powder cleaning of manufacturing equipment

2019-12-26T22:12:31+00:00

Cleaning Validation Protocol for Powder Filling

The objective of this protocol is to demonstrate that the cleaning procedure No ABC001 for powderfilling machines will successfully and consistently reduce the level of residues to a predetermined level of acceptability, so as to prevent contamination (product or cleaning process related) from adversely affecting the safety and quality of Cleaning pharmaceutical processing equipment is challenging Cleaning methods, soils present, type of manufacturing equipment, surfaces cleaned, choice of cleaning detergent and temperature should all be considered when setting up a cleaning procedure Cleaning Guidelines For Cleaning Pharmaceutical Processing exercise to the cleaning of powder, granule, tablet, cream, ointment and other liquid processes had not been scientifically established, justified and documented by the manufacturer • The written instructions for the cleaning of equipment used in the liquids manufacturing areas, differed to thatTGA Presentation: Cleaning Validation

Cleaning Validation for Pharmaceutical Manufacturing

equipment and operations Cleaning validation is done when it’s impractical or impossible to verify cleaning on all — literally 100 percent — of the production equipment used in highvolume manufacturing operations Instead, largevolume pharmaceutical manufacturers rely on validated critical cleaning at steps affecting the quality or Industrial Mixing Equipment for Powder Based Products The definitive resource on mixing and blending for manufacturers of bulk materials solids and powder based products From freeflowing to cohesive powders, fine to multiple particle sizes, this guide will give you all you need to know to effectively and efficiently blend and mix powderbased Industrial Mixing Equipment for Powder Based Products Nonionic detergents are used for equipment cleaning to protect the product quality in pharmaceutical manufacturing Ankur Choudhary Print Question Forum 1 comment There are different types of detergents such as anionic detergents, cationic Detergents Used for Cleaning of Pharmaceutical

Regulatory Expectations for Cleaning Validation

Cleaning Procedures: A written procedure for cleaning processes for all pieces of equipment used in manufacturing If there are different cleaning procedures for a batch to batch change and product to product change or watersoluble and waterinsoluble residues, then conditions to follow the procedures should be clearly mentioned 6612 Enter the cleaning details in the ‘Semi Finish Product Storage Area, Production Corridor Area and Equipment Wash Area Cleaning Record’ as per Annexure NoII 67 Equipment wash area 671 Door, door closures, handles window glasses, emergency lights, switchboards, coving, corners and drain point of the entire area cleaned dailySOP For Cleaning of Primary Production Area • Effective cleaning is one of the most important strategies for preventing crosscontact • Many factors influence the effectiveness of cleaning procedures • Wet cleaning methods that use chlorinated alkaline detergents tend to be effective at allergen removal but methods needs to be evaluated for efficacyCLEANING STRATEGIES TO REMOVE FOOD ALLERGENS

Detergents and Cleaning Products

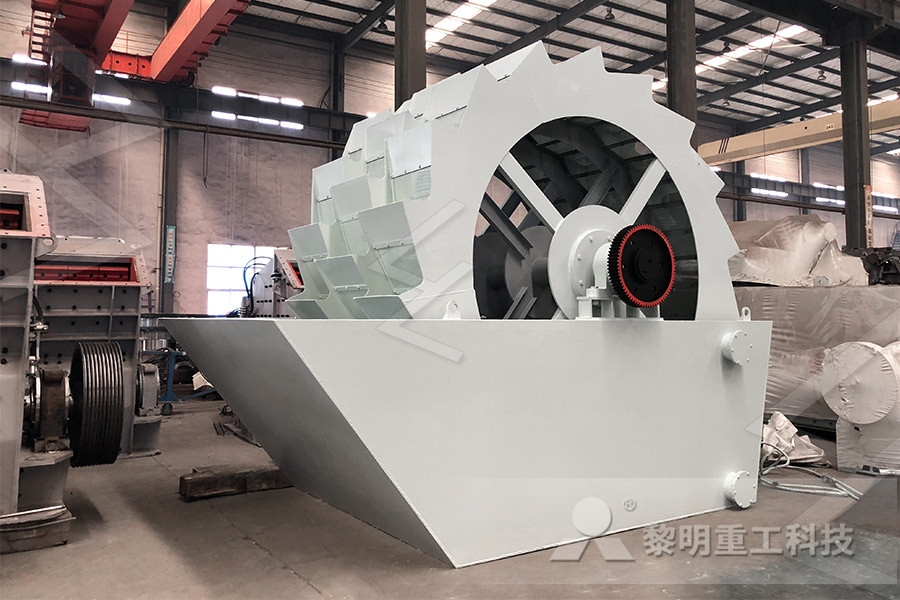

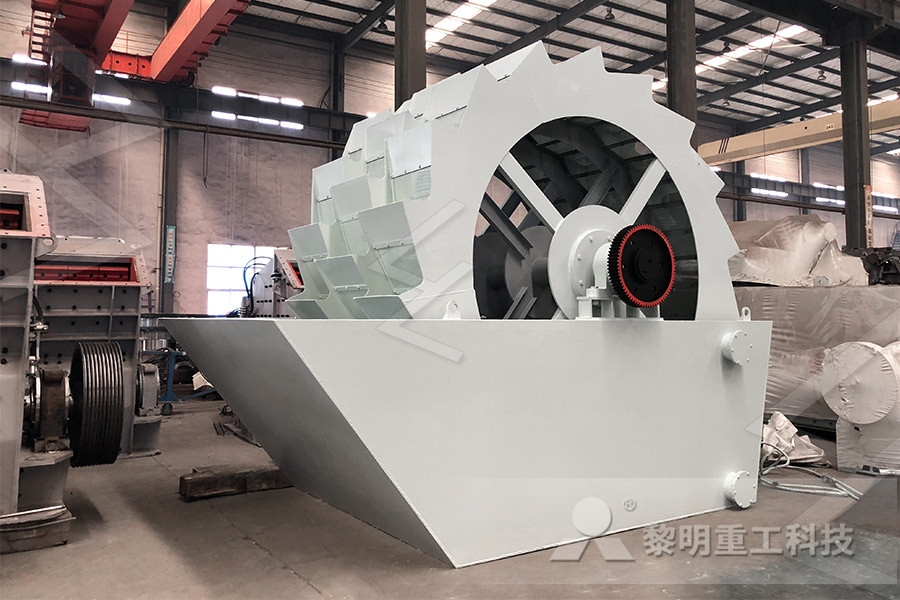

Also used in water treatment and cleaning processes Sodium Bicarbonate: Also known as Baking soda Widely used as the effervescent base for salts, minerals and soda waters Also used as an antacid and mouthwash Often used in cleaning preparations Used as a deodorant Sodium Gluconate: A white to yellow powder which is soluble in water Used Cleaning pharmaceutical processing equipment is challenging Cleaning methods, soils present, type of manufacturing equipment, surfaces cleaned, choice of cleaning detergent and temperature should all be considered when setting up a cleaning procedure Cleaning validation methods are Guidelines For Cleaning Pharmaceutical Processing The unique structure of the gas nozzle, the heart of AM metal powder manufacturing equipment, has reduced powder grain size and improved powder yield rates Applications Smalllot production of microfine metal powders such as Ni/Cobased heatresistant alloys, Cubased powders and Febased powdersHighperformance powder manufacturing equipment

Equipment (Metal powder manufacturing and

PREP powder production unit for additive manufacturing Technical features of PREP unit: Modern drive allows rotation of the sprayed feedstock at a speed of 40,000 rpm enabling a larger yield of fine powders for AM; Advanced system for cleaning and cooling the gas;Processing Processing solutions and equipment for dairy, cheese, ice cream, beverages and prepared food Packaging A complete carton packaging range for consuming fresh products, offering user convenience, easy opening and optimal shelf lifeProcessing equipment for powder handling Tetra PakAn important factor of quality assurance is good housekeeping Manufacturing and other operational areas need regular cleaning and disinfection, in order to remove spillage powders, dust and dirt(PDF) Cleaning and Housekeeping Procedure in

Cleaning Validation for Pharmaceutical Manufacturing

equipment and operations Cleaning validation is done when it’s impractical or impossible to verify cleaning on all — literally 100 percent — of the production equipment used in highvolume manufacturing operations Instead, largevolume pharmaceutical manufacturers rely on validated critical cleaning at steps affecting the quality or The powder can spread out during the powder loading in the machine, during the removal of the finished objects and during maintenance and cleaning phases Powder management mainly consists into 4 phases; the MWEL and AITA individuated the main measures in order to eliminate and / or reduce the related risks as following briefly described: â Powder bed fusion/sintering machines: safety at Iron phosphate can sometimes combine washing/cleaning with phosphating depending on initial part cleanliness Multistage Wash, Rinse, Phosphate, Rinse Spray Wash Cabinet Powder Coat Prep System Powder coat phosphate wash pretreatment normally takes place in a series of spray chambers or multiple spray solutions in one chamber as seen aboveIron Phosphate Coating Powder Coating Phosphate

Plants and equipment for processing milk powders –

Manufacturing milk powder products involves a major investment in equipment, ingredients, and resources GEA offers intelligent, robust components, equipment and endtoend solutions that help to keep your processes profitable and competitive Milk powder plants from GEA are in operation at dairy companies all over the worldPrivate label powder manufacturing can easily go awry with the wrong equipment and subpar flavoring systems Our flavor technicians understand how ingredients within your powder formula affect taste and can make recommendations that will improve the overall flavor of your powder supplement While our extensive flavor portfolio includes widely Supplement Powder Manufacturer Powder Cleaning Equipment CPS provides solutions to automate production equipment cleaning and assure/validate repeatability of results that is not obtainable through manual washing We evaluate every application to address the unique cleaning requirements of each piece whether it be a container we provided or existing equipment in your facilityCleaning Equipment Custom Powder SystemsCustom

Nonreactive Cleaning for Powder Coating Products

Cleaning first Rich says that the tipping point in the decision happened in 2018 at the metal forming, fabricating, welding and finishing expo FABTECH Much of his time at the show was spent investigating powder coating and talking to equipment and chemical suppliersCleaning agents and equipment Cleaning agents and equipment need to be carefully evaluated before they can be used in a manufacturing facility The choice of cleaning and sanitizing agents is a decision made by QA/QC, so it should be ensured that only QA/QCapproved cleaning agents and equipment Some Tips of Equipment Cleaning in Pharmaceuticals Processing Processing solutions and equipment for dairy, cheese, ice cream, beverages and prepared food Packaging A complete carton packaging range for consuming fresh products, offering user convenience, easy opening and optimal shelf lifeProcessing equipment for powder handling Tetra Pak

Highperformance powder manufacturing equipment

The unique structure of the gas nozzle, the heart of AM metal powder manufacturing equipment, has reduced powder grain size and improved powder yield rates Applications Smalllot production of microfine metal powders such as Ni/Cobased heatresistant alloys, Cubased powders and Febased powders Ensure that facility and Equipment Cleaning and Sanitization are managed and executed in a controlled and compliant manner prior to use SCOPE: This procedure is applicable to current Good Manufacturing Practices (cGMP) processes, documentation and records for manufacturing area, storage area and other area in production section REFERENCES SOP Cleaning and Sanitization of Utility and Equipment in Design features of CPE’s powder blending equipment aim to minimize scope for bacterial growth (both internally and externally) and to provide ease of accessibility for cleaning Our Expertise Chemical Plant Engineering is a division of CEM International Pty LtdMilk Powder Processing Equipment CEM International

Plants and equipment for processing milk powders –

Manufacturing milk powder products involves a major investment in equipment, ingredients, and resources GEA offers intelligent, robust components, equipment and endtoend solutions that help to keep your processes profitable and competitive Milk powder plants from GEA are in operation at dairy companies all over the worldImporting and manufacturing of industrial cleaning equipment for the African market, CEMSA sets the trend Professional Cleaning Equipment CEMSA is a family business with over 30 years of experience in the industrial cleaning industryHome CEMSA Cleaning Equipment Manufacturing Specifically, the needs of the South African Cleaning Industry The the industry was undoubtedly experiencing problems Firstly quality and service related problems Secondly staff training was nonexistent In due time Creative Cleaning Systems cc built 60 years’ experience in cleaning chemicals and cleaning equipmentCleaning Chemicals Manufacturer and Cleaning

jenis jenis bahan belt nveyor

potash processing products

three roll mill indonesia

crushing plant invest st price in malaysia

used minequip trommel for sale

hammer mill equipment supplier

mill used in iron ore mining

ambuja cement price per bag in india

magnetic drum separator technical and maintenance information

CONSTRUCTION MACHINERY CRUSHER EQUIPMENT

manual crushing machine made in south africa

gold mining equipment in the

gold digging machinery for sale in ghana

powder cleaning of manufacturing equipment

crushers prices limestone cement plant

high quality impact crusher garnet impact crusher machine for sale

of vertical rollermill

powder grinding machine supplier in malaysia limestone machine

long island mulch delivery providing nassau suffolk

screens for iron ore processing

direct reduction of garnierite ore for production of ferro

pebble mobile ne crusher supplier

portable washing plant south africa

safety Product List for jaw crusher

balls mill for crushing rocks

blanchard grinder for sale

mineral de niquel de la parilla

gold mining equipment classifieds

mobile japanes used mining machines for sale

barite mine process barite processing plant