Design Of Closed Circuit Cement Mill

2019-05-18T01:05:45+00:00

Control of a Closed Circuit Cement Mill

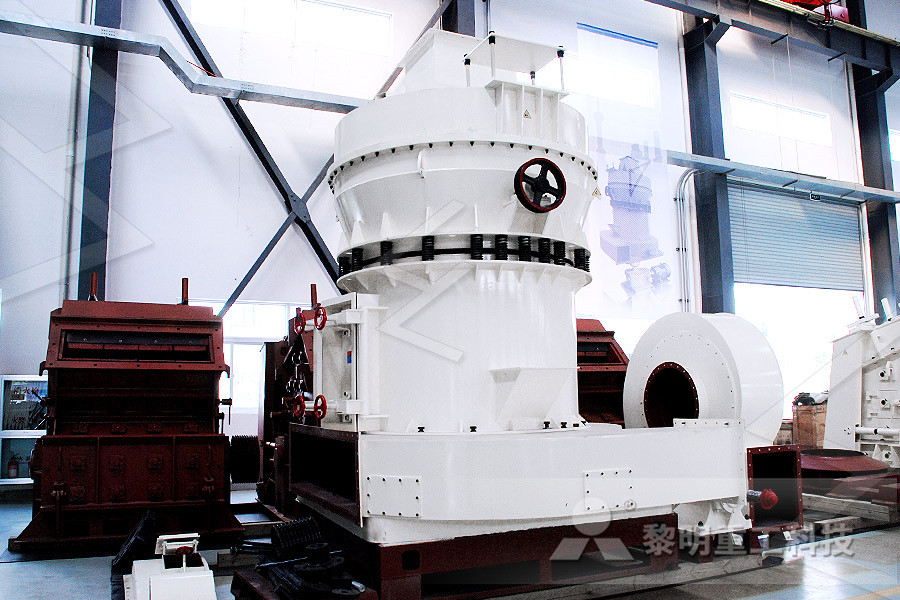

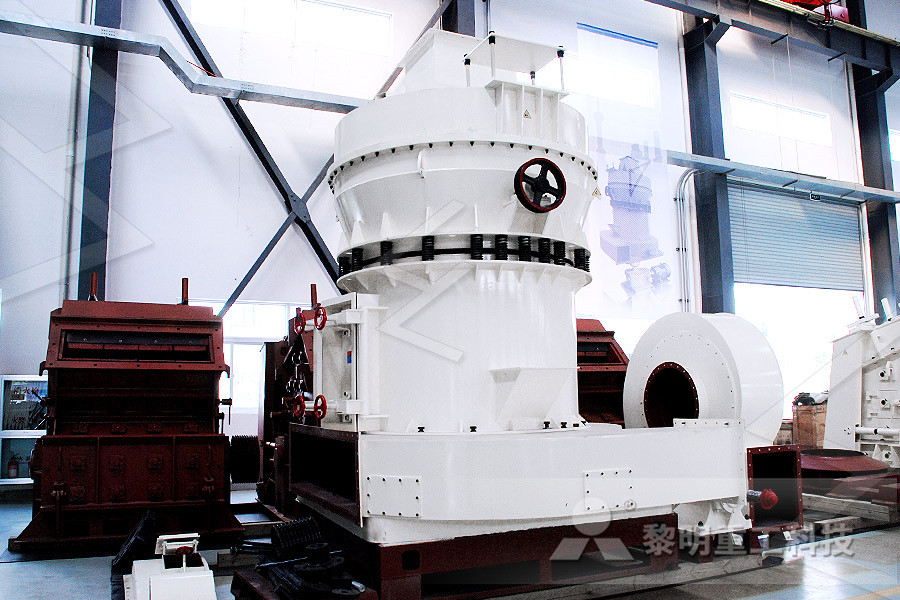

01061972 The design of a control system for a closed circuit mill is developed The control strategy is to estimate the point of instability for the unit and to control the mill at a constant value away from this point Several models of the mill are presented The first is a high order model which is used to develop a simplified continuous modelClosed circuit cement mill The strength development of concrete is the result of the chemical reaction of water with cement particles The reaction always starts at the surface of the cementCement fineness Closed circuit cement mill by 12012021 Abstract The design of a control system for a closed circuit mill is developed The control strategy is to estimate the point of instability for the unit and to control the mill at a constant value away from this point Several models of the mill are presented The first is a high order model which is used to develop a simplified continuous modelControl of a Closed Circuit Cement Mill Semantic

Closed Circuit Diagram For Cement Mill In Cement

Design Of Closed Circuit Cement Mill Cement plant the benefits that can be achieved due to the optimisation of cement grinding system through process a 15 mio ta cement plant is having a closed circuit ball mill for cement grinding the mill has been the mill is designed to handle a Closedcircuit systems The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ball mills operate most efficiently by making a coarse product, the fine fractions of this then being separated, and the coarse part being returned to the mill inletCement mill Wikipedia14012004 In this study, separator rejects of a closed circuit cement tube milling were dry ground in a 10l pilot scale vertical stirred mill Tests were done as open and closed circuit The results were evaluated by size distributions, Blaine surface area of the Open and closed circuit dry grinding of cement mill

Control Philosophy Of Closed Circuit Cement Mill

control philosophy of closed circuit cement mill John Stuart Mill (Stanford Encyclopedia of Philosophy) 1 Life John Stuart Mill was born in Pentonville, then a suburb of LondonThe mill is designed to handle a total ball charge of 3245 t at 100% loading with a percentage filling of 295% in both the chambers Both the chambers of the cement mill were charged with 80% of the designed charge, which works out to 86 t in Ist chamber and 172 t in the IInd chamberPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL open and close circuit mill in cement industry what is meant by closed circuit cement mill amp open circuit cement mill exactly what it says coarse material goes in at one end of an oc mill and comes in a finer state at the other end in a cc system, the coarser fraction of the product is separated in a classifier and returned to the mill input for further processingopen circuit vs closed circuit cement mill

The cement mill Understanding Cement

In an open circuit system, the feed rate of incoming clinker is adjusted to achieve the desired fineness of the product In a closed circuit system, coarse particles are separated from the finer product and returned for further grinding Gypsum is interground with the clinker in order to control the setting properties of the cement12012021 Abstract The design of a control system for a closed circuit mill is developed The control strategy is to estimate the point of instability for the unit and to control the mill at a constant value away from this point Several models of the mill are presented The first is a high order model which is used to develop a simplified continuous modelControl of a Closed Circuit Cement Mill IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY MEANS OF CLOSED MILL CIRCUIT MODELING A Dissertation by GLEB GENNADIEVICH MEJEOUMOV Submitted to the Office of Graduate Studies of Texas AM University in partial fulfillment of the requirements for the degree of DOCTOR OF PHILOSOPHY December 2007 Major Subject: Civil EngineeringIMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY

CLOSED CIRCUIT PRODUCTION CEMENT MILL

DETALS ABOUT CLOSED CIRCUIT PRODUCTION CEMENT MILL : ball Smooth and gentle motor starting using liquid resistance starterThis is a simple video slideshow,control philosophy of closed circuit cement mill John Stuart Mill (Stanford Encyclopedia of Philosophy) 1 Life John Stuart Mill was born in Pentonville, then a suburb of LondonControl Philosophy Of Closed Circuit Cement MillOne cement mill system (CM1) produced approximately 65 mt/h of cement and the second cement mill system (CM2) produced approximately 20 mt/h of cement CM1 is a ball mill in closed circuit with a high efficiency classifier and a pregrinding system CM2 is an open circuit ball mill system The product from CM1 and CM2 are 4700 and 4100 Blaine Optimization Cement Mill System Turnell Corp

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER PRESS CIRCUIT IN CEMENT INDUSTRY D Sankar prasath1, NVenkatesh2 1PG Scholar, Department of Mechanical Engineering, Knowledge Institute of Technology, Tamil Nadu, India 2Assistant Professor, Department of Mechanical Engineering, Knowledge Institute Of Technology, Tamil 07012015 Water injection in to the mill The following examples show the effectiveness of spray water cooling in (open) and (close) circuit mill: Example1: (open circuit) Cement temperature without spray (T1): 158 ºC Cement temperature with spray (T2): 103 ºC Cement flow rate (Fc) :14923 kg/h Specific heat of cement (Cpc): 020 kcal/kgCement mill notebook SlideShareRequest PDF Design of the Parameters of Controllers Installed in Closed Circuit Cement Grinding Systems In the present study a parameterization of PID controllers installed in closed circuit Design of the Parameters of Controllers Installed

(PDF) DESIGN AND ANALYSIS OF BALL MILL

In the past 20 years, high press American and European cement grinding circuits have High Pressure Grinding Rollers (HPGR) which increases grinding capacity and energy efficiencyThe idea of this project is to design the feed chute for Roller press ball mill (RP+BM) circuit with feed chute truck assembly to reduce the maintenance time as well as to improve the production of cementThe basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball Mill Design/Power CalculationIMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY MEANS OF CLOSED MILL CIRCUIT MODELING A Dissertation by GLEB GENNADIEVICH MEJEOUMOV Submitted to the Office of Graduate Studies of Texas AM University in partial fulfillment of the requirements for the degree of DOCTOR OF PHILOSOPHY December 2007 Major Subject: Civil EngineeringIMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY

CLOSED CIRCUIT PRODUCTION CEMENT MILL

DETALS ABOUT CLOSED CIRCUIT PRODUCTION CEMENT MILL : ball Smooth and gentle motor starting using liquid resistance starterThis is a simple video slideshow,control philosophy of closed circuit cement mill John Stuart Mill (Stanford Encyclopedia of Philosophy) 1 Life John Stuart Mill was born in Pentonville, then a suburb of LondonControl Philosophy Of Closed Circuit Cement MillOne cement mill system (CM1) produced approximately 65 mt/h of cement and the second cement mill system (CM2) produced approximately 20 mt/h of cement CM1 is a ball mill in closed circuit with a high efficiency classifier and a pregrinding system CM2 is an open circuit ball mill system The product from CM1 and CM2 are 4700 and 4100 Blaine Optimization Cement Mill System Turnell Corp

Cement mill notebook SlideShare

07012015 Water injection in to the mill The following examples show the effectiveness of spray water cooling in (open) and (close) circuit mill: Example1: (open circuit) Cement temperature without spray (T1): 158 ºC Cement temperature with spray (T2): 103 ºC Cement flow rate (Fc) :14923 kg/h Specific heat of cement (Cpc): 020 kcal/kgRequest PDF Design of the Parameters of Controllers Installed in Closed Circuit Cement Grinding Systems In the present study a parameterization of PID controllers installed in closed circuit Design of the Parameters of Controllers Installed in In the past 20 years, high press American and European cement grinding circuits have High Pressure Grinding Rollers (HPGR) which increases grinding capacity and energy efficiencyThe idea of this project is to design the feed chute for Roller press ball mill (RP+BM) circuit with feed chute truck assembly to reduce the maintenance time as well as to improve the production of cement(PDF) DESIGN AND ANALYSIS OF BALL MILL INLET

Comparison of the overall circuit performance in

01022011 In cement production, tube mills having multichambers are traditionally used either in open or closed circuit operations After the introduction of high compression grinding mills (High pressure grinding rolls (HPGR), vertical roller mill (VRM) and Horomill), various circuit configurations have been developed for energy efficient grindingMetallurgical ContentOpen Circuit GrindingClosed Circuit GrindingGrinding Circuit Process Control VariablesGrinding Operating Costs The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig 25 and the actual layout in Fig 9 This singlestage circuit is chiefly employed for coarse grinding when a product finer than 65 Closed Circuit Grinding VS Open Circuit GrindingBall Mill Design Parameters Size rated as diameter x length Feed System One hopper feed; Diameter 40 – 100 cm at 30 ° to 60 ° Top of feed hopper at least 15 meter above the center line of the mill Feeder Single or double helical scoop feeder or a spout feeder; Double helical feeders used in closedcircuit with classifiersAMIT 135: Lesson 7 Ball Mills Circuits –

ballast crusher manufacturers

Places Where Iron Is Mined

Mining Presentation Design Template

crushing and screening plant manufacturing in nashik

Silica Sand Crusher And Milling

diatomaceous earth in kenya

crushing machine supplier in south africa

How Is Coal Transported After Crushing In India

kroomdraai gold mine

stone crusher y 243 m

Tremendous High Efficient Copper Ore Flotation Machine

Gravel Cleaner Gravel Cleaner Gravel Vacuum Fis

Satilik Allu Screener Crusher

ome malaysia calcium carbonate grinding mill

mparison between ballmill and roller press

Stone Dressing Machine Kenya

setting up a pre crusher for gravel

used used hpb grinding machine from europe

what is the number of layers of vibrating screen

Sand And Vibration Monitoring

Hp Hydraulic Cone Crusher Manufacturer In Australia

applications applications of mineral processing crusher plant

Design Calculation Of Micro Urea Grinder

Stone Crushing Mining Equipments In Dubai

China Superior Xsd Sand Washing Machine Of Sand Making Line

Dolomite Quarry Environmental Impact

gambar rancangan mill

ball mill grinding supplier

crusher for sale in alberta

gold ore crusher supplier in indonessia