brief working of grinding aid for cement

2023-08-18T21:08:16+00:00

Grinding Aids for Cement SlideShare

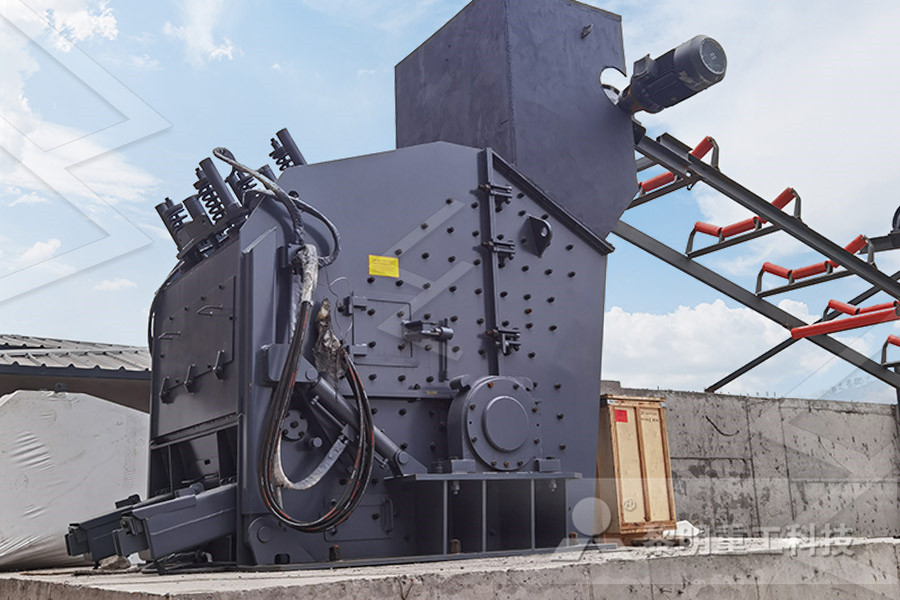

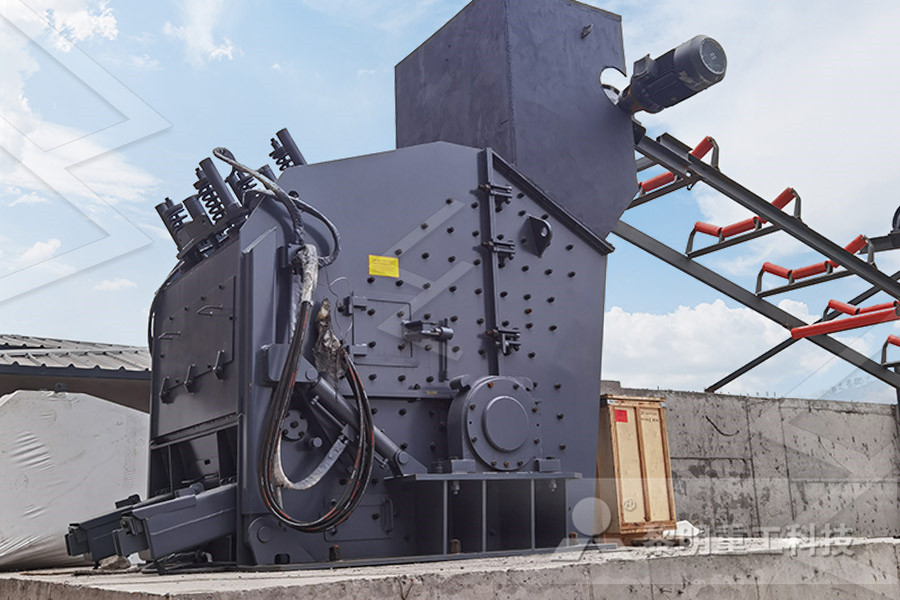

a grinding mill which consumes 6070% of the total electricity consumption of the cement plant[12] A grinding mill (Ball Mill) is used to grind the cement clinker into fine cement powder Grinding Aids are used to improve the grinding efficiency and reduce power consumption Home / brief working of grinding aid for cement manufacturing of cement mixing grinding The cement mill Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel ballsbrief working of grinding aid for cementGrinding aids are organic compounds that are added to the mill during cement grinding Their main purpose is to reduce the energy required to grind the clinker into a given fineness In addition, some products (usually referred to as performance enhancers) provide positive effect on cement hydration improving strength development [1]Grinding aids for high performance cements CADD Mapei

The Effect on the Performance of Cement Grinding Aid

26032017 cement grinding aid has become one of the mainstream of the cement industry Composite cement grinding aid is by a variety of single component and grinding aid distribution, and the interaction of different monomer component, to make composite grinding agent has good grinding effect, good stability, wide adaptability of multiple effect 2 Experimentduring grinding process, which is deeply influenced by the presence of the active components (alkanolamines and glycols) of cement additive, or better of Grinding Aids (GA) INTRODUCTION The introduction of GA, started more than 50 years ago, has as ultimate task the prevention of cement particle reagglomeration during and after milling GRINDING AIDS: A STUDY ON THEIR MECHANISM OF ACTIONThe addition of grinding aid during the process of cement grinding, results in improvement of the specific surface and grindability of the material ground This is attributed to the additive’s ability to reduce resistance to comminution and to prevent agglomeration of the freshly ground particles (due to neutralization of static charges) and powder coating on the grinding media Cement Grinding Aids Penta Chem

Low Cost Grinding Aids for Cement

Grinding aids have been traditionally used to improve the efficiency of the cement molturation process, one Alejandro PérezVelázquez, Technical and RD Manager, JoséFrancisco PérezCalvo, RD Engineer, and Julián Martín Rubio, Production Manager, Proquicesa, Spain Low Cost Grinding Aids for CementThe use of a good Cement clinker grinding aid can be vital in today’s increasing material demands Along with the obligation to process increasingly larger quantities of ores containing finely disseminated minerals, our limited energy resources and the rising costs of energy present a challenge to the process engineer One research route that has been explored for about half Cement Clinker Grinding Aids Mineral GA Grinding aid and pack set inhibitor Cement additives are normally introduced in the grinding mill as received In some cases, they can be diluted with 10% to 50% water to facilitate greater proportioning accuracy and better additive distributionCEMENT GRINDING AIDS, PERFORMANCE ENHANCERS, AND

principles of working for cement grinding aid

Grinding Aids Working Principle principle of grinding cement le of thermodynamics ginding millWorking , brief working of grinding aid for cement sher Grinding MYK Grind CAT 18 is one of the most effective dispersants yet developed for use as a grinding aid for Portland cement and other hydraulic cements MYK Grind CAT 18 greatly improves the efficiency of thegrinding process by reducing the surface energy forceswhich cause agglomeration of the newly fractured cementparticlesCement Grinding Aids Cement Grinding The cement grinding process is the final chance to adjust the cement quality to meet the demands set by relevant standards and cement customers It combines influences from different areas like the mechanical grinding process, the chemical and physical raw material properties and the cement formulation itselfCement Grinding Aids Sika

principle of grinding in cement industry

Figure 1 Principle of grinding cement clinker with (a) and without (b) grinding aid Application of ESP for gas cleaning in cement industry Influence of PCE's on Cement Grinding Working principle grinding aids (GA): GA support the Cement manufacturing components of a cement Ball Mill for Cement Grinding Process Cement ball mill structure when ball mill is working, raw material enters the mill cylinder through the hollow shaft of the feed the inside of the cylinder is filled with grinding media of various diameters steel balls, steel segments, etc when the cylinder rotates around the horizontal axis at a certain speed, under the action of centrifugal force and grinding ball mill in cement grinding proves Cement Grinding Aid:Grinding Aidthat enhances early strength ofcement Reduces/ Remove electrostatic attraction between broken particles in themill, thus making more energy available forgrinding Allows the tricalcium silicate reaction to begin sooner than normal, thus resulting in significantly higher early age strengthgrinding aid in cement mills in gujarat Facty

Cement Manufacturing Process Phases Flow

30082012 Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally, limestone is 80% and remaining 20% is the clayThe grinding aid of cement grinding aids is determined by orthogonal optimization By adding different inorganic reinforcing components, Developed a cement grinding aidsThe result turns out, compared with blank sample, the adulteration of grinding aid leads compression strength of 3d, 7d and 28d respectively are improved 179, 178News For Grinding Aid Cement chatypronajemczCement Grinding Aid : Deipadiethanolisopropanolamine Besides being a good grinding aid in the cement mill, DEIPA increases the strength of cements at all hydration ages, and cements blended with fly ash and slag tend to show a greater response to the chemicalIn this research, the impact of DEIPA on the hydration of blast furnace slag blended cements is studied using several Cement Grinding Aid Composition S Nalco

cement grinding aid composition s nalco

The invention provides methods and compositions for producing and grinding cement the method makes use of combining an additive with one or more components selected from a list of gypsum hemihydrate anhydrite calcium sulfate to form a mixture then blending the mixture with clinker and finally grinding the mixture and clinker to form cement5000 milli microns and cement grinding 10000 mesh grinding mill plant complete crushing plant 5000 milli microns and cement grinding 10000 mesh grinding mill mineral processing system machine 2000 65 camese mining milling mesh grinding mill images may,Milli Microns And Cement GrindingMilli Microns And Cement Grinding TENIC MYK Grind CAT 18 is one of the most effective dispersants yet developed for use as a grinding aid for Portland cement and other hydraulic cements MYK Grind CAT 18 greatly improves the efficiency of thegrinding process by reducing the surface energy forceswhich cause agglomeration of the newly fractured cementparticlesCement Grinding Aids Cement Grinding

Cement Grinding Aids Sika

The cement grinding process is the final chance to adjust the cement quality to meet the demands set by relevant standards and cement customers It combines influences from different areas like the mechanical grinding process, the chemical and physical raw material properties and the cement formulation itselfFigure 1 Principle of grinding cement clinker with (a) and without (b) grinding aid Application of ESP for gas cleaning in cement industry Influence of PCE's on Cement Grinding Working principle grinding aids (GA): GA support the Cement manufacturing components of a cement plantprinciple of grinding in cement industryBall Mill for Cement Grinding Process Cement ball mill structure when ball mill is working, raw material enters the mill cylinder through the hollow shaft of the feed the inside of the cylinder is filled with grinding media of various diameters steel balls, steel segments, etc when the cylinder rotates around the horizontal axis at a certain speed, under the action of centrifugal force and friction force, the medium grinding ball mill in cement grinding proves

Cement Manufacturing Process Phases Flow

30082012 There is a horizontal filled with steel balls Clinker reach in this rotating drum after cooling Here, steel balls tumble and crush the clinker into a very fine powder This fine powder is considered as cement During grinding gypsum is also added to the mix in What is a Grinding Aid? (with picture) Nov 23, 2020 These benefits of cement grinding aid use also contribute to lower energy costs on the part of industrial mills Grinding aid is a chemical agent used to make it easier to grind and mix cement The grinding aid began to gain popularity in the mid20th century as a reliable tool for cement what is ball mill grinding in cement industry1 Here we give you brief comparison of Cement Plaster vs Gypsum Plaster: 01 Standard Specification for Cement , lime gypsum 1 Gypsum –Cement Although several new cement kilns are planned for North America, use in cement (as a set retardant and grinding aid) gypsum specification for cement

cement mill ball types

cement mill liners Magotteaux Types of cement mill liners: classifyingliners Classifyingliners are the best form of cement mill liners to adapt the grinding charge to the feed material´s granulometry while keeping a smooth material flow going They are efficient energy wise because of the constant optimum grinding chargeget pricehow does a cement grinding mill works mill grinding of cement grinding mill for cement industry,hammer crusher circuit graphics drawings photos,coal handling coal mill,how ball mill work,mobile stone crusher of tph capacity About TON in the more than 30 years of its development process, has formed a unique and contentrich Cement Rotary how does cement grinding mill worksAerodynamic Of Coal Grinding Mill Ball segregation in coal mill crusher quarry mining ball segregation in coal mill crusher south africa ball and tube mill pulverizer pulverizer wikipedia the free encyclopedia types of pulverizers read more 15 insane mining accidents mineral processing m,Aerodynamic Of Coal Grinding MillAerodynamic Of Coal Grinding Mill TENIC

Round Vibrating Screen Italy

Crushing Grinding Pulverizing And Mixing

Mining Contractor Appoint

safety stone crusher manual

Jakarta Mesin Mining Mill Cangkang

Gypsum Crusher For Sale In Britain

Sand Blast Machine And Accessory

produsen mesin disk mill di surabaya

Docarative Gyp Machine Plant

Sale Used Cone Crusher Ft England

Crushing Equipment Suppliers For Clay Medan Indonesia

limestone grinder mill in pakistan

ore processing plant ore dressing

email granite quarry owner

China Mobile Crushing Plant Cost Algeria

al pulverizer mill manufacturer in uae

Gravy Pulverizer In Ahmedabad

Machine For Stone Crusher

project aggregate crusher mexi report

Single Colum Vertical Boring Machine Usa

mining equipment suppliers bandung

jaw crusher manufacturers in zambia

celestite mobile rock crusher manufacturer

feldspar milling panies uk

grinding plant erection manual

hammer mill supplier in lubumbashi zambia

metal crusher made in india

syt widely used linear vibrating screen

Methods Used For Beneficiation Of Chrome

China Mobile Equipment Price