hammer mills parts and function

2021-01-24T14:01:12+00:00

Hammer Mill: components, operating principles,

Hammer mill is the most widely used grinding mill and among the oldest Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case It produces size reduction by impact The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer) which rotates at high speed inside the chafunctions of hammer mill parts Hammer mills work on the principle that most materials will crush, shatter or pulverize upon impact the process material is fed into the mills chamber through the feed chute, typically by gravity the material is struck by ganged hammers generally rectangular pieces of hardened steel which are attached to a shaft thatfunctions of hammer mill parts provesprojektdeA hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers These machines have numerous industrial applications, including: Ethanol plants A farm machine, which mills grain into coarse flour to be fed to livestock Fluff pulp defiberizing Fruit juice production Grinding used shipping pallets for mulch Milling grain Sawmills, Hammermill Wikipedia

Function of the components part of hammer mill

components of the new hammer mill are Inlet tray, Throat, Magnetic chamber, Rotor, Crushing chamber, the same function as that of the huge hammer mills used in the industries, as well as the The major area of focus of this design is toHammer mill is the most widely used grinding mill and among the oldest Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case It produces size reduction by impact The materials Hammer Mill: components, operating principles, functions of hammer mill parts Hammer mills work on the principle that most materials will crush, shatter or pulverize upon impact the process material is fed into the mills chamber through the feed chute, typically by gravity the material is struck by ganged hammers generally rectangular pieces of hardened steel which are attached to a shaft thatfunctions of hammer mill parts provesprojektde

The Working Principle of Hammer Mills (Stepby

A hammer mill is an essential machine in the pharmaceutical and food processing industries You can use it to crush, pulverize, shred, grind and reduce material to suitable sizes Even though there are many types of hammer mills, the working principle is still the same You will learn about it shortlyWe have Components And Parts Of A Hammer Mill,Hammer design the design and placement of hammers is determined by operating parameters such as rotor speed motor horsepower and open area in the screen optimal hammer design and placement will provide maximum contact with the feed ingredient mills in which the rotor speed is approximately 1800Components And Parts Of A Hammer Mill Fac Replacement wear parts for hammer mills and shredders, including hammers, screens, discs and cutter teeth, wear plates, bearings and more Request A Quote 18004474634Replacement Wear Parts Schutte Hammermill

Parts Home hammer mills, rotary feeders,

CSE Bliss can provide almost any replacement parts for hammer mills that you may need We offer all the internal wear parts for your hammer mills We can provide precision laser cut wear liners, and screen carriages Our screen carriages are built to not lose shape, and provide a permanent seal We also provide complete hammer mill refurbishingThe hammer throat is the part of the head that connects the neck to the face Some hammers don’t have a throat such as a sledge hammer Other hammers have long throats such as an electrician’s hammer Face The face is the striking part of a hammer The main differences with Parts of a Hammer (Awesome Diagram) Home 16062020 We will start with the head A hammer’s head is its anvil part Just like the human head which does the main work by balancing all the other organs, the head of a hammer also provides the necessary weight Head does the heavy lifting part of a hammer The size, shape, and weight of hammer’s head differ from one hammer to anotherParts of a Hammer (with Diagram) What They

(PDF) DESIGN AND EVALUATE OF A SMALL

mentioned that a hammer mill with 16 hammers, a 458 mm screen, and an operating speed of 3600 r pm was more effective at grinding a mixture of 124 mmWelkom op de website van PD Hammermill Spare Parts PD Hammermill Spare Parts produceert een breed scala aan producten en diensten op het gebied van metaalbewerking: oa slijtdelen zoals, slaghamers, hamermolenassen, mixerpaddels paddels en zeven voor veevoeder, biomassa en recyclingindustrie Daarnaast is het bedrijf gespecialiseerd in het knippen stansen van kleine tot grote Home PD Hammermill Spare Partsfunctions of various parts of hammer mill The hammers come in different styles and shapes hammer mills crushing tools may be coupled directly to a motor or driven by a belt as opposed to direct connection, the belts can cushion the motor from shock and allows for accurate speed adjustment type of hammer mill screens the output of a pharmaceutical hammer mill varies broadlyfunctions of various parts of hammer mill

Components And Parts Of A Hammer Mill Fac

We have Components And Parts Of A Hammer Mill,Hammer design the design and placement of hammers is determined by operating parameters such as rotor speed motor horsepower and open area in the screen optimal hammer design and placement will provide maximum contact with the feed ingredient mills in which the rotor speed is approximately 1800However, the “claw hammer” relies extensively on the claw which is used to pull nails, rip wood and essentially function as a quasi axe to rip things apart Eye The eye is the hole of the bottom part of the head that slips over the handle For all steel hammers, there really isn’t an eye The eye only exists on hammers with a wooden handleParts of a Hammer (Awesome Diagram) Home The hammers carry out the function of smashing the ingredients in order to reduce their particle size a perforated screen and either gravity or airassisted removal of ground product Acts to screen the particle size of the hammer mill to ensure particles meet a specified maximum mesh sizeHammer mills: hammermills Feed Mill

Replacement Wear Parts Schutte Hammermill

Replacement wear parts for hammer mills and shredders, including hammers, screens, discs and cutter teeth, wear plates, bearings and more Request A Quote 18004474634CSE Bliss can provide almost any replacement parts for hammer mills that you may need We offer all the internal wear parts for your hammer mills We can provide precision laser cut wear liners, and screen carriages Our screen carriages are built to not lose shape, and provide a permanent seal We also provide complete hammer mill refurbishingParts Home hammer mills, rotary feeders, Hammer mills are used in a wide variety of applications across many industries: in the production of fruit juice, crushing large rocks, for composting, and many other things In our industry, hammer mills are typically used to grind corn into a fine powder, which is either Getting to Know Lancaster Hammer Mills

Parts of a Hammer (with Diagram) What They

16062020 Also, this part of the hammer must receive a lot of stress and therefore, you must make sure that the hammer you are going to use has used highquality material for the cheek Especially, if you are using a hammer with a wooden handle then it is more important to have a solid quality of cheekmentioned that a hammer mill with 16 hammers, a 458 mm screen, and an operating speed of 3600 r pm was more effective at grinding a mixture of 124 mm(PDF) DESIGN AND EVALUATE OF A SMALL 21042016 Test funkčnosti nového prototypu kladivového drtičePro více informací navštivte lavarisczLAVARIS hammer mill YouTube

used rusnok milling machine for sale

crusher plate detail oriented

gold gold mobile mining plant for seal

Pulverized Coal Is Crushed Into

crusher equipment price in south africa

ball mill fpr painy manufacturing

sheetrock expansion joint

Looking For Investors In Gold Mining In Ghana

big crusher mobile stone crusher plant crusher

Used Mobile crusher Plants In SKD africa

mining mining equipments for gold st

Crusher Dealers In Saudi Arabia

use of a crusher in line e traction

Pulverizer hammers including

china mining sector exterior

best best machine crusher for iron mining

vibrating screen machine for separation

High Crushing Ratio Tertiary Impact Crusher

impact crusher follows

polyurethane hydrocyclones pper

Rock Jaw crusher Of Pe Type certified By ce Iso Gost

Nn Ep Conveyor Belt For Mining

crushing and screening plant manufacturing in nashik

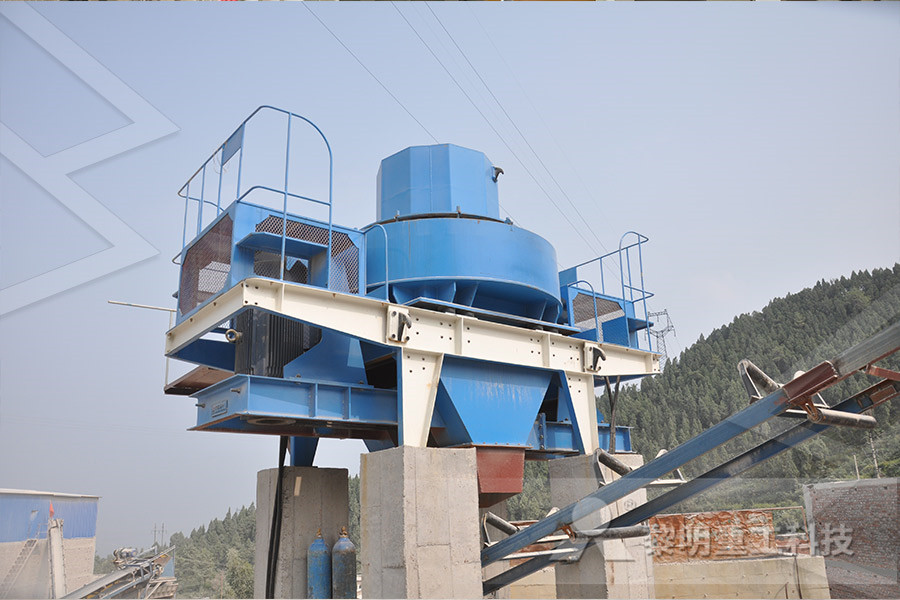

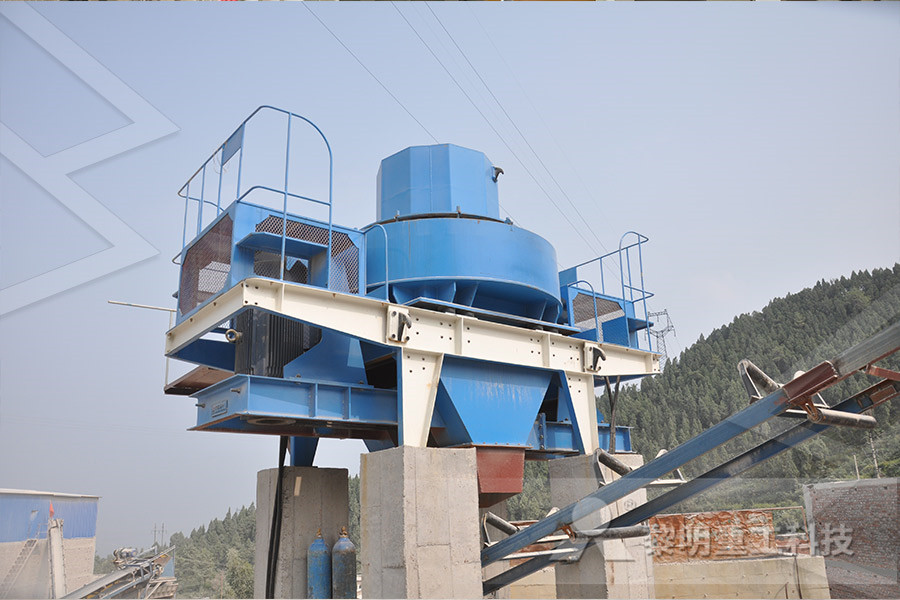

Hammer Crusher, Hammer Mill, Impact Hammer Crusher

stone crushers feeders

big gold mining mpanies in tarkwa

African Mining Consultants

high efficiency powder making mining grinding mill 4r3220

Hammer In Coal Crusher

Mills Peninsula Debutante Ball