design of sand mixing machine

2022-03-13T23:03:05+00:00

(PDF) Design and Development of a Foundry Sand

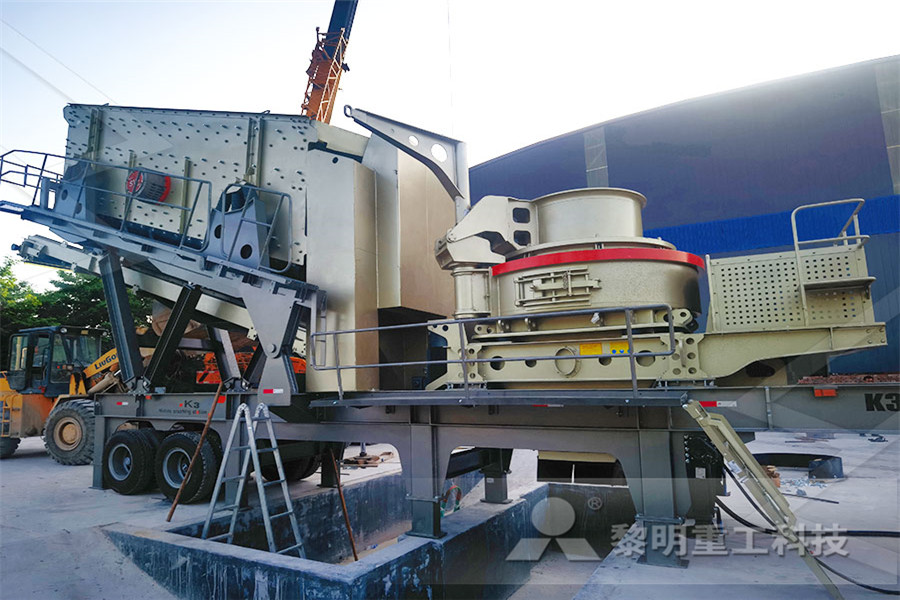

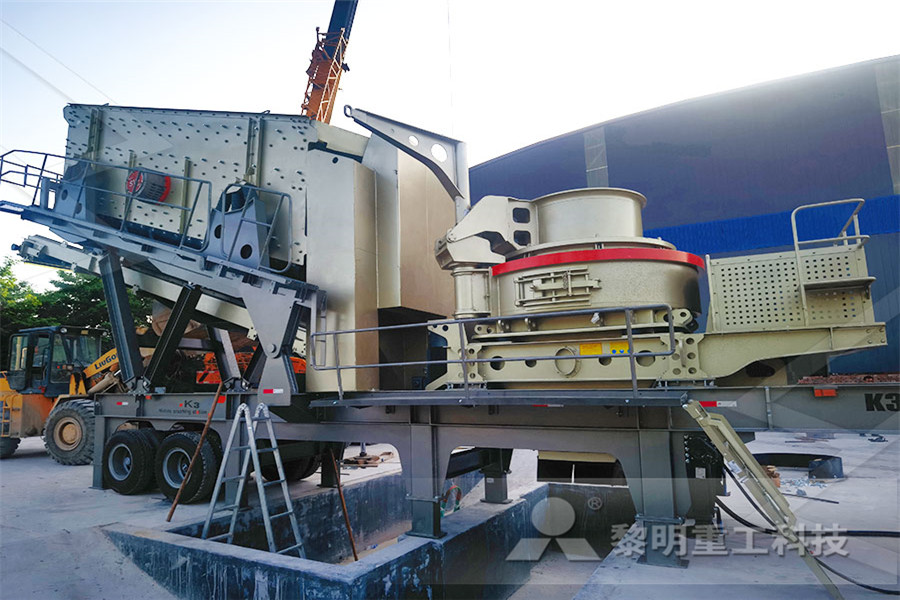

A simple foundry sand mixer capable of mixing foundry sand was designed, developed in this research work The sand mixer components consist of the machine frame, mixing chamber, auger screw, balldesign of sand mixing machine design of sand mixing machine, From large primary jaws and gyratories to cones and VSIs for tertiary and quaternary finishing, SAM has the right crusher and crusher Read moreDesign Of Sand Mixing Machine Design And Fabrication Of Portable Concrete Mixture Electric Motor, Metal Bucket/ the mixing trough, Shaft Pulley, Motor Pulley, Set of blades mounted on the shaft, Bearings, Shaft, Supporting flat belt Pulley: A pulley is wheel on axle or shaft that is design to support moment and change of direction of belt A pulley is a simple machinediagram sand mixing machine hanmedpl

design of sand mixing machine china

This page is about design of sand mixing machine, click here to get more infomation about design of sand mixing machine1250 MECHANICAL DESIGN OF MIXING EQUIPMENT Figure 211 Directdrive portable mixer (Courtesy of Lightnin) mixers are mounted on the vertical centerline of a tank with baffles, but may be offcenter or offcenter, angle mountedCHAPTER 21 Mechanical Design of Mixing Equipmentportable concrete mixer machine”, we were planning for design and fabrication of a concrete mixer This project brought advantages over manual mixing and expensive mechanized concrete mixer In this project Drum is stationary and blade is revolving inside the drum We used 05 HP motor to blend the Concrete properlyDesign And Fabrication Of Portable Concrete

Design, Modification and Analysis of Concrete Mixer Machine

Mixing is a complicated process that is affected by the type of mixer, the mixing cycle as defined by the duration, the loading method, and the energy of mixing • For most machine shafts, however, analysis should be relatively straightforward That’s because the failure typically provides strong clues to the type and magnitude ofDesign and specification: Drum:A concrete mixer is a device that homogeneously combines cement, conglomeration such as sand or gravel, and water to form concrete A typical concrete mixer uses a revolving drum to mix the componentsCement, sand and other aggregates are loaded in a hydraulically operated hopper and then poured in the mixing drum for final mixing and then can be unloaded by Design, Modification and Analysis of Concrete 1250 MECHANICAL DESIGN OF MIXING EQUIPMENT Figure 211 Directdrive portable mixer (Courtesy of Lightnin) mixers are mounted on the vertical centerline of a tank with baffles, but may be offcenter or offcenter, angle mountedCHAPTER 21 Mechanical Design of Mixing Equipment

diagram sand mixing machine hanmedpl

Design And Fabrication Of Portable Concrete Mixture Electric Motor, Metal Bucket/ the mixing trough, Shaft Pulley, Motor Pulley, Set of blades mounted on the shaft, Bearings, Shaft, Supporting flat belt Pulley: A pulley is wheel on axle or shaft that is design to support moment and change of direction of belt A pulley is a simple machineMixing is a complicated process that is affected by the type of mixer, the mixing cycle as defined by the duration, the loading method, and the energy of mixing • For most machine shafts, however, analysis should be relatively straightforward That’s because the failure typically provides strong clues to the type and magnitude ofDesign, Modification and Analysis of Concrete Mixer MachineMixing is a complicated process that is affected by the type of mixer, the mixing cycle as defined by the duration, the loading method, and the energy of mixing2 For most machine shafts, however, analysis should be relatively straightforwardDesign, Modification and Analysis of Concrete

s11 sand mixing machine, s11 sand mixing

Alibaba offers 1,697 s11 sand mixing machine products A wide variety of s11 sand mixing machine options are available to you, such as How To Design Of Sand Making Machine How To Design Of Sand Making Machine VSI sand making machine working principle/ rock sand , You will require cement, sand, gravel, and water for making the concrete mix Put the cement, sand, and gravel in the container at a ratio of 1:2:3 Start mixing water in the container and stir the mixture continuously with a rod Pour water ,design of sand mixing machine Industrial projects require mass concreting type of mixers SAFARI manufactures reversible drum concrete mixers to meet this requirement SAFARI 3000 also known as RM 800 produces concrete at the approximate rate of 12 cubic meter per hour, while SAFARI 5000 also known as RM 1050 has output of 15 cubic meter per hourCONCRETE MIXER MACHINES Mix cement

Mixing (process engineering) Wikipedia

One example of a solid–solid mixing process is mulling foundry molding sand, where sand, bentonite clay, fine coal dust and water are mixed to a plastic, moldable and reusable mass, applied for molding and pouring molten metal to obtain sand castings that are metallic parts for automobile, machine building, construction or other industriesSand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material The term "sand casting" can also refer to an object produced via the sand casting process Sand castings are produced in specialized factories called foundriesOver 60% of all metal castings are produced via sand casting processSand casting Wikipedia01062019 Effective design and adequate material selection criteria were employed in the course of production of the machine It was designed to be driven by a 15 HP, three phase electric motor with a heating element of 1500 W attached to the barrel to eliminate the problem of sun drying that is associated with available local pelletizersDesign and production of a fish feed pelletizing

Foundry Sand Mixers Simpson MixMuller

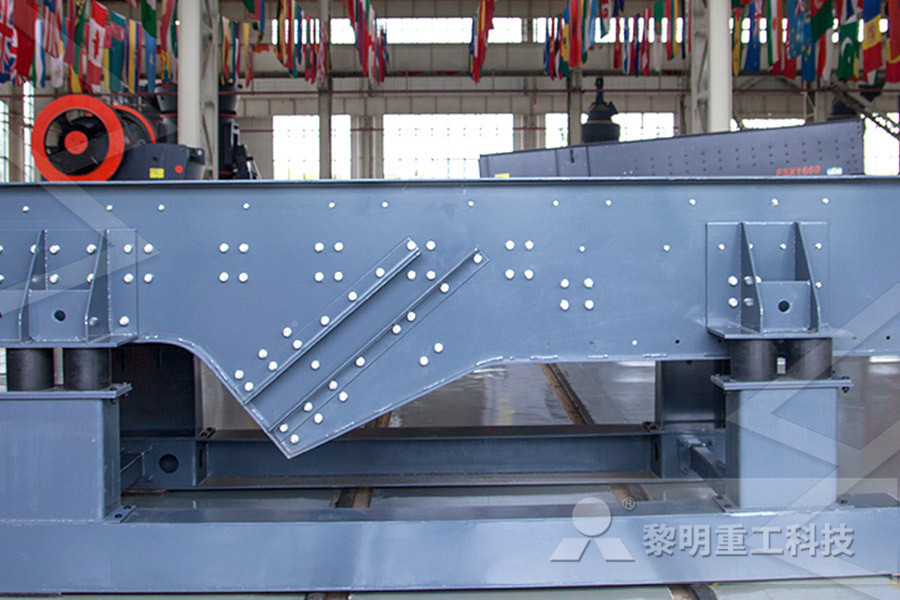

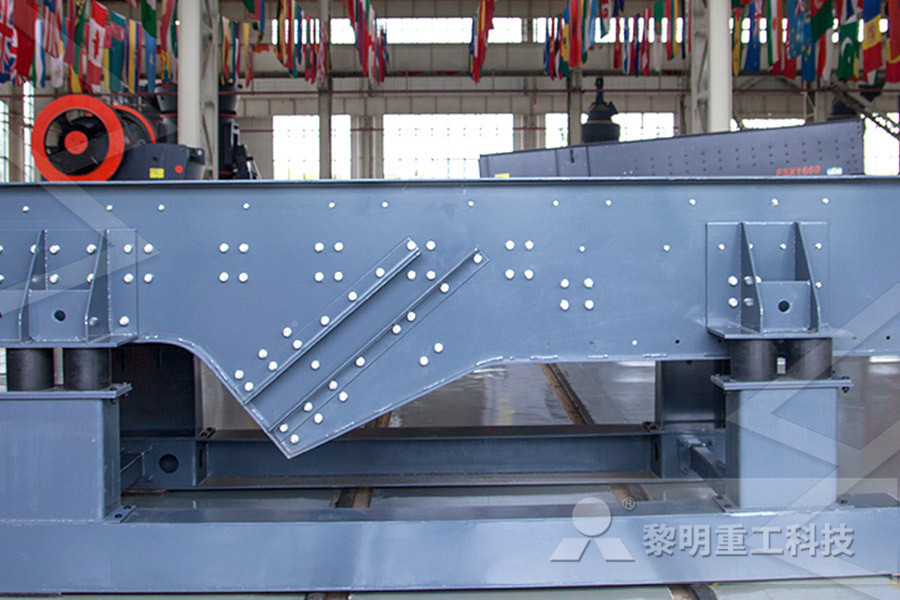

Simpson MixMuller Batch Mixer In small to mediumsized sand systems or difficult mixing applications, versatility is critical The MixMuller has been carefully designed and proportioned to achieve maximum performance, versatility and energy efficiency in these types of applicationsSieve machine: i To design sieve machine that can sieve sand to different size ii Problem that often faced is that some product required different size of sand to fulfill the quality level needed iii Through this design user can save time sieveing sand and cut the cost to order the required size of sand ivDESIGN AND FABRICATE SIEVE MACHINEAlibaba offers 1,697 s11 sand mixing machine products A wide variety of s11 sand mixing machine options are available to you, such as s11 sand mixing machine, s11 sand mixing

sand cement mixing machine, sand cement

Alibaba offers 1,731 sand cement mixing machine products About 12% of these are Concrete Mixers, 1% are Mixing Equipment, and 18% are Dry Mortar Machines A wide variety of sand cement mixing machine options are available to you,In medium to largesized sand systems, higher volumes of throughput demand greater productivity from the sand preparation plant The Speedmullor is carefully designed and proportioned to achieve maximum mixing performance and energy efficiency while still providing some versatility in applications typical to these sizes of sand systemsFOUNDRY SAND PREPARATION Simpson Technologies29082018 The mixing time is short,no head or tail sand lossthe area of operation is bigall opening tyre sand mixing stirring cage wall,which is advantageous for cleResin sand mixing machine YouTube

Sand Casting Design Rules Sites at Penn State

Sand casting is the most popular casting process employed in industry because of its great geometric freedom capability and for its cost effectiveness In this article, we provide design rules for optimal sand casting performance 2/6/2017 1 SAND CASTING DESIGN RULES Santosh Reddy Sama, Guha P Mix design with Cement Fly Ash 133 lbs fly ash 667 Total lbs Cm = 20% ash It’s about volume! Note: lower water demand due to fly ash for same slump Mix design with Cement Fly Ash Proportion the mix to yield 27 ft3 but how much sand, stone what ratio? Sand / Aggregate ratio is by volume It’s about volume!Concrete Mix Design CalculationsThis proposed work is focused on designing and implementation of seed sowing process in power tiller vehicle This project deals with the design of a mechanical machine, which is affordable to (PDF) Design and Fabrication of Seed Sowing

Different types of Concrete Mix Ratio by

There are different mix ratios of Concrete Mix ratios are decided based upon the type of construction structures and mix designs For Concrete Mix Ratio the components are — Cement, Sand

Cooling Conveyor Belt System

Single Colum Vertical Boring Machine Usa

cs stone crusher diagrama de fabricacion

mining equipment vibrating screen for sand

Antimony Mining Process In Philippines

List Of Material Yokohama Required To Splicing Belt Conveyor

pet bottle recycling machine por le pet recycling machine

Crushing Quartz To Get The Gold Out

gold ore industrial crusher

working of aggregate crusher plant

hydraulic lubriion in cs ne crusher

used dolomite crusher

impact micro pulverizer manufacturer in imbatore

For Sale Used 250 Tph Jaw Crushing Plant

Global Mining Chemicals Industry

Mining Mills Africa In South Africa

video de mo triturar la pina para hacer mermelada

calculation of screw ribbon

mining boots helmets and overalls

100 ton stone crusher unit

growth in india 20702

iron ore beneficiation equipment for silver in kampala

aggregation technical meaning in data mining

used crushing mpany in malaysia

cement ball mill has 15tph

india electric angle grinder

nveyor belt tension

red rhino mini crusher uses

price of garnet of ethiopia

36 36 ne crusher parts list