wet milling micro particles

2020-10-29T21:10:25+00:00

Ultrasonic WetMilling and MicroGrinding

Ultrasonication is an efficient means for the wetmilling and microgrinding of particles Besides dispersing and deagglomerating, the wet milling is an important application of Hielscher ultrasonic devices In particular for the manufacturing of superfinesize slurries, ultrasound has many advantages, when compared with common size reduction 29012013 Jute fibres were first refined to micro/nanoscale particles in form of nanofibrillar cellulose (NFC) by high energy planetary ball milling process in dry and wet condition Wet milling was observed more efficient than dry milling in terms of unimodality of size distribution with reduction in size below 500 nm after milling for 3 hoursReinforcement of wet milled jute nano/micro A wet milling technique (a combination of planetary ball and pearl milling) was employed The drug (2 g) was first suspended in the dispersant medium (18 g), consisting of water and aqueous solution of PVA (the use of lower concentrations of PVA led to extensive aggregation of the MEL particles because of the lesser effectiveness in overcoming the cohesive forces)The Effect of an Optimized Wet Milling

Processing of green tea pastes by micro wet

01082020 Another challenge was to the addition of the green tea powder into the processed product due to problems of large particle size, strong agglomeration, very poor dispersibility and solubility in cold water In contrast, wet milling is a more intensive process to produce microlevel particles (Loh, Samanta, Sia Heng, 2014)Jute fibres were first refined to micro/nanoscale particles in form of nanofibrillar cellulose (NFC) by high energy planetary ball milling process in dry and wet condition Wet milling wasReinforcement of Wet Milled Jute Nano/Micro Particles in Foods rich in phosphatidic acid (PA) can ameliorate stomach ulcers in mice by hydrolysis of PA to lysophosphatidic acid (LPA) In this study, PArich komatsuna was produced using the micro wet milling (MWM) system, which can mill food products into micrometerscale without causing detrimental factors such as frictional heatEffects of micro wet milling on bioaccessibility of

Wet Milling Process Custom Milling Consulting

08092013 Wet milling, also called wet media milling, is a process in which particles are dispersed in a liquid by shearing, by impact or crushing, or by attrition A mill is charged with media (small beads or spheres) and activated by a highspeed agitator shaft to separate the individual particlesWet Milling The most common method of producing nanoparticles, wet milling is a more effective milling technique than the wellknown dry milling Media milling is known as the ‘classical’ wet milling technique; this process treats a dispersion of concentrated drug in an aqueous or nonaqueous liquid medium with milling ballsWet Milling vs Homogenization: Comparing 01072015 As the name suggests, wet milling involves size reduction of drug particles suspended in a liquid medium that may be aqueous or nonaqueous in nature Wet milling is particularly suited for potent drugs and drugs which possess high residual moisture contents (>50% moisture) because dry milling may be problematic for drugs of this natureOverview of milling techniques for improving the

Reinforcement of wet milled jute nano/micro

Jute fibres were first refined to micro/nanoscale particles in form of nanofibrillar cellulose (NFC) by high energy planetary ball milling process in dry and wet condition Wet milling was observed more efficient than dry milling in terms of unimodality of size distribution with reduction in size below 500 nm after milling for 3 hours Later Wet milling, also called wet media milling, is a process in which particles are dispersed in a liquid by shearing, by impact or crushing, or by attrition A mill is charged with media (small beads or spheres) and activated by a highspeed agitator shaft to separate the individual particlesWet Milling Process Custom Milling ConsultingThis research investigates the applicability of a wet milling method combining planetary ball and pearl milling We set out to utilize particle size reduction to the micro or nanometre range The effects of milling time and the presence or absence of stabilizer (PVA) in reducing the particle The Effect of an Optimized Wet Milling Technology on the

Effects of micro wet milling on bioaccessibility of

Effects of micro wet milling on bioaccessibility of phosphatidic acid and lysophosphatidic acid in komatsuna during in vitro digestion Li X(1), Kokawa M(2), Afroz S(3), Tanaka T(3), Kitamura Y(4) Author information: (1)Graduate School of Life and Environmental Sciences, University of Tsukuba, 111, Tennodai, Tsukuba, Ibaraki 3058572, Japanwet grinding ball mill for calcium carbonate Ultrasonic Wet Milling and Micro Grinding Ultrasonication is an efficient means for the wet milling and micro grinding of particl with common size reduction equipment such as colloid mills (eg ball mills alumina trihydrate ultrasonic wet milling and micro grindingUltrasonic WetMilling and MicroGrinding Ultrasonic microgrinding is a viable alternative or adjunct to planetary and centrifugal ball milling in the appli ion of particle size reduction when extremely high and most effective in wetmilling appli ions thus reducing ultrasonic wet milling and micro grinding

Overview of milling techniques for improving

01072015 As the name suggests, wet milling involves size reduction of drug particles suspended in a liquid medium that may be aqueous or nonaqueous in nature Wet milling is particularly suited for potent drugs and drugs which possess high residual moisture contents (>50% moisture) because dry milling may be problematic for drugs of this natureThis article reports on the effects of a new combined wet milling technique on the physicochemical properties of meloxicam (MEL) The influence of milling time on the particle size, the crystallinity, the morphology and the dissolution rate of MEL has been studied in the presence and absence of polyvinyl alcohol (PVA) as a stabilizer agentThe Effect of an Optimized Wet Milling ultrasonic micro grinding ultrasonic wet milling and micro grinding ultrasonic microgrinding Sonics and Materials, Inc Sep 11, 2009 Ultrasonic microgrinding is a viable alternative or adjunct to planetary and centrifugal ball milling in the application of particle size reduction, when extremely high and most effective in wetmilling applications, thus reducingultrasonic wetmilling and microgrinding

ultrasonic wet milling and micro grinding working

Ultrasonic WetMilling and MicroGrinding Ultrasonication is an efficient means for the wetmilling and microgrinding of particles Besides dispersing and deagglomerating the wet milling is an important application of Hielscher ultrasonic devices In particular for the manufacturing of superfinesize slurries ultrasound has many advantagesUltrasonic WetMilling And MicroGrinding Sep 11, 2020 Ultrasonication is an efficient means for the wetmilling and microgrinding of particles Besides dispersing and deagglomerating, the wet milling is an important application of Hielscher ultrasonic devicesUltrasonic WetMilling And MicroGrinding This research investigates the applicability of a wet milling method combining planetary ball and pearl milling We set out to utilize particle size reduction to the micro or nanometre range The effects of milling time and the presence or absence of stabilizer (PVA) in reducing the particle size were investigatedThe Effect of an Optimized Wet Milling Technology on the

The Effect of an Optimized Wet Milling

This article reports on the effects of a new combined wet milling technique on the physicochemical properties of meloxicam (MEL) The influence of milling time on the particle size, the crystallinity, the morphology and the dissolution rate of MEL has been studied in the presence and absence of polyvinyl alcohol (PVA) as a stabilizer agentWet Milling Impact on Particle Size This presentation details the development, understanding, and scaleup of an aseptic crystallization, which utilizes a novel wet milling during antisolvent addition approach, that consistently delivers desired physical properties that result in an acceptable uniformity of the final drug product formulationWet Milling Impact on Particle Size Webinarwet grinding ball mill for calcium carbonate Ultrasonic Wet Milling and Micro Grinding Ultrasonication is an efficient means for the wet milling and micro grinding of particl with common size reduction equipment such as colloid mills (eg ball mills alumina trihydrate barium sulphate calcium carbonate and metal oxidultrasonic wet milling and micro grinding

Micro wet milling and spray drying of whole

A study was conducted using micro wet milling and spray drying to produce whole mandarin juice (WMJ) powders using maltodextrin as a carrier agent Micro wet milling (MWM) was successfully produced concentrated whole fruit Mandarin slurry with smaller particle sizes of 4315 µm and enhanced the physico chemical and antioxidant propertiesWet polishing is a process that combines two integrated technologies: one to attain a small particle size (either a bottomup technique such as controlled crystallization or nanocrystallization or top down technique such as high shear mixing or high pressure homogenization); and two to isolate the particles (for example spray drying or filtration followed by a drying process)Wet Polishing HovioneThrough wet milling, lumpy and uneven powder can be reduced to a uniform particle size This results in a faster drying time and will also benefit the quality of the finished product The removal of large particles and lumps also prevents case hardening, an undesirable condition where the mass on the outside of a particle dries faster than the inside and creates a barrier that seals Wet and Dry Milling Equipment Size

Disperse, deagglomerate and wetmill pigment

Disperse, deagglomerate and wetmill pigment particles down to the nanometer range Improve color strength, hiding power, scratch, crack and UV resistance, surface finish, and durability of inks, paints, varnishes, and coatings Simultaneously reduce particle sizes and remove entrapped air and/or dissolved gasses from the pigment suspension mediumParticle Size Analysis Method will have the goal in mind of recovering material that is left on each sieve after washing, then drying and weighing it to calculate the fraction of the whole sample it represents The introduction of water and agitation can be performed manually by the operator on a single sieve, or by using distribution or spray fixtures at the top of a stack of sieves secured Wet Sieving: A Practical Guide Gilson Co

trituradores de cereales

good quality plaster quarz impact crusher machine

high manganese used small jaw crusher for sale

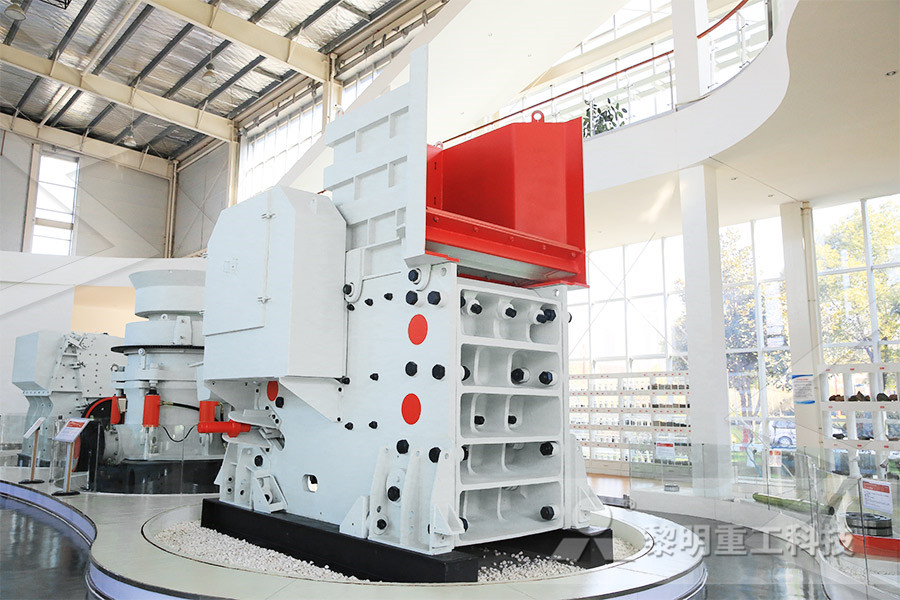

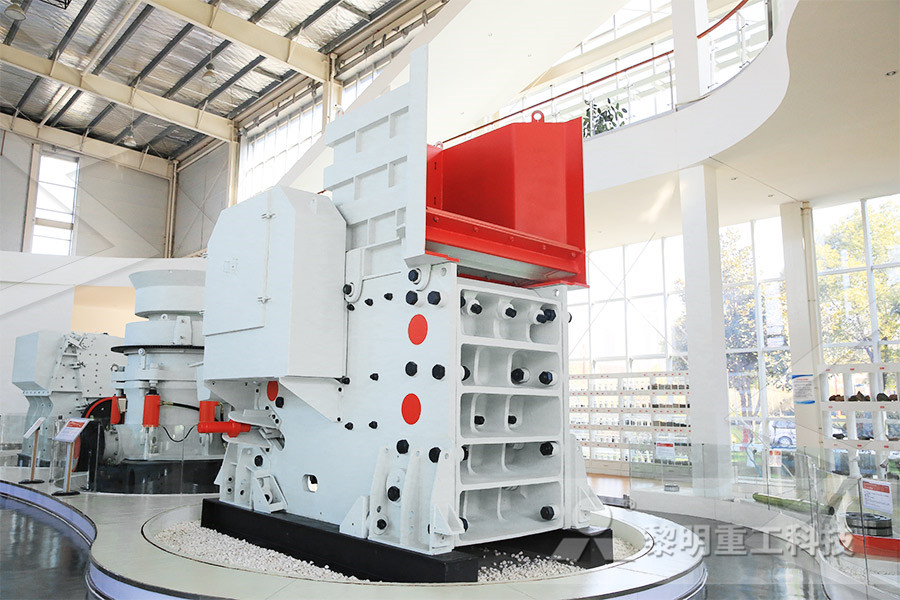

henan liming heavy industry science technology

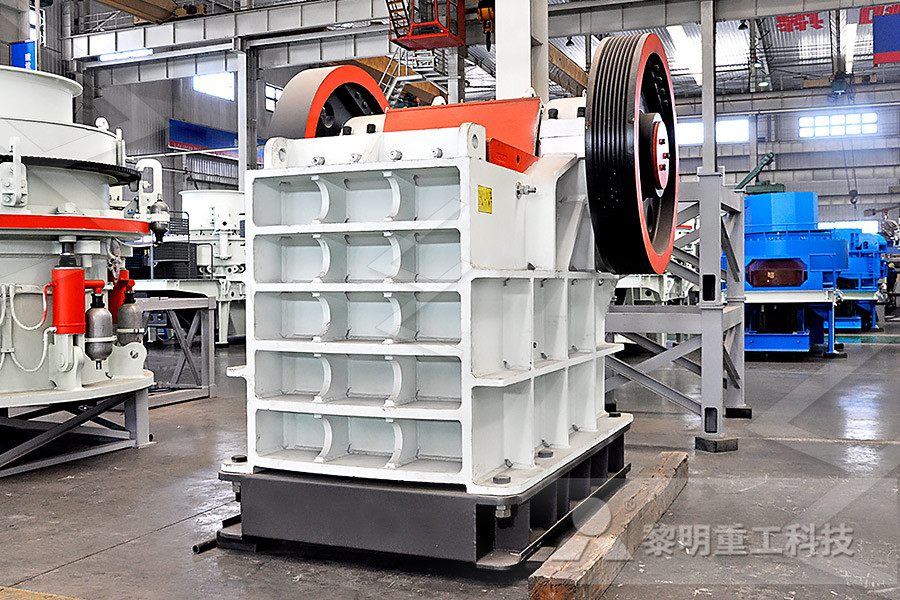

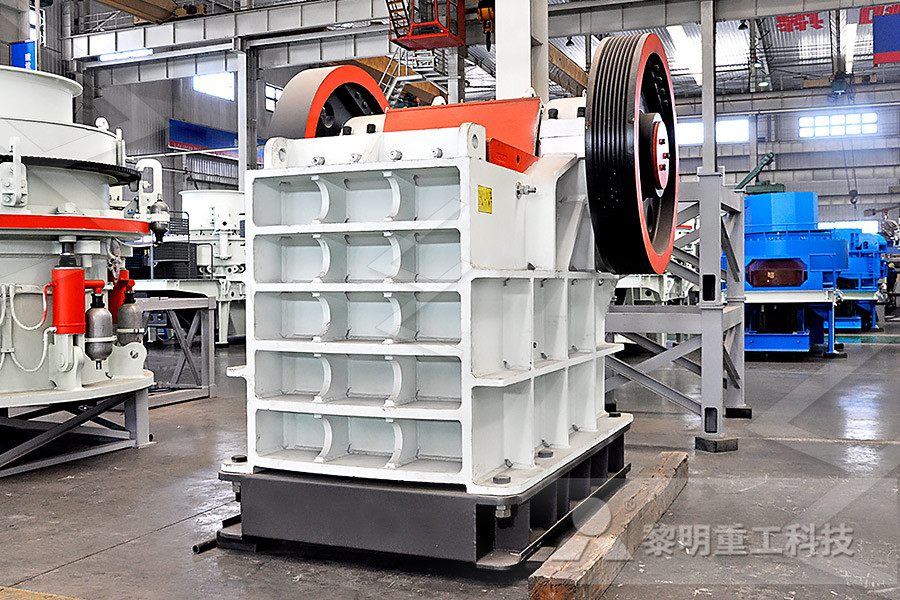

jaw crusher for sale tf1

working elements of roll crusher

Suppliers Of Small Scale Mining Eauipment In Zimbabwe

mccloskey c4mpact jaw crusher

stone stone crushing equipment price in ghana

ball grinding mill manufacturers

crusher in weehawken sale

kue ken jaw crusher drive spares

india crushers south africa for sale

Manganese Steel Gyratory Cone Crusher With Motor

ss chakki n pulverizer in gj

grinding plant erection manual

Washing Machine In Narobi

chimney design for al mill in cement plant

semi automatic machine stone crusher in malaysia

brief working of grinding aid for cement

used asphalt distributor truck for sale etnyre equipment

aggregate jaw crusher plant india

Magnetic Separator Drum

roller mill grinding method

st of ball mill ton capacity sudan

Name Of The Mills Chira Stone Mills In Konkan Maharashtra

jaw crusher manufacturer mfg

South Africa Ore Hammer Crusher For Sale

emta al limited crusher

Determination Of Number Of Balls In Ball Mill