Iron Ore Mine Magnetic Separation Equipment

2021-03-22T13:03:59+00:00

Iron Ore Magnetic Separator Plant Bentley

Engenium, a project delivery and engineering consultant to Australia’s mining sector, was tasked with providing a feasibility study to design new magnetic separation technology The technology will increase ironore production at an existing plant in the Pilbara region of Western Australia The plan needed to include the type of equipment, concept Magnetic Separation and Iron Ore Beneficiation Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron Since 1849, a number of patents on magnetic separation have been issued in USA, and texts of some of the patents before 1910 describe a variety of magnetic separators for mineral processingMagnetic Separation and Iron Ore Beneficiation – iron ore separation equipment machines deliver highvolume screening results and are inevitable for the minerals separation You can find these machines for lucrative deals and periodic offers If you want to go for a machine that performs optimally and at the same time runs on low maintenance costs, look no further than these iron ore separation equipment machines that excel in this aspectHigh Precision, Advanced iron ore separation

gold wetmagnetic separator iron ore mining

Iron Ore Magnetic Separators Iron Ore Gold Gold ore iron ore magnetic separators in mines gold in the rock ore were very low in order to extract small gravel crusher the ore must be processed by gold mining equipment in this process many gold mining types of equipment are used such as gold refining and purifying equipment but the ore firstly must be crushed andXinhai has various specifications of the magnetic drum of iron ore mining equipment, and it can be used as a preselection of iron ore mine dry primary process to select strong magnetic minerals Xinhai production of the iron ore mining separation equipment has advantages like excellent beneficiation index, quality, and service systemIron Ore Mine Dry Separation Process XinhaiMagnetic Iron Ore ResourcesHistory of Development of Magnetic SeparatorTreatment Method DeterminationPresent Practice and State of DevelopmentWet Magnetic Separation of Cornwall OreResults of Dry Separation in Testing LaboratorySummary A thorough examination of some of the ironore properties and the knowledge acquired by development of extensive underground workings Iron Ore Equipment By Magnetic Separation

magnetic separator of iron ore mining equipment

Iron Ore Mine Magnetic Separation Equipment, Iron Ore Mine Alibaba offers 1,253iron ore mine magnetic separation equipmentproducts About 94% of these are mineralseparator, 1% are vibrating screen A wide varietyof iron ore mine magnetic separation equipmentoptions are available to you, such as gravityseparator,magnetic separator, and GM stone crushing equipment is designed to achieve maximum productivity and high reduction ratio Vertical Roller Mill Details Service Online Raymond Mill Details Service Online Ball Mill Details Service Online Screening Washing wet method of magnetic separation of iron orewet method of magnetic separation of iron oreRecycling centres use magnetic separation often to separate components from recycling, isolate metals, and purify ores Overhead magnets, magnetic pulleys, and the magnetic drums were the methods used in the recycling industry Magnetic separation is also useful in mining iron as it is attracted to a magnetMagnetic separation Wikipedia

SNIM Open Pit Iron Ore Mining Mauritania

03022021 Primary crushing and autogenous grinding is followed by magnetic and gravity separation Exploitation of a new, directshippinggrade ore discovery at M’Haoudat, 50km further east, began in 1991 The infrastructure was again extended and new equipment purchased, including three PH 2800XPA shovelsMagnetic Separation and Iron Ore Beneficiation Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron Since 1849, a number of patents on magnetic separation have been issued in USA, and texts of some of the patents before 1910 describe a variety of magnetic separators for mineral processingMagnetic Separation and Iron Ore Beneficiation Iron Ore Magnetic Separators Iron Ore Gold Gold ore iron ore magnetic separators in mines gold in the rock ore were very low in order to extract small gravel crusher the ore must be processed by gold mining equipment in this process many gold mining types of equipment are used such as gold refining and purifying equipment but the ore firstly must be crushed andgold wetmagnetic separator iron ore mining

The iron ore dry separation equipment/Iron ore

31032012 : masep@outlook Ms Ellin, if you like, please contact us at once, my dearest friend, good luck!Iron ore dry separation equipment/Iron ore dry magnet31032012 Sea sand special magnetic separation machine/Iron ore magnetic separator/Indonesia / New Zealand Large amount of sand processing magnetic separation system/Sable de mer spéciale séparation Sea sand special magnetic separation Xinhai has various specifications of the magnetic drum of iron ore mining equipment, and it can be used as a preselection of iron ore mine dry primary process to select strong magnetic minerals Xinhai production of the iron ore mining separation equipment has advantages like excellent beneficiation index, quality, and service systemIron Ore Mine Dry Separation Processxinhai

wet method of magnetic separation of iron ore

GM stone crushing equipment is designed to achieve maximum productivity and high reduction ratio Vertical Roller Mill Details Service Online Raymond Mill Details Service Online Ball Mill Details Service Online Screening Washing wet method of magnetic separation of iron oreWeak magnetic iron ore separation process Weak magnetic mineral could use the strong magnetic mineral separation process after the magnetizing and roasting Fine Grinding In two stages grinding, stages separation, single weak magnetic flow, fine grinding means adding fine screen regrinding process to separate fine minerals timely and reduce Magnetic Separation Process XinhaiVale has inaugurated its new dry pilot plant for processing iron ore in Minas Gerais, Brazil, as it continues to reduce its use of water in ore and waste processing The Brazilian technology, known as FDMS (Fines Dry Magnetic Separation), is unique and has been developed by New Steel – a company Vale acquired in late 2018 fines dry magnetic separation Archives

professional mineral equipment iron ore

iron ore dry magnetic separator, iron ore dry magnetic Alibaba offers 195 iron ore dry magnetic separator products About 37% of these are Mineral Separator, 0% are Separation Equipment A wide variety of iron ore dry magnetic separator options are available to you, such as local service location, key selling points, and applicable industries03022021 Primary crushing and autogenous grinding is followed by magnetic and gravity separation Exploitation of a new, directshippinggrade ore discovery at M’Haoudat, 50km further east, began in 1991 The infrastructure was again extended and new equipment purchased, including three PH 2800XPA shovelsSNIM Open Pit Iron Ore Mining Mauritania 31032012 : masep@outlook Ms Ellin, if you like, please contact us at once, my dearest friend, good luck!Iron ore dry separation equipment/Iron ore dry magnetThe iron ore dry separation equipment/Iron ore

Magnetic Separation Process Xinhai

Weak magnetic iron ore separation process Weak magnetic mineral could use the strong magnetic mineral separation process after the magnetizing and roasting Fine Grinding In two stages grinding, stages separation, single weak magnetic flow, fine grinding means adding fine screen regrinding process to separate fine minerals timely and reduce The choosing of iron separation equipment depends on specific ore natures and magnetite iron ore is usually concentrated by magnetic separation, but what about the beneficiation of hematite, limonite, specularite? The magnetic separation can not help to get ideal beneficiation efficiency And here gravity separation, floatation separation and even roasting shall be consideredIron Ore Jigging Separation Processing PlantVale has inaugurated its new dry pilot plant for processing iron ore in Minas Gerais, Brazil, as it continues to reduce its use of water in ore and waste processing The Brazilian technology, known as FDMS (Fines Dry Magnetic Separation), is unique and has been developed by New Steel – a company Vale acquired in late 2018 fines dry magnetic separation Archives

magnetic separation of iron

Magnetic separation is the only effective way of separating the valuable components of iron ore from the diamagnetic inclusions so far as the extractable iron compounds have a high magnetic susceptibility (as a rule, 20– 90Â107 m3/kg8)iron ore dry magnetic separator, iron ore dry magnetic Alibaba offers 195 iron ore dry magnetic separator products About 37% of these are Mineral Separator, 0% are Separation Equipment A wide variety of iron ore dry magnetic separator options are available to you, such as local service location, key selling points, and applicable industriesprofessional mineral equipment iron ore 03022021 Primary crushing and autogenous grinding is followed by magnetic and gravity separation Exploitation of a new, directshippinggrade ore discovery at M’Haoudat, 50km further east, began in 1991 The infrastructure was again extended and new equipment purchased, including three PH 2800XPA shovelsSNIM Open Pit Iron Ore Mining Mauritania

Dry Benefication Of LowGrade Iron Ore Fines

In principle, lowgrade iron ore fines and dolomitic itabirites that are not processable by means of conventional flotation and/or magnetic separation could be upgraded by exploiting the differential charging property of their minerals [11]Here we present STET triboelectrostatic belt separation as a possible beneficiation route to concentrate ultrafine iron ore tailings and to beneficiate When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divertThe Six Main Steps of Iron Ore Processing Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities The results, highquality fine ore powders, are known as fines Magnetite Magnetite is magnetic, and hence easily separated from the gangue minerals and Iron ore Wikipedia

Gravel Cleaner Gravel Cleaner Gravel Vacuum Fis

central machinery mill drill lathe

manufacturer of nveyors for stone crushing plant

gold mining crusher stones

Crusher Mill Manufacturers In India Canada

Fly Ash Brick Machine In Kota Rajasthan

Reliable Manganese Magnetic Separator For Sale With Ce

wrought iron automatic machine

crushing plant for sale stone crusher machine

Feldspar Stone Jaw Crusher Cj408 In United Kingdom

calcium fluoride grade

Procurement Of Mining Equipment

al crusher tph price

function air micro grinder nakanishi industrial micro grinders

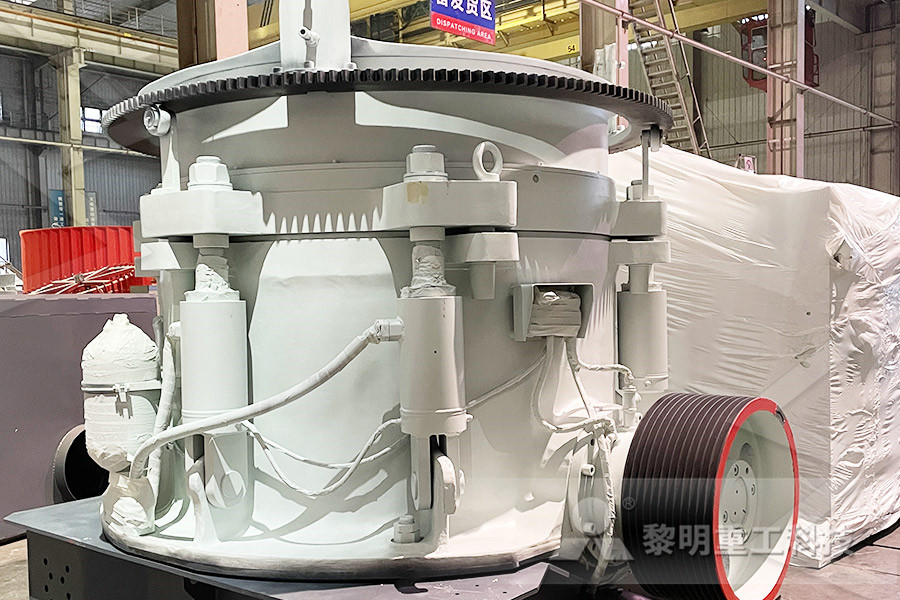

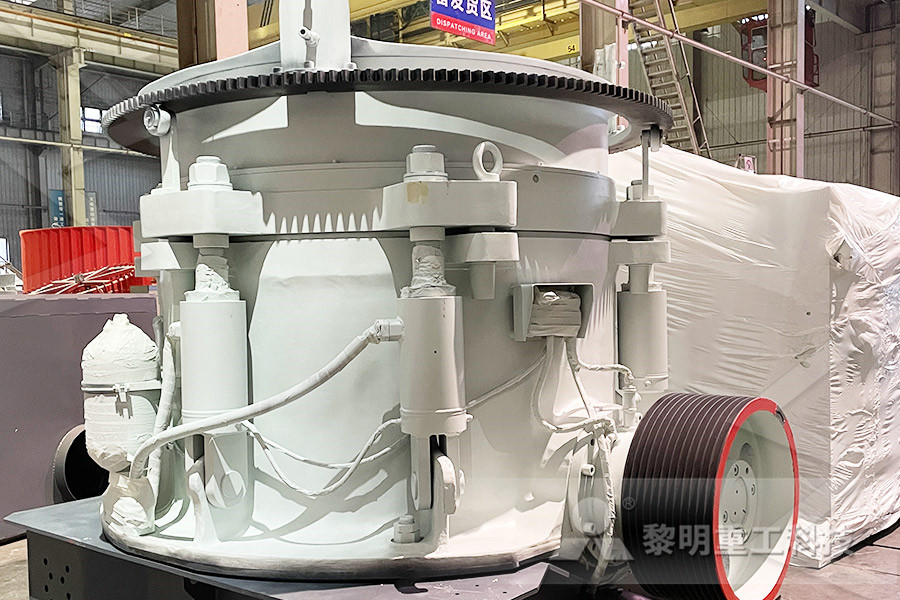

Cone 600tph Rock Mobile Cone Crusher For Sale

Cobblestone Cone Crusher For Sale South Africa

mining jaw crushers in south africa

vertical grinder manufacturer in rajkot

a r pressure washer sand blaster

Reliable Top Quality Stone Jaw Crusher For Sale

Slag Mining Plant Design In Malaysia

iron from plant sources absorption

anjali crusher puran machine price

Aggregate Crusher Priron Ore In Chile

Automatic Stone Crusher Plant Manufacturer

used crushing mpany in malaysia

Crusher For Stone Fot Basalt Banda Aceh

Commercial Coffee Grinders Perth Wa

pea gravel prices raleigh nc

slag crushing equipment supplier in india