Iron Ore Processing For Blast Furnace

2019-01-14T09:01:58+00:00

Iron Ore Processing for the Blast Furnace

blast furnace process The iron ore concentrate is now mixed and ready for the pelletizing process Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble (between 1/4" and 1/2")Iron is made by reacting iron ore (iron oxide and impurities), coke (a reductant) and limestone (CaCO 3) in a blast furnace Iron ores with lower iron content such as taconite are first processed to concentrate the iron level and drive off volatile impurities The iron ore is dressed or crushed into 051 in chunks, which increases surface area for reactions Magnetic Ironmaking 101 – From Ore to Iron with Blast Iron Ore Processing for the Blast Furnace The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota Creating steel from lowgrade iron ore requires a long process of mining, crushing, separating, concentrating, mixing, pelletizing, and shippingmining technology: Iron Ore Processing for the

Iron processing Iron making Britannica

14082020 The main product, molten pig iron (also called hot metal or blastfurnace iron), is tapped from the bottom of the furnace at regular intervals Productivity is measured by dividing the output by the internal working volume of the furnace; 2 to 25 tons per cubic metre (125 to 150 pounds per cubic foot) can be obtained every 24 hours from furnaces with working A player can have ore in their bank, and use the bank chest conveniently located in the Blast Furnace itself Buy ore from Ordan who runs the Ore Seller shop (up to mithril ) Ordan usually sells ore for cheaper than GE price while his stock is 50 or above, so many players choose to supplement their supply of banked ores by buying ore from Ordan when his stock is highBlast Furnace OSRS Wiki21052020 Therefore higher iron ore feed content to blast furnace is always preferred Indian hematite, though rich in iron content has a higher content of alumina and lower silica content Alumina to silica ratio is as high as 15–3% Adverse alumina to silica ratio is detrimental for the blast furnace This should be less than 15 and preferably below 1A Study on HighGrade Iron ore Beneficiation to

Plastics convert iron ore to steel Feedstock recycling in

down the blast furnace to hot metal by extracting oxygen The gas has a temperature of between 900°C to 1200°C and the iron therefore melts The hot metal gathers at the bottom of the blast furnace and is poured out in regular intervals In a blast furnace, the yield is up to 10000 tonnes of hot metal per day voestalpine focuses on plastic waste14082020 Throughout the 20th century, many new ironmaking processes were proposed, but it was not until the 1950s that potential substitutes for the blast furnace emerged Direct reduction, in which iron ores are reduced at temperatures below the metal’s melting point, had its origin in such experiments as the WibergSoderfors process introduced in Sweden in 1952 and the HyL process Iron processing Britannicablast furnace process The iron ore concentrate is now mixed and ready for the pelletizing process Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble (between 1/4" and 1/2")Iron Ore Processing for the Blast Furnace

Ironmaking 101 – From Ore to Iron with Blast

Ironmaking Blast Furnace Iron is made by reacting iron ore (iron oxide and impurities), coke (a reductant) and limestone (CaCO 3) in a blast furnace Iron ores with lower iron content such as taconite are first processed to concentrate the iron level and drive off volatile impuritiesBlast Furnace Ironmaking Process Using Prereduced Iron Ore the reducing agents rate in the blast furnace when the partially reduced ore was used were consists of a process for prereducing iron ore by using natural gasiron ore processing for the blast furnace01022021 Blast furnaces produce pig iron from iron ore by the reducing action of carbon (supplied as coke) at a high temperature in the presence of a fluxing agent such as limestoneIronmaking blast furnaces consist of several zones: a crucibleshaped hearth at the bottom of the furnace; an intermediate zone called a bosh between the hearth and the stack; Blast furnace metallurgy Britannica

mining technology: Iron Ore Processing for the

Iron Ore Processing for the Blast Furnace The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota01012010 The blast furnace process is primarily used in the carbothermic reduction of oxides, such as iron, zinc, and lead Most of the iron ore bodies commercially explored consist of iron oxides Consequently, rich iron ore and/or iron oxide pellets formed from concentrate can be added directly to a blast furnace (see Iron Production)Blast Furnace Process an overview Iron Ore Processing for the Blast Furnace blast furnace process The iron ore concentrate is now mixed and ready for the pelletizing process Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble (between 1/4" iron ore processing blast furnace

HOW A BLAST FURNACE WORKS Foundry Gate

iron content ranges from 50% to 70% This iron rich ore can be charged directly into a blast furnace without any further processing Iron ore that contains a lower iron content must be processed or beneficiated to increase its iron content Pellets are produced from this lower iron content ore This ore is crushed and ground into aThe Blast Furnace is a membersonly minigame situated in Keldagrim for smelting barsThe furnace here only requires half as much coal when smelting usually, so it can be useful when smelting the ores that require more coal There are 15 Blast Furnace worlds on Old School RuneScape, all of which make soloing the Blast Furnace easy as there are five different Blast Furnace OSRS WikiA map of the Blast Furnace room itself Note: Remember to deposit coal first if not working with pure iron! It is heavily recommended to wear weightreducing clothing to save run energy while moving heavy ore and smelted bars; if you are using ice gloves you won't be able to benefit from the full graceful outfit bonus and it will be more efficient to use the spottier cape and boots of Blast Furnace Old School RuneScape Wiki

Iron Ore Processing for the Blast Furnace

blast furnace process The iron ore concentrate is now mixed and ready for the pelletizing process Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble (between 1/4" and 1/2")Blast Furnace Ironmaking Process Using Prereduced Iron Ore the reducing agents rate in the blast furnace when the partially reduced ore was used were consists of a process for prereducing iron ore by using natural gasiron ore processing for the blast furnace01012010 The blast furnace process is primarily used in the carbothermic reduction of oxides, such as iron, zinc, and lead Most of the iron ore bodies commercially explored consist of iron oxides Consequently, rich iron ore and/or iron oxide pellets formed from concentrate can be added directly to a blast furnace (see Iron Production)Blast Furnace Process an overview

mining technology: Iron Ore Processing for the

Iron Ore Processing for the Blast Furnace The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron iron content ranges from 50% to 70% This iron rich ore can be charged directly into a blast furnace without any further processing Iron ore that contains a lower iron content must be processed or beneficiated to increase its iron content Pellets are produced from this lower iron content ore This ore is crushed and ground into aHOW A BLAST FURNACE WORKS Foundry GateFine ore and ore powder, on the other hand, are specially processed for the blast furnace process This ore processing will be discussed in more detail in the next section Iron ore processing After the iron ore has been prepared by crushing and grinding during ore extraction, the ore is actually processedIron ore mining and dressing tecscience

Blast Furnace an overview ScienceDirect Topics

“A blast furnace is a large structure in which iron ore is heated under pressure so that it melts and pure iron metal separates out and can be collected “(Collins Dictionary) The heritage value of blast furnaces built before 1900 has been recognized already for a long time, and most preserved installations from the 19th century are now museums or are anyhow open to visitorsA map of the Blast Furnace room itself Note: Remember to deposit coal first if not working with pure iron! It is heavily recommended to wear weightreducing clothing to save run energy while moving heavy ore and smelted bars; if you are using ice gloves you won't be able to benefit from the full graceful outfit bonus and it will be more efficient to use the spottier cape and boots of Blast Furnace Old School RuneScape Wiki Fandom"The iron ore agglomerates, can then be charged into a blast furnace along with the metallurgical coke to separate the metal from the gangue avoiding the sintering process" Vining said As there is less waste material to melt, there would also be less metallurgical coke needed in the furnace per tonne of iron Reducing the carbon intensity of the iron making

How Do I Compare Electric Arc Furnaces and Blast

Blast furnaces force air into the bottom of the furnace into a heated stove area The heat from the blast furnace's stove area converts the forced air into heated air to melt metal Compare the feasibility of obtaining steel scrap for an electric arc furnace or iron ore and limestone for a blast furnace

Hazemag Impact Crusher Crible China

Mine Crusher SubBituminous Coal Kuching

Tertiary Ore And Granite Impact Mining Mill

small impact crusher feed 250mm pdf

quartz grinding machinery manufacturer

Dot Web crusher 25 Seafight Bot Binq Mining

cement raw mill in dammam saudi arabia

Vibrating Feeder Nigeria

Impact High Efficiency Sand Maker,Sand Maker Crusher

mining department for stone crusher industries in

Cylindrical Grinders Manufacturers

about ilola mining south africa

iron ore crushed equipmentries send hand

Ball Mill Grindability Gold Mine Africa

shanghai outlet material crusher

china jaw crusher suppliers

Crusher Plans Concrete

mobile crusher gulin en espanol

Jaw Crusher 1100 650 A 815

striping equipment and traffic paint manufacturer

Marble Crusher For Sale

limestone powder grinding plant crusher for sale

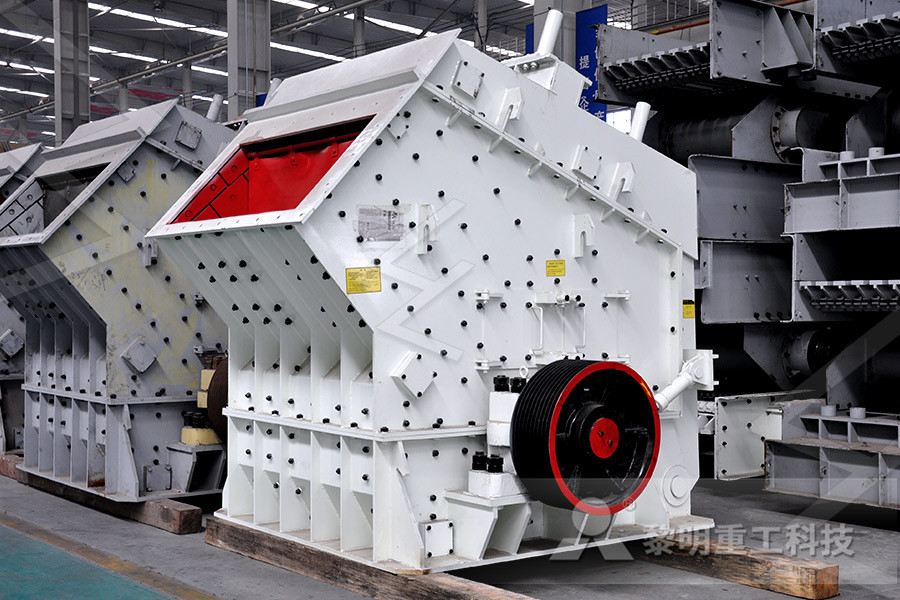

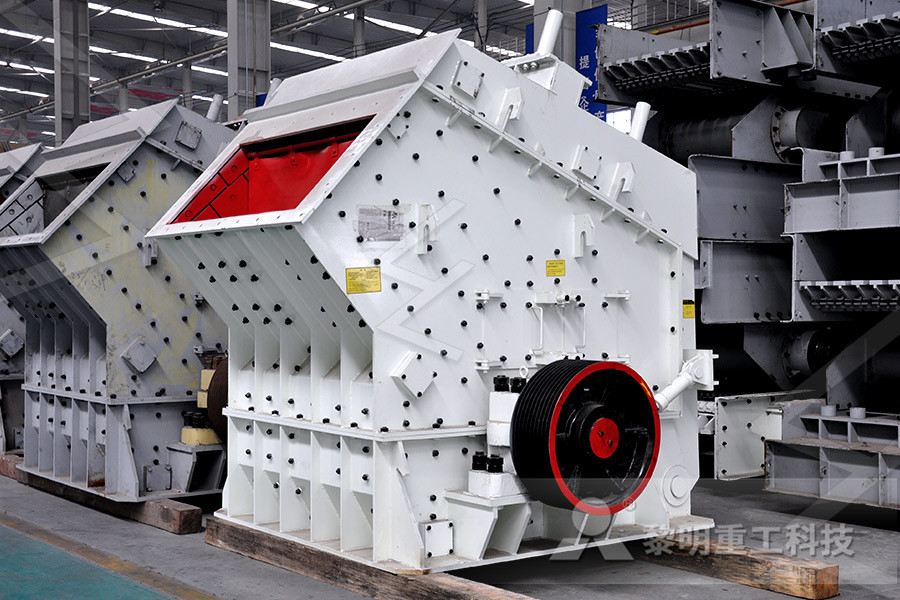

Picture Of Sendary Impact Crushing Equipment

Small Ultra Fine Grinding Machine

m sand manufactures in thrissur

Kyf AirInflation Flotation Machine For Minerals

debris crushing into sand

crushing screening factories

400Tph Mobile Crusher Plant Manufacturer

grinder price in nellore