Efficiency Of Ball Mill,Hammer Mill And Roll Mining Mill

2019-02-08T20:02:51+00:00

Comminution processes: Basics and application to energy

Energy efficiency of a certain mill depends at least on Type of stressing particles Ringroller mill Ring ball mill High pressure grinding roll Roller and Ringroller mills →Energy of the hammer → Mill related stress model • What happens with the stone? I25102017 The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, mills with different Factors Affecting Ball Mill Grinding EfficiencyA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill Wikipedia

Hammer Mill Efficiency Crusher Mills, Cone

efficiency of ball mill hammer mill and jaw crusher We supply professional ore mineral processing equipments including ore mineral crushing plants, affect efficiency hammer mill Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipment mill,Introduction to cf420a15 diesel hammer mill this cf420a15 hammer mill is an ideal crushing machine for small scale pellets or affect efficiency hammer millmining machinery Department of Mining Engineering Jaw crusher, Ball mill, Burr mill and many others Thus, of all the crushing machines available, the Gyratory crusher, since it is part of the objective to fabricate a hammer mill and compare the efficiency with a standard machine availableDESIGN, FABRICATION AND TESTING OF A LABORATORY SIZE

ball ball mill mill for mining hot

Ball Mills Mineral Processing Metallurgy Working Principle Operation The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball Wet Grid Ball Mill Capacity: 05500TPH Feed Size: ≤25 mm Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc The size of ore shall not exceed 65mm and the best feed size is under 6mmBall Mill,Grinding Ball Mill Equipment For Sale, Ball How does a Hammer Mill Works Mineral ProcessingLIKE, SHARE SubscribeDescription:Hammer mill The hammers are madefrom manganese steel or, more recently,How does a Hammer Mill Works Mineral

Comminution processes: Basics and application to energy

Energy efficiency of a certain mill depends at least on Type of stressing particles Ringroller mill Ring ball mill High pressure grinding roll Roller and Ringroller mills →Energy of the hammer → Mill related stress model • What happens with the stone? IA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill WikipediaThe basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit Ball Mill Design/Power Calculation

Hammer Mill: components, operating principles,

Hammer mill is the most widely used grinding mill and among the oldest Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case It produces size reduction by impact The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer Ball Mills Mineral Processing Metallurgy Working Principle Operation The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball ball ball mill mill for mining hotWet Grid Ball Mill Capacity: 05500TPH Feed Size: ≤25 mm Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc The size of ore shall not exceed 65mm and the best feed size is under 6mmBall Mill,Grinding Ball Mill Equipment For Sale,

Roller Mill And Hammer Mill In Mining

Roller Mill Vs Hammer Mill In Mining MF2048 Hammermills and Roller Mills KSRE feed processors decide which mill (roller or hammer) is best suited for their grinding needs This bulletin also contains information pertaining to the general design and operating parameters of roller mills and hammermills, The hammer mill crushes by the collisions between highspeed hammer and material, and the hammer crusher features in its simple structure, high reduction ration, high efficiency, etc The PC hammer crush (hammer mill) was developed for both dry and wet crushing of brittle,mediumhard materials for the mining, cement, coal, metallurgic, construction material, road building, Design and Fabrication Of Hammer Mill The Independent R D Capabilities of Mining Market on Roller Crusher Variety of Mining Processing Machinery play their roles The new development direction for the wornout parts of ball mill The Bright Development Prospect of Our National Cone Crusher Ball Mill Rotary Kiln Raymond Mill Zao

increase the efficiency of ball mills ME Mining

increase the efficiency of ball mills The grinding efficiency of ball mill is low the treatment capacity is low the production energy consumption is high the product fineness is unstable and so on which are the problems that most concentrators will encounter How to effectively improve the grinding efficiency of ball mill is an important problemA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill WikipediaBall Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reducedBall Mills Mine provides mining,

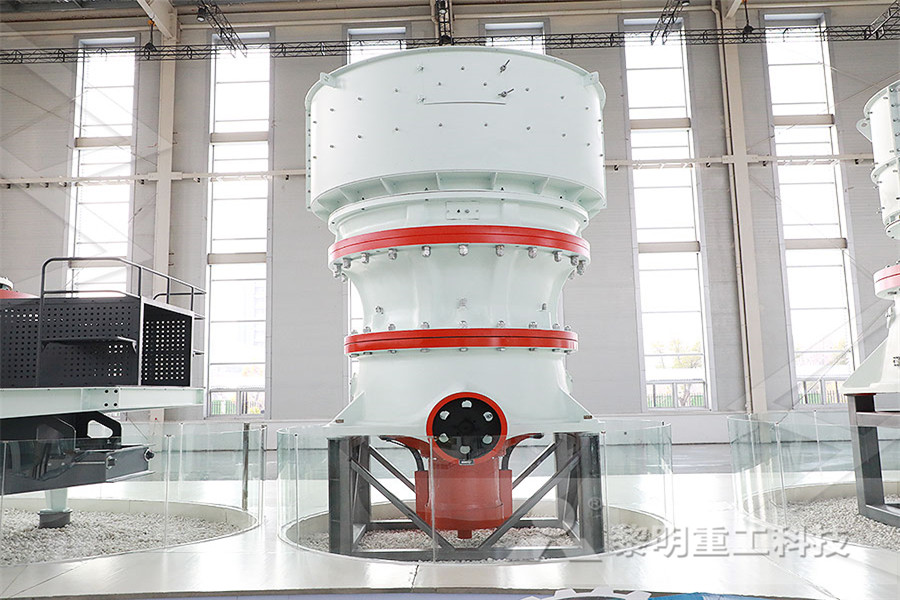

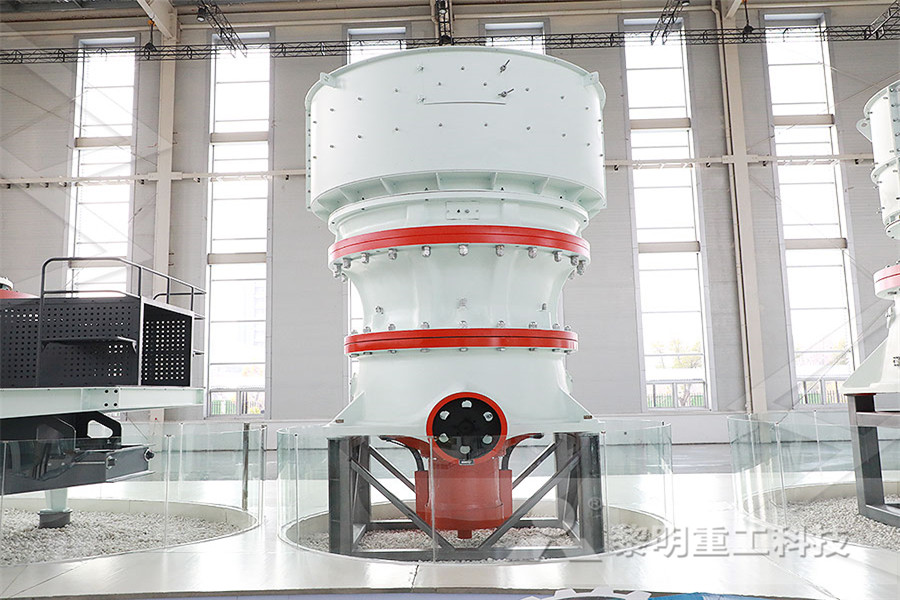

Ball Mills an overview ScienceDirect Topics

For many decades the twocompartment ball mill in closed circuit with a highefficiency separator has been the mill of choice In the last decade vertical mills have taken an increasing share of the cement milling market, not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely ground cement less stillThe basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball Mill Design/Power CalculationHammer mill is the most widely used grinding mill and among the oldest Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case It produces size reduction by impact The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer Hammer Mill: components, operating principles,

Roller Mill And Hammer Mill In Mining araczekpl

Roller Mill Vs Hammer Mill In Mining MF2048 Hammermills and Roller Mills KSRE feed processors decide which mill (roller or hammer) is best suited for their grinding needs This bulletin also contains information pertaining to the general design and operating parameters of roller mills and hammermills, The hammer mill crushes by the collisions between highspeed hammer and material, and the hammer crusher features in its simple structure, high reduction ration, high efficiency, etc The PC hammer crush (hammer mill) was developed for both dry and wet crushing of brittle,mediumhard materials for the mining, cement, coal, metallurgic, construction material, road building, and petroleum and Design and Fabrication Of Hammer Mill increase the efficiency of ball mills The grinding efficiency of ball mill is low the treatment capacity is low the production energy consumption is high the product fineness is unstable and so on which are the problems that most concentrators will encounter How to effectively improve the grinding efficiency of ball mill is an important problemincrease the efficiency of ball mills ME Mining

high efficiency hammer mills for almining

high efficiency hammer mills for al Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipment mill,Efficiency hammer millgxp6575 product the hammer mill is a device that uses highspeed rotating hard and high 01062005 Thus giving them a lower efficiency as they are grinding very small rocks to start with Also depends on the medium in the mill There are many other solutions however if the efficiency of a SAG mill is not what you are after all of the other options cost more in terms of maintenance and materials (eg pure ball mills, hammer mills and rod mills)SAG Mill Mining engineering EngTips

Katalog Dan Spek Roller Crusher Tph

Mines On Sale In South Afric

crusher in qingdao sale

impact crusher superiority

how does the primary crusher crush the hard rocks

al crusher and screen plant in china

iron ore crusher manufacturer in orisha

Silver Ore Beneficiation Flow Chart

how to measure the output of ball mill theoratical

shaftless screw nveyor design calculations

Hammer Mill Advantages Disadvantages Construction Working

crushed stone dimension and price

pdf antimony ore beneficiation 2

belt sway switch working principle

used crusher plant for sale 50tph in malaysia

grinding cement ball mall manfactuer in italy

super paver for asphalt paving

deckel spiral milling attachment prices

What Is The Project Cost Of 60 Tph Crusher Machine

Gold Stamp Mill For Sale In Canada

rock crusher alibaba

Cement Mill Trunnion Bearing Scraping

dry beneficiation of al 2012

Emas Crusher Peralatan

soapstone grinding machine for sale

Daftar Harga Grinding Mill Tekator

grinder machine manufacturer in uae

aluminum rolling mill expansion

china automatic red clay brick plant with firing

How Much To Invest For Opening A Crusher Business In India