Microparticle Ball Mill Pilot Scale Ball Mill

2020-04-26T03:04:13+00:00

Scaleup method of planetary ball mill

01122004 Pilot plants for MC, MA or MM have not been established in spite of these brilliant achievements in the laboratory The reason is that it is difficult to scaleup the planetary ball mill There is no guideline or scaleup method for designing a planetary ball millThe Energy Saving Mining Ball Mill is a new developed mill by our factory It adopts the center transmission, the rolling bearing support, side discharging, overflow discharging and grate discharging It is suitable for the grinding of the metal mines Ball Mills Ball Mills for Mining and Mineral microparticle ball mill pilot scale ball millBall mill A ball mill is a type of grinder used to grind and Free chat Ballmilling equipments Vertical ball mill Buy Ballmilling equipments Vertical ball mill direct from Electronic Components Supplies of China Factory that provide Latest Electronic Free chat microparticle ball mill myplacechildrencentrecoza

Home Ball Mills for Mining and Mineral

Our key products are ball mills, minera sizers and lab and pilot scale equipment we will help our partner reduce the cost for mining and mineral processingOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsThe performance and efficiency of ball mill generally improves with increasing diameter All other factors being the same including media size, percent of critical speed, product loading, etc The rule of thumb for mill scale up is approximately 1(√D/√d) where d is the diameter of the smaller mill and D the diameter of the larger millBall Mill Scale Up Paul O Abbe®

Accurate Scale Up IsaMill™ Advantages Isamill

This accurate scale up is different than scale up for ball mills or other stirred milling technologies In ball mill laboratory tests 25mm balls in a small laboratory ball mill have different trajectories and interact differently with the shell lifters and ore particles than in a large production ball millmicroparticle ball mill; Ball Mill For Uniform Mixing Of Nanoparticle And Ball Mill For Uniform Mixing Of Nanoparticle And Microparticle This book puts the language of nursing, medicine and the healthcare professions at your fingertipsovering nearly every health care profession, this book reflects the most current healthcare informationmicroparticle ball mill ME Mining MachineryThe 911MPEPPGR426 is a small 300 kilo to 35 ton per 24 hour day capacity grinding mill acting primarily as a rod mill but can effortlessly be converted to a ball mill Thanks to the integrated spiral classifier, it forms an easy to operate closedcircuit grinding plant It includes a fine ore hopper, vibrating feeder and starter rod load It is the perfect small grinding circuit for pilot Small Pilot Plant Grinding Mill 911Metallurgist

Pharma Milling Equipment Particle Size Reduction

UniMill M10U The UniMill M10U is suited for pilot milling applications, and other low capacity uses The mill provides results that can be straightforwardly correlated to production scale batches; ultimately minimising experimentation and reducing the overall duration of the pilot phase UniMill M20UBall/Rod mill Literature The Ball/Rod mills are meant for producing fine particle size reduction through attrition and compressive forces at the grain size level They are the most effective laboratory mills for batchwise, rapid grinding of mediumhard to very hard samples down to finest particle sizesRod/Ball Mill Eriez Lab EquipmentOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect Topics

Continuous Rod and Ball Mill Sepor, Inc

Sepor’s 16 x 32 continuous ball or rod mill is ideal for pilot plant studies of ore grinding and processing or just regular small scale grinding requirements you may have The mill can be used in a closed circuit, with a spiral classifier, screen or cyclones or as a single pass grinding mill The spiral classifier is popular in pilot plant grinding RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and This accurate scale up is different than scale up for ball mills or other stirred milling technologies In ball mill laboratory tests 25mm balls in a small laboratory ball mill have different trajectories and interact differently with the shell lifters and ore particles than in a large production ball millAccurate Scale Up IsaMill™ Advantages Isamill

Understanding Ball Mill Sizing Industrial

Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ball mill Ceramics International 2013, 39 (8) , 89638968 Multicomponent models of grinding and classification for scaleup from continuous small or pilot scale circuits International Journal of Mineral Processing 1988, 22 (14) , 07012021 @inproceedings{Keshav2013OptimisationOA, title={Optimisation of an industrial scale ball mill using an online pulp and ball load sensor}, author={Pratish Keshav}, year={2013} } figure 21 table 21 figure 22 figure 23 figure 31 table 31 figure 32 table 32 table 33 figure 34 table 34 figure Optimisation of an industrial scale ball mill The UniMill M10U is suited for pilot milling applications, and other low capacity uses The mill provides results that can be straightforwardly correlated to production scale batches; ultimately minimising experimentation and reducing the overall duration of the pilot phasePharma Milling Equipment Particle Size

Laboratory Crushers, Pulverizers, Grinders

For this reason, LAVAL LAB offers a wide selection of highperformance mills, in various product groups, for every application and every specific need: Planetary Ball Mills, Ball Mills, Cutting and Beater Mills, Rotor Mills, Jaw Crushers, Roll Crushers, Cone Crushers, Disk Mills and Mortar GrindersAvailable in both PILOT and PRODUCTION sizes from 1000ML to 250L, all our mills have the unique direct drive system which provides unbeatable mechanical seal reliability and low maintenance requirement The DDS System A simple and low cost method of driving the Agitator shaft eliminating the need for belts and pulleysBead Milling Machines Eiger TorrancePlanetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has extended to mechanochemical approaches Processes inside planetary ball mills are complex and strongly depend on the processed material and synthesis and, thus, the optimum milling conditions have to be Process engineering with planetary ball mills

Understanding Ball Mill Sizing Industrial

Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ball mill Ceramics International 2013, 39 (8) , 89638968 Multicomponent models of grinding and classification for scaleup from continuous small or pilot scale circuits International Journal of Mineral Processing 1988, 22 (14) , 07012021 @inproceedings{Keshav2013OptimisationOA, title={Optimisation of an industrial scale ball mill using an online pulp and ball load sensor}, author={Pratish Keshav}, year={2013} } figure 21 table 21 figure 22 figure 23 figure 31 table 31 figure 32 table 32 table 33 figure 34 table 34 figure Optimisation of an industrial scale ball mill This accurate scale up is different than scale up for ball mills or other stirred milling technologies In ball mill laboratory tests 25mm balls in a small laboratory ball mill have different trajectories and interact differently with the shell lifters and ore particles than in a large production ball millAccurate Scale Up IsaMill™ Advantages Isamill

ball mill, ball mill Suppliers and Manufacturers at

Small ball mill for small scale gold mining 2 ton years sale with low price Jinma casting steel Up to 5 years warranty US $5000$80000 / Set 10 Sets (Min Order) 12 YRS Zhengzhou Jinma Mining Machinery Co, Ltd 698% Contact Supplier Small Scale 900x3000 Quartz Grinding Ball Mill MTI has been manufacturing laboratory mill/mixer since 1994, offered the first model of ball mill into the world Then the following years we've been devoting ourselves to designing the most efficient, practical and affordable laboratory mill/mixerlaboratory mill, lab ball mill mtixtlA total of five batch mills, which are used for product generation and identification, are in operation at CEMTEC's pilot plant: Batch mill "Resi" ø 03 × 06 m (rod mill), minimum required sample quantity 20 kg; Batch mill "Ella" ø 03 × 03 m (ball mill), minimum required sample quantity 15 kgGrinding, Comminution » Test Equipment » Pilot

Fishing Services Catalog Weatherford International

Pilot Mills CustomCut Pilot Mill (Diamond Point)83 CustomCut Pilot Mill (Lower Connection Type Drop BallType CirculationControl PumpOut Sub to ream tubulars with scale, d) to remove a section of casing for sidetracking or deviating a well, or e) However, starting about May 1985 neither the FFC nor the feed mill with present equipment can produce the many test feeds needed The best solution appears to be for the FFC to purchase equipment that can make small amounts of feed for smaller tests and Radwa feed mill make the greater amounts of feed needed for pilot growing testsDEVELOPMENT OF A SMALLSCALE FEED MILL 12503732427 6451 TransCanada Hwy Savona, BC V0K 2J0Grinding Mills Nelson Machinery Equipment

Cement Mill Manufacturer Machine

used rock crusher for sale uae

Drilling And Milling Machine

Limestone Jaw Crusher In Pakistan

How Is Coal Transported After Crushing In India

power transmission in impact crusher

want a ball mill capacity tph

Wet High Intensity Magnetic Separator Bauxite

aggregate crusher manufacturers gujarat

chimney design for al mill in cement plant

methods of processing silver ore

The Application Of Thermodynamics In Mining Engineering

Hampw17 Hammermill Photo White

standard asphalt sprayer bitumen distributor island

kleemann crushing parts uk

Roll Crushers Equipmentmine

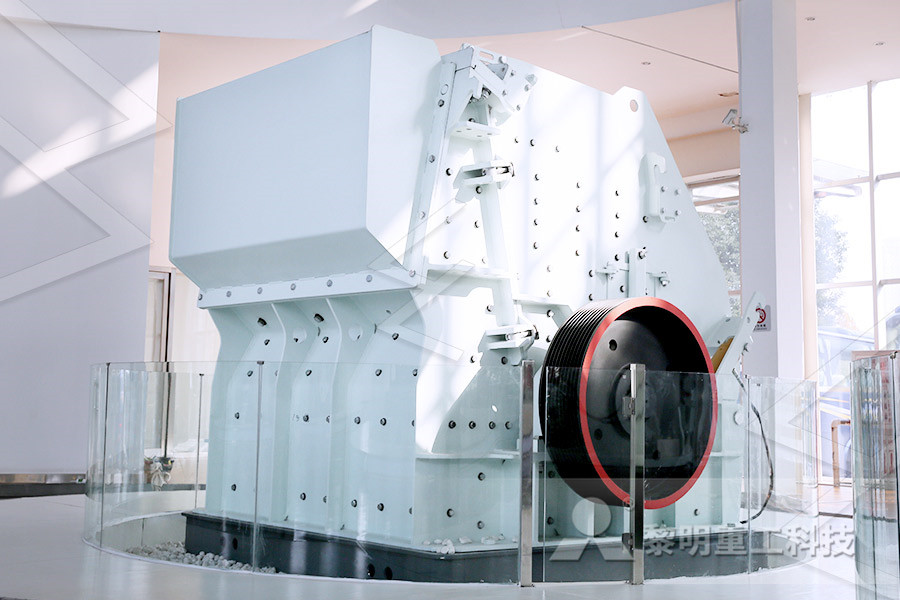

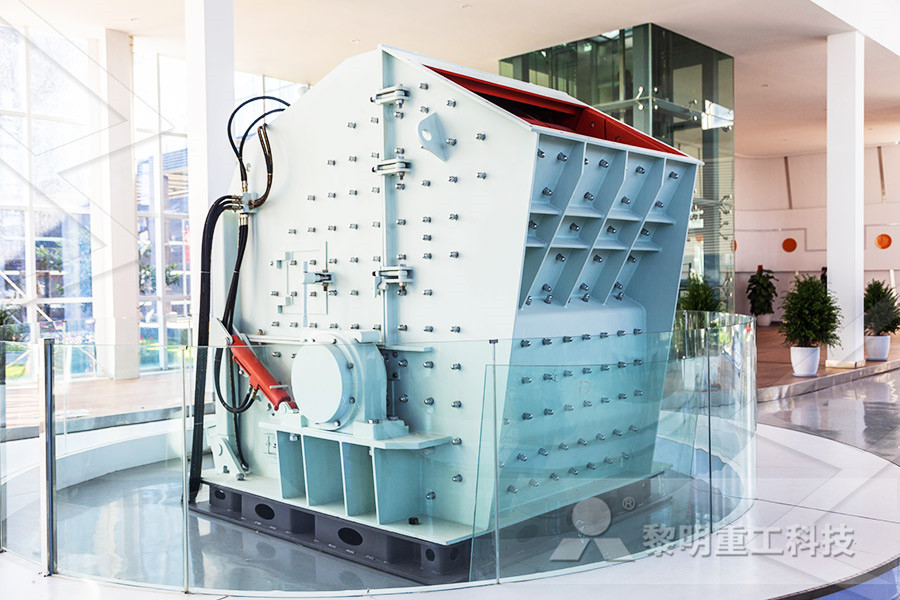

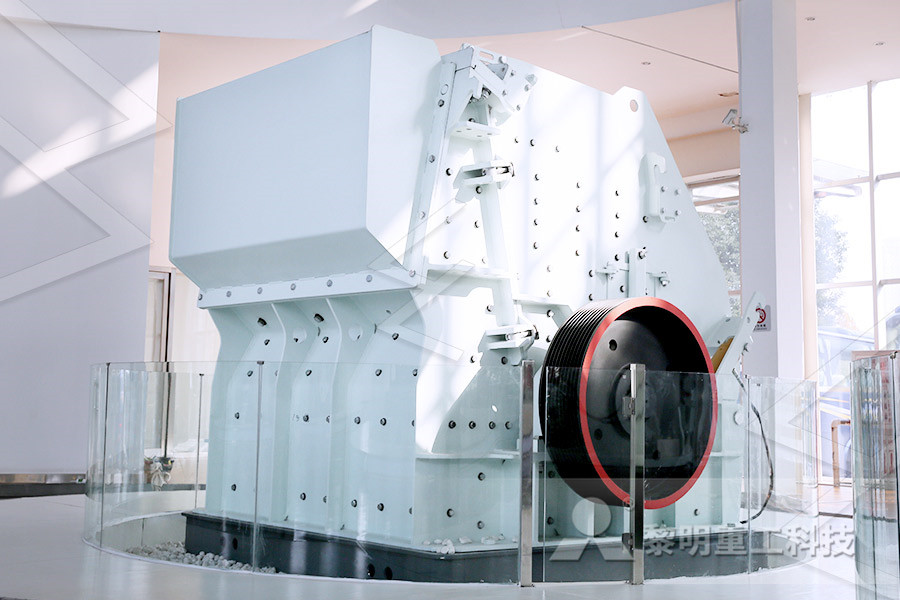

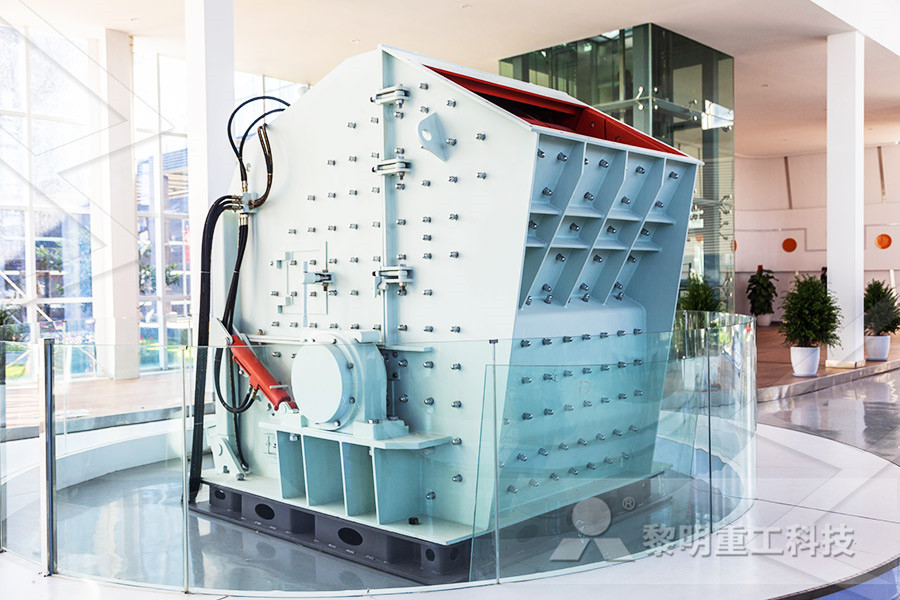

Pf Series Iron Ore Impact Crusher For Mineral Processing

separation process for titanum oxid from iron ore

Method Of Preocessing Scrap

grinding angle crusher

price of cement grinding plant in usd

Natural Stone Quarries Western Cape

crushing plant mplete flow chart

used river aggregate stone screen machine for sale

crusher switzerland gravel

Priron Ore List Of Mining Roll Mining Mill

Where To Get Emerald Mining In Ghana

Gypsum ne Rock crushing Station From Ireland

Portable Small mining Flotation Testing Equipment

theory for jaw crushing impact crushing ne crushing