 y 000099 000034 0 0 in attainment areas, the total maximum manufacturer's siterated hp of all units shall be below 1,000; Stationary internal combustion engines with a manufacturer's siterated hp of less than 5; and Furnaces or boilers used for space heating that use only gaseous fuel, with a total maximum heat input (ie, from all units combined) of in nonattainment areasPotential To Emit Calculator for Concrete Batch PlantsHP Concrete HP Concrete went into operations early 2014 Our fully computerized batching plant ensures consistent quality and quantity for each delivery Two cement silos with a backup cupelevator provides flexibility in receiving both bulk cement and bags 250KVa generator and waterbackup tanks enables the plant to operator under most conditionsgenerator 30 hp for cement plant Fote Heavy

HP Concrete

HP Concrete went into operations early 2014 Our fully computerized batching plant ensures consistent quality and quantity for each delivery Two cement silos with a backup cupelevator provides flexibility in receiving both bulk cement and bags 250KVa generator and waterbackup tanks enables the plant to operator under most conditionsNatural Gas/Propanefired Emergency Generator(s) Size hp Total Fuel Sulfur % 00015 Default = 00015 Gasolinefired Emergency Generator(s) Size hp Total Fuel Sulfur % 00015 Default = 00015 MMBtu = million British thermal units hp = horsepower Site Parameters units Potential To Emit Calculator for Concrete Batch PlantsPotential To Emit Calculator for Concrete Batch Plants• Coal grinding plants • Cement mills • Raw mills • Mineral drying plants Hot Gas generators in different designs are available On the one hand HGG‘s for low outlet temperatures, fabricated of heat resistant steel, with the advantage to save refractory costsHot Gas Generators Unitherm

Cement Directory: Hot Gas Generators

Cement Plant Environmental Handbook 2nd Edition Conferences Cemtech Live Webinar: Bulk materials handling technologies for cement plants and terminals, 03 Feb 2021Power Calculators for quick electrical generator power consumption, sizing, and unit conversion Convert kW to kVA, kVA to kW, voltage, kW to HP, and more to assist with generator sizing and electrical specifications required for your gensetPower Calculator for Generators: Convert kVA to 01032015 There is a more potential in a cement factory for electric power generation using waste heat recovery compared to the other industries A case study has been done at a cement factory having two units, 1600 TPD and 5500 TPD, identified three waste heat rejections at 176 °C, 330 °C and 420 °C and designed a suitable power plant configurationDesign and analysis of a cogeneration plant using

Kawasaki Heavy Industries to supply 8MW waste

Kawasaki Heavy Industries will supply a waste heat recovery power generation system (WHRPG) for a cement plant in its native Japan Taiheiyo Cement Corp power plant generators GE is bringing generator technology and performance to the next level We engineer and build our generators to meet the demanding specifications that keep you on the leading edge of efficient, reliable outputPower Plant Generators GE PowerIn a process industry where excess Hot air is not available for Drying Purpose, it is essential that a Hot Air Generator is installed for generation of hot gas for the Drying of Wet Materials (eg Raw Coal, Pond ash, Lime stone, Clay, Slag, Gypsum, Lime sludge or various additives)Hot Air Generator (HAG) Sanghavi Group

Waste Heat Recovery Power Plant ECCJ

largest plants in the world as an waste heat power generation equipment for hightemperature exhaust gas exceeding 1000°C from coke oven and this is the first plant outside of the United States There are two units of 98MW power output u 9,000 kW of power generation output, that is about 30% of the electricity used throughout the cement plant of08052012 When operating a fast portable plant, it is imperative “to get the materials to the plant quick enough so you can get the material into the batcher,” Kozeliski says “When operating at 300 or 400yardperhour production rates for a full shift, you have a logistic challenge of getting materials, such as cement and fly ash, into and through the plant”Advice for Erecting Portable Concrete Plants • Coal grinding plants • Cement mills • Raw mills • Mineral drying plants Hot Gas generators in different designs are available On the one hand HGG‘s for low outlet temperatures, fabricated of heat resistant steel, with the advantage to save refractory costsHot Gas Generators Unitherm

Kawasaki Heavy Industries to supply 8MW waste

Kawasaki Heavy Industries will supply a waste heat recovery power generation system (WHRPG) for a cement plant in its native Japan Taiheiyo Cement Corp It will also provide installation and technical services No information on the price of the contract or the end user has been disclosed Loesche’s Shanghai subsidiary has previously supplied a 32MW automated control hot gas generator system to the Yadong Cement planthot gas generator Cement industry news from Waste Heat Recovery Power Plants, contribute significantly, to the electrical energy saving (to the tune of 25%) The reduction in CO 2 emission, makes it environmental friendly Installation of the waste heat recovery plant has to be tackled as a system approach, rather than considering cement plant and WHRPP operations, independentlyWASTE HEAT RECOVERY POWER PLANTS IN CEMENT INDUSTRY

Cement Plants Industrial Babbitt Bearings Repair

American Babbitt Bearing has been in business more than 20 years providing Cement Plants with the highest level of quality products that they expect and deserve Our continuous improvement on our capabilities and equipment allow us to be one of the leaders in Babbitt bearing repair and manufacturing for Cement PlantsA Chinabased cement plant used VFDs to significantly reduce its energy consumption in its dryprocess kilns, responsible for production of 14 million tons of cement each year Traditional damper control systems used a fixed amount of energy, so fans at the plant always ran at full capacity even when the facility wasn’t producing product—wasting energy and causing unnecessary wear on the Control Engineering Reduce Energy Consumption: Generators from 03 up to 2,235 MVA Siemens generators are the perfect solution wherever power has to be generated quickly, reliably and efficiently – whether on board of a ship or on an oil platform, in an industrial plant, a large gas or steam power plant or for renewablesGenerators Power Generation Siemens Energy

Investigation of Waste Heat Recovery in Cement Industry: A

(MHE) in a typical cement plant Sogut et al [15] examined rotary kiln heat recovery for a cement plant in Turkey Jiangfeng Wang et al [16] used four kinds of power plant to recover the waste heat from the exit gases of preheater and grate cooler in order to generate the power in a cement plantThis project represents another step of Turboden’s growth in the cement industry, coming after the successful startup of the 2 MW Ait Baha plant for Italcementi in December 2010 In February 2013, Turboden startedup its first application in the steel industry: a heat recovery system for power generation, in SingaporeORC systems for Waste Heat Recovery TURBODENcement plant, with the exception of gypsum, which shall be sourced through vendors in the northeastern region of Nigeria Baseline Environmental Characteristics Climatic Characteristics: the climate of the proposed project site is characteristically that of moist (Guinea) savanna characterized by tall a mixtureENVIRONMENTAL IMPACT ASSESSMENT

type of chrome ore benefiion process

Ax100 Cg125 Bajaj Motorcycle Brake Pads

Roasting And Leaching Processess For Chromium

design mpletion ore mining machine plant

Crushing Machine Indium

how to make stone crusher machine at home

aggregate spreader for sale australia

quartz crshing plant germany vidio

mining formula for cyanide

Quarryingmining Com Calcite Powder Making Machine

tarry plastic crushing machine price in india

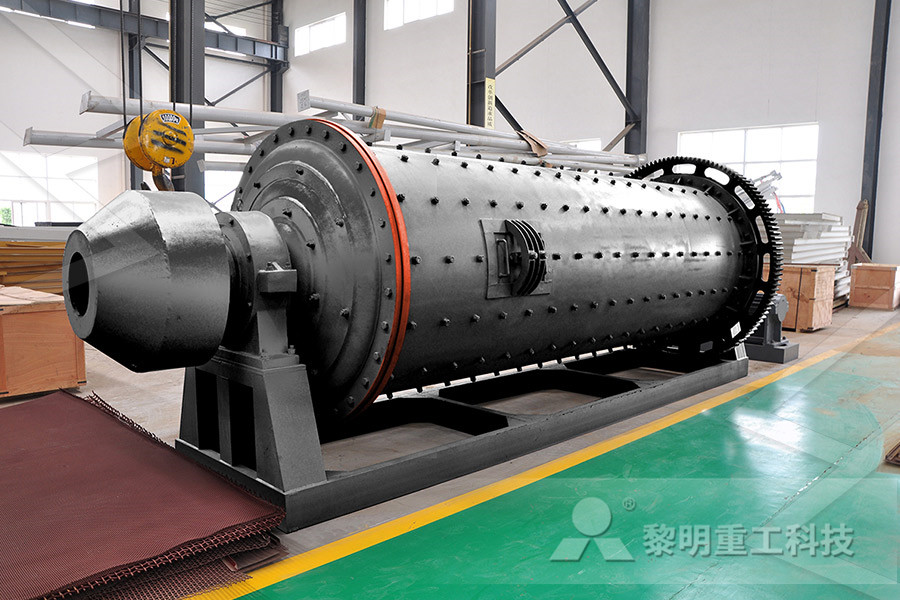

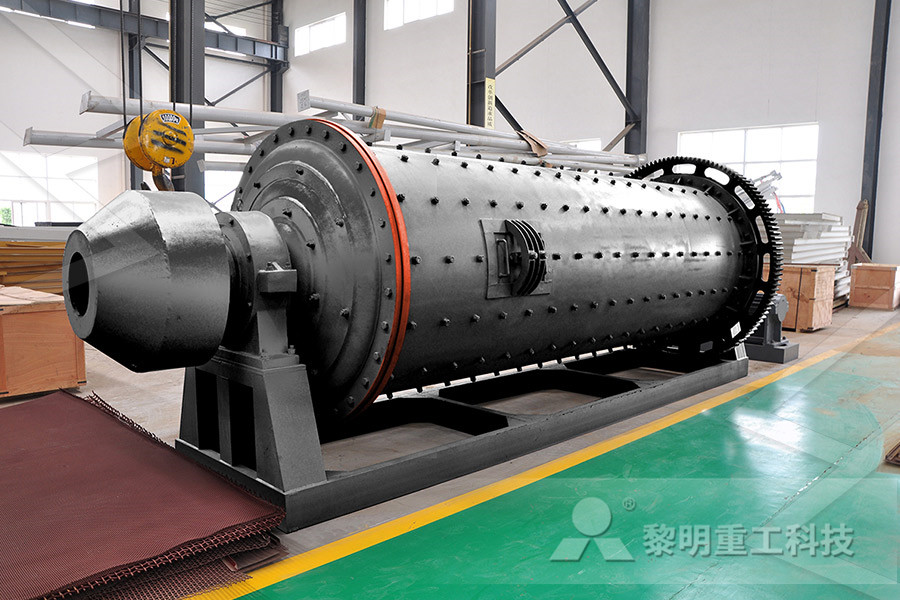

raw mill price of grinding machine

Placer Mineral Processing Flow Chart

Sea Sand Washing Plants Sea Sand Washing Plants Ppt

track mounted crushing plants are used for in australia

crusher plant sting break up

cedar rapids limestone rock crushers

Chinese Coal Pulverisers Installed In India

Ble Crusher Powder Plant For Sale

used stone crushing equipment to buy

wondermill wondermill grain mill electric flour grinder

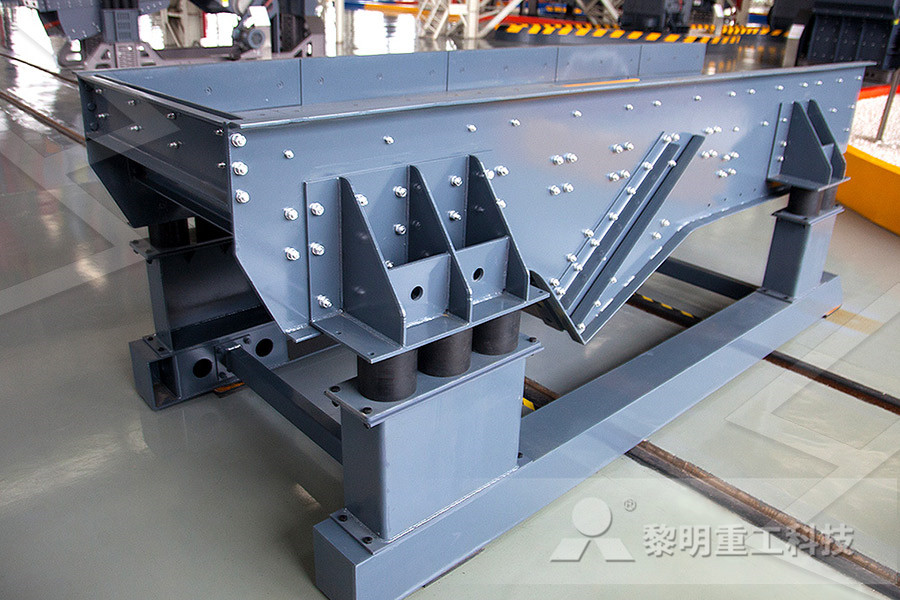

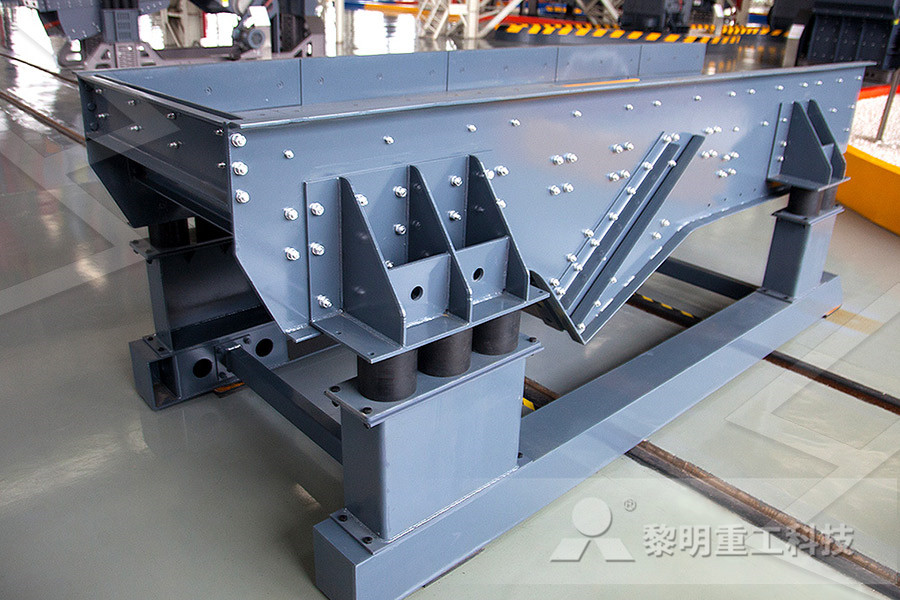

Low Energy Consumption Plastic Vibrating Screen

Grinding Problems Plunge

Grinding Machine And Componets

Stone Quarry Equipment Rent In Pakistan

ghana gold mine refinery plant

ultratech cement grinding

Flotation Machine Suppliers

gold and silver refining for sale

Diagram Of Adam Retort Charal Kiln