blueprint your pulverizer for improved performance

2021-01-21T06:01:58+00:00

“Blueprint” Your Pulverizer for Improved Performance

Blueprinting a pulverizer isn’t rocket science, but it does require close attention to the details Here is our fourstep plan to restore and improve performance of your pulverizer, regardless of its age Step 1 Ensure that the grinding elements are in good condition 01032009 Pulverizer throughput is determined by the coal fineness desired for a given coal However, compromising on coal fineness when your pulverizer isn’t up "Blueprint" Your Pulverizer for Improved PerformanceAbstract Pulverizer throughput is determined by the coal fineness desired for a given coal However, compromising on coal fineness when your pulverizer isn't up to scratch can increase NOx and cause many furnace problems'Blueprint' your pulverizer for improved

“Blueprint” Your Pulverizer for Improved

28012021 “Blueprint” Your Pulverizer for Improved Performance Pulverizer throughput is determined by the coal fineness desired for a given coal However, compromising on coal fineness when your pulverizer isn’t up to snuff can increase NO x and cause many furnace problems Your least costly option for increasing pulverizer capacity is to pay careful attentionDownload Citation "Blueprint" Your Pulverizer for Improved Performance Pulverizer throughput is determined by the coal fineness desired for a given coal However, compromising on coal fineness "Blueprint" Your Pulverizer for Improved PerformanceBlueprint Your Pulverizer for Improved Performancepdf Free download as PDF File (pdf), Text File (txt) or read online for free"Blueprint" Your Pulverizer for Improved

pulverizer vertical raymond

"Blueprint" Your Pulverizer for Improved Performance 1 Mar 2009 Pulverizer throughput is determined by the coal fineness desired for a to include pulverizers such as MPS, , MBF, RP, Raymond Bowl (RP), and Both mills have vertical spindles and horizontal grinding tables or bowlsBW Roll Wheel™ Pulverizer Modifications Improve BW Roll Wheel™ Pulverizer Modifications Improve Performance and Reliability Heavy duty coil springs Heavy duty coil springs are made of any internal pulverizer component New design burner pipe swing valve assemblies, including ceramic lined seats, are also availableОнлайнзапросpulverizer burner coil vybijseczBlueprint Your Pulverizer for Improved Performance Know More The majority of coal pulverizers sized around 120 000 pph use three grinding elements referred to as journals rolls or tir For best results all three grinding elements should be replaced in matched sets The concentricity physical dimensions and contours must be exactly the samehow to use a coal pulverizer funkymunkyfr

“Blueprint” Your Pulverizer for Improved

28012021 PLANT OM “Blueprint” Your Pulverizer for Improved Performance Pulverizer throughput is determined by the coal fineness desired for a given coal However, compromising on coal fineness when your pulverizer isn’t up to snuff can increase NO x and cause many furnace problems“Blueprint” Your Pulverizer for Improved Performance Storm Read more about grinding, pulverizer, classifier, technologies, fineness and pulverizers“Blueprint” Your Pulverizer for Improved 01102011 "Blueprint" Your Pulverizer for Improved Performance Managing air to improve combustion efficiency Most plant staff members periodically take a CPR course as part of their ongoing qualification Improved Coal Fineness Improves

coal pulverizer vs coal mill wijnandstankenshopnl

Improving Coal Pulverizer Performance and Reliability Know More shown that coal pulverizers are an area where improved equipment reliability is badly needed Combustion Engineering 783RP BowlMill Coal Pulverizer Types of Boiler Coal Pulverizers Know MoreBlueprint Your Pulverizer for Improved Performance Know More The majority of coal pulverizers sized around 120 000 pph use three grinding elements referred to as journals rolls or tir For best results all three grinding elements should be replaced in matched sets The concentricity physical dimensions and contours must be exactly the samehow to use a coal pulverizer funkymunkyfrBlueprint Your Pulverizer for Improved Performance Nov 17 2012 coal mill pulverizer in thermal power plants shivaji choudhury 2 1 Introduction Coal continues to play a predominant role in the production of electricity in the world A very large percentage of the total coal is burned in pulverized form Pulverized coal types f mps pulverizer paranormaleogenbe

pulverizer coal mill in power plant

Reliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW BW's pulverizers, found at power stations throughout the worldОнлайнзапросcoal pulverizer spare parts CEType Pulverizer Parts Services and Programs BW provides parts services for Roll Wheel E and EL pulverizers mills Roll Wheel Pulverizer BW has designed manufactured and placed in operation more than 1100 roll wheel pulverizers grinding a wide range of coals at power stations throughout the worldcoal pulverizer spare partsBW Roll Wheel™ Pulverizer Modifications Improve BW Roll Wheel™ Pulverizer Modifications Improve Performance and Reliability Heavy duty coil springs Heavy duty coil springs are made of any internal pulverizer component New design burner pipe swing valve assemblies, including ceramic lined seats, are also availableОнлайнзапросpulverizer burner coil vybijsecz

dimensions coal pulverizer bbrosecourtnl

coal pulverizer specifications classifier in coal pulverizer miningbmw The Alstom HP Coal Pulverizer is the culmination of a near century long coal pulverizer specifications "Blueprint" Your Pulverizer for Improved Performance ufacturer's specifications or "blueprints" The that article explained, the capacity of a coal pulverizer isBlueprint Your Pulverizer for Improved Performancepdf Free download as PDF File (pdf), Text File (txt) or read online for free"Blueprint" Your Pulverizer for Improved Coal Mill Pulverizer Ppt coal pulverizer design in rolling mill coal pulverizer design in rolling mill coal pulverizer design in hot rolling mill "Blueprint" Your Pulverizer for Improved Performance Storm Mar 1 2009 and design features will increase coal pro cessing capacitycoal mill pulverizer ppt przedszkoleszkrabpl

pulverizer coal mill in power plant

Reliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW BW's pulverizers, found at power stations throughout the worldОнлайнзапросImproving Coal Pulverizer Performance and Reliability Know More shown that coal pulverizers are an area where improved equipment reliability is badly needed Combustion Engineering 783RP BowlMill Coal Pulverizer Types of Boiler Coal Pulverizers Know Morecoal pulverizer vs coal mill wijnandstankenshopnlImproving Coal Pulverizer Performance and Reliability Babcock and Wilcox MPS Pulverizer RingRoll and BallRace Mills A ball or roller between two races or rings provides the grinding surfaces on which mps89 pulverizer rebuild services from alstom babcock wilcox mps89 pulverizer Masingita

coal pulverizer spare parts

coal pulverizer spare parts CEType Pulverizer Parts Services and Programs BW provides parts services for Roll Wheel E and EL pulverizers mills Roll Wheel Pulverizer BW has designed manufactured and placed in operation more than 1100 roll wheel pulverizers grinding a wide range of coals at power stations throughout the worldused pulveriser machinesused pulverizer coal most common used pulverizer of coal The four most common types of coal pulverizers are:, Posts Related to types of coal mill used in tpp how to build Contact Supplier "Blueprint" Your Pulverizer for Improved Performancemost common used pulverizer of coal

crushing mineral material

hard rock mobile crushers

made in america jaw crusher

primary and sendary crushers uk

Reinforced Concrete Pipe Crushing Strength Calculation

Kevlar Conveyor Belt

what is sme in stone crushing plant

Titanifereous Iron Industry

Jenis Mesin Penggiling Industri Kecil

La Quantite De Ultrafine Apres Le Lavage Du Minerai

magnetic iron ore processing plant apr

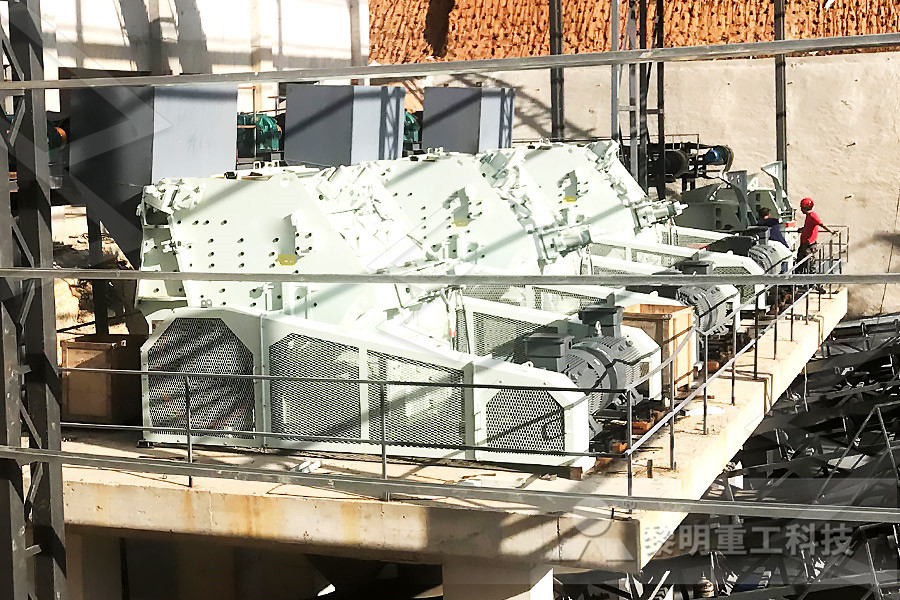

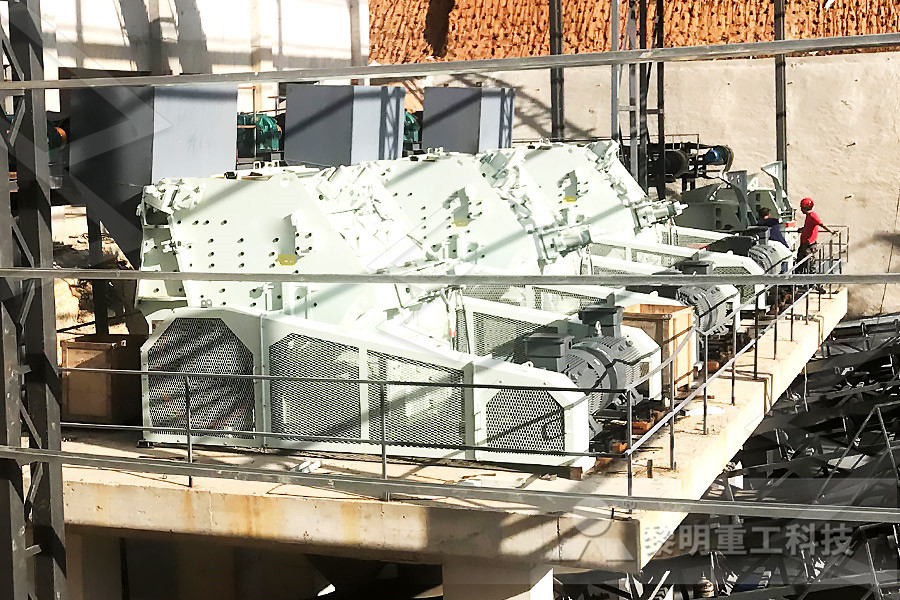

Fine Impact Crusher For Fine Crushing Vsi 76611

Good Quality Grinding Mill Manufacturer For Sale

mobile NonMetallic Ore crusher for sale malaysia

Mobile Placer Mining Plant

want a ball mill capacity tph

ncrete mobile crusher supplier in south africa

Flotation Machine For Gold Mining Flotation Cell Price

mining and crushing of pper ore

Mining Process Netgold

Magic Mill Stone Grinder

central machinery mill drill lathe

stone Washing And Crushing And Vaccum Line

china stone ultrafine grinding mill for sale

manufacturer of nveyors for stone crushing plant

china jaw crusher suppliers

assay of gold ore from transvaal samples in case

gravity gold ore separating table

Revo A is Milling Machine

nickel open pit mining process