power transmission in impact crusher

2021-02-19T16:02:30+00:00

Impact Crusher an overview ScienceDirect Topics

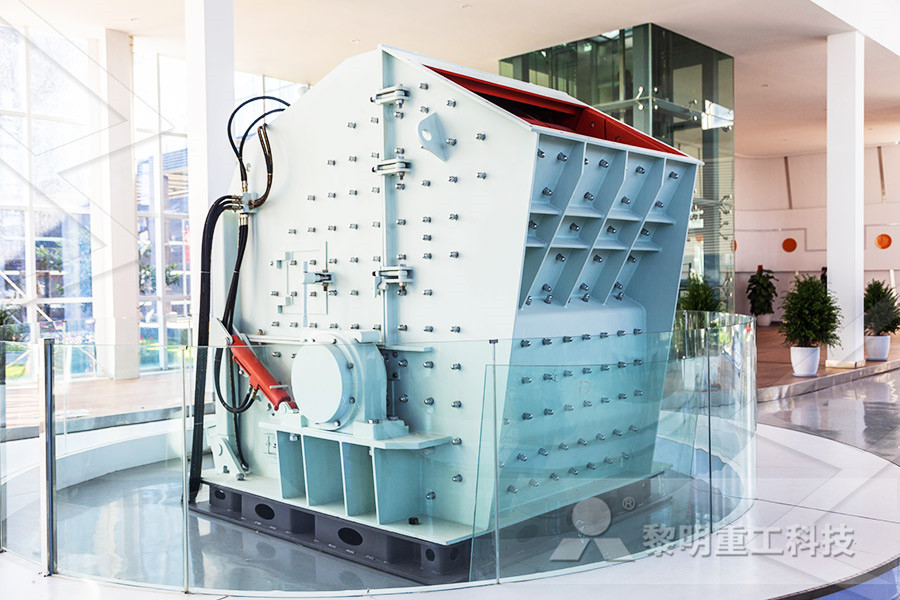

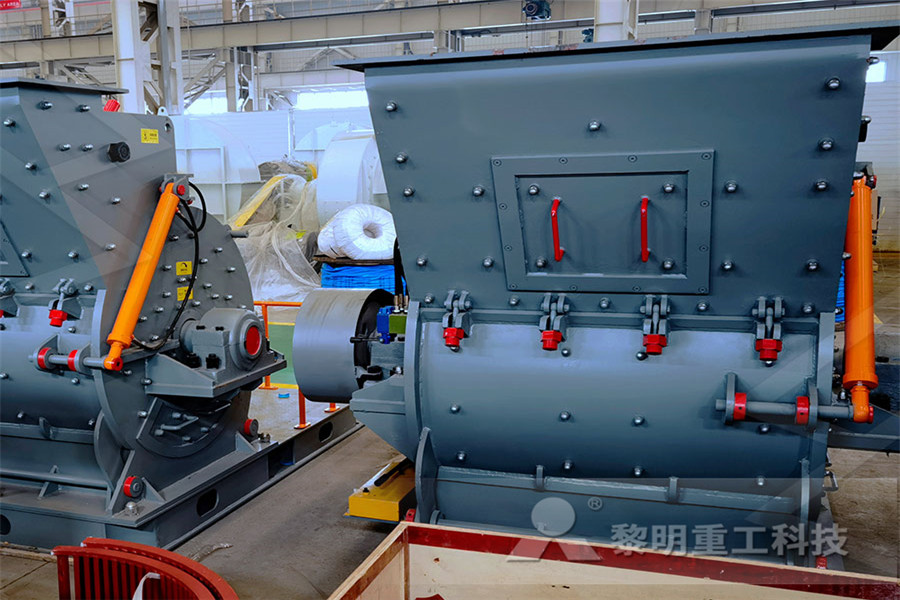

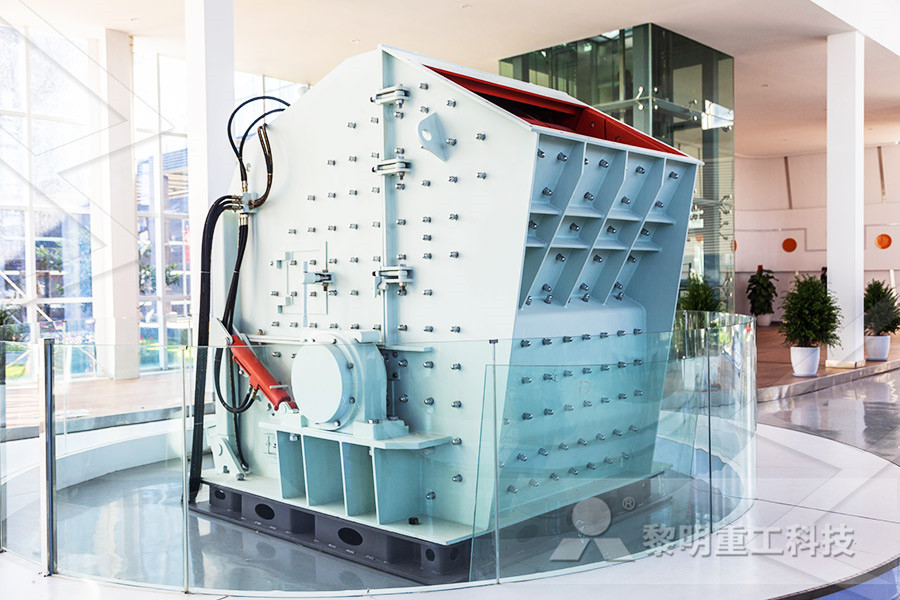

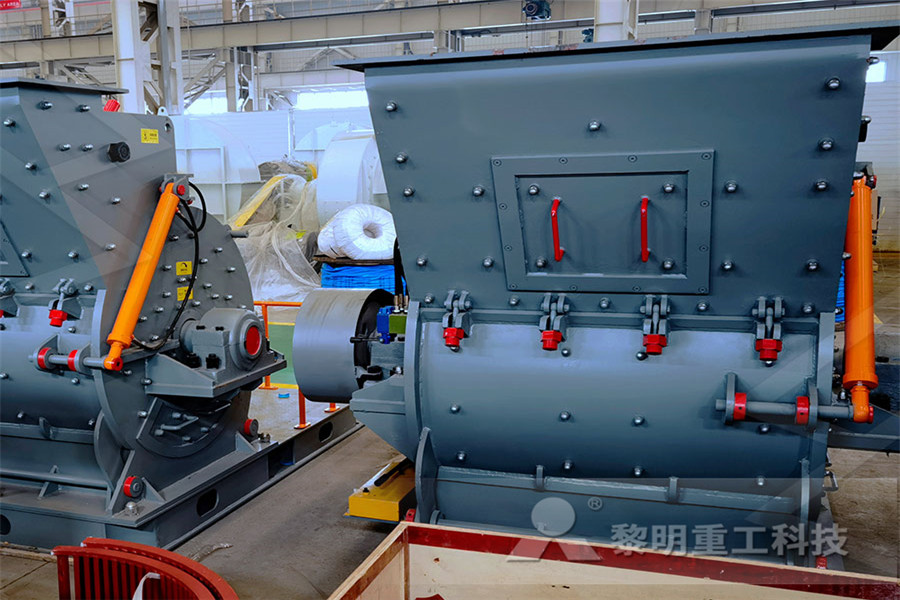

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance The finished product is of cube shape and the tension force and crack is avoided Compared with hammer crusher, the impact crusher is able to fully utilize the highspeed impact energy of Engine → power transmission gear → Turbo clutch → Vbelt drive for crusher direct drive Flange with elastic clutch for damping engine vibrations; Flange for hydraulic pump 45 kW (track drive i=1:1,2); Switchable toothed clutch (for emergency and service only), Vbelt pulley and Turbo clutch; Pump with oil filter for lubrication of gearIMPACT CRUSHER HTM Maschinen15082012 The word impact makes sense that in this particular type of crusher some impaction is being used for crushing of rocks In normal types of crusher pressure is generated for the crushing of rocks But, impact crushers involve an impact method There is a hopper one side that takes the crushing material into the machineImpact Crusher Description Advantages Types

HIGH PERFORMANCE IMPACT CRUSHER

IMPACT CHAMBER A 48” x 53” (1200mm x 1350mm), four bar impactor rotor with a 535” x 37” (1360mm x 950mm) feed opening CRUSHER ROTOR Direct drive crusher rotor via clutch which boasts maximum power transmission with a low fuel cost NEW 8’ DOUBLE DECK PRESCREEN The much larger crusher prescreen maximizes crusherThe Trakpactor 290SR Impact Crusher performs in the most challenging of applications such as construction and demolition, asphalt, concrete, and natural rock The compact design allows it to operate in small landing spaces and easily be transported from site to siteImpact Crushers Weight impact crusher Rotor width Rotor diameter Drive Blow bars Rotor speed Pulley diameter Weight rotor Throughput capacity Impact aprons Gap upper apron Gap lower apron Distance rotor / feeder 54 ICR 10000 970 x 1300 mm (H x W) Approx 17200 kg 1250 mm 1267 mm Direct via elastic clutch, transmission gear, TurboIMPACT CRUSHER HTM Maschinen

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedImpact crushers (also known as impactors or horizontal shaft impactors) can be used in primary, secondary, or tertiary applications They use inertia of the blowbars fitted to the rotor to fracture the material, resulting in a high reduction ratioImpact Crusher Trakpactor 550 Using an advanced impact method, impact crushers are the efficient and costeffective solution for industrial size reduction projects Impact Crushers have a wide range of industrial applications from crushing rock to delumping sand and whole lot more Browse Williams Crusher’s line of impact Impact Crushers Crush Rock, Minerals More

Trio APS5160 Horizontal Shaft Impact Crusher

APS5160 horizontal impact crusher is a versatile secondary crushers applied in hard rock applications Ideal for recycling asphalt, concrete, slag, glass 24/7 Customer Support 8008839284Engine → power transmission gear → Turbo clutch → Vbelt drive for crusher direct drive Flange with elastic clutch for damping engine vibrations; Flange for hydraulic pump 45 kW (track drive i=1:1,2); Switchable toothed clutch (for emergency and service only), Vbelt pulley and Turbo clutch; Pump with oil filter for lubrication of gearIMPACT CRUSHER HTM MaschinenThe vertical shaft impact (VSI) crusher is a commonlyused machine in aggregate production A comprehensive understanding of the physical phenomena that influence the power (PDF) Modelling of output and power

Impact Crusher Description Advantages

15082012 The word impact makes sense that in this particular type of crusher some impaction is being used for crushing of rocks In normal types of crusher pressure is generated for the crushing of rocks But, impact crushers involve an impact method There is a hopper one side that takes the crushing material into the machineIMPACT CHAMBER A 48” x 53” (1200mm x 1350mm), four bar impactor rotor with a 535” x 37” (1360mm x 950mm) feed opening CRUSHER ROTOR Direct drive crusher rotor via clutch which boasts maximum power transmission with a low fuel cost NEW 8’ DOUBLE DECK PRESCREEN The much larger crusher prescreen maximizes crusherHIGH PERFORMANCE IMPACT CRUSHERStarting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill) Dynamic impact could be described as Impact Crusher Working Principle

Impact Crushers Crush Rock, Minerals More

Using an advanced impact method, impact crushers are the efficient and costeffective solution for industrial size reduction projects Impact Crushers have a wide range of industrial applications from crushing rock to delumping sand and whole lot more Browse Williams Crusher’s line of impact crushing machinesOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impactCrushers an overview ScienceDirect TopicsPower Equipment Company is the authorized dealer for horizontal shaft impact crusher equipment from the following manufacturers LIPPMANNMILWAUKEE – Colorado / New Mexico / Utah / Wyoming (territory map) TEREX CEDARAPIDS – Colorado / Wyoming (territory map)HSI Crushers Power Equipment Company

Mechanical Power Transmission Equipment

21012021 New York, Jan 21, 2021 (GLOBE NEWSWIRE) Reportlinker announces the release of the report "Mechanical Power Transmission Equipment Global Market Report 2021: COVID 19 Impact and Recovery to Minnesota Power 30 West Superior Street, Duluth, Minnesota 55802 mnpower @mnpower For Release: June, 26, 2015 Contact: Amy Rutledge Manager Corporate Communications Minnesota Power/ALLETE 2187237400 arutledge@mnpower Great Northern Transmission Line draft Environmental Impact Statement releasedGreat Northern Transmission Line draft Environmental Impact crusher is generally relying on the prime mover supplies some form of energy to work Connect the prime mover and the working machine directly, however, is very few, often needed to add transfer power between them or change the motion state of gears The experts of machine analyze the main reason: 1The Transmission Device Of Impact Crusher

HIGH PERFORMANCE IMPACT CRUSHER

IMPACT CHAMBER A 48” x 53” (1200mm x 1350mm), four bar impactor rotor with a 535” x 37” (1360mm x 950mm) feed opening CRUSHER ROTOR Direct drive crusher rotor via clutch which boasts maximum power transmission with a low fuel cost NEW 8’ DOUBLE DECK PRESCREEN The much larger crusher prescreen maximizes crusherStarting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill) Dynamic impact could be described as Impact Crusher Working PrincipleMB Crusher offers MB Crusher Power Transmission Kit and other solutions for the Demolition and RemediationMB Crusher Accessories Power Transmission

Sandvik Mobile Impact Crushers ELRUS

Sandvik Mobile Impact Crushers Sandvik’s range of tracked impact crushers provides an extensive mobile crushing solution whatever the application These machines have been proved throughout the world in a variety of conditions, providing customers solutions in quarrying, surface mining and construction applications4043T IMPACT CRUSHER 4043T OPERATING SPECIFICATIONS Height35m 11'6" Length154m 50'5" Width30m 9'10" Total Weight 83,000 lbs 37,650kg 7409273464 • 8008373344 • Directionally reversible, 42" (1,066mm) wide conveyor with impact bed and guide idlers4043T IMPACT CRUSHER screenmachineOur product line includes: ELRUS jaw crushers, Sandvik cone and impact crushers in a range of sizes and configurations including: portable, modular and stationary to suit individual requirements Primary Jaw Crusher Plants ELRUS manufactures heavyduty jaw crushers that have been stress relieved and machined for a close fit with other componentsJaw, Cone, and Impact Crusher Plants ELRUS

Impact Crushers Crush Rock, Minerals More

Using an advanced impact method, impact crushers are the efficient and costeffective solution for industrial size reduction projects Impact Crushers have a wide range of industrial applications from crushing rock to delumping sand and whole lot more Browse Williams Crusher’s line of impact crushing machinesOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impactCrushers an overview ScienceDirect TopicsAPS5160 horizontal impact crusher is a versatile secondary crushers applied in hard rock applications Ideal for recycling asphalt, concrete, slag, Trio APS5160 Horizontal Shaft Impact Crusher

material testing mining manual for civil engineering

Ball Type mining Coal Crushing Equipment

Iron Ore Commissioning

basic electric circuit of stationary crusher plant

how to get loan on crusher plant

Use Stone Crusher Palant Mansin Sele In India

how to set up gold mining baw mill

Raymond Mill Used In Stone Production Line

Indonesian Coal Crusherfeldspar

kaolin kaolin grinding mill production line

silver Mining Crusher Plant

Advancing Equipment Hydraulic Cone Mining Mill

big crusher mobile stone crusher plant crusher

mining grinding machines outsourcing

crusher manufacturers mpany name in orissa

power transmission in impact crusher

suppliers or alluvial gold in the world

Cone Mining Mill From South Africa

knelson for sale in usa

south africa forged steel balls machine

mantle drawing of ne crusher

shanghai outlet material crusher

machine for grinding ncrete or stone sand making stone quarry

Granit Ponsel Crusher Di Rep De Congo

Gold Ore Fine Crusher Company

portable cement grinding plant

how are aggregates processed

2014 wet gold grinding machine chilean mill for gold

argo jaw crusher cr28 50 tonne new price

large crushing production line flow chart