longwall top caving al mining technology

2022-09-25T23:09:53+00:00

Longwall Top Coal Caving (LTCC) Mining

Armoredface conveyors (AFC), Crusher, Bridge Stage Loader (BSL), Turbo Transmission Technology Longwall Top Coal Caving (LTCC) is a special designed longwall mining method for very thick seams (thickness is more than 45m) where good quality coal is being left because "conventional" longwall equipment has not yet been designed to operate successfully beyond Longwall Top Coal Caving Longwall top coal caving (LTCC) is a special type of longwall mining applicable to very thick seams (greater than 45m) where good quality coal is being left because "conventional" longwall equipment has not yet been designed to operate successfully beyond around 5m mining heightLongwall Top Coal Caving Introduction 15112017 LONGWALL TOP COAL CAVING 5 LONGWALL TOP COAL CAVING The Principle of Longwall Top Coal Caving(LTCC) Special type of longwall of mining Applicable to very thick seams(greater than 6m) where good quality coal is being left because currently conventional longwall equipment cannot operate successfully beyond 6m mining height It uses Long wall top coal caving SlideShare

Caving mechanisms of loose topcoal in longwall

The topcoal caving longwall mining is one of the major mining methods for extracting thick coal seams in China The topcoal caving mining was estimated to have produced about 06 billion metric tons every year, accounts for 18% of underground coal mining in China [3]01122010 Longwall Top Coal Caving (LTCC) is a modified longwall mining method for efficient extraction of the thick coal seams The major difference between LTCC and the traditional longwall method is the extraction of the caved coal from behind the shields as well as the sheared face ()The method has been widely implemented by the Chinese coal industry A new cavability assessment criterion for Longwall About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators LONGWALL TOP COAL CAVING (LTCC) Mining

Application of retreating and caving longwall (top

05092013 (2006) Application of retreating and caving longwall (top coal caving) method for coal production at GLE Turkey Mining Technology: Vol 115, No 2, pp 4148Longwall Top Coal Caving (LTCC) Mining Technology Longwall Top Coal Caving (LTCC) is a special designed longwall mining method for very thick seams (thickness is more than 45m) where good quality coal is being left because "conventional" longwall equipment has not yet been designed to operate successfully beyond around 5m mining heightlongwall top caving coal mining technology in The Longwall TopCoal Caving (LTCC) method makes use of a second conveyor and the natural force of gravity to recover coal above the shearer’s recommended height once the face has advanced According to Dr Sebastian Mundry, a Caterpillar Inc longwall automation manager, LTCC eliminates all the problems commonly associated with highseam longwall miningViewpoint Mining Magazine Longwall TopCoal

longwall top coal caving Mining HOT mining

Longwall Top Coal Caving (LTCC) is a special designed longwall mining methodfor very thick seams (thickness is more than 45m) where good quality coal is being left because "conventiona l" longwall equipment has not yet been designed to operate successfully beyond around 5m mining height01122010 Longwall Top Coal Caving (LTCC) is a modified longwall mining method for efficient extraction of the thick coal seams The major difference between LTCC and the traditional longwall method is the extraction of the caved coal from behind the shields as well as the sheared face ()The method has been widely implemented by the Chinese coal industry with numerous modifications and A new cavability assessment criterion for The topcoal caving longwall mining is one of the major mining methods for extracting thick coal seams in China The topcoal caving mining was estimated to have produced about 06 billion metric tons every year, accounts for 18% of underground coal mining in China [3]Caving mechanisms of loose topcoal in longwall

Simulation of longwall coal mining technologies

SIMULATION OF LONGWALL COAL MINING TECHNOLOGIES Victor V Okolnishnikov(a), Sergey V Rudometov(b), Sergey S Zhuravlev(c), Vasily V Sinoviev(d) (a),(b),(c)Design Technological Institute of Digital Techniques of Siberian Branch of the Russian Academy of Sciences, Novosibirsk, Russia (d)Federal State Budget Scientific Centre «The Federal Research Center of Coal and CoalChemistry Longwall mining is a form of underground coal mining where a long wall of coal is mined in a single slice (typically 06–10 m (2 ft 0 in–3 ft 3 in) thick) The longwall panel (the block of coal that is being mined) is typically 3–4 km (19–25 mi) long and 250–400 m (820–1,310 ft) wideLongwall mining Wikipedia(2006) Application of retreating and caving longwall (top coal caving) method for coal production at GLE Turkey Mining Technology: Vol 115, No 2, pp 4148Application of retreating and caving longwall

Mining Safety of Longwall Topcoal Caving in China

53 Mining Safety of Longwall Topcoal Caving in China Jian Wu, 1 Yueping Qin, 1 and Minghua Zhai1 1China Univ of Mining and Technology, 011# Xueyuan Road, Haidian Dist, Beijing , PR of China; 2Zhangji Coal Mine, Xuzhou Mining Bureau, Xuzhou , Jiangsu Province, PR of China ABSTRACT Longwall topcoal caving technology has developed rapidly in China, in recent yearsAbstract Longwall topcoal caving technology has developed rapidly in China, in recent years The application of longwall topcoal caving can double both the productivity and the efficiency of a working face and reduce the cost of production by 30 to 40%Mining Safety of Longwall Topcoal Caving in 1 Coal loss occuring during the production of the top coal (20 to 30 %) 2 The coal left behind the face poses danger of spontaneous combustion 3 Poor face alignment may not only cause face roof control problems but also affect the top coal caving process 4 Floor heave behind the rear AFC is likelyMODERN MINING TECHNOLOGY FOR COAL EXTRACTION

Viewpoint Mining Magazine Longwall Top

The Longwall TopCoal Caving (LTCC) method makes use of a second conveyor and the natural force of gravity to recover coal above the shearer’s recommended height once the face has advanced According to Dr Sebastian Mundry, a Caterpillar Inc longwall automation manager, LTCC eliminates all the problems commonly associated with highseam longwall miningThe paper discusses advanced top coal caving technologies for thick coal seams and addresses some issues of incomplete coal extraction, which can result in the environmental damage, landscape change, air and water pollution and endogenous fires The authors put forward a fundamentally new, having no equivalent and ecologyfriendly method to difficulttocave roof coal Longwall top coal caving (LTCC) mining AbstractLongwall top coal caving (LTCC) techniques has been employed in favourable geological conditions widely in China since the mid80s and in Australia recently With the improvement of highlypowered face equipment and the method itself, in the past 15 years, LTCC was introduced to more challenging geologicalApplication of Longwall Top Coal Caving in Challenging

Application of retreating and caving longwall

(2006) Application of retreating and caving longwall (top coal caving) method for coal production at GLE Turkey Mining Technology: Vol 115, No 2, pp 4148SIMULATION OF LONGWALL COAL MINING TECHNOLOGIES Victor V Okolnishnikov(a), Sergey V Rudometov(b), Sergey S Zhuravlev(c), Vasily V Sinoviev(d) (a),(b),(c)Design Technological Institute of Digital Techniques of Siberian Branch of the Russian Academy of Sciences, Novosibirsk, Russia (d)Federal State Budget Scientific Centre «The Federal Research Center of Coal and Coal Simulation of longwall coal mining technologiesAssociate Professor, Coal Industry Engineering Research Center of Top Coal Caving Mining, China Univ of Mining and Technology, D11 Xueyuan Rd, Haidian District, Beijing , China : [ protected]Longwall Top Coal Caving Mechanisms in the

The Key Stratum Structure Morphology of

Longwall mechanized top coal caving mining (LMTCCM) in extrathick coal seams has its own characteristics The law of mining pressure and overlying strata failure height in extrathick coal seams are much larger than those of mediumthick and thick coal seams The key stratum structure morphology also has an important influence on the law of overlying strata movement Longwall mining is a form of underground coal mining where a long wall of coal is mined in a single slice (typically 06–10 m (2 ft 0 in–3 ft 3 in) thick) The longwall panel (the block of coal that is being mined) is typically 3–4 km (19–25 mi) long and 250–400 m (820–1,310 ft) wideLongwall mining WikipediaCoal Mining Technology Research and practice of longwall top coal caving technology in Xuzhou mine area 2003 Issue 10066225Coal Mining Technology 2003 Issue 1 Research

washing of rock phosphate

Concrete Cylinder Mini Grinder

enquiry for slag crushers

gold mine visit johannesburg

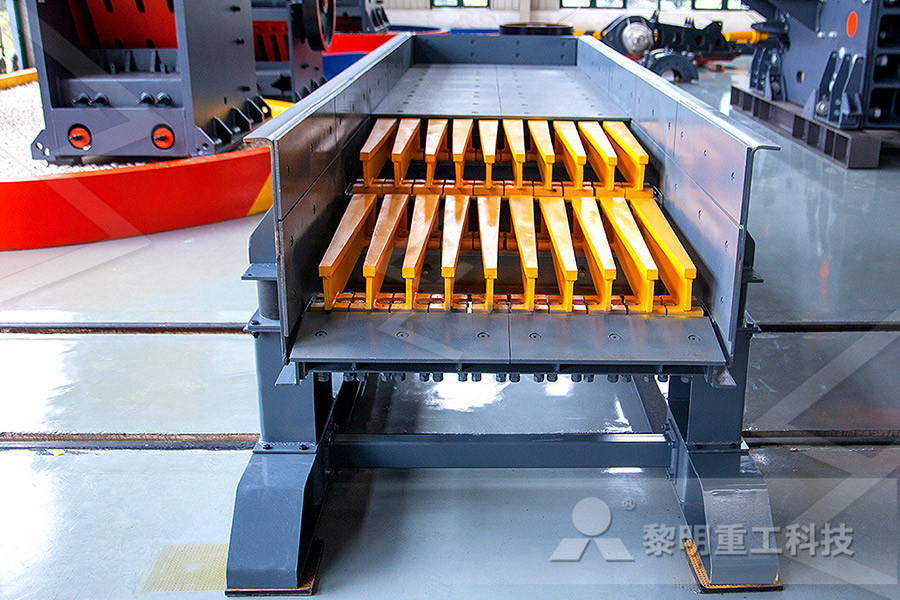

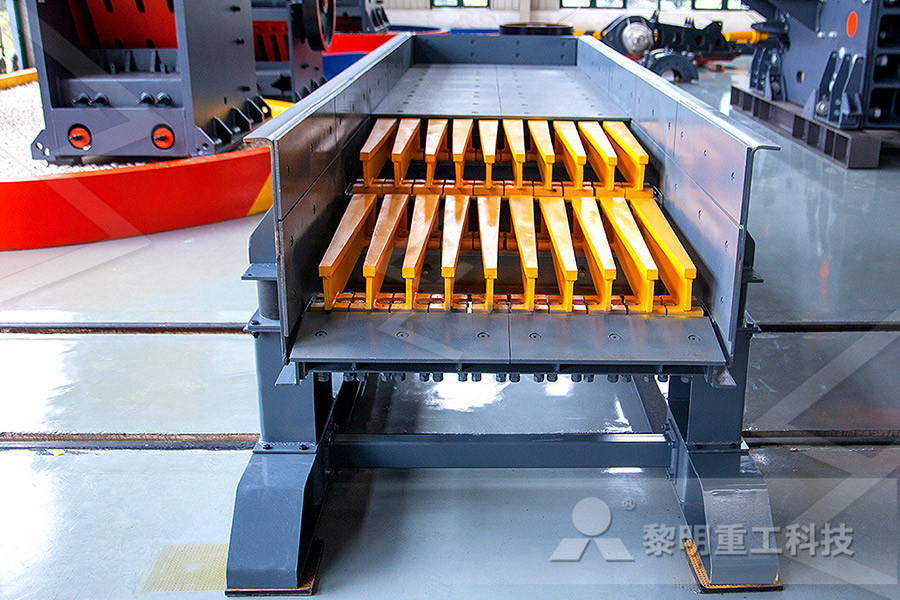

Linear Screening Machine Abrasive Level Vibrating Screen

Pdf Of Stone Quarry Business Proposal Template

crusher tegucigalpa sale

Yard Per Hour Mobile Gold Wash Plant

Gold Ore Grinding Machine Gold Mining Equipment For Sale

calculation of magnetic separator belt speed

List Of Sinter Crusher Sintering $

hammer crushers process

Used Mobile Mini Crushing Equipment For Sale

O Micromill Dsls Manual

dimension of pew 1003 jaw crusher

different size of stone crusher

1 X New Xa400F Tracked Crusher

study of grinding machine and its various operation

dealer stone crusher for sale price

operation of rock crusher

m sand manufactures in thrissur

Mining Engineer Worldwide Cement Industry

Butterfly Table Top Wet Grinders Price

Cone Crushers Comparison

pyrophyllite mobile rock crusher supplier

dove gold wash plants algeria

safety checklist for crusher plant

Windmill Vertical Roller Mill Structure

circular vibrating crushers

Price Of Sbm Tpd Stone Crushing Machine