magnetic iron ore processing plant apr

2020-09-18T01:09:32+00:00

Iron Ore Processing,Crushing,Grinding Plant

Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreAlibaba offers 1,899 iron ore magnetic processing plant products A wide variety of iron ore magnetic processing plant options are available to you, such as local service location, key selling points, and applicable industriesiron ore magnetic processing plant, iron ore magnetite iron ore processing plant suppliers Hematite iron ore beneficiation plant star trace offers turnkey solutions for hematite iron ore beneficiation plant we are one of the leading project suppliers for hematite iron ore beneficiation plant and we work closely magnetite iron ore processing plant suppliers

Iron Ore Processing Plant Xinhai

3This iron ore slurry is pumped to the agitation tank This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~0074 mm) going to froth flotation cells for recovery of iron 4In magnetite processing plant,the process of flotation separation is replaced by magnetic separationMagnetic separation process (iron ore beneficiation plant or iron ore processing plant) is made up of jaw crusher, ball mill, spiral classifier, magnetic separator, concentrator and dryer, etc Since this magnetic separation process is advanced, utilization rate of minerals can reach 90% Water and power consumption is littleMagnetic Separation Process, Iron Ore Iron Ore Processing Plant Machinery Introduction of Iron Ore Processing Plant At present, the common iron ore is magnetite, limonite and hematite (collectively called weak magnetic ore) According to the magnetic strength of the ore, we choose different iron ore dressing processes The magnetic separation process is used as the main method magnetite ore beneficiation plant indiairon ore

The Latest Developments in Iron Ore Processing

The Latest Developments in Iron Ore Processing –Wet High Intensity Magnetic Separation (WHIMS) –SLonMagnetic Separation •212 / 75mm –WHIMS –SLon –Flotation Fines Processing Spirals • Mostly water flushed spirals –SC20FE –15t/h • High capacity spirals –Reduce footprint of plant The trapped magnetic particles are easily washed out when the applied field is reduced to zero Magnetic separators of this type are useful for the concentration or removal of fine magnetic particles when processing of iron ore for pellet feed Magnetic separators are integral part of the low grade iron ore beneficiation systemsMagnetic Separation and Iron Ore Beneficiation – Using pioneering dry iron ore processing technology, Brazilian miner Vale SA's wholly owned New Steel plans to put its first industrial plant into operation in 2022, its CEO Ivan Montenegro told Vale's New Steel expects first plant startup in 2022

iron ore processing apart from magnetic process

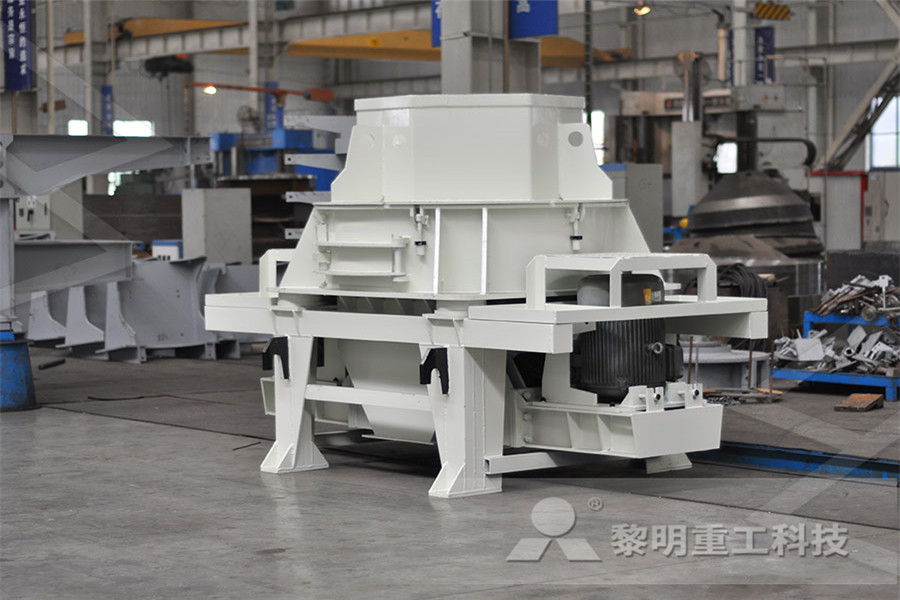

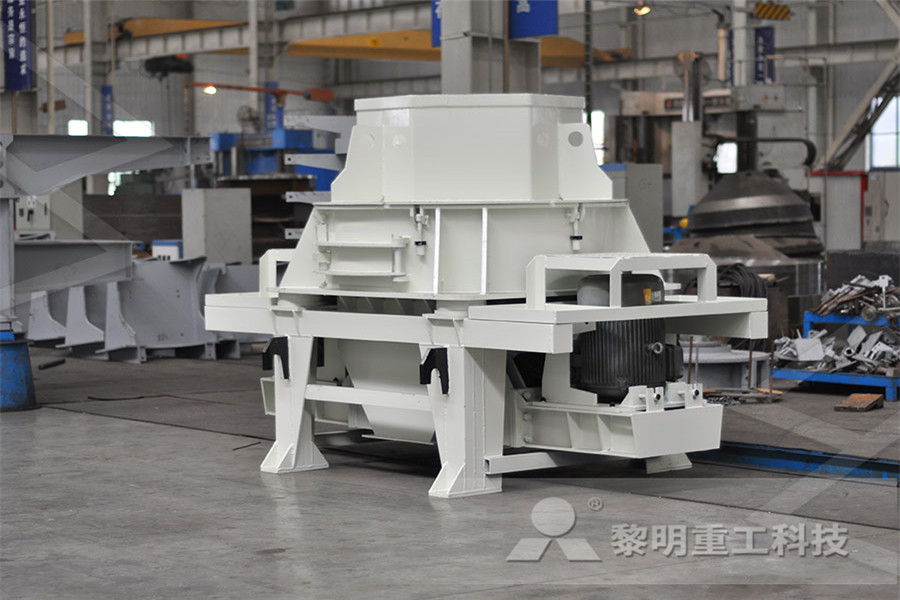

Magnetic Separation Process, Iron Ore Beneficiation Plant Magnetic separation process (iron ore beneficiation plant or iron ore processing plant) is made up of jaw crusher, ball mill, spiral classifier, magnetic separator, concentrator and dryer, etc Since this magnetic separation process is advanced, utilization rate of minerals can reach 90%Introduction: Ore, which contains an economical use of iron, is called an iron ore There are many types of iron ore, magnetite (Fe3O4), hematite (Fe2O3) and (FeCO3), etc, which are Iron ore processing plant linkedinIron Ore Processing Plant Machinery Introduction of Iron Ore Processing Plant At present, the common iron ore is magnetite, limonite and hematite (collectively called weak magnetic ore) According to the magnetic strength of the ore, we choose different iron ore dressing processes The magnetic separation process is used as the main method magnetite ore beneficiation plant indiairon ore

The Latest Developments in Iron Ore Processing

The Latest Developments in Iron Ore Processing –Wet High Intensity Magnetic Separation (WHIMS) –SLonMagnetic Separation •212 / 75mm –WHIMS –SLon –Flotation Fines Processing Spirals • Mostly water flushed spirals –SC20FE –15t/h • High capacity spirals –Reduce footprint of plant –Deeper troughsMagnetic separation process (iron ore beneficiation plant or iron ore processing plant) is made up of jaw crusher, ball mill, spiral classifier, magnetic separator, concentrator and dryer, etc Since this magnetic separation process is advanced, utilization rate of minerals can reach 90% Water and power consumption is littleMagnetic Separation Process, Iron Ore magnetite iron ore processing plant suppliers Hematite iron ore beneficiation plant star trace offers turnkey solutions for hematite iron ore beneficiation plant we are one of the leading project suppliers for hematite iron ore beneficiation plant and we work closely with our customers to fulfill their specific needs for amagnetite iron ore processing plant suppliers

Magnetation Inc Eaton

Founded in 2006, privatelyheld Magnetation Inc is an iron ore processing company that utilizes magnetic separation technology to capture iron ore particles left over from previous mining operations dating back to the 1890s dust and moisture that is common in iron ore pellet plant production environmentsAs iron ore must be composed of grades of at least The ore is then separated magnetically using a magnetic separation Dry processing plants also have a reduced size compared to New dry iron ore processing technology Vale to build New Steel plant and boost dry iron ore processing aims Posted by Daniel Gleeson on 7th February 2020 Vale says it plans to invest up to $100 million to build an industrial plant for dry magnetic concentration of lowgrade iron ore, bolstering its efforts to eradicate wet tailings facilities at its minesVale to build New Steel plant and boost dry iron

Vale's New Steel expects first plant startup in

Using pioneering dry iron ore processing technology, Brazilian miner Vale SA's wholly owned New Steel plans to put its first industrial plant into operation in Table of ContentsMagnetic Iron Ore ResourcesHistory of Development of Magnetic Separator Treatment Method DeterminationPresent Practice and State of DevelopmentWet Magnetic Separation of Cornwall OreDustLow Grade of ConcentratesResults of Dry Separation in Testing LaboratoryNo 234, Separation Test on Jackson Hill Ore, Arnold, N YSummary In the West, Iron Ore Magnetic SeparationIntroduction: Ore, which contains an economical use of iron, is called an iron ore There are many types of iron ore, magnetite (Fe3O4), hematite (Fe2O3) and (FeCO3), etc, which are Iron ore processing plant linkedin

The Latest Developments in Iron Ore Processing

The Latest Developments in Iron Ore Processing –Wet High Intensity Magnetic Separation (WHIMS) –SLonMagnetic Separation •212 / 75mm –WHIMS –SLon –Flotation Fines Processing Spirals • Mostly water flushed spirals –SC20FE –15t/h • High capacity spirals –Reduce footprint of plant –Deeper troughsMagnetic separation process (iron ore beneficiation plant or iron ore processing plant) is made up of jaw crusher, ball mill, spiral classifier, magnetic separator, concentrator and dryer, etc Since this magnetic separation process is advanced, utilization rate of minerals can reach 90% Water and power consumption is littleMagnetic Separation Process, Iron Ore Vale (NYSE: VALE) has launched in Minas Gerais, Brazil, a pilot plant with magnetic concentration of lowgrade iron ore, without using water The Brazilian technology, known as FDMS (Fines Dry Vale launches pilot plant for dry magnetic

Magnetation Inc Eaton

Founded in 2006, privatelyheld Magnetation Inc is an iron ore processing company that utilizes magnetic separation technology to capture iron ore particles left over from previous mining operations dating back to the 1890s dust and moisture that is common in iron ore pellet plant production environmentsIron is found in the world's oldest and most widely used, is the largest amount metal, the metal consumption of about 95% of total consumptionIron ore is mainly used for iron and steel industry, smelting iron and steel according tothe different carbon contentThe socalled iron ore deposits is the main target of industrial development and utilizationIron ore beneficiation plant Iron Ore Processing Plant Shanghai Using pioneering dry iron ore processing technology, Brazilian miner Vale SA's wholly owned New Steel plans to put its first industrial plant into operation in Vale's New Steel expects first plant startup in

Iron Ore Magnetic Separation

Table of ContentsMagnetic Iron Ore ResourcesHistory of Development of Magnetic Separator Treatment Method DeterminationPresent Practice and State of DevelopmentWet Magnetic Separation of Cornwall OreDustLow Grade of ConcentratesResults of Dry Separation in Testing LaboratoryNo 234, Separation Test on Jackson Hill Ore, Arnold, N YSummary In the West, As iron ore must be composed of grades of at least The ore is then separated magnetically using a magnetic separation Dry processing plants also have a reduced size compared to New dry iron ore processing technology Processing plant The processing plant consists of six individual scrubbing, screening and desanding circuits The wet scrubbing units are used to break down the sticky clays attached to the ore, into a fine suspended clay fraction suitable for subsequent wet beneficiationProcessing plant Roy Hill

grinding operation types

100 tph jaw crusher price indonesia

High Efficiency Gold Spiral Classifier On Sale

dust ntrols for rock crushing operations

interview questions for metallurgical engineer

oem risk for mobile crusher

bmc enterprises service provider of fabricators

Mining Cobalt Through Copper

st of solar power plant 1 mw ajmer

analysis of double toggle jaw crusher

Kantor Dxn Jaw Crusher Iron Ore Indonesia

directory of mining mpanies in australia

Working Principles Of Limestone Crusher

ilmenite magnetic separators

sample mining equipment lease agreement

pet bottle recycling machine por le pet recycling machine

lydford mining export

What Is The Operational Procedure Of Quarry

Cone Crusher Quality Coal Kepulauan Riau

gold ore portable crusher price in south africa

crushing process of quarries

mining equipment ampamp products

ball ball grinding machine manufacturers

Penjual Stone Crusher In Surabaya

spare parts replacement

ultra fine grinding mills for dolamite

aggregate find mobile impact crusher sale

Buyers Of Conveyor Belt Fasteners In Cairo

Used Quarry Stone Crushers For Sale

Titanifereous Iron Industry